When manufacturing activewear in China, a detailed tech pack is your key to success. This document serves as a blueprint, ensuring your designs are accurately transformed into high-quality garments. Without it, critical details like seam types or fabric specs may be overlooked, leading to costly errors. Here’s what you need to know:

- What to Include: Flat sketches with construction notes, precise size charts with tolerances, and a complete Bill of Materials (BOM).

- Preparation Tips: Study existing garments, annotate sketches, and organize files with version control.

- Communication: Use bilingual PDFs, platforms like WeChat for updates, and set clear timelines to avoid delays.

- Common Mistakes: Avoid mixing units, expect multiple revisions, and finalize materials before starting production.

A well-prepared tech pack ensures consistent quality, reduces sampling rounds, and saves costs. Partnering with experienced manufacturers like New Dong Huang Garment Co., Ltd. can further streamline the process, leveraging their expertise in activewear production and advanced equipment. By focusing on clear communication and attention to detail, you can bring your designs to life effectively.

How to Make a Tech Pack for Clothing Production

What to Include in a Tech Pack for Chinese Factories

When working with Chinese manufacturers to produce activewear, a well-prepared tech pack is essential. It acts as your blueprint, ensuring your designs are accurately translated into finished garments. A complete tech pack typically includes three key elements, each playing a crucial role in clear communication with the factory.

