Reducing production costs without sacrificing quality is achievable by focusing on key cost drivers and improving efficiencies. Here’s how:

- Fabric Efficiency: Fabric accounts for 60-70% of costs. Use tools like CAD software for pattern nesting to minimize waste and choose cost-effective materials like polyester blends.

- Labor Optimization: Streamline workflows, improve productivity, and use skill matrices to identify inefficiencies in factory processes.

- Simplify Designs: Reduce pattern complexity and embellishments to lower production time and material usage.

- Smart Sourcing: Leverage China’s manufacturing capabilities to lower costs, plan ahead for order timing, and choose reliable suppliers with clear contracts.

- Advanced Technology: Invest in automated cutting and smart factory tools for precise, efficient production.

- Quality Control: Use detailed tech packs, conduct in-line inspections, and train factory teams to prevent defects and reduce costly returns.

These strategies ensure cost savings while maintaining the performance and durability customers expect from activewear. Start by analyzing your cost breakdown, focus on fabric efficiency, and build strong supplier relationships for long-term success.

How To Negotiate Like a Pro: Fashion Factory Pricing Strategies for Brand Owners & Designers

What Drives Production Costs in Activewear

Activewear Production Cost Breakdown by Component

Production Cost Components

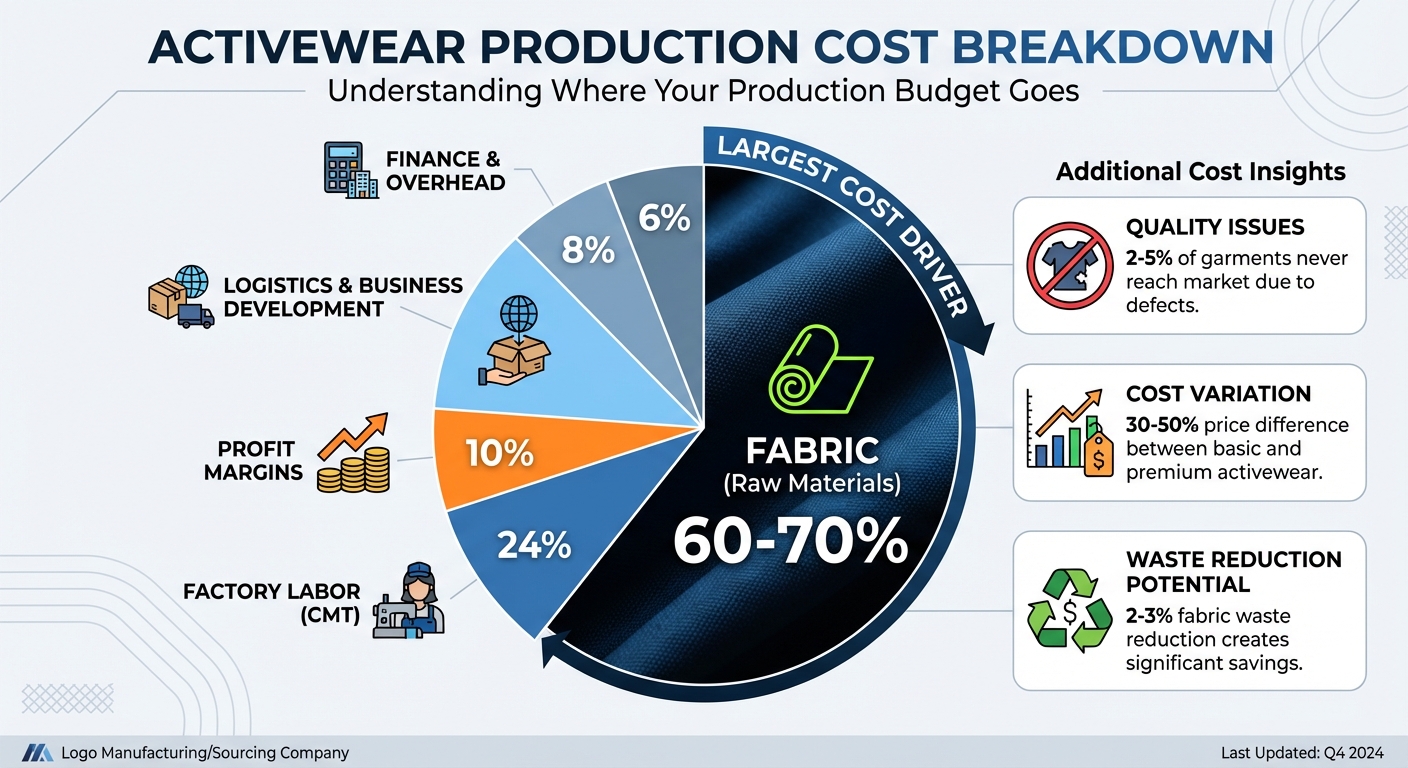

Understanding your production costs starts with knowing where your money goes. In activewear manufacturing, fabric is king, making up a whopping 60–70% of raw material expenses. It’s the single largest slice of your production budget.

Other key expenses include factory labor (about 24%), logistics and business development (around 8%), finance and overhead (6%), and profit margins (roughly 10%). Labor costs – especially for cut, make, and trim (CMT) – come in as the second-biggest expense. These charges can vary widely depending on location, the complexity of your designs, and the size of your production orders.

Don’t overlook the smaller details. Trims, labels, and packaging may seem minor, but they’re essential for both the construction and branding of your products. Then there’s technology – investments in automation or quality control software might seem like an upfront expense, but they often pay off by boosting efficiency. Logistics, including sourcing location, freight methods, insurance, and duties, also play a role in shaping your overall cost structure.

Breaking down these components gives you a clear picture of where your money is going – and where you might find opportunities to save.

Where to Focus Your Cost-Cutting Efforts

Once you’ve identified your cost drivers, the next step is to zero in on areas with the biggest potential for savings. Start with fabric – since it’s your largest expense, even small reductions in usage can lead to noticeable savings. Improving labor efficiency is another key area, but it’s crucial to maintain quality while doing so.

Another way to trim costs is by optimizing yields. On average, 2–5% of garments never make it to market due to quality issues, resulting in direct losses. Additionally, the cost difference between basic and premium activewear can be as much as 30–50%, driven by variations in material quality, construction complexity, and added performance features. Knowing these factors can help you make smarter decisions about where to focus your resources for the best return.

How to Use Costing Worksheets

A well-organized costing worksheet is your secret weapon for managing production expenses. Break everything down – fabric, trims, labor, overhead, and logistics – into actual dollar amounts and percentages. This detailed view helps you identify where you can make the most impactful changes.

For fabric, track utilization by grouping rolls based on width and matching them to specific pattern pieces using spreadsheets. Keep records of leftover materials and consider recutting to reduce waste. On the labor side, analyze productivity metrics and efficiency ratios. Use skill matrices to spot inefficiencies in man-to-machine allocations.

Your worksheet should also account for how order volumes affect unit costs. Larger runs often bring down per-piece costs – as long as your quality control systems can handle the scale without slipping. Regularly updating your worksheet creates a feedback loop, helping you refine your strategy over time and stay on top of your cost management game.

Choosing Fabrics and Trims That Save Money

Picking the right fabrics and trims can help you cut costs without compromising on performance.

How to Select Performance Fabrics

Choosing the right fabric is all about finding the sweet spot between cost and function. Synthetic materials like polyester and nylon are popular for their durability and affordability. Polyester, for instance, is known for its moisture-wicking properties and budget-friendly price, while nylon often offers added performance benefits, especially for activewear. On the other hand, natural fibers like merino wool and bamboo bring perks like temperature regulation and odor control, but they tend to be more expensive and require extra care. If you’re looking to balance performance with cost, fabric blends – such as polyester-spandex or nylon-elastane – are a smart choice. These blends combine the best qualities of multiple fibers while keeping expenses manageable.

Getting the most out of your fabric is just as important as choosing the right one.

Getting More From Your Fabric

Since fabric typically accounts for over 50% of manufacturing costs, using it efficiently can lead to big savings. Techniques like pattern nesting – where pattern pieces are arranged tightly together, almost like a puzzle – help minimize waste. Modern CAD software takes this a step further by optimizing marker layouts in real-time, reducing fabric waste by up to 30%. It’s worth reviewing your current marker layouts to identify areas for improvement. Additionally, maintaining proper alignment with the fabric grain is critical to ensure the final product behaves as intended during wear and washing.

Once your fabric usage is optimized, paying attention to trims can further trim down costs (pun intended).

Simplifying Trims and Components

Though trims may seem like a small expense, they can add up significantly in large production runs. Standard trims like buttons, plastic zippers, elastic, and drawstrings are usually affordable while meeting essential performance standards such as durability, washability, and color consistency. To keep costs under control, avoid unnecessary customization of trims. Sticking to functional, straightforward options ensures you maintain quality without overspending.

Making Production Processes More Efficient

Improving production processes is key to reducing the costs of activewear while maintaining its quality. By refining how activewear is manufactured, you can save on both labor and materials without compromising the final product.

Simplifying Design and Patterns

Streamlined designs and fewer pattern pieces can make production faster and more efficient. Reducing the number of panels in a garment not only cuts sewing time but also lowers thread use and minimizes the chances of errors during assembly. Designing with minimal waste in mind can lead to quick savings – just a 2–3% reduction in fabric use can significantly lower costs. Additionally, limiting embellishments can help keep production expenses down. Simpler designs often yield higher profit margins; for example, a basic T-shirt can be more profitable than a complex formal gown, even if the latter has a higher price tag.

The next step in improving efficiency is selecting the right seams for your garments.

Choosing the Right Seam Types

Seam selection plays a major role in both production costs and garment performance. For activewear that’s worn close to the skin, flatlock seams are a great choice – they’re comfortable and durable, though they require more labor. On the other hand, bonded or heat-sealed seams eliminate the need for thread, creating a smooth, sleek finish ideal for high-performance garments. However, these advanced seam options can increase unit costs by 10–30%. To balance cost and function, use standard overlock seams for basic items, and reserve flatlock or bonded seams for premium pieces that demand extra comfort. Choosing the wrong seam type can lead to early product failures, rejected items, and costly returns – all of which eat into your profits.

In addition to seam selection, leveraging advanced manufacturing technologies can further enhance efficiency.

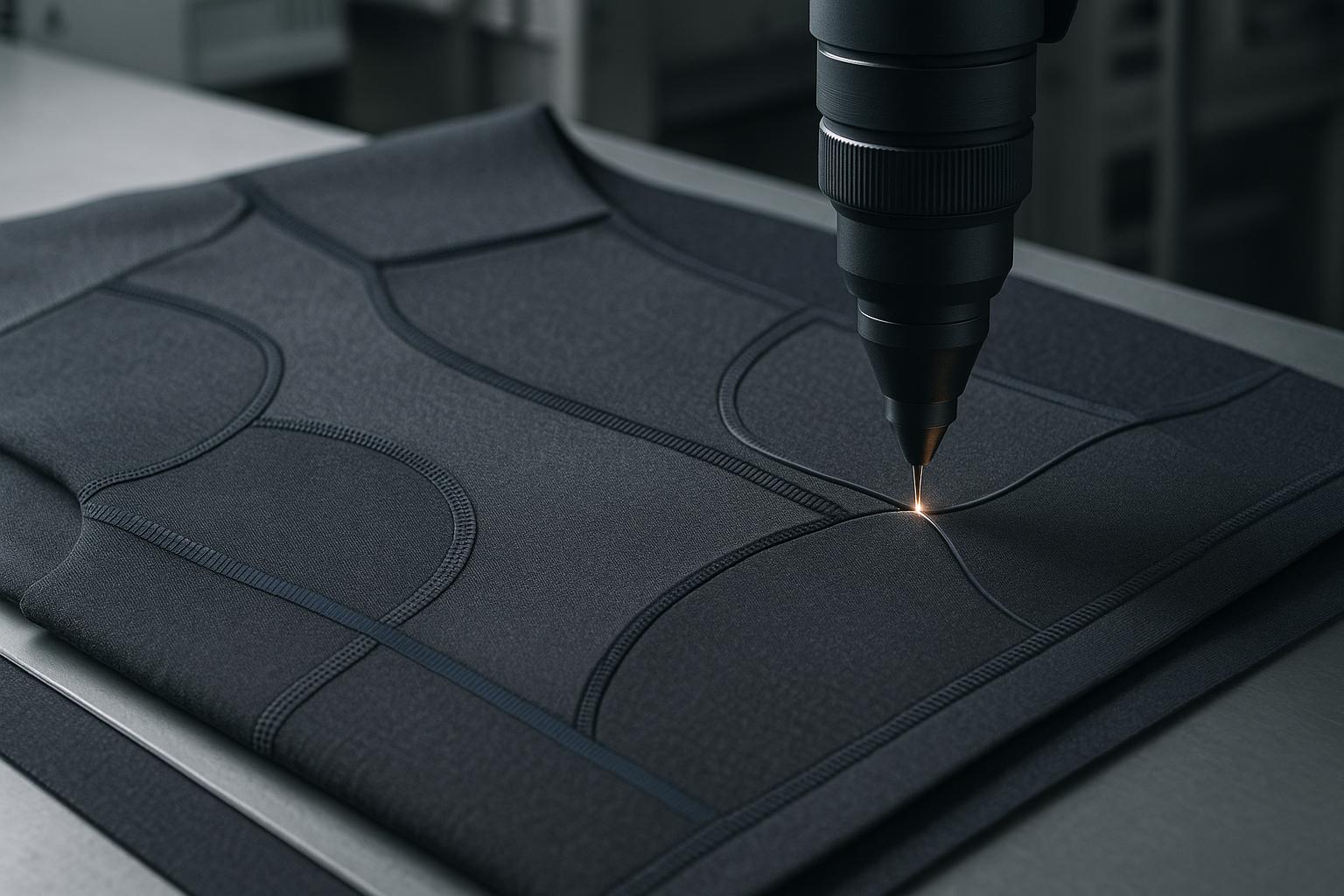

When to Use Advanced Manufacturing Techniques

Technologies like automated cutting, laser cutting, and ultrasonic welding can dramatically improve efficiency by working faster and more precisely than manual methods. These tools reduce mistakes and material waste, making them ideal for large-scale production. If you’re producing high volumes, investing in these technologies pays off. Start with automated cutting systems and expand to other advanced processes as needed. Companies such as Kuris and Zünd offer cutting-edge digital cutting solutions that enhance both speed and accuracy. For sewing operations, machines from brands like Brother, Juki, and Jack can be integrated with smart factory software to optimize workflow and balance production lines. Reserve these advanced techniques for products where the added performance justifies the higher production costs.

sbb-itb-8dbc09a

Improving Factory Communication and Quality Control

Maintaining strong communication with your factory and implementing robust quality control systems can save you from expensive mistakes and production setbacks. When specifications are unclear or quality checks are overlooked, the result is often rejected items, delays, and extra sampling rounds – all of which drive up costs. One of the most effective ways to avoid these issues is by creating a clear, detailed tech pack.

Creating Clear Tech Packs

A well-prepared tech pack is your best defense against production errors. This document should include precise measurements, fabric details, construction guidelines, and a comprehensive Bill of Materials (BOM) that lists every component required for manufacturing. A detailed tech pack ensures that factories have all the necessary information to execute orders accurately, covering every style element, material specification, and even updates or changes.

Using software to manage version control is highly recommended, as it ensures that factory teams always have access to the most up-to-date specifications. Without this clarity, miscommunications can occur, leading to unexpected costs, delays, or even product rejection. Once your technical documentation is in place, the next step is fostering effective collaboration with factory teams to ensure both quality and efficiency.

Working With Factory Teams

Involving factory engineering and quality control teams early in the pre-production process is a smart move. Their hands-on experience allows them to identify potential production issues and offer practical solutions before mass production begins. These teams can provide valuable insights into what works on the production line and help refine your specifications to ensure smoother workflows.

Experienced factory teams, especially those with dedicated quality control personnel, can collaborate with you during pre-production to address concerns and optimize processes. This proactive partnership reduces surprises and helps ensure production runs go as planned.

Setting Up Quality Control Systems

A solid quality control system is essential for catching defects before they reach customers, helping you manage costs and protect your brand’s reputation. Conduct in-line inspections during production and end-line checks once items are completed to address issues while they are still fixable.

Training factory teams on specific quality requirements – like fabric performance tests, seam strength evaluations, and colorfastness checks – is crucial. Aligning these practices with ISO 9001 standards can help streamline processes and minimize waste. By identifying and recording defects early, you can avoid the financial losses and reputational harm that come with product returns.

How to Source in China for Lower Costs

Once you’ve streamlined your production processes, sourcing effectively in China can further cut costs while keeping quality intact.

China is a global powerhouse when it comes to manufacturing athletic footwear and sports gear, producing over 60% of the world’s supply. For example, while a yoga mat might cost $7–9 in the U.S., the same item is priced at just $2–3 in China. These savings stem from factors like large-scale production, lower material costs, and well-established infrastructure. However, to take full advantage of these cost benefits without compromising quality, you need a solid strategy for managing orders, logistics, and supplier relationships.

Planning Order Quantities and Timing

Chinese manufacturers typically operate on slim profit margins of 3–4%, which means they rely on high production volumes to stay profitable. To negotiate lower minimum order quantities (MOQs), submit your full order list upfront. You can also reuse materials across different products to meet subcontractor MOQs while diversifying your product range.

Timing is another crucial factor. Chinese New Year can disrupt production for 2–4 weeks as factories shut down, leading to delays, order backlogs, and higher shipping costs. To avoid these issues, plan several months in advance. Build extra lead time into your schedule and order additional inventory to cover this downtime. Sharing sales forecasts with your manufacturers allows them to prepare materials ahead of time, ensuring production can start promptly once your order is placed. These strategies not only help with production but also simplify logistics.

Reducing Logistics and Shipping Costs

For large orders, ocean freight is the most cost-effective option, while air freight should be reserved for smaller, urgent shipments. Consolidating shipments is another simple way to distribute fixed costs over more units and streamline customs clearance.

Work closely with your factory to optimize packaging dimensions and weight, as shipping costs are calculated based on both. Additionally, understanding your supply chain – including component suppliers – can help you anticipate and resolve potential delays, minimizing the need for costly air freight.

Building Long-Term Factory Relationships

Establishing stable partnerships with experienced factories can lead to consistent quality and better pricing over time. In Chinese business culture, long-term relationships are highly valued. Regular visits and joint meetings go a long way in building trust and fostering collaboration. For instance, factories like New Dong Huang Garment Co., Ltd., with over 27 years of experience, bring extensive technical expertise and proven quality systems that reduce errors and rework costs.

Clear, written contracts are essential. They should outline quality standards, testing protocols, and procedures for addressing issues. These agreements protect both parties and create a foundation of trust. When suppliers feel appreciated and see a long-term partnership with your brand, they’re more likely to accommodate special requests and proactively solve problems before they escalate. Together, these strategies can significantly reduce costs while maintaining high-quality standards.

Conclusion

Cutting production costs while maintaining quality is all about working smarter, not cutting corners. Since fabric often accounts for the largest portion of production expenses, even minor improvements in efficiency can lead to significant savings. Pair this with streamlined production processes, effective factory communication, and thoughtful sourcing strategies, and you have a formula that protects your profits and your brand’s reputation.

Consistent quality issues can lead to costly setbacks. Strengthening quality control and refining processes can save thousands of dollars without increasing operational expenses. This approach not only reduces losses but also supports sustainable growth, ensuring your products stay competitive in a crowded market.

The strategies outlined here show that cost-efficiency and quality can go hand in hand. Industry leaders like New Dong Huang Garment Co., Ltd. demonstrate how brands can balance these priorities. With expertise in fabric innovation, advanced manufacturing, comprehensive quality checks, and transparent costing, NDH provides valuable support to brands aiming to achieve this balance. Their global certifications highlight that reducing costs doesn’t have to mean compromising on performance.

Whether you’re focusing on smarter fabric use, improving production methods, or fostering strong supplier relationships, the guidance in this guide offers a clear pathway to effective cost management. Start with fabric efficiency and quality control, then expand your efforts to production and sourcing improvements. These steps will help drive sustainable growth while keeping your products competitive in today’s market.

FAQs

How does improving fabric efficiency help lower production costs?

Maximizing fabric efficiency plays a major role in slashing production costs. By keeping a close eye on fabric usage, using automated cutting tools, and opting for eco-conscious materials, manufacturers can significantly cut down on waste and avoid unnecessary rework. These strategies help reduce material costs without compromising the quality of the final product.

Efficient fabric management isn’t just about saving money – it can trim costs by as much as 30% while still delivering top-notch results. Striking this balance between cost savings and consistent quality is essential for staying competitive and maintaining sustainable manufacturing practices.

How can I improve labor efficiency while maintaining product quality?

To boost labor efficiency without sacrificing quality, it’s essential to fine-tune workflows and ensure your team is equipped for success. Begin by evaluating your production processes to pinpoint bottlenecks and uncover areas where tasks can be streamlined. Training employees to handle multiple roles can also introduce flexibility and cut down on idle time.

Consider integrating ergonomic workplace designs to improve both comfort and productivity. Tools like 6S or SMED from lean manufacturing can help trim waste and optimize efficiency. Use data analysis to track performance metrics and make well-informed adjustments as needed. Above all, keep strong quality control systems in place to ensure your products consistently meet top-tier standards.

How can sourcing from China help reduce production costs without compromising quality?

Sourcing products from China can be a game-changer for businesses aiming to cut production costs without compromising on quality. Thanks to China’s extensive manufacturing infrastructure, skilled workforce, and cost-effective production methods, companies can produce goods efficiently and at competitive prices.

To maintain quality, it’s crucial to thoroughly evaluate potential suppliers, set clear production standards, and carry out regular quality inspections. Establishing strong, long-term relationships with suppliers not only builds trust but also encourages collaboration, ensuring consistent quality and smoother operations over time. For many manufacturers, sourcing from China strikes the perfect balance between affordability and reliability.