Recycled fabrics outperform virgin materials in reducing carbon emissions, energy use, and water consumption. For activewear manufacturers, switching to recycled alternatives like polyester and nylon offers a practical way to address climate concerns without compromising product performance. Here’s what you need to know:

- Carbon Emissions: Recycled polyester cuts emissions by 45–60%, while recycled nylon reduces emissions by up to 50%.

- Energy Savings: Producing recycled polyester uses 59% less energy compared to virgin polyester.

- Water Use: Recycled fabrics like polyester and cotton significantly lower water consumption – up to 70% in some cases.

- Waste Reduction: Recycled materials repurpose waste like plastic bottles and fishing nets, helping tackle landfill and ocean pollution.

- Performance: Recycled fibers can match virgin materials in durability, moisture-wicking, and stretch, though blending with virgin fibers may be needed for optimal quality.

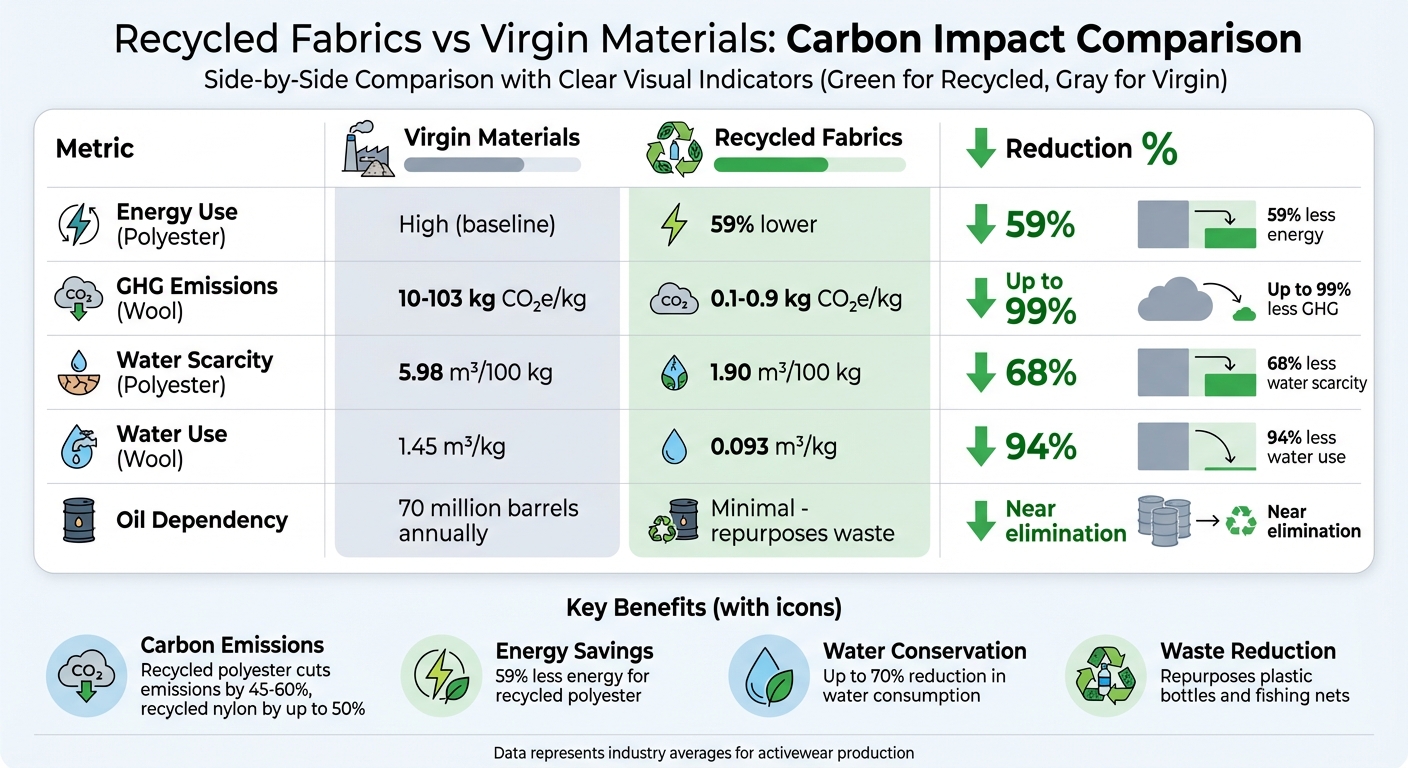

Quick Comparison

| Metric | Virgin Materials | Recycled Fabrics | Reduction |

|---|---|---|---|

| Energy Use (Polyester) | High | 59% lower | 59% |

| GHG Emissions (Wool) | 10–103 kg CO₂e/kg | 0.1–0.9 kg CO₂e/kg | Up to 99% |

| Water Scarcity (Polyester) | 5.98 m³/100 kg | 1.90 m³/100 kg | 68% |

| Oil Dependency | 70 million barrels annually | Minimal – repurposes waste | Near elimination |

Recycled fabrics offer a clear path to reducing the fashion industry’s carbon footprint. While they involve higher initial costs, growing demand and technological advancements are expected to make them more accessible. For manufacturers, the shift to recycled materials isn’t just an option – it’s a smart, measurable way to lower their impact and meet consumer expectations.

Recycled vs Virgin Fabrics: Carbon Footprint Comparison

Carbon Footprint of Virgin Materials

Energy Use and Greenhouse Gas Emissions

The production of virgin materials for activewear comes with significant energy demands and a heavy reliance on fossil fuels. Take virgin polyester, for example – it begins with crude oil extraction, followed by chemical processes to create precursors like paraxylene and ethylene. These steps, combined with chemical synthesis and fiber extrusion, require substantial amounts of electricity and heat, making them major contributors to activewear’s carbon emissions.

To put this into perspective, producing 100 kilograms of virgin polyester textiles results in about 119.59 kilograms of CO₂ emissions. A significant portion – 45.83% – of these emissions comes from the production of terephthalic acid (PTA), a key component in polyester manufacturing. This highlights the role activewear production plays in global greenhouse gas emissions.

Virgin cotton production isn’t much better. It’s energy-intensive due to the extensive use of fertilizers, pesticides, and irrigation. Add to that the effects of intensive land tillage and heavy water usage, and it becomes clear that the environmental costs of cotton production are also steep.

These energy-intensive processes, paired with a dependency on fossil fuels, amplify the environmental toll of virgin materials.

Fossil Fuel Dependency and Waste

The reliance on petroleum-based feedstocks for virgin polyester creates a cascade of environmental challenges. Each kilogram of virgin polyester depends on these feedstocks, and the petrochemical supply chain – from oil extraction to processing – introduces multiple environmental stress points. On top of this, the waste generated during production and disposal further exacerbates the carbon footprint.

When it comes to waste, the story gets worse. Most synthetic fibers used in activewear eventually end up in landfills. Roughly 75% of global textile waste is landfilled, and synthetic materials, being non-biodegradable, can linger for decades. The industry generates an estimated 92 million tons of waste annually, yet less than 1% of used textiles are recycled into new fibers. Additionally, incinerating textiles is a significant climate issue, ranking just behind plastics as the second most harmful type of municipal waste.

These staggering energy requirements and waste figures emphasize the need to explore recycled fabrics as a lower-carbon alternative to virgin materials.

Carbon Footprint of Recycled Fabrics

Lower Greenhouse Gas Emissions

Recycled fabrics significantly cut greenhouse gas emissions. For example, recycled polyester reduces CO₂ emissions by 59%, while recycled wool emits just 0.1–0.9 kg CO₂e per kilogram, compared to the hefty 10–103 kg CO₂e for virgin wool.

The key lies in using existing resources like plastic bottles, discarded fishing nets, or garment scraps. Unlike virgin materials, which require energy-heavy processes like crude oil extraction for polyester or livestock farming for wool, recycled fabrics sidestep these high-emission steps.

The recycling method also matters. Mechanical recycling, which involves shredding or breaking down fibers, typically uses less energy than chemical recycling, which processes fibers at a molecular level. While chemical recycling can produce higher-quality yarns, it demands more energy. The use of renewable energy, such as hydropower, in the recycling process can further amplify its environmental advantages.

Take Manteco SpA, an Italian company that created MWool® in 2019. By blending 15% pre-consumer and 85% post-consumer wool waste and manually sorting it by color in Prato, Italy, they eliminated the need for re-dyeing. This process resulted in a carbon footprint as low as 0.1 kg of CO₂e per kilogram, a stark contrast to the 10.4 kg minimum for virgin wool.

These impressive reductions in carbon emissions also pave the way for major water and energy savings – key metrics for manufacturers aiming to lower the environmental impact of activewear.

Water and Energy Savings

Recycled fabrics not only lower emissions but also slash water and energy consumption. For instance, recycled polyester uses far less water, with a water scarcity footprint of 1.90 m³/100 kg compared to 5.98 m³/100 kg for virgin polyester – a nearly 70% reduction. This is largely because recycled fibers bypass the water-intensive cultivation and dyeing stages required for virgin materials.

Recycled cotton offers similar benefits. In cotton production, organic cotton accounts for 54% of the water scarcity potential, while post-consumer and post-industrial recycled cotton contribute only 24% and 22%, respectively. A great example is Portuguese company Valérius 360, which transforms 100% post-industrial cotton waste from garment scraps into new yarns, cutting down the need for virgin cotton and the water-intensive farming it requires.

Energy savings follow a similar pattern. Organic cotton, often used in recycled blends, reduces energy demand for processes like machinery and ginning by 62%. Even when factoring in the energy required for collecting, sorting, and reprocessing materials, recycled fabrics generally come out ahead. However, logistics like collection and international transport can still influence the overall carbon footprint.

These reductions in water and energy use make recycled fabrics a smart choice for activewear manufacturers focused on sustainable production methods.

Direct Comparison: Recycled Fabrics vs Virgin Materials

Comparison Table: Carbon Metrics

Looking at the carbon footprint data side by side, the environmental benefits of recycled fabrics become strikingly clear. For instance, recycled polyester uses 59% less energy than virgin polyester, and recycled wool can slash carbon emissions by up to 99% compared to its virgin counterpart. These reductions in energy use and emissions mark a meaningful step forward in making activewear production more sustainable.

Wool production stands out as a significant case. Virgin wool generates between 10 and 103 kg of CO₂ equivalent per kilogram, largely due to methane emissions from sheep. In comparison, recycled wool – like MWool®, introduced by Manteco SpA in 2019 – emits only 0.1 to 0.9 kg of CO₂ equivalent per kilogram. This massive difference underscores the potential for recycled materials to transform industries heavily reliant on high-emission processes.

Water consumption is another area where recycled fabrics shine. A study conducted in June 2025 at SunFibre Industry in Lahore, Pakistan, found that blending 50% recycled PET with 50% virgin cotton reduced water usage by 14% while also cutting overall environmental impacts. The table below highlights these key metrics:

| Metric | Virgin Materials | Recycled Fabrics | Reduction |

|---|---|---|---|

| Energy Use (Polyester) | High (baseline) | 59% lower | 59% |

| GHG Emissions (Wool) | 10–103 kg CO₂ eq./kg | 0.1–0.9 kg CO₂ eq./kg | Up to 99% |

| Water Scarcity (Polyester) | 5.98 m³/100 kg | 1.90 m³/100 kg | 68% |

| Water Use (Wool) | 1.45 m³/kg | 0.093 m³/kg | 94% |

| Oil Dependency | 70 million barrels annually | Minimal – repurposes waste | Near elimination |

Fossil fuel consumption further highlights the divide. Virgin polyester production requires 70 million barrels of oil each year, while recycled polyester dramatically reduces this dependency by utilizing plastic waste instead of extracting new petroleum. This shift not only conserves resources but also addresses plastic waste, making recycled fabrics a smarter choice for the planet.

What Is Recycled Polyester? Is It A Sustainable Fabric? Everything You Need To Know About the Debate

sbb-itb-8dbc09a

Performance and Cost Considerations in Activewear

Striking the right balance between performance and cost is a key challenge in producing sustainable activewear.

Performance: Durability, Stretch, and Moisture-Wicking

Recycled polyester and nylon can deliver moisture-wicking, durable, and breathable qualities on par with virgin materials. However, the recycling process can alter fiber structure, affecting performance. For instance, mechanical recycling, which dominates the recycled polyester market (99% of it, to be exact), tends to shorten fibers during processing. To counter this, manufacturers often blend recycled fibers with virgin ones to retain the strength and flexibility essential for high-performance garments [2,9].

On the other hand, chemical recycling offers a more refined approach. By breaking fibers down to their monomer or polymer components, this method creates regenerated yarns that can match or even surpass virgin quality without the fiber-length limitations of mechanical recycling [2,9]. For example, cellulose carbamate recycling produces fibers with "cotton-like" characteristics that rival virgin man-made cellulosics in performance. Ultimately, fabric construction plays a more significant role in determining performance than whether fibers are recycled or virgin.

These advancements in fiber recycling set the stage for understanding how costs factor into sustainable activewear production.

Cost Implications

Recycled fabrics, while offering strong performance, come with higher initial costs. Recycling involves additional steps – gathering, sorting, cleaning, and reprocessing waste into usable yarns – all of which increase production expenses [15,24]. Labor-intensive processes, lower economies of scale, and the need for specialized equipment and certifications (like GOTS or Fair Trade) further drive up costs [15,24,25].

However, these upfront costs can translate into long-term benefits. Recycled fabrics provide durability, give brands a competitive edge, and align with a growing consumer willingness to pay more for sustainable products. As demand for eco-friendly activewear grows, scaling up production is expected to lower per-unit costs [24,25]. Additionally, ongoing improvements in recycling methods and sustainable dyeing processes are gradually reducing the expenses traditionally associated with eco-conscious fashion.

At New Dong Huang Garment Co., Ltd., these cutting-edge strategies are at the heart of creating activewear that meets high performance standards while staying true to sustainability goals.

Impact on Manufacturing Practices

Recycled fabrics are changing the way activewear is made by shifting the focus from extracting raw materials to using advanced collection and sorting systems. For example, under EU regulations, textile waste must be collected separately by 2025, prompting manufacturers to develop textile hubs. These hubs rely on manual sorting for reuse and technologies like near-infrared (NIR) and RFID to recycle materials by fiber type and color. This shift not only reduces landfill waste but also cuts down on incineration, directly lowering the industry’s carbon footprint. Essentially, these efforts tie the earlier benefits of carbon reduction to broader manufacturing improvements.

One challenge in this process is pre-sorting recycled fabrics. Fasteners must be manually removed from post-consumer materials. A notable example is Valérius 360 in Portugal, which, as of June 2025, requires manufacturers to separate waste by composition and color before sending it to recycling units. This step ensures fiber quality but adds complexity to the supply chain. However, this extra effort supports a closed-loop system, keeping materials in use longer.

Certifications like the Global Recycled Standard (GRS) now play a crucial role in verifying recycled content throughout the production process. To meet GRS standards, products must include at least 20% recycled material while adhering to environmental and social compliance measures.

While recycled materials reduce the impact of raw materials, the manufacturing stages – such as spinning, dyeing, and finishing – can still have significant environmental effects. In fact, these steps can account for up to 96% of water scarcity for certain fabrics. To address this, manufacturers are pairing recycled sourcing with low-impact dyeing techniques and digital printing to minimize waste and carbon emissions.

Activewear Applications and Industry Trends

These advancements in manufacturing align with the growing incorporation of recycled fabrics into activewear. Today, recycled polyester and nylon are widely used in high-performance gear like leggings, sports bras, and jackets. This trend is driven by consumer demand and regulatory changes. In 2025 alone, the fashion industry was responsible for around 1.2 gigatons of CO₂ emissions, accounting for 3%–10% of global climate impact.