Flat Sketches and Construction Notes

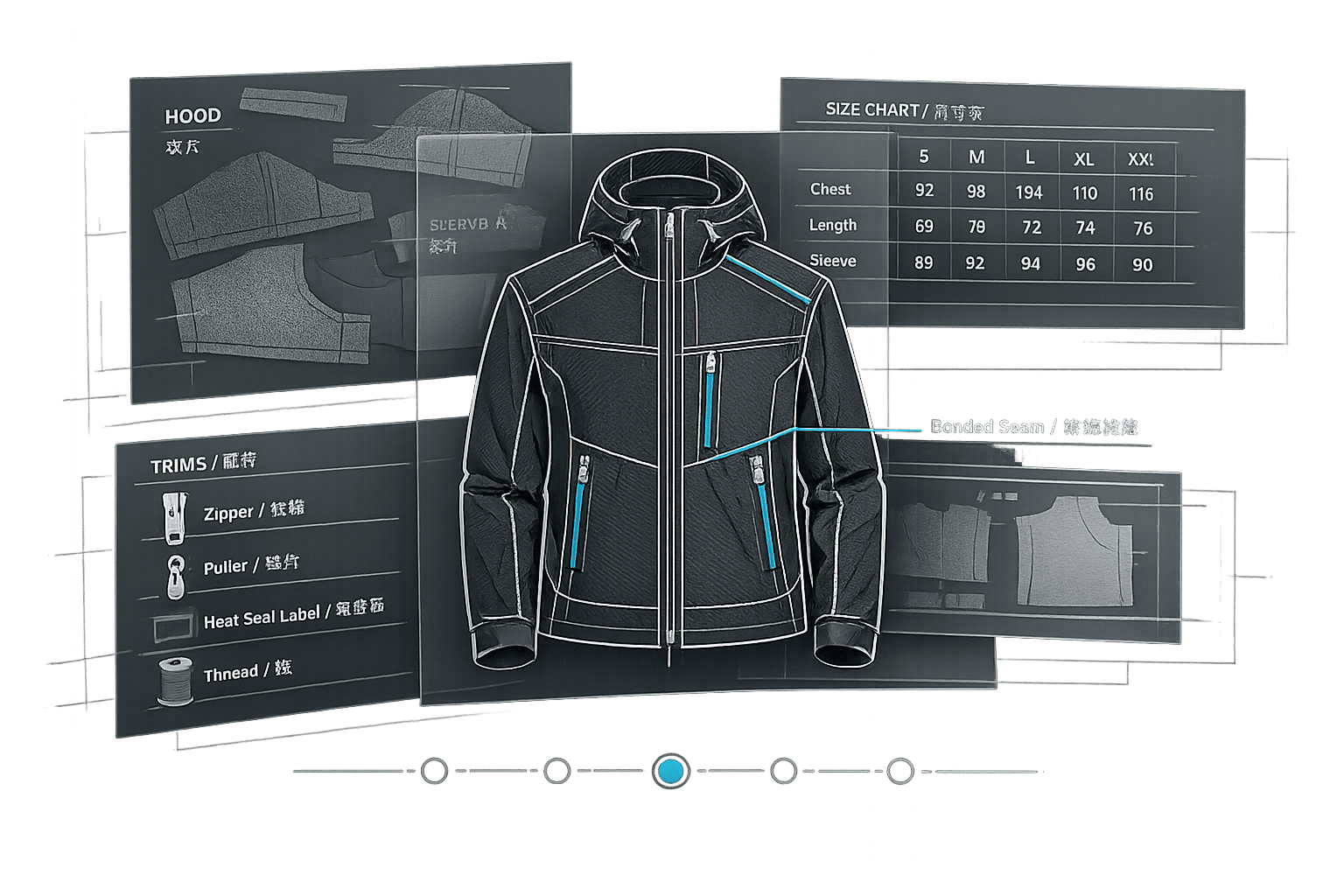

Flat sketches, or technical drawings, are the visual foundation of your tech pack. These black-and-white illustrations should show the garment from every angle – front, back, side, and even the interior. Use solid lines for seams and dashed lines for stitching, and label every detail with arrows pointing to features like collars, cuffs, fastenings, and bar tacks.

For activewear, construction notes are equally critical. Be specific about techniques like 4-needle 6-thread flatlock seams, bonding, laser cutting, or ultrasonic stitching. Detail the exact stitch types (e.g., lockstitch, chainstitch, or overlock), the Stitches Per Inch (SPI), and seam allowances (commonly 3/8 inch or 1 cm). Highlight reinforcement stitching for high-stress areas such as armholes or crotch seams to ensure durability.

Size Charts and Tolerances

A well-detailed size chart is non-negotiable. Include a Point of Measurement (POM) diagram with arrows to indicate where each measurement should be taken. Start with a base size, such as Medium, and outline precise grading rules for other sizes. Be clear if measurements are for the full circumference or "half" (garment laid flat).

To maintain quality, define tolerances for each measurement point – typically ±0.5 cm (around 1/4 inch). This ensures everyone understands the acceptable range of variance during production. Including both metric and imperial measurements is a good practice to avoid confusion.

Bill of Materials (BOM)

The Bill of Materials (BOM) is your checklist of every component in the garment. Break it down into main fabric, lining, interlining, thread, trims, closures, labels, and even packaging. For fabrics, include details like composition (e.g., 88% polyester, 12% spandex), weight in GSM, and any performance features such as moisture-wicking, UV protection, or anti-odor properties. Use Pantone codes to specify colors with precision.

If you have preferred suppliers for certain materials, list their details. For example, note specific components like YKK Vislon 5CN Zippers or Framis bonding tape. As Techpacker emphasizes, "A well-defined BOM table is important to ensure your factory doesn’t miss any components". Supporting this, White2Label Manufacturing found that clients using detailed tech packs had an 82% chance of achieving production in two sampling rounds or fewer, compared to an average of 4.5 rounds without one.

How to Prepare a Tech Pack for Chinese Manufacturing

Tech Pack Preparation Process for Chinese Manufacturing

Before drafting your tech pack, take some time to study completed garments. Pay attention to details like construction, seam placement, and finishing touches. Here’s a step-by-step breakdown of what to include in an effective tech pack for manufacturing in China.

