Scaling activewear collections comes with a big challenge: managing Minimum Order Quantities (MOQs). Here’s the problem: manufacturers set MOQs to cover their production costs, but for brands, this often means committing to large orders upfront. When you add multiple styles, colors, and sizes, the numbers – and costs – can skyrocket. This leads to cash flow issues, inventory risks, and overstocking, especially for newer or expanding brands.

Key Takeaways:

- MOQs are the minimum units you must order, often based on product complexity, fabric, or color.

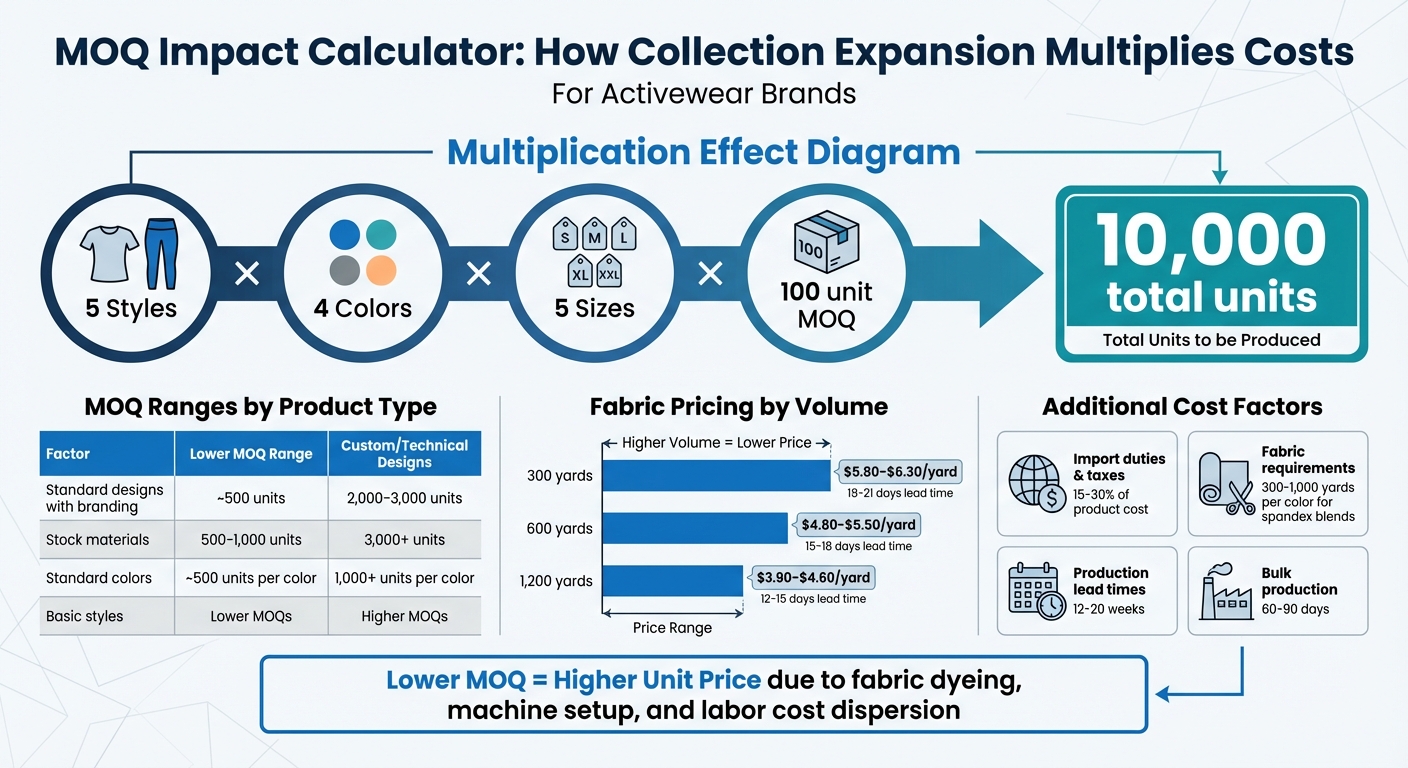

- Expanding collections increases costs – e.g., 5 styles × 4 colors × 5 sizes with a 100-unit MOQ = 10,000 units.

- Custom materials and colors demand even higher MOQs, sometimes up to 3,000 units per order.

