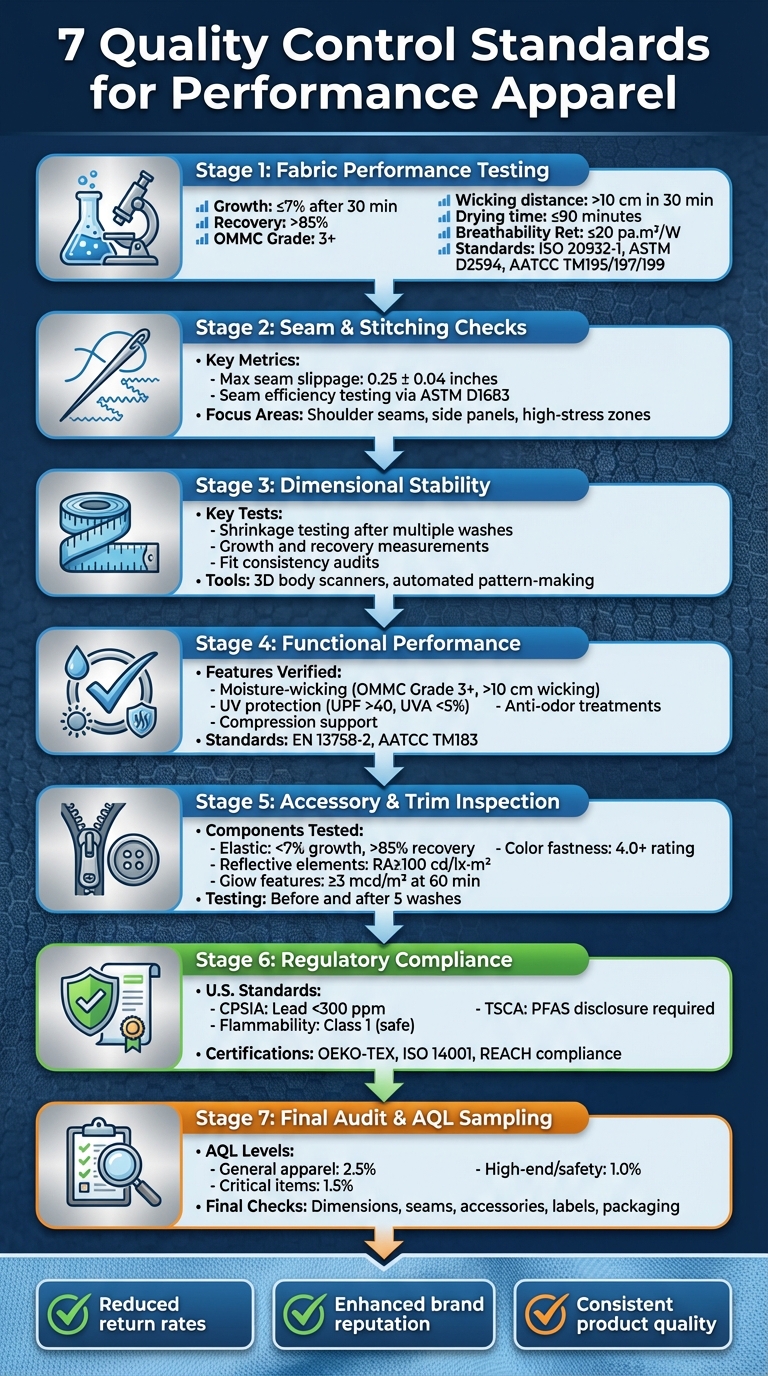

Performance apparel is not just about style – it must perform under tough conditions. From staying durable after countless washes to maintaining fit and functionality during intense activities, quality control is the backbone of delivering reliable activewear. Poor quality can lead to high return rates, wasted materials, and damaged brand reputation. To avoid these pitfalls, manufacturers focus on these key quality control checkpoints:

- Fabric Performance Testing: Ensures durability, stretch recovery, moisture-wicking, breathability, and quick-dry capabilities meet benchmarks.

- Seam and Stitching Checks: Verifies seam strength, slippage resistance, and durability in high-stress areas.

- Dimensional Stability and Fit Consistency: Tests for shrinkage, stretch, and fit accuracy over time.

- Functional Performance Verification: Confirms features like UV protection, moisture-wicking, and anti-odor treatments work as intended.

- Accessory and Trim Inspection: Evaluates zippers, elastic bands, and reflective elements for durability and performance.

- Regulatory Compliance and Safety: Ensures adherence to chemical safety and flammability standards, like CPSIA and ISO certifications.

- Final Product Audit and AQL Sampling: Conducts thorough inspections and statistical sampling to catch defects before shipment.

7 Quality Control Standards for Performance Apparel Manufacturing

Apparel Quality Control Standards And Procedures

1. Fabric Performance Testing

Before production kicks off, fabrics go through a series of rigorous lab tests to prove their durability and functionality. This is the starting point of quality control – where materials are scientifically evaluated to ensure they meet performance expectations.

These tests are grouped into three main categories: chemical, physical, and performance tests. For activewear, the focus is on physical and performance properties that guarantee durability during workouts. Key tests assess tensile strength, abrasion resistance, and stretch recovery. These ensure the fabric can handle tension, friction, and repeated stretching. Industry benchmarks set a Growth percentage at ≤7% after 30 minutes of relaxation and a Recovery percentage above 85%. Testing protocols vary based on fabric type – knitted fabrics adhere to ISO 20932-1 and ASTM D2594, while woven fabrics follow ISO 20932-1 and ASTM D3107 standards. The goal is to ensure activewear retains its appearance and functionality, even after heavy use.

One of the most critical aspects of activewear is moisture management – this is what separates ordinary fabrics from the ones athletes actually prefer. Tests like AATCC TM195 and TM197 confirm whether fabrics can wick sweat effectively, with benchmarks such as an OMMC Grade of 3 and a wicking distance of over 10 cm within 30 minutes. Quick-dry capabilities are also evaluated using standards like AATCC TM199, which requires drying times of 90 minutes or less.

Breathability, another essential feature, is measured using the Ret method (ISO 11092, with a score of ≤20 pa.m²/W) and water vapor transmission tests (≥600g/m²/24h or ≥10,000g/m²/24h). These tests ensure fabrics allow airflow and moisture evaporation, delivering comfort during intense activities. By relying on these measurable results, manufacturers can confidently select materials that meet performance promises before they are turned into finished garments.

Once fabric performance is validated, the next step is to evaluate seam and stitching integrity.

2. Seam and Stitching Integrity Checks

Even the most advanced fabrics can fail if their seams are weak. Testing seam strength is crucial to determine how much force a seam can handle before breaking, ensuring it can endure the wear and tear of regular use. The ASTM D1683 method is commonly used for this purpose. It applies force perpendicular to the seams until failure, measuring not just the breaking strength but also the seam efficiency. This efficiency is calculated by comparing the strength of the seamed fabric to that of the unseamed base material. While strength is a key factor, seam slippage is another issue that can compromise durability.

Seam slippage happens when the fabric’s yarns shift under stress, leading to puckering, loss of shape, and eventual failure. Industry standards generally allow a maximum slippage of 0.25 ± 0.04 inches – anything beyond that can weaken the garment. To address this, specific tests evaluate how well stitching resists slippage, with particular focus on high-stress areas like shoulder seams and side panels.

"The apparel quality largely depends on fabric quality and also on seam quality. Seam performance and appearance largely correlate with fabric characteristics, sewing-thread properties, selection of stitches and seams, and also with sewing conditions such as size of needle, sewing-thread tension, number of stitches per inch, and maintenance and operation of sewing machine." – Suprit Borse, Kamlesh Sonawane, Madhuri V. Kakde, and Tushar A. Shinde, IntechOpen

This quote underscores the importance of precision in stitching techniques when it comes to overall garment quality. Seams must also pass laundering and abrasion tests to ensure they maintain their strength and appearance over time. These tests follow standardized protocols, and combining lab results with visual inspections helps manufacturers pinpoint weak spots and adjust sewing methods before moving into mass production.

Testing seam integrity early in the process is critical. Skilled factory operators should handle the preparation of seams, as improper stitching or handling can damage samples and produce inaccurate results. By addressing potential issues at this stage, manufacturers can avoid costly production setbacks. Once seam and stitching quality are confirmed, the focus can shift to evaluating the garment’s fit and stability.

3. Dimensional Stability and Fit Consistency

When it comes to performance apparel, keeping garments true to their size and shape – even after countless washes and uses – is non-negotiable. Dimensional stability testing plays a big role here, replicating real-life conditions to catch potential issues early on. For instance, shrinkage testing mimics the washing and drying process to measure how much a fabric shrinks or stretches over time. With this data, manufacturers can fine-tune cutting sizes and sewing methods to ensure garments maintain their intended fit, no matter how many times they’re laundered.

Using precise measurement protocols – like checking shoulder width or sleeve length – and incorporating advanced tools like 3D body scanners can drastically reduce errors. Collaborating with production facilities that utilize automated pattern-making and fabric-cutting software further minimizes inconsistencies, especially for performance-focused garments.

For stretchable materials, growth and recovery tests are essential. These tests measure how well fabrics stretch and bounce back to their original shape. Testing samples both upon arrival and after several washes helps manufacturers gauge how well the fabric holds up over time. This is particularly critical for activewear, which needs to retain its compression and support features throughout its lifespan.

Regular fit audits are another layer of quality control. By working with professionals and conducting sample fittings, manufacturers can spot size deviations before they become widespread issues. Applying anti-shrink treatments is another way to preserve garment dimensions and keep them consistent.

Finally, gathering feedback from actual users is invaluable. While lab tests are thorough, real-world wear often uncovers subtle issues that controlled environments miss. Combining standardized measurement practices with insights from consumers ensures a more complete approach to fit consistency. This careful evaluation process guarantees that garments not only meet dimensional stability standards but are also ready for the next stage of performance testing.

4. Functional Performance Verification

Fabric tests might confirm material properties, but functional verification goes a step further – it ensures these properties deliver consistent performance in the final product. Once dimensional stability is confirmed, it’s time to check if features like moisture-wicking, UV protection, anti-odor, and compression hold up under real-world conditions.

For moisture-wicking, testing measures how well fabrics transport and evaporate sweat. Standards often require a minimum wicking height (e.g., over 10 cm within 30 minutes) and an Overall Moisture Management Capability (OMMC) grade of 3 or higher. These benchmarks ensure garments maintain reliable moisture management across production batches.

UV protection is another crucial feature, assessed using protocols like EN 13758-2 and AATCC TM183. These tests measure how effectively the fabric blocks harmful ultraviolet rays. A UPF rating above 40 and UVA transmittance below 5% are typically required. Testing the finished garment is essential because design details – like seam placement or layering – can impact UV protection.

Anti-odor and compression features undergo rigorous testing too. Garments are subjected to repeated washing and stress cycles to confirm that odor-control treatments and support features remain effective over time. These checks ensure the product performs as promised, even with regular use.

sbb-itb-8dbc09a

5. Accessory and Trim Quality Inspection

After functional performance checks, it’s time to examine the quality of accessories and trims, ensuring every detail meets the demands of activewear.

Performance apparel isn’t just about the fabric – components like zippers, elastic bands, drawcords, and reflective elements also need to withstand heavy use. These tests mirror earlier assessments for fabric and seam durability but focus on the smaller details that make a big difference.

Accessories are put through pull, fatigue, and stretch tests to measure durability and resilience. For elastic bands, industry standards require less than 7% growth after 30 minutes and more than 85% recovery, following ISO 20932-1 or ASTM D2594 guidelines. Similarly, zippers and drawcords are subjected to mechanical stress tests to simulate extended wear and ensure they hold up under repeated use.

Trims must also undergo colorfastness testing to ensure they maintain their appearance. Using weathering tests like Xenon-arc (AATCC TM16.3) or UV exposure (AATCC TM186), trims typically need to achieve a color change rating of 4.0 or higher. Reflective elements are evaluated for retroreflective performance, with a minimum standard of RA≥100 cd/lx·m² in compliance with ANSI 107 or ISO 20471. Glow-in-the-dark features are tested for luminous intensity, often requiring at least 3 mcd/m² at 60 minutes per ISO 17398.

To ensure long-term reliability, components are tested both before and after five washes. Additional checks include drawcord pull strength, snap button force for secure yet releasable attachments, and water-repellent performance for trims, assessed using spray tests (AATCC TM22) or hydrostatic pressure methods (AATCC TM127).

Quality inspections are conducted at multiple stages – pre-production, during production, and as a final check – to catch defects before products reach customers. Clear specifications for every component, from thread strength to button attachment force, help maintain consistency across production batches. This thorough approach ensures that every accessory and trim meets the high standards expected in activewear.

6. Regulatory Compliance and Safety Standards

Before performance apparel lands in the hands of consumers, it must comply with strict regulatory requirements. In the U.S., these regulations ensure that products meet essential safety standards, which include rigorous chemical and flammability testing.

Chemical Safety Regulations in the U.S.

The Consumer Product Safety Improvement Act (CPSIA) limits lead content in children’s clothing to 300 ppm and restricts the use of phthalates. Similarly, the Federal Hazardous Substances Act (FHSA) prohibits harmful chemicals like formaldehyde, often used in wrinkle-resistant treatments. Under the Toxic Substances Control Act (TSCA), manufacturers must disclose the use of PFAS and are barred from using decaBDE flame retardants in textiles. Additionally, California Proposition 65 requires warning labels for products containing high levels of substances like lead acetate, cadmium, chromium, or phthalates.

Flammability Standards

Flammability testing is governed by the Flammable Fabrics Act (FFA) and 16 CFR Part 1610. Fabrics are categorized as follows:

- Class 1: Normal flammability, considered safe for apparel.

- Class 2: Intermediate flammability, applicable to raised surface fabrics.

- Class 3: Dangerously flammable, banned for use in clothing.

Children’s sleepwear faces even stricter regulations under 16 CFR Parts 1615 and 1616, requiring flame-resistant materials that self-extinguish when ignited.

Certification Requirements

The type of certification required depends on the product. General apparel must have a General Certificate of Conformity, while children’s products need a Children’s Product Certificate to confirm compliance with all relevant standards.

Global Standards for Safety and Sustainability

Beyond U.S. laws, international frameworks like REACH add another layer of safety by ensuring chemicals used in production are not harmful to human health or the environment. Certifications like OEKO-TEX also verify that textiles meet stringent safety criteria. Meanwhile, ISO 14001 offers guidelines for environmental management systems, helping manufacturers maintain sustainable practices throughout their operations.

7. Final Product Audit and AQL Sampling

After extensive testing in earlier stages, the final audit serves as the ultimate checkpoint to catch any lingering defects. This process ensures that garment dimensions, seam quality, accessory installation, labels, and packaging align with the design specifications. The audit examines every critical aspect, including the strength of accessories, overall appearance, label accuracy, and packaging integrity. By the end of this stage, the quality assurance process comes full circle.

AQL sampling simplifies quality control by focusing on random checks instead of inspecting every single item. The Acceptable Quality Limit (AQL) is a statistical benchmark that defines the maximum allowable number of defects in a random sample from a production batch. Instead of evaluating each garment, this method provides an efficient way to determine if the entire lot meets quality standards. The AQL is typically expressed as a percentage or ratio, showing the number of defective items allowed relative to the total items in the batch.

"Inspections should be conducted using standardized sampling methods, such as Acceptable Quality Limits (AQLs), which specify the acceptable level of defects in a specific batch." – QIMA

For brands that demand flawless quality, 100% inspection is an option. However, AQL sampling – often set at 2.5% for general apparel, 1.5% for more critical items, and 1.0% for high-end or safety-sensitive products – offers a practical balance between thoroughness and efficiency. When it comes to performance apparel featuring specialized properties like moisture-wicking, breathability, or UV protection, stricter AQL levels are typically applied to ensure these features function as promised. The choice of AQL level depends on factors such as brand standards, product complexity, market expectations, and regulatory requirements.

Once products pass this final stage, they are cleared for shipment. This step ensures that performance apparel consistently upholds the rigorous standards expected by consumers.

Conclusion

Creating performance apparel that lives up to its promises requires meticulous quality control at every step of production. From rigorous fabric testing to final product inspections, these seven key standards ensure activewear can handle intense workouts, retain its shape, and deliver functional benefits like moisture-wicking and breathability. Each stage targets potential weak points that could impact the garment’s durability, comfort, or safety.

Adopting these quality control measures not only protects your brand’s reputation but also helps reduce production costs. When your products consistently meet performance expectations, customer satisfaction increases, return rates decrease, and your position in the market strengthens.

These practices do more than guarantee performance – they also uphold your brand’s integrity. Investing in thorough quality checks leads to more durable products and loyal customers. Over time, this commitment builds a strong, positive brand image that resonates with consumers who expect activewear to perform as promised.

By embedding these standards throughout the production process, manufacturers can differentiate themselves in a crowded market. Steps like fabric testing, seam inspections, and final audits ensure consistency across batches while meeting regulatory requirements. Moreover, pairing these practices with sustainable manufacturing methods appeals to environmentally conscious consumers, showcasing a commitment to corporate responsibility.

Focusing on continuous improvement at every stage is critical. By prioritizing fabric performance, seam strength, dimensional stability, functional features, trim quality, regulatory compliance, and final audits, brands can deliver activewear that not only meets but exceeds customer expectations.

FAQs

What tests are used to ensure performance apparel fabrics are durable and reliable?

To ensure performance apparel fabrics hold up under demanding conditions, several critical tests are performed. These include abrasion testing (utilizing methods like Martindale and Wyzenbeek), tensile strength testing, tear strength testing, and pilling resistance testing. Each test focuses on a specific aspect of durability – evaluating how fabrics handle wear, stretching, tearing, and surface damage over time.

These thorough evaluations are essential for confirming that performance apparel can maintain its quality and functionality during active use, delivering the reliability users expect.

How do manufacturers keep performance apparel fitting well after repeated washes?

Manufacturers design performance apparel to hold its shape even after numerous washes by using durable, shrink-resistant fabrics like polyester or specially crafted blends. Many of these garments also incorporate pre-shrunk materials, reducing the risk of size changes during laundering.

To keep the fit intact, it’s important to follow care instructions closely. This typically includes washing in cold water, selecting a gentle cycle, and opting to air dry or use a low-heat setting on the dryer. These simple steps help the clothing retain its original shape and performance qualities.

Why is regulatory compliance important for ensuring the quality of performance apparel?

Regulatory compliance plays a key role in ensuring performance apparel meets all legal requirements for safety, environmental impact, and proper labeling. These rules are in place to safeguard consumer health, avoid costly product recalls, and reduce legal risks for brands.

For activewear manufacturers, following these standards means their products can deliver on performance and durability while also being safe and reliable for customers. Beyond that, compliance signals a dedication to ethical practices and responsible production – values that are becoming more important to consumers in the U.S. market.