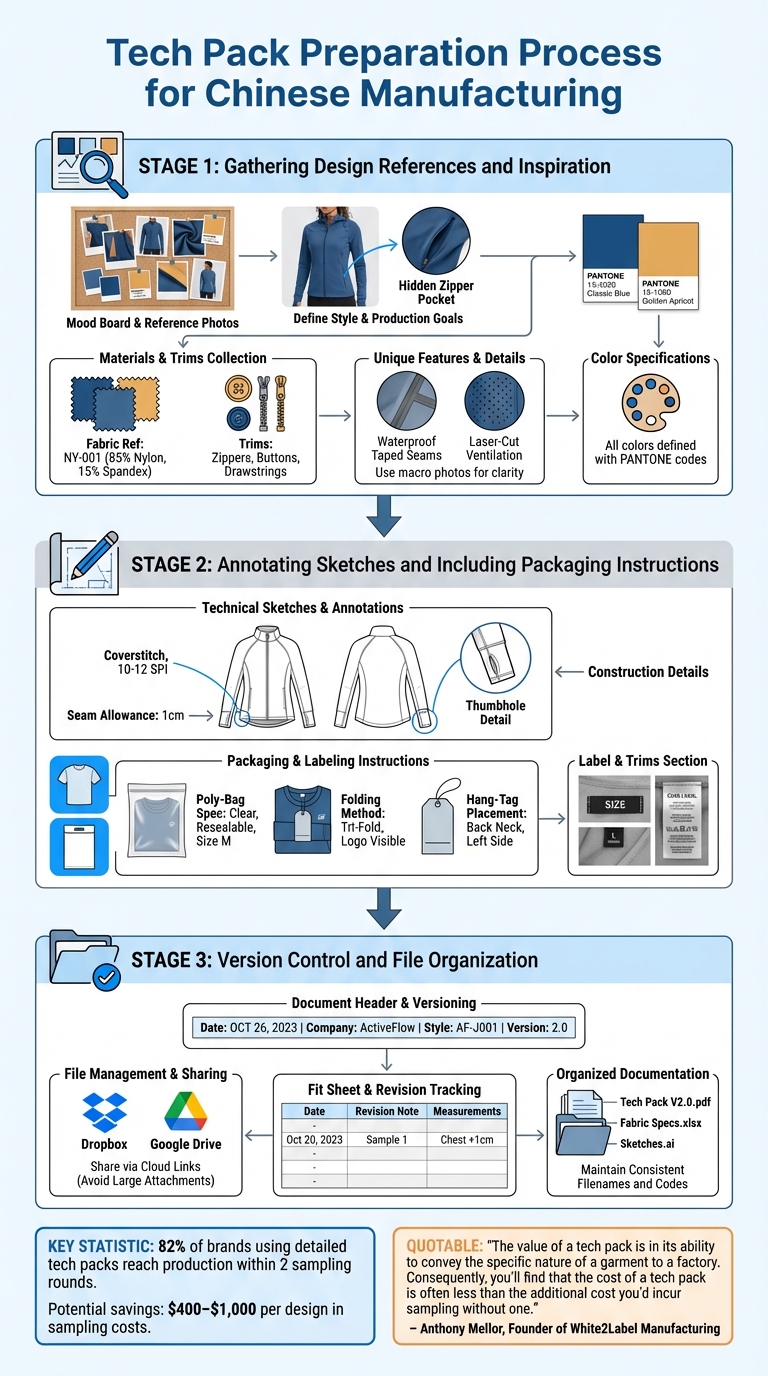

Gathering Design References and Inspiration

Start by creating a mood board to define your style and set clear production goals. Use photos of existing products to highlight specific details like branding placement, fabric textures, or trim designs. Add annotations to your reference images with arrows and notes (e.g., "use this topstitch style") to ensure clarity for the factory team.

Collect fabric and trim swatches, assign reference codes, and include them in your tech pack. For specialized items like activewear, include close-up images of unique features such as hidden pockets, waterproof seams, or embroidery that might not be obvious in a standard sketch. Be precise with color specifications by using Pantone codes for all elements – fabric, linings, zippers, and threads – to avoid miscommunication across borders.