Take-back programs are also gaining traction, allowing consumers to return used garments for recycling. A standout example is the New Cotton Project, which, in July 2024, tested a circular value chain for a hoodie made with 60% chemically recycled cellulose carbamate fiber. Using a take-back system, the garments were collected after use and processed in Finland. The results showed reduced climate impact and lower land use compared to conventional cotton.

New Dong Huang Garment Co., Ltd. has embraced these practices, combining recycled fabric sourcing with cutting-edge manufacturing techniques. Their approach delivers high-performance activewear that meets sustainability goals while adhering to industry certifications.

Conclusion: Making Informed Material Choices

Recycled fabrics dramatically reduce carbon emissions compared to virgin materials. For instance, recycled wool emits only 0.1–0.9 kg CO₂e per kg, while virgin wool ranges from 10–103 kg CO₂e per kg. Similarly, recycled polyester cuts the water scarcity footprint from 5.98 to 1.90 m³ H₂Oeq per 100 kg. These numbers clearly highlight the environmental benefits of choosing recycled fabrics. Experts back this up:

"Textiles manufacturing using recycled fibres generally gives lower impacts than using virgin ones." – Lucia Rigamonti and Mario Grosso, Waste Management

In the activewear industry, where both performance and sustainability are non-negotiable, the pressure to reduce environmental impact is immense. With the sector projected to generate 1.2 gigatons of CO₂ emissions by 2025, transitioning to recycled materials is no longer optional – it’s essential. Recycled polyester and nylon deliver the durability, stretch, and moisture-wicking properties that activewear requires, proving that sustainability doesn’t mean sacrificing quality.

Brands can take this further by focusing on mechanically recycled fibers, using color-sorted waste to avoid dyeing, and introducing take-back programs to secure consistent material streams. Companies like New Dong Huang Garment Co., Ltd. demonstrate how these practices can produce high-performance activewear while meeting sustainability goals.

For brands committed to reducing their environmental footprint, recycled fabrics offer a practical solution – delivering measurable carbon reductions without compromising performance. It’s a step forward that aligns with both industry standards and the planet’s needs.

FAQs

What’s the environmental impact of recycled fabrics compared to virgin materials?

Recycled fabrics tend to have a much smaller impact on the planet compared to materials made from scratch. By reusing fibers that already exist, recycled textiles skip the energy-heavy steps of growing, harvesting, and processing raw materials. This can lead to a reduction in greenhouse gas emissions by 30% to 50% for every kilogram of yarn produced. Plus, they use far less water – recycled polyester can slash water usage by up to half, while recycled cotton cuts water consumption by around 50% compared to traditional cotton farming methods.

Another benefit? Recycled fabrics help keep textile waste out of landfills, cutting down on methane emissions and preserving valuable resources. That said, some recycling methods, like mechanical shredding, can slightly weaken fiber quality, which might impact how long garments last. Even so, most studies agree that recycled fibers provide clear environmental advantages, making them a smart and eco-friendly option for activewear.

How do recycled fabrics compare to virgin materials in activewear performance?

Recycled polyester (rPET) performs almost exactly like virgin polyester because the recycling process preserves the chemical structure of the fibers. Both materials deliver excellent strength, durability, moisture-wicking, and quick-drying capabilities, making them perfect for high-performance activewear.

One noticeable difference is that recycled fabrics often feel a bit softer and smoother, which many people prefer for activities like yoga or running. While there might be slight variations in tensile strength, recycled fabrics still offer the essential qualities – stretch, breathability, and color retention – that athletic wear demands. This makes rPET a more environmentally friendly choice without compromising on performance or comfort.

Why are recycled fabrics more expensive than virgin materials even though they’re better for the environment?

Recycled fabrics often come with a steeper price tag upfront. Why? Turning waste materials into quality yarn is no small feat – it involves intricate steps like collecting and sorting materials, plus the use of cutting-edge recycling technologies. All of this demands a hefty investment in specialized equipment and infrastructure.

On top of that, recycled materials are typically made in smaller batches compared to their virgin counterparts, which drives up production costs. Even so, the environmental perks are hard to ignore. By cutting down on waste and reducing carbon emissions, recycled fabrics stand out as a smart, eco-friendly option for brands and shoppers who care about the planet.