Solutions Include:

- Simplify Collections: Focus on core products, limit experimental pieces, and standardize fabrics and trims.

- Flexible Manufacturing: Use in-stock materials or opt for private label/ODM options with lower MOQs.

- Negotiate with Suppliers: Offer long-term commitments, staggered deliveries, or higher per-unit prices for smaller orders.

- Plan Smarter: Use data to forecast demand, optimize size distribution, and schedule production in off-peak months.

MOQ Impact Calculator: How Collection Expansion Multiplies Order Quantities in Activewear

Common MOQ Problems When Scaling Activewear Lines

Cash Flow and Inventory Risk

As activewear collections grow, financial challenges become more pressing. One of the biggest hurdles is the upfront capital needed before making any sales. Expanding your collection magnifies this issue because MOQs (minimum order quantities) often apply to each style and color. For example, a 500-unit MOQ across five styles and four colors adds up to 10,000 units. That’s a hefty investment in capital, storage, and marketing.

Misjudging demand can lead to dead stock and added storage costs. While ordering smaller quantities might seem like a safer option, it usually drives up unit costs due to expenses like machine setup, labor, and fabric dyeing. For instance, orders under 220 lbs often incur extra setup fees, further increasing landed costs.

"Lower MOQ = Higher Unit Price (due to fabric dyeing, machine setup, and labor cost dispersion)." – CozyActive

On top of this, import duties and taxes can tack on an additional 15% to 30% of your product cost. These added expenses can strain cash flow, making it harder to invest in marketing, product development, or exploring new opportunities.

Managing Multiple Styles, Colors, and Sizes

Scaling a collection introduces complex MOQ challenges. Fabric suppliers often require 300 to 1,000 yards per color for spandex blends, meaning you’re locked into purchasing large quantities of fabric even before production starts. For four custom colors, this could mean committing to 1,200 to 4,000 yards – far more than a small collection might need.

Size distribution adds another layer of complexity. A 500-unit MOQ for a style might force you to over-order less popular sizes like XS or XL, leading to inventory imbalances. This issue becomes even trickier when managing multiple styles, each with unique sizing demands and sales patterns. These overlapping requirements amplify the cash flow pressures mentioned earlier.

| Factor | Lower MOQ Range | Custom/Technical Designs |

|---|---|---|

| Standard designs with branding | ~500 units | Fully custom designs: 2,000–3,000 units |

| Stock materials | 500–1,000 units | Custom-developed materials: 3,000+ units |

| Standard colors | ~500 units per color | Custom dyed colors: 1,000+ units per color |

| Basic styles (tanks, leggings) | Lower MOQs | Complex styles (bras, jackets): Higher MOQs |

Working with Factory MOQ Requirements

Factories often set rigid MOQs based on product complexity, and these thresholds are typically non-negotiable, especially for newer brands without a proven track record. This can create challenges for brands trying to scale while staying flexible.

Lead times, which can range from 12 to 20 weeks, add another layer of difficulty. Committing to large orders months before sales data is available means locking in inventory without knowing how the market will respond. Any unexpected changes to MOQ terms can disrupt production schedules and throw off inventory planning.

"Excess inventory ties up capital, restricts cash flow, and introduces additional storage and operational expenses." – JOOR

Production Planning and Forecasting Limits

The rigid nature of MOQs makes production planning and forecasting especially challenging. Brands often need to predict demand six months in advance. With bulk production lead times of 60 to 90 days, orders are placed well before receiving any meaningful market feedback. This is particularly risky in the activewear industry, where trends shift quickly and seasonal demand can be unpredictable. The result? Brands may end up with large quantities of items that don’t align with customer demand, limiting their ability to offer the variety that shoppers expect. Adapting inventory strategies to these MOQ realities is key to maintaining growth in activewear collections.

Practical Solutions for MOQ Challenges

Overcoming MOQ (Minimum Order Quantity) challenges in scaled activewear collections requires smart planning, flexible manufacturing strategies, and careful financial management.

Structuring Your Collection to Minimize MOQ Challenges

The way you organize your product line can significantly reduce the impact of MOQs. One effective approach is to create a tiered product lineup: include a core collection of bestsellers, a smaller seasonal range, and a few limited test styles. This allows you to focus higher order volumes on core items while keeping experimental pieces to a minimum.

Another strategy is standardizing fabrics and trims. By using the same base fabric – such as a polyester-spandex blend with consistent GSM, fiber content, and finish – across multiple styles like leggings, hoodies, and sports bras, you can hit supplier minimums without overstocking. This way, a single fabric order can serve an entire collection rather than requiring separate orders for each style.

Color planning also plays a big role. A shade grouping strategy lets you split a single dye lot (e.g., 1,000 yards) into several similar tones, meeting dyehouse requirements while offering variety. Similarly, using the same trims – like identical zippers, elastic bands, and labels – across your collection helps avoid multiple component MOQs.

If custom production feels overwhelming, consider ODM (Original Design Manufacturing) or private label options. With ODM, you work with pre-designed styles and add your branding, which reduces MOQs to around 200–400 units and shortens production timelines to 6–10 weeks. Private label models can lower minimums even further, sometimes to as few as 100 units, with a turnaround of 4–6 weeks, though customization options are more limited.

Leveraging Manufacturing Flexibility to Lower MOQs

Collaborating with the right manufacturers can make a huge difference in reducing MOQs. Start by asking for in-stock materials. Many manufacturers keep greige (unfinished) fabrics or pre-approved colors in their inventory. For example, a European activewear brand cut its initial inventory by 40% by sourcing 500 yards of polyester-spandex jersey in four colors from in-stock greige fabric, with the supplier batching the dyeing process to share costs across colorways.

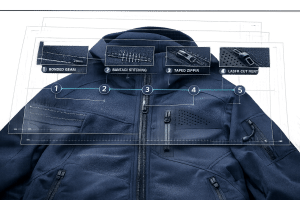

Factories with advanced production capabilities often offer greater flexibility. For instance, New Dong Huang Garment Co., Ltd. uses specialized equipment, like bonding machines and laser cutters, to streamline production. Their ability to work with various fabric blends, such as 70/30 or 90/10 nylon-spandex, allows brands to consolidate orders across different performance requirements.

Timing can also work in your favor. Off-season production scheduling – during slower periods like December through February – can help negotiate lower MOQs. One Australian swimwear startup reduced its fabric MOQ by 50% by sharing a white base fabric with another client and dyeing each portion in unique colors later.

These tactics not only lower MOQ requirements but also help reduce financial risks, which is the next hurdle to address.

Managing Financial Risks from Large Orders

Large orders often come with financial risks, but there are ways to manage them effectively. One option is to use rolling purchase orders, which spread out inventory deliveries. For example, instead of receiving 1,000 units at once, you could negotiate for 300 units upfront and the rest in smaller monthly shipments. This approach preserves cash flow and minimizes overstocking.

Another method is open-to-buy budgeting, where you allocate a specific inventory budget each quarter. Invest more in proven bestsellers and less in experimental styles to avoid tying up too much capital.

Data-driven size planning is also crucial. Use historical sales data to predict demand for different sizes. For instance, if medium sizes account for 35% of sales, while small and large sizes each make up 25%, and extra-small and extra-large sizes only account for 5% and 10%, respectively, structure your orders accordingly instead of ordering equal quantities across all sizes.

| Order Volume | Estimated Price per Yard | Lead Time |

|---|---|---|

| 300 yards | $5.80–$6.30 | 18–21 days |

| 600 yards | $4.80–$5.50 | 15–18 days |

| 1,200 yards | $3.90–$4.60 | 12–15 days |

The table above from SzoneierFabrics highlights how increasing order volume can lower costs and shorten lead times. However, paying a small premium (10–20%) on smaller orders can sometimes be a smarter move than overcommitting to large inventories.

Negotiating Better MOQ Terms

Negotiating MOQs is about finding mutually beneficial solutions with suppliers. Start by showcasing your growth potential. For example, an online yoga brand launched with just 50 units per style across three items (leggings, tanks, and hoodies) and scaled to monthly orders of over 1,000 units within 18 months. Suppliers are often more willing to accept lower MOQs if they see long-term growth opportunities.

"MOQ negotiation isn’t just about asking for less – it’s about offering suppliers a tradeoff that makes sense for their production line."

– Eric, Fabric Expert, SzoneierFabrics

You can also offer price-for-quantity adjustments. For instance, instead of ordering 1,000 units at $12 each, you might negotiate 500 units at $13.50 each, paying a higher per-unit price to avoid excess inventory.

Proposing yearly volume commitments is another effective strategy. For example, commit to ordering 5,000 units annually but request flexibility in how those units are distributed across the year. This arrangement helps factories manage production schedules while giving you better control over inventory.

Providing detailed tech packs – complete with measurements, construction details, and quality standards – can reduce a factory’s perceived risk, making them more open to smaller orders. Additionally, you might offer to cover setup costs as a flat fee instead of rolling them into the per-unit price, which can lead to more favorable MOQ terms.

sbb-itb-8dbc09a

Aligning Inventory Management with MOQ Requirements

Refining your production strategy means ensuring that inventory management aligns seamlessly with Minimum Order Quantities (MOQs). This requires a mix of precise demand forecasting, strategic production planning, and clear communication with suppliers to strike the right balance.

Forecasting Demand to Match MOQ Orders

Accurate demand forecasting is the backbone of aligning inventory with MOQ needs. By analyzing historical sales data and factoring in seasonality, you can set informed reorder points. For instance, if last quarter’s sales hit 400 units and you’re projecting 20% growth, plan for 480 units in the upcoming period.

For new product launches, where sales history is unavailable, use the performance of similar products as a guide. If your high-waisted leggings sell 600 units monthly, a new seamless version might start with an estimate of 300–400 units. Pre-order commitments can also validate these projections.

The reorder point formula – (Average Daily Sales × Lead Time in Days) + Safety Stock – is key to ensuring timely restocking. For example, if you sell 15 units daily, your lead time is 90 days, and you maintain 45 days of safety stock, your reorder point would be (15 × 90) + (15 × 45) = 2,025 units. This calculation helps prevent overstocking while keeping cash flow steady. Different product types require tailored approaches: core items like basic leggings or sports bras might need 60–90 days of safety stock, while seasonal pieces may only need 30–45 days. A good inventory turnover ratio for activewear is typically 4–6 turns per year for core styles and 6–8 turns for seasonal items.

Once you’ve nailed your forecasts, you can plan production runs that align with these numbers.

Planning Multiple Production Runs

Staggered production runs can help smooth out inventory buildup and reduce strain on storage and cash flow. Instead of ordering 2,000 units at once, negotiate staggered deliveries – such as 500 units upfront, followed by 500 units monthly over the next three months. This approach optimizes warehouse space and financial resources.

Another strategy is to use the same performance fabric across multiple styles, like leggings, sports bras, and tops. This allows you to meet the fabric supplier’s MOQ without overcommitting to a single product.

Activewear production lead times typically range from 12 to 20 weeks, so it’s crucial to reorder well before inventory runs low. To account for peak seasons, consider adding an extra 1–3 weeks of lead time during busier production periods. This buffer ensures smoother operations and avoids last-minute surprises.

Sharing Sales Data with Factories

Sharing your sales and performance data with suppliers is a game-changer. It helps factories plan resources more effectively, reducing the risk of overproduction or stock shortages. When suppliers understand your sales patterns, they can better align their production schedules with your needs.

This practice also minimizes the bullwhip effect, where small changes in retail demand can cause significant production fluctuations upstream. In the apparel industry, demand signals often take months to reach secondary suppliers, so providing real-time data can significantly shorten this lag.

Your sales data can also be a powerful negotiation tool. For high-risk new styles, offering a higher per-unit price might secure a lower MOQ. On the other hand, strong historical performance on core items can help you negotiate better terms for larger orders.

Collaborating with experienced manufacturers, like New Dong Huang Garment Co., Ltd., which has over 27 years in the industry, can also provide valuable insights. When you share your sales data, they can help identify which products are likely to succeed, ensuring you maintain consistent inventory management across your growing activewear collection.

Conclusion: Better MOQ Management for Growing Activewear Brands

Effectively managing MOQs boils down to three main strategies: accurate demand forecasting, strong supplier relationships, and smart collection planning. By forecasting demand accurately and calculating reorder points with precision, brands can avoid the cash flow pitfalls that have caused up to 90% of fashion startups to fail. It’s also crucial to align production timelines (typically 12–20 weeks) with realistic sales projections and maintain sufficient safety stock.