Anthony Mellor, Founder of White2Label Manufacturing, emphasizes the importance of tech packs:

"The value of a tech pack is in its ability to convey the specific nature of a garment to a factory. Consequently, you’ll find that the cost of a tech pack is often less than the additional cost you’d incur sampling without one".

Once you’ve gathered your references, you can move on to creating detailed technical drawings.

Annotating Sketches and Including Packaging Instructions

Using your research, develop technical sketches that clearly show how the garment should be constructed. Stick to black-and-white sketches to make details like seams and darts stand out. For complex features – like pockets, stitching patterns, or waterproof seams – add close-up sketches to avoid confusion.

Annotate your sketches with specific construction details, such as stitches per inch (SPI), seam allowances, and stitch types. Don’t forget to include a section for packaging instructions. This should cover folding methods, poly-bag specifications, and the placement of hang-tags and care labels. You can also photograph examples of hang-tags, poly-bags, and folding techniques to include in a "Label and Trims" section.

Version Control and File Organization

To keep everything organized, label each page with the update date, your company name, the style number, and the version number. Number the pages and include key style details to avoid confusion if the document is printed. Use consistent file names and reference codes for swatches to maintain order.

When sharing your tech pack, avoid sending large files via email, as they might get caught in spam filters. Instead, use shared platforms like Dropbox or Google Drive. Add a "Fit Sheet" or revision page to track measurements from samples compared to your original specifications.

Staying organized pays off. Brands that use detailed tech packs are 82% more likely to reach production within two sampling rounds, potentially saving $400–$1,000 per design in sampling costs.

How to Communicate Effectively with Chinese Manufacturers

The way you share and follow up on your tech pack plays a crucial role in determining the success of your sampling process. Clear and well-structured communication reduces mistakes and keeps everything on schedule. Here’s how you can stay in sync with your factory partner throughout production.

Using Clear and Organized Documentation

Effective communication starts with well-prepared documentation. Create a bilingual PDF that includes clear headers, issue dates, version numbers, and tolerance specifications. Organize the details across labeled pages to make the document easy to navigate. Including Chinese text alongside English ensures that factory workers on the floor fully understand the instructions, while tolerance columns provide quality control teams with measurable criteria to follow.

Leveraging WeChat and Email for Updates

Combine email and instant messaging to keep communication smooth. Use email for confirmations and formal documentation, while platforms like WeChat allow for real-time updates. This approach ensures you have a record of key decisions and the flexibility to address issues quickly during the sampling phase.

To avoid problems with large file sizes, use cloud-sharing tools like Dropbox, Google Drive, or WeTransfer. These platforms make it easy to share high-resolution files and CAD drawings. Updating specifications directly in the cloud ensures your supplier always has access to the latest version, reducing confusion caused by outdated files.

For critical agreements, such as sample order terms, request that the manufacturer prints, signs, and stamps a physical copy. As Gronkvist emphasizes, “Terms listed in an excel or word file carries no significance whatsoever.”

Set clear timelines from the beginning to ensure smooth transitions between tech pack updates and sample revisions.

Setting Realistic Sampling Timelines

Plan for 7–12 days for initial samples and 3–5 days for each revision. Create a sample order document that specifies how many revisions are allowed and sets deadlines for each stage. This prevents endless revision cycles and helps both you and the manufacturer stay accountable.

Keep in mind potential delays during peak seasons and holidays like Chinese New Year and Golden Week. Adding a 10–15% buffer to your schedule can help you navigate unexpected slowdowns. Before starting the sampling process, finalize your Bill of Materials and secure sourcing to avoid interruptions.

