- Top Causes: Material shortages, miscommunication, sampling delays, and quality issues.

- Material Sourcing: Late deliveries and custom fabric orders can stretch timelines. Solutions include diversifying suppliers, using forecasting tools, and consolidating fabric options.

- Factory Miscommunication: Unclear instructions and scattered communication lead to errors. Fix this with detailed tech packs, centralized communication tools, and regular updates.

- Sampling Delays: Poor-quality samples and slow approvals waste time. Digital sampling and streamlined processes can speed things up.

- Quality Control: Defects and non-compliance lead to rework and delays. Regular inspections and clear standards help maintain quality.

Key Takeaway: Early planning, better communication, and reliable quality control are essential to avoid delays and protect your bottom line.

Manufacturing Delays: Key Statistics and Impact on Activewear Production

How to Reduce Lead Times in Your Supply Chain?

Material Sourcing Delays

Material sourcing delays can throw a wrench into activewear production even before manufacturing begins. These disruptions often stem from fabric shortages or suppliers delivering raw materials late or with inconsistent quality. When fabrics are unavailable, it sets off a chain reaction – sampling gets stalled, production timelines are pushed back, and delivery deadlines are missed. For activewear brands relying on performance fabrics with properties like moisture-wicking or stretch, these delays can have a significant ripple effect.

The financial impact is enormous. Poor inventory management and out-of-stock materials cost brands billions each year. The main culprits? Inefficient material planning and a lack of real-time visibility into fabric availability. Without a clear view of the supply chain, delays multiply, driving up costs, shrinking margins, and jeopardizing timely product launches. Let’s break down the key factors contributing to these delays and explore potential solutions.

How Supplier Lead Times Cause Delays

Long lead times from suppliers, especially for performance fabrics, can stretch production schedules by weeks – or even months. The problem worsens when suppliers fail to disclose inventory or capacity issues. Brands relying solely on one supplier for specialized fabrics are particularly vulnerable. If that supplier encounters a hiccup, there’s often no alternative plan in place.

To mitigate these risks, brands should strengthen supplier relationships and leverage digital tools for real-time tracking of material availability. Negotiating shorter lead times, especially for repeat orders, can provide some breathing room when unexpected challenges arise. Diversifying suppliers for critical materials is another way to safeguard against disruptions.

How Customization Affects Material Availability

Custom fabric orders, such as proprietary blends, unique colors, or specialized finishes, can be a double-edged sword. While customization helps brands stand out, it often means waiting for suppliers to create materials from scratch instead of pulling from existing stock. To address this, many activewear brands have consolidated 70% of their fabrics to streamline production and minimize delays.

A balanced approach works best. Limiting custom orders to standout pieces while using readily available fabrics for core styles allows brands to maintain uniqueness without sacrificing speed. Additionally, accurate forecasting of material needs, as outlined below, can help avoid unnecessary delays.

How to Improve Material Forecasting

Accurate material forecasting is essential to prevent last-minute scrambles caused by fabric shortages. Investing in production planning software and AI-driven demand forecasting can make a measurable difference. For example, one company improved its store-level sales forecast accuracy by 5% using AI.

A leading activewear brand adopting an on-demand production model has achieved impressive results, including a 40-day inventory turnover and an unsold inventory rate of under 2%. The secret? An agile supply chain that adapts to changing demand rather than relying on static projections.

Centralizing supply chain operations and implementing end-to-end digital systems can connect merchandising, design, and supply teams, creating the transparency needed for accurate forecasting. Brands should also conduct thorough market research to stay on top of consumer trends and adjust material orders accordingly. Better forecasting is a proactive way to tackle sourcing challenges and keep production timelines on track.

Factory Miscommunication Problems

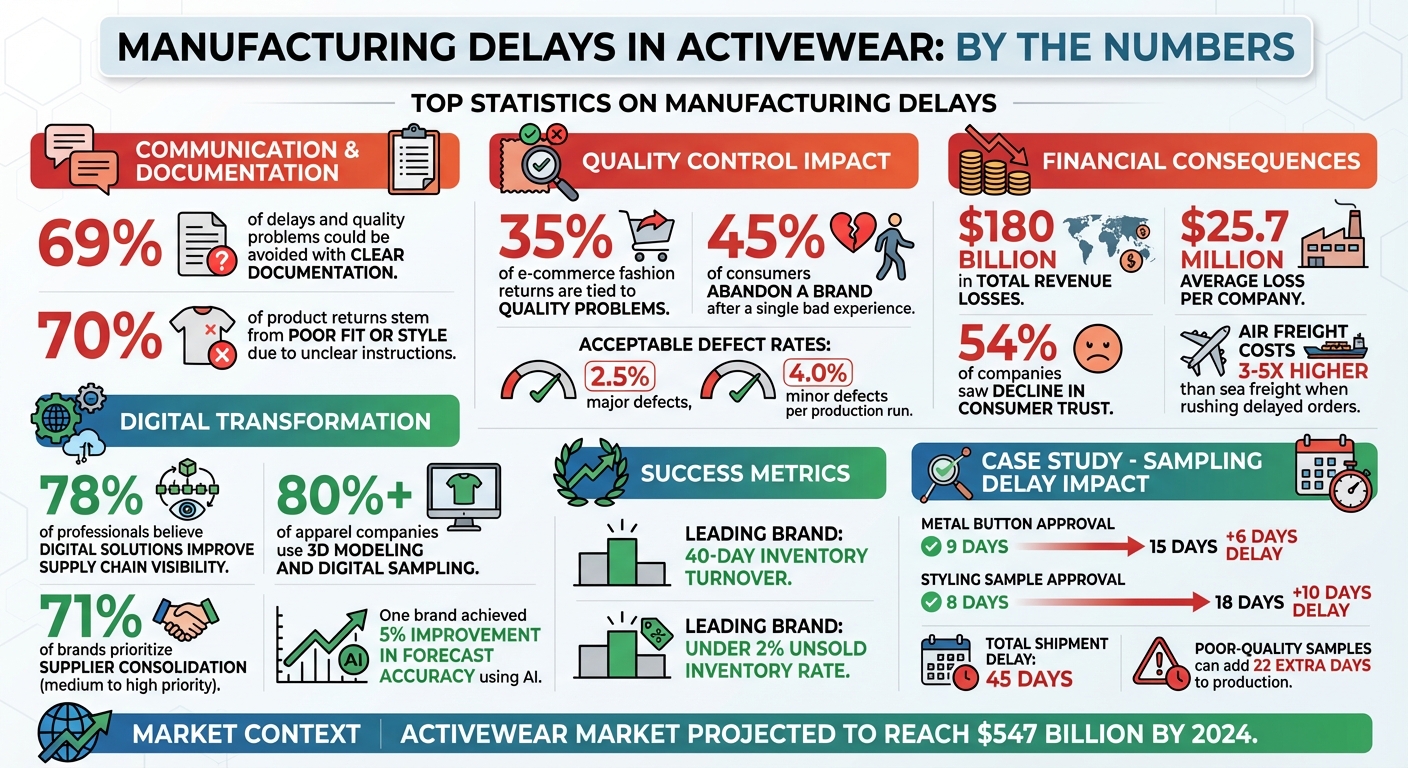

Miscommunication with factories can be just as disruptive as material sourcing challenges, often leading to costly delays and missed launch deadlines. One of the primary reasons behind manufacturing setbacks is poor communication between brands and factories. When instructions are unclear or scattered across multiple emails, errors pile up, creating a domino effect of production issues. In fact, research indicates that 69% of delays and quality problems could be avoided if changes were clearly documented. These communication breakdowns not only slow down production but also result in expensive rework, missed deadlines, and frustration for both brands and factories.

Several factors contribute to these issues, including incomplete tech packs, unorganized communication channels, language barriers, and the absence of digital tracking systems throughout the supply chain. Without clear and centralized communication, factories often misinterpret requirements, leading to mistakes that need to be corrected, further delaying production. Additionally, internal teams struggle to catch problems early enough to prevent them from escalating. Below, we’ll explore some of the most common miscommunication pitfalls.

Typical Miscommunication Problems

One of the most frequent issues is incomplete or unclear tech packs. When technical documentation is missing key details – such as measurements, specific construction instructions, or a complete Bill of Materials – factories are left to make assumptions. These guesses often result in samples that don’t meet expectations, requiring multiple rounds of revisions and wasting valuable time.

Disorganized communication is another major problem. When conversations are scattered across emails, phone calls, and messaging apps, important details often get lost. Teams can spend hours searching for specifications or past decisions, delaying production even further. Language barriers add another layer of complexity, especially with overseas factories. Misunderstandings can lead to incorrect fabric choices, sizing errors, or construction methods that deviate from the original design.

Another critical issue is failing to document changes. Even small adjustments – whether to measurements, materials, or construction techniques – must be clearly communicated and recorded. When this doesn’t happen, factories may continue working with outdated specifications, resulting in products that don’t meet current requirements. It’s worth noting that 70% of product returns stem from poor fit or style, often due to unclear instructions or misaligned expectations between brands and factories.

How to Communicate Clearly with Factories

Clear communication starts with creating precise, detailed tech packs. These should include technical sketches from multiple angles, exact measurements with Point of Measurement (POM) diagrams, comprehensive size charts, a complete Bill of Materials, construction details, stitch and seam specifications, and branding artwork. Focus on including all necessary information while avoiding unnecessary clutter. Always review tech packs for errors before sending them to the factory.

To overcome language barriers, use simple, straightforward language and supplement written instructions with visual aids like photos and diagrams. Consider using neural machine translation tools to translate tech packs into the factory’s native language, which can significantly reduce misunderstandings. Learning basic garment manufacturing terminology can also help brands convey their ideas more effectively.

Adopting digital tracking systems and cloud-based PLM platforms can transform communication by centralizing all production-related information. These tools replace outdated methods like paper notes and scattered emails, creating a single, reliable source where all stakeholders – designers, suppliers, and manufacturers – can access up-to-date information. They also provide real-time updates on production status and automatically generate reports on milestones and potential issues.

Finally, prioritize regular updates and collaborative communication. Schedule weekly video calls or check-ins to address potential problems before they escalate. Respond promptly to factory inquiries, as even a one- or two-day delay in approvals can set back timelines by weeks. Recognize that factories often face additional rescheduling challenges when delays occur, so maintaining a partnership mindset – with flexibility and mutual understanding – can lead to better results for everyone involved. By improving communication practices, brands can not only reduce delays but also streamline the entire production process.

Sampling Delays and Their Impact

Sampling delays can wreak havoc on production schedules and budgets, often leaving brands with tough decisions and hefty costs. When sampling processes take longer than expected, the ripple effects are hard to ignore: shipment delays, overlapping production schedules, higher expenses, quality issues, and even penalties or order cancellations. For instance, a case study on a knit ladies’ t-shirt order (73,890 pieces) revealed how a simple metal button approval stretched from 9 to 15 days, while the styling sample approval jumped from 8 to 18 days. Together, these delays pushed the shipment date back by a staggering 45 days.

The financial blow of such delays is significant. Extended timelines result in reduced cash flow, missed sales opportunities, increased inventory costs, unhappy customers, and a weakened competitive edge. To make matters worse, brands often resort to air freight instead of sea freight to meet deadlines, with transportation costs soaring 3 to 5 times higher. Beyond the immediate financial strain, the damage to a brand’s reputation can be long-lasting. Consumers expect timely deliveries and high-quality products, and failing to meet these expectations can erode trust. A study of 7,000 companies highlighted that 54% saw a decline in consumer trust, leading to revenue losses totaling over $180 billion – an average of $25.7 million per company. These challenges underline the need for efficient workflows, as sampling delays often stem from a mix of preventable issues.

What Causes Sampling Delays

Sampling delays can arise from several sources, often involving both brands and factories. One common culprit is poor-quality sample submissions that require rework – issues like mismatched lab dips, incorrect print strike-offs, or size set errors can add up to 22 extra days to production schedules. When factories fail to meet quality standards, the endless cycle of revisions and approvals eats away at precious time.

Another key factor is slow approval processes, where samples must physically move between offices and await sign-offs from multiple stakeholders. The problem worsens with frequent design changes and incomplete specifications – when brands make constant tweaks or fail to provide detailed technical instructions, factories are forced to restart the process repeatedly. Notably, 69% of delays and quality issues could be avoided if changes were clearly documented.

Limited factory capacity during peak seasons is another bottleneck. When factories prioritize bulk production orders over sample development, sampling timelines stretch further. Additionally, delays in raw material availability, especially for custom trims or specialty fabrics, can bring the process to a halt until materials are secured.

How to Speed Up Sampling

Fortunately, there are practical ways to cut down on sampling delays. Start by streamlining approvals: use a comprehensive requisition checklist to confirm raw materials and construction details upfront, and build buffer time into production schedules. To speed up fit approvals, some brands rely on buyer-approved dummies or body forms, eliminating the need to wait for physical sample shipments. Others are adopting digital garment samples, which allow teams to review 3D renderings instead of waiting for physical prototypes – a move that can save significant time. Transitioning from manual to electronic approval processes can also shave days or even weeks off timelines.

Documenting issues encountered during sampling can create a style history record, helping to prevent similar mistakes in future production. Building a dependable network of vendors for trims and materials ensures smoother processes, avoiding delays caused by unavailable components. Advanced planning is another game-changer – some brands plan production runs as far as 2 years in advance. Finally, having a well-structured contingency plan is critical, as manufacturing rarely goes perfectly. Collaboration between merchandising and product development teams also ensures clear communication, especially when it comes to buyer-prescribed tolerances for fabric shrinkage, GSM variation, or trim placement.

sbb-itb-8dbc09a

Quality Control Problems

Quality control issues can disrupt production, lead to rejected batches, and require costly rework. For activewear brands, these challenges are particularly damaging – 35% of e-commerce fashion returns are tied to quality problems, and 45% of consumers abandon a brand after a single bad experience. The financial hit, combined with a tarnished reputation, is tough to recover from, making quality control a non-negotiable priority. Maintaining consistent quality is key to avoiding delays and safeguarding a brand’s image. To tackle these obstacles, robust quality control measures are essential throughout the production process.

Common Quality Control Failures

Activewear manufacturing comes with its own set of quality hurdles. Incorrect sizing is a recurring issue, often caused by fabric shrinkage or pattern mistakes that render garments unusable. Fabric defects – such as shrinkage, pilling, deformities, or color inconsistencies – can derail entire production runs, especially when performance fabrics fail to meet durability expectations. Poor workmanship, like skipped stitches, uneven seams, or weak flatlock stitching, not only affects aesthetics but also compromises functionality, particularly in high-stress areas like waistbands or inseams.

Defective materials are another common problem. Faulty zippers, broken snaps, or subpar elastic can slip through if suppliers aren’t thoroughly vetted. Non-compliance with safety regulations is equally concerning, whether it’s garments failing flammability tests or containing harmful chemicals. Sharp objects, like broken needles or pins left in finished products, pose serious safety risks that demand immediate attention. Each of these issues often requires rework or re-manufacturing, delaying shipments and driving up costs.

How to Build a Reliable QC Process

Creating a dependable quality control (QC) process involves proactive steps at every stage of production. Pre-production inspections are a must – these include checking all raw materials and trims, along with lab tests for shrinkage, colorfastness, and strength. Reviewing fabric test reports during pre-production meetings and ensuring proper fabric storage can help prevent damage. Additionally, detailed tech packs, as highlighted in the Factory Miscommunication Problems section, can significantly reduce errors from the outset.

During production, in-line inspections should be conducted at critical stages to catch defects early and stop minor issues from escalating. Establish clear quality standards for elements like stitching, fabric weight (GSM), and durability, and make sure these are documented so that everyone – from factory workers to managers – understands the expectations. Many companies adopt a zero-tolerance policy for critical defects, while allowing up to 2.5% major defects and 4.0% minor defects per production run.

Before shipment, a final inspection using AQL (Acceptable Quality Level) testing ensures that finished goods meet the brand’s standards. Partnering with third-party inspection agencies can provide an extra layer of verification, and approving production samples before bulk orders is a smart move. Beyond inspections, fostering continuous improvement is vital. Regular training for production workers, documented for consistency, can make a significant difference. Implement systems to manage sharp objects, conduct random metal detection checks, and create designated storage areas for compliant, non-compliant, and failed goods. Leveraging technology like ERP and RFID systems can streamline processes and improve visibility across the production line.

How to Prevent Manufacturing Delays

Avoiding manufacturing delays requires a proactive mindset and careful planning to tackle potential roadblocks before they disrupt production. By refining workflows, setting timelines that are both practical and achievable, and collaborating with skilled factories, activewear brands can keep production on track and sidestep costly disruptions. Below, we’ll explore strategies to help create a well-rounded prevention plan.

How to Improve Production Workflow

Streamlining production workflows starts with strong planning and control. This includes setting clear Planned Cut Dates (PCD) and assigning specific styles to the appropriate sewing lines to optimize efficiency. Leveraging modern tools like digital tracking systems and cloud-based platforms can provide real-time updates, making it easier to monitor progress and address issues as they arise.

It’s also important to tackle common causes of delays, such as lengthy approval processes, inferior materials, rework, and raw material supply hiccups. Introducing rigorous quality control measures at every step – from inspecting raw materials to cutting and final checks – can help catch problems early. On-demand manufacturing models can further enhance flexibility by centralizing production, integrating the supply chain, and eliminating the need for high minimum order quantities (MOQs). This approach allows brands to adapt quickly to market trends.

Once workflows are optimized, the next step is to ensure production timelines are realistic and well-planned.

How to Set Realistic Production Timelines

Effective production planning hinges on understanding the typical production cycle, which usually spans 2 to 6 months (or 12 to 20 weeks) from concept to delivery. A detailed plan that maps out every stage – from design to final shipment – is essential to stay organized and maintain momentum.

Building buffer periods into the timeline is a smart way to prepare for unexpected challenges, like material shortages or production snags. Working backward from a target launch date can help pinpoint key milestones, ensuring each phase gets the attention it needs. This approach balances speed with quality, reducing the risk of rushed work that might lead to defects or missed deadlines.

Even with a solid timeline, success often depends on choosing the right manufacturing partners.

Working with Experienced Factories

Teaming up with experienced factories can make all the difference in ensuring a smooth production process. Factories with expertise in handling specialized fabrics – like Lycra, polyester blends, moisture-wicking materials, and four-way stretch – are well-equipped to meet the demands of high-performance activewear. These facilities often provide end-to-end solutions, covering everything from product development and design to material sourcing, production, and logistics.

Take New Dong Huang Garment Co., Ltd., for example. With advanced in-house capabilities and cutting-edge facilities, they demonstrate how experienced factories can deliver efficient, high-quality production. Such factories emphasize robust quality control, ethical practices, and effective management of production capacity, accommodating both small and large orders. To ensure a factory aligns with your brand’s values, request product samples and verify certifications like Fair Trade or GOTS for responsible manufacturing.

Conclusion

Tackling production delays in activewear manufacturing starts with early planning, clear communication, and smart partnerships. By identifying the root causes – whether it’s material sourcing issues, miscommunication, sampling slowdowns, or quality control challenges – you can avoid costly setbacks.

Data offers a strong case for these proactive measures. For instance, companies that diversify suppliers regionally have been less impacted by recent supply chain disruptions. Additionally, 78% of surveyed professionals believe digital solutions can improve visibility and transparency across supply networks. These numbers highlight the importance of forward-thinking strategies.

Technology plays a key role here. Tools like 3D modeling and digital sampling – already used by over 80% of apparel companies – boost efficiency and provide greater transparency. Digital tracking systems, cloud platforms, and AI-driven forecasting tools help identify potential delays early, enabling quicker responses to market demands. While technology streamlines operations, strong supplier relationships ensure consistent production.

Consolidating your supplier base is another effective approach. 71% of brands have identified supplier consolidation as a medium to high priority over the next five years. Why? Because deeper partnerships lead to better communication and more reliable outcomes.

With the activewear market projected to hit $547 billion by 2024, refining production strategies is critical. From accurate material forecasting to setting realistic timelines, these steps help meet growing demand while maintaining quality. By combining strategic planning, cutting-edge technology, and strong partnerships, your brand can confidently navigate production challenges and stay ahead in this booming industry.

FAQs

What are the best ways to handle material sourcing delays in activewear production?

To handle material sourcing delays effectively, consider spreading your supplier network across various regions. This approach helps reduce reliance on a single source and adds flexibility to your supply chain. Building strong, long-term partnerships with suppliers is also key, alongside having backup options ready to mitigate unexpected disruptions.

Think ahead by factoring in extended lead times – often ranging from 12 to 20 weeks – and aim to place orders during off-peak seasons when possible. Stay in regular contact with your suppliers to confirm material availability and include extra time in your production schedule to manage unforeseen setbacks. These strategies can help you stay on track and avoid costly production delays.

How can I improve communication with factories to prevent production delays?

Effective communication with factories plays a critical role in keeping production on track. To start, set up clear and reliable communication methods – whether it’s through email, video calls, or project management platforms. Make sure to share comprehensive product details, including visual aids like sketches or tech packs, to avoid misunderstandings.

Plan for regular check-ins to stay updated on progress and tackle any potential problems early. Incorporating digital tracking tools can provide real-time insights into production status, keeping you informed every step of the way. Focus on building a strong working relationship with your suppliers by prioritizing trust and open communication. Finally, create practical timelines that include a buffer for unforeseen delays, helping ensure smoother operations and timely deliveries.

How can technology help streamline manufacturing processes and prevent delays?

Technology has become a game-changer for boosting manufacturing efficiency and cutting down delays. It provides tools that enhance planning, improve communication, and automate processes. Take digital twins, for example – they create virtual replicas of production systems. This allows manufacturers to test and fine-tune operations before rolling them out, helping to avoid bottlenecks and costly mistakes.

Then there’s Industry 4.0 technologies like IoT, AI, and automation. These innovations enable real-time monitoring, predictive maintenance, and better team collaboration. By streamlining workflows and shortening production cycles, they help manufacturers tackle potential problems early, keeping operations smooth and dependable.