Building lasting relationships with manufacturers is essential for minimizing MOQ challenges. Instead of viewing each order as a one-off transaction, experienced factories prioritize your brand’s long-term success. For example, New Dong Huang Garment Co., Ltd., with over 27 years of experience in activewear production, demonstrates how a trial order can grow into larger, regular production runs as your brand scales.

The trend toward strategic sourcing is gaining momentum. In fact, deep supplier relationships accounted for 26% of the apparel supplier base in 2019, climbed to 43% by 2023, and are expected to reach 51% by 2028. Brands that share sales data, outline multi-year plans, and collaborate on fabric consolidation strategies often secure more flexible MOQ terms while also lowering inventory risks. These strategic adjustments pave the way for practical solutions to ease MOQ pressures.

On a tactical level, steps like using the same performance fabric across multiple styles, negotiating staggered delivery schedules, and placing orders during off-peak months (December–February) can immediately reduce MOQ challenges. Partnering with New Dong Huang’s specialized team provides access to production efficiencies and fabric libraries that make smaller production runs more feasible. These practical measures support a broader strategy for sustained growth.

FAQs

How can small activewear brands handle high MOQs when growing their collections?

Managing high minimum order quantities (MOQs) can be a tough hurdle for small activewear brands trying to grow. These high MOQs typically stem from costs tied to fabric cutting, tooling, and keeping production lines efficient. However, for newer brands, they can stretch budgets and limit options.

Here are a few ways brands can tackle this issue:

- Negotiate with suppliers: Share your growth plans and offer to pay a slightly higher per-unit price in return for lower MOQs. This can create a win-win situation for both parties.

- Streamline designs: Opt for widely available fabrics like nylon-spandex blends and avoid overly complex features. This simplifies production, which can help bring MOQs down.

- Use pre-orders or limited drops: By collecting customer commitments ahead of production, you can reduce financial risks and justify larger batch sizes.

New Dong Huang Garment Co., Ltd. (NDH) offers a solution for brands facing these challenges. With more than 27 years of experience, NDH specializes in small-batch production while maintaining the high-quality standards activewear demands. Working with a seasoned supplier like NDH gives brands the chance to negotiate practical MOQs, manage inventory smartly, and expand their collections – all without sacrificing quality or design ambitions.

How can brands reduce financial risks when managing high MOQs for activewear production?

High minimum order quantities (MOQs) can put a strain on your cash flow, pile up excess inventory, and create financial headaches if demand doesn’t hit expected levels. To navigate these challenges, try negotiating with suppliers to lower MOQs or explore tiered pricing models that reward larger orders only when sales justify the need. Breaking up orders by color or style is another smart way to keep inventory under control. Additionally, opting for off-season production might give you more wiggle room in terms of flexibility.

Another approach is to spread production across multiple suppliers or regions. This reduces your dependency on a single factory and minimizes risks like delays or quality issues. Stick to your core designs, and consider limited-edition or on-demand runs to test new products without the risk of overstocking. If you need to place larger orders, work on securing extended payment terms or partial deposits to keep your cash flow steady.

Partnering with a manufacturer like New Dong Huang Garment Co., Ltd. could make a big difference. With 27 years of experience in activewear, they offer tailored production runs, efficient material planning, and a sample-first approach to ensure your needs are met. Their expertise allows you to grow your collection without taking on unnecessary financial risks.

What are some effective strategies for negotiating lower MOQs with suppliers?

Negotiating lower MOQs starts with understanding why suppliers set them in the first place. These minimums often cover costs like setup fees, fabric requirements, and labor efficiency. To work around this, you can explore options like using in-stock fabrics, simplifying your product designs, or bundling multiple styles that use the same materials. Another strategy? Share a realistic sales forecast or commit to future orders. Suppliers might agree to lower MOQs if you’re willing to pay a slightly higher per-unit cost or offer partial payment upfront.

Collaborating with an experienced manufacturer, such as New Dong Huang Garment Co., Ltd., can simplify this process. With over 27 years of expertise, they specialize in small production runs using flexible fabric options, allowing you to scale as your demand grows. Maintaining open communication, setting clear timelines for repeat orders, and highlighting the potential for a long-term partnership can also encourage suppliers to offer more flexible terms.