Once samples arrive, review and approve them quickly to keep production moving. Elaine Zhou, Business Director at Shanghai Fumao, highlights the importance of this step:

"Sample development is not a small step – it is the backbone of successful apparel production."

sbb-itb-8dbc09a

Cultural Considerations and Common Mistakes to Avoid

Understanding cultural differences and steering clear of common pitfalls can save you both time and money. How you handle relationships, documentation, and planning plays a crucial role in ensuring your tech pack flows smoothly through production. These cultural insights also help fine-tune the technical details of your tech pack, making the production process more efficient.

Respecting Hierarchy and Building Relationships

In Chinese business culture, hierarchy and long-term partnerships are highly valued. Show respect to senior contacts and take the time to build trust with your manufacturing partners. One way to establish this trust is through sample development. Providing clear and detailed documentation reflects professionalism and signals your commitment to quality. When you deliver a well-prepared tech pack, you’re doing more than sharing specifications – you’re laying the groundwork for a strong working relationship that can extend well beyond a single project. Consistent and respectful communication strengthens this bond and ensures your detailed tech pack is used effectively.

Avoiding Mixed Units and Ambiguities

Mixing imperial and metric units can create confusion and disrupt production. Stick to one measurement system throughout your tech pack for clarity. Since factory workers often rely more on visuals than text, include clear and precisely scaled diagrams. As Sally from Business in Guangzhou points out:

"Imagine the tech pack is created for Chinese clothing factory workers, most of whom don’t speak English at all, let alone reading English. When drawing the diagrams, it’s essential to keep them accurate and easy to scale."

Use standardized terminology and clearly indicate whether measurements are taken on a laid-flat or full-circumference basis. Be sure to include tolerance specifications (e.g., +/- 0.5 cm) for every measurement point. Beyond the technical details, expect to refine your samples through multiple iterations.

Planning for Revision Cycles

Perfect samples rarely happen on the first try. Elaine Zhou, Business Director at Shanghai Fumao, emphasizes:

"One common mistake buyers make is expecting perfection in the first sample. In reality, good sample development requires several stages."

Typically, you should anticipate two to three revisions before finalizing a sample. To keep the process organized, draft a formal sample order terms document. This document should outline production timelines for each revision and include clauses that hold both parties accountable during the revision process. A well-structured approach to revisions not only improves the final product but also ensures the technical details in your tech pack are thoroughly validated.

Working with Experienced Manufacturers like New Dong Huang Garment Co., Ltd.

After crafting a solid tech pack and establishing clear communication, the next key step is choosing the right manufacturing partner. The manufacturer you select can significantly influence how smoothly your tech pack translates into finished garments. Partnering with a specialist in activewear, like New Dong Huang Garment Co., Ltd., provides access to decades of expertise and efficient processes. Since 1999, NDH has been producing activewear, bringing over 27 years of experience to the table. Their deep knowledge helps ensure seamless tech pack execution and top-notch sample quality.

Advanced Equipment and Technical Expertise

NDH stands out with its dedicated R&D department, where engineers develop prototypes and conduct fit tests on dummies to catch design flaws early. The facility is equipped with cutting-edge manufacturing technology, such as bonding machines and ultrasonic sewing, which are crucial for achieving seamless finishes and premium activewear construction. They also specialize in advanced stitching techniques, including:

- 4-needle, 4-thread construction for durable weightlifting gear

- Flatlock stitching for yoga apparel

- Interlock seams for smooth panel connections

Their structured five-step process – Idea, Tech Pack, Sourcing, Sampling, and Pre-Production – ensures every design specification is accurately translated into physical garments. This meticulous approach reduces miscommunication and boosts sampling success rates by over 60%. With these capabilities, NDH ensures your tech pack is implemented with precision and attention to detail.

Quality Standards and Certifications

NDH upholds rigorous quality standards, backed by certifications like BSCI (Business Social Compliance Initiative) and GRS (Global Recycled Standard). Their eco-conscious fabric options meet international benchmarks, including OEKO-TEX 100 and Bluesign certifications. The company has also passed audits by major brands like Nike and New Balance, showcasