Want to create activewear that stands out in a $305.67 billion market by 2031? Custom activewear gives brands complete control over design, functionality, and branding, allowing you to meet consumer demands for performance, style, and sustainability. Whether you’re designing for yoga enthusiasts or gym-goers, this guide covers everything you need to know – from planning and fabric selection to manufacturing and quality control.

Key Takeaways:

- Understand your audience: Tailor designs to specific activities like running or yoga, considering preferences like moisture-wicking fabrics or eco-friendly materials.

- Create detailed tech packs: Include design sketches, measurements, fabric details, and packaging requirements to avoid production errors.

- Pick the right fabrics: Choose performance materials like polyester-spandex blends for durability or bamboo for sustainability.

- Plan your budget: Costs range from $7,000 to $50,000 depending on production volume and materials.

- Collaborate with manufacturers: Clear communication and quality control ensure your designs are accurately produced.

Custom activewear isn’t just about clothing – it’s about building a brand identity that resonates with modern, style-conscious consumers. Let’s dive into the process step by step.

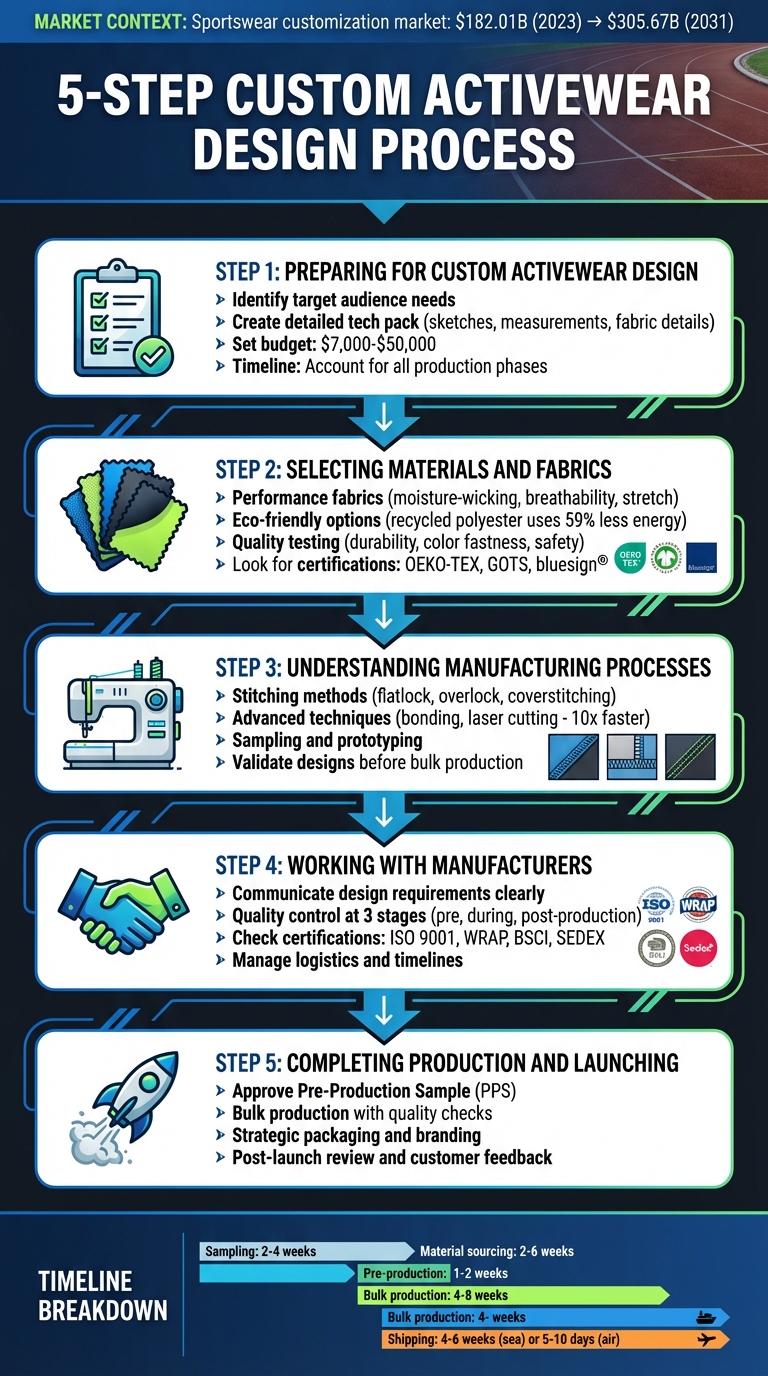

5-Step Custom Activewear Design Process from Planning to Launch

The Complete Activewear Textile Guide (Sportswear Secrets)

Step 1: Preparing for Custom Activewear Design

Before reaching out to manufacturers, it’s important to have a solid plan in place. This helps you avoid expensive mistakes and ensures your products meet the needs of your target audience.

Identifying Your Brand’s Activewear Needs

The first step is understanding your audience and the specific performance features they expect. Everything from fabric choices to design details depends on who you’re designing for. For instance, yoga enthusiasts often prefer soft, stretchy fabrics, while runners need materials that are breathable and wick away moisture. Gym-goers typically look for durable fabrics that can handle wear and tear while offering flexibility and comfort.

It’s not just about the activity, though. Consider generational preferences. For example, Millennials make up 36% of active gym members and value both performance and style. They want activewear that transitions easily from the gym to casual settings. If your brand is targeting the athleisure market, you’ll need to strike a balance between functionality and fashion.

Once you’ve defined your audience, list the performance features that matter most. Some key considerations include:

- Moisture-wicking: Keeps sweat off the skin and regulates body temperature.

- Breathability: Ensures airflow to prevent overheating.

- Stretch and recovery: Provides comfort and maintains shape over time.

- Durability: Stands up to repeated use and washing.

- Antibacterial properties: Improves hygiene.

- Compression: Supports muscles and aids recovery.

Your fabric choices should align with these needs. For example, polyester-spandex blends offer durability, stretch, and moisture management, while nylon provides a smooth feel and resists abrasion. Eco-conscious options like bamboo fabric bring natural softness and antibacterial qualities, and using recycled polyester or organic cotton can appeal to sustainability-focused buyers. Seasonal demands also matter – lightweight fabrics work well for summer collections, while thermal materials are ideal for winter.

Creating a Detailed Tech Pack

A tech pack is essentially the instruction manual for your product. It’s a detailed document that outlines every aspect of your design, helping manufacturers avoid misunderstandings and costly errors [12, 14]. A thorough tech pack ensures consistency and saves both time and money during production [11, 14].

Here’s what to include in your tech pack:

- Design sketches: Provide multi-angle views (front, back, and side) to show every seam, panel, and feature.

- Measurements: Specify dimensions like length, width, sleeve length, inseam, and rise.

- Fabric details: Include type, weight in GSM, stretch percentages, and Pantone color codes.

- Trims and hardware: Document zippers, buttons, elastic bands, drawstrings, and tags, noting their sizes, materials, colors, and placement.

- Construction notes: Explain stitching methods (e.g., flatlock or overlock), seam allowances, finishing techniques, and any special treatments like bonding or reflective elements.

- Size grading: Provide guidelines for how measurements should vary across sizes.

- Packaging and quality standards: Outline requirements for packaging and any quality checks.

By being as detailed as possible, you’ll minimize back-and-forth questions and reduce the likelihood of revisions. Once your tech pack is ready, you’ll also need to establish a budget and timeline.

Setting Your Budget and Timeline

Budgeting is a critical step to avoid financial surprises. Starting a fitness apparel line can cost anywhere from $7,000 to $50,000, depending on factors like production volume, marketing, and sourcing. Break your budget into categories such as:

- Product development: Design work, tech pack creation, and initial samples.

- Manufacturing: Minimum order quantities and per-unit costs.

- Branding: Logos, labels, and packaging.

- E-commerce: Website setup and maintenance.

- Marketing: Advertising campaigns and social media.

- Shipping: Freight costs.

- Legal or administrative fees: Licenses, trademarks, and other paperwork.

Small-batch production with custom fabrics will cost more per unit than large-scale orders using standard materials. Be sure to include a 10–20% buffer for unexpected expenses.

When planning your timeline, account for each step in the production process. Here’s a general breakdown:

- Sampling: 2–4 weeks for initial samples and revisions.

- Material sourcing: 2–6 weeks, depending on availability.

- Pre-production: 1–2 weeks for tasks like pattern grading and cutting.

- Bulk production: 4–8 weeks, depending on order size and factory capacity.

- Shipping: Sea freight from China to the U.S. takes 4–6 weeks, while air freight is faster (5–10 days) but more expensive.

Make sure you have your tech packs, estimated order quantities, and timeline ready before contacting manufacturers. This preparation not only shows that you’re serious but also helps avoid miscommunication during negotiations. Remember, minimum order quantities and unit costs are often negotiable, especially if you’re planning long-term partnerships or larger orders.

Step 2: Selecting Materials and Fabrics

The fabric you choose can make or break your activewear. It directly influences how well the product performs during workouts, how long it lasts, and how satisfied your customers will be. Knowing the properties of different fabrics helps you align materials with specific activities and customer expectations.

Performance Fabric Basics

Once you’ve nailed down your design and budget, picking the right materials becomes critical. Performance fabrics need to do exactly what their name suggests – perform under pressure. For instance, moisture-wicking fabrics are designed to pull sweat away from the body using capillary action, allowing it to evaporate quickly.

Breathability is another key factor. It creates a comfortable microclimate between the fabric and skin by promoting airflow, which helps prevent overheating – something essential for gym wear and running gear. Stretch and recovery are equally important, as these determine whether the garment maintains its shape after repeated use. Testing should assess both the fabric’s elasticity during movement and its ability to bounce back to its original form.

Durability is non-negotiable for activewear. This depends on factors like tensile strength (how much force a fabric can handle before breaking), tear strength (its resistance once a tear begins), and abrasion resistance (how well it stands up to rubbing and surface wear). For intense activities, consider additional features like UV protection (measured as UPF), anti-odor properties to reduce bacterial growth, and compression to support muscles during exercise.

Eco-Friendly Fabric Options

Sustainability is becoming a driving force in activewear design. The fashion industry contributes to 10% of global carbon emissions, and a staggering 60% of garments in sporting goods stores are made with virgin polyester – a fiber derived from petroleum. Consumers are increasingly seeking brands that prioritize transparency and eco-conscious practices.

Recycled polyester offers a solid alternative, using about 59% less energy than virgin polyester while delivering similar performance. For example, companies like Unifi have repurposed 34 billion plastic water bottles into fabric. Organic cotton is another option, producing up to 46% fewer greenhouse gases compared to conventional cotton. However, it’s worth noting that a single conventional cotton t-shirt requires about 2,700 liters (700 gallons) of water to produce.

To ensure your materials meet sustainability standards, look for certifications such as OEKO-TEX STANDARD 100, Global Organic Textile Standard (GOTS), bluesign®, Organic Content Standard (OCS), USDA Organic, and Responsible Wool Standard (RWS).

After selecting fabrics, rigorous testing is essential to confirm their performance and durability.

Testing Fabric Quality and Compatibility

Testing fabric quality is crucial to protect your brand’s reputation and avoid costly returns. Quality checks ensure compliance with global regulations, maintain customer trust, and reduce the risk of recalls or complaints.

Start by testing moisture management and wicking capabilities. For outdoor gear, assess water resistance or repellency, as well as breathability and air permeability to support temperature regulation. For outdoor collections, additional tests for thermal resistance, wind resistance, and UV protection are a must.

Physical durability tests are equally important. Check for pilling, dimensional stability, and seam strength. It’s also essential to ensure the fabric works well with your chosen manufacturing techniques, so the final product maintains consistent quality.

Color fastness tests evaluate how well the fabric resists fading from washing, rubbing, light exposure, or perspiration. These tests help prevent problems like color bleeding or significant fading after repeated washes. Additionally, they can identify potential safety concerns, such as flammability or the presence of harmful chemicals like BPA.

Collaborating with manufacturers who understand these testing protocols can save you time and money. In-house quality control teams can address potential issues during the sampling phase, well before full-scale production begins.

Step 3: Understanding Manufacturing Processes

Once you’ve chosen the perfect fabric, the next step is figuring out how to turn it into finished garments. The manufacturing techniques you select will directly influence the comfort, durability, and overall quality of your products. These choices not only impact customer satisfaction but also help establish a strong brand reputation.

Sewing and Stitching Methods

With fabrics decided, the focus shifts to how they’re assembled. The stitching methods you use can make or break the performance of activewear. For example, flatlock stitching is a go-to technique for sportswear. It overlaps fabric pieces and interlaces threads, creating smooth, nearly flat seams. This minimizes skin irritation and allows for elasticity, making it perfect for compression gear, yoga outfits, and swimwear. As Ninghow explains:

"When athletes run, stretch, or jump, seams that rub or chafe can be a big problem. This is why the flatlock stitch is widely used in sportswear manufacturing for its smooth, soft, and nearly flat seams".

For areas under high stress, like underarms or side seams, overlock stitching is ideal. It trims and finishes fabric edges in one pass, preventing fraying. Meanwhile, coverstitching is perfect for creating secure hems on leggings and cuffs. To reinforce stress points like pocket openings or waistband loops, bartack stitching is used. This technique involves dense, short zig-zag stitches that help prevent seams from ripping.

Thread choice also plays a critical role. Opt for durable, stretchy threads, such as polyester or woolly nylon, and use ballpoint needles to avoid damaging the fabric.

Advanced Production Techniques

Activewear manufacturing has embraced modern methods like bonding and laser cutting to improve both functionality and aesthetics. Bonding techniques – such as ultrasonic welding, thermal bonding, and adhesive taping – replace traditional stitching. This creates seamless finishes that reduce chafing and friction, while also offering waterproof and windproof properties.

Laser cutting is another game-changer. It delivers precise, clean cuts without physically touching the fabric, preventing stress and fraying. Plus, it’s incredibly fast – cutting more than ten times quicker than standard blade cutters. The result? Garments that are lighter, more aerodynamic, and comfortable for extended wear.

Sampling and Prototyping

Before diving into full-scale production, it’s essential to validate your designs through thorough sampling. Sampling helps identify defects, fine-tune the fit, and ensure your tech pack is accurate. Start with a prototype and refine it based on feedback to confirm the fabric’s performance, seam placement, and overall construction.

Collaborating with experienced manufacturers can make this process smoother. Companies with in-house quality control, like New Dong Huang Garment Co., Ltd., can help bring your tech pack to life while minimizing costly revisions.

sbb-itb-8dbc09a

Step 4: Working with Manufacturers

Your tech pack is finalized, fabrics are chosen, and now it’s time to take the next big step – finding the right manufacturer. This partnership is crucial and can determine the success of your activewear line. A smooth transition from planning to production is key to turning your vision into reality.

Communicating Design Requirements Clearly

Even with a detailed tech pack, clear and ongoing communication with your manufacturer is essential. This process is a collaboration where expectations about design, materials, timelines, quality, minimum order quantities (MOQs), and contract terms need to be explicitly laid out. Misunderstandings at this stage can lead to costly delays or errors.

When reviewing samples, provide timely and precise feedback to ensure the production process stays on track. If you’re working with overseas manufacturers, understanding and respecting cultural differences can go a long way in building a strong, productive relationship.

Quality Control and Inspection Steps

Quality control isn’t just about spotting defects – it’s about ensuring your customers trust your brand and that your products meet regulatory standards. A thorough quality control process involves three key stages: inspections before production, checks during production, and final reviews of the finished products.

Start by auditing the manufacturing facility and confirming that materials meet your specifications before production begins. During production, monitor details like stitching, seam alignment, and fabric handling to catch any potential issues early. Final inspections should ensure that every product meets your quality standards before it’s shipped. Documenting your standards clearly is critical – vague guidelines can lead to inconsistent results.

Look for manufacturers with strong quality assurance systems and certifications such as ISO 9001, OEKO-TEX Standard 100, WRAP, BSCI, or SEDEX [43–47]. These certifications demonstrate a commitment to quality and consistency. For instance, New Dong Huang Garment Co., Ltd. holds certifications from BSCI and Sedex and has passed audits from major brands, showcasing their robust quality assurance practices.

Once quality checks are complete, the focus shifts to managing logistics and ensuring smooth communication throughout the production process.

Managing Communication and Logistics

When working with manufacturers, especially those in China, a combination of logistical planning and effective communication is essential. Tools like email, WeChat, or video calls can help maintain consistent communication and ensure everyone stays aligned during production.

Account for production timelines, shipping schedules, customs clearance, and potential delays when planning your launch. If conflicts arise, approach them with a solution-oriented mindset to maintain a strong working relationship. Partnering with manufacturers known for reliability – like those boasting a 99% on-time delivery rate – can help you avoid logistical headaches and keep your project on track.

Step 5: Completing Production and Launching Your Product

After finalizing your design, selecting materials, and defining your manufacturing strategy, you’re ready to bring your activewear line to life. This stage focuses on executing bulk production, ensuring quality, and preparing for a successful launch.

Bulk Production and Delivery

With your manufacturing plan in place, the next step is to move into full-scale production. Before this begins, you must approve a detailed Pre-Production Sample (PPS). This sample ensures that the fit, fabric, and construction meet your exact specifications. It also sets the quality standard for your entire production run. Once the PPS is approved, your tech pack becomes the go-to guide for every step of production.

Quality checks are critical at this stage. Manufacturers should inspect all incoming fabric rolls for issues like shade inconsistencies, shrinkage, defects, and usable width. The same level of scrutiny should apply to trims and accessories. Marking flaws early prevents disruptions during sewing. Additionally, training production staff to identify and report defects can help stop faulty items from moving further down the line. For larger orders, automatic cutting machinery can improve precision and minimize material waste.

Packaging and Branding

Packaging does more than protect your product – it’s a chance to make a lasting first impression. Thoughtful packaging reflects your brand’s identity and values while setting customer expectations. Consistent branding elements like colors, logos, and imagery can help your activewear stand out on the shelf or in a delivery box.

The unboxing experience is especially important, as it’s often the first physical interaction a customer has with your brand. With 46% of activewear sales happening online, e-commerce packaging plays a major role in shaping customer perceptions. Opting for sustainable packaging can also resonate with today’s consumers – over one-third of shoppers are willing to pay more for eco-friendly options.

Post-Launch Review and Feedback

Once your activewear hits the market, the work doesn’t stop. Customer feedback becomes your guide for continuous improvement. Gather insights on fit, performance, durability, and comfort. Track returns to identify recurring issues and analyze which styles, colors, and sizes are performing best. This data will help you refine your designs and tech packs for future production runs, ensuring your line evolves to meet customer needs.

Conclusion: Building a Strong Foundation for Activewear Success

Creating custom activewear isn’t just about designing clothes – it’s about crafting a strategic asset that embodies your brand’s identity and fuels long-term growth. With the sportswear customization market valued at $182.01 billion in 2023 and projected to climb to $305.67 billion by 2031, it’s clear that investing in custom design places your brand within a booming industry.

Success in this space requires meticulous attention to every detail. Developing comprehensive tech packs, selecting top-tier performance fabrics, and crafting unique designs not only ensure quality but also provide the flexibility to adapt if you need to change manufacturers. Many top brands have built multi-million-dollar enterprises by prioritizing custom designs and premium materials, cultivating strong customer loyalty, and achieving impressive profit margins.

"Custom activewear is not just clothing – it’s a strategic tool. It represents brand identity, delivers superior product quality, and serves as a growth engine that can drive customer loyalty, boost perceived value, and position your brand for long-term success in the competitive athleisure market." – Ohsurewear

Quality control and sampling play a critical role in the production process. Testing prototypes before moving to bulk production helps avoid costly mistakes and ensures the final product meets both performance standards and customer expectations. Clear communication with your manufacturing partners is equally important, as it minimizes delays and ensures consistency in quality. This thorough approach lays the groundwork for ongoing product improvements.

The journey doesn’t end with the launch. Post-launch reviews are just as vital as pre-production checks. Pay close attention to customer feedback, analyze return data, and track the performance of different styles. This real-world data can guide you in refining your designs and enhancing your product line. With custom designs offering the potential for substantial profit margins, grounding your activewear brand in research, quality, and customer engagement is key to standing out in a competitive market.

FAQs

What should I look for when selecting fabrics for custom activewear?

When selecting fabrics for custom activewear, it’s important to focus on a few key qualities. Moisture-wicking fabrics help keep the wearer dry by drawing sweat away from the skin. Durability ensures the material can handle repeated use, while stretchability provides the flexibility and comfort needed for a wide range of movements. Another essential factor is breathability, especially for high-intensity workouts, as it helps regulate body temperature. Don’t overlook support and fabric weight – these elements contribute to a secure fit without feeling overly restrictive.

It’s also smart to consider the climate where the activewear will be used. For warmer environments, lightweight and breathable materials work best, while colder conditions call for thicker, insulating fabrics. By keeping these factors in mind, you can create activewear that balances functionality with performance.

What’s the best way to clearly communicate my activewear design ideas to manufacturers?

When presenting your design ideas, it’s crucial to create a comprehensive tech pack. This should outline all the necessary details, including precise measurements, material specifications, and any additional features. Visual aids like sketches or mockups can help bring your concepts to life and make them easier to understand. Be thorough with technical details – mention stitching techniques, fabric choices, and elements like reflective accents. Adding comments directly within the tech pack can also clarify any intricate parts of your design. Maintaining clear and consistent communication with your manufacturer will help minimize confusion and ensure your design is executed exactly as envisioned.

How can I ensure high-quality standards in custom activewear production?

To ensure top-notch standards in activewear production, begin with a comprehensive quality control checklist. This should cover everything from visual inspections to accurate measurements and performance evaluations. Make sure your quality expectations are crystal clear to your manufacturer, and schedule on-site inspections during production to address any issues early. Test both materials and finished products for durability, functionality, and safety to confirm they align with your standards. Lastly, keep detailed records of all findings to pinpoint areas for improvement and maintain consistency in your future production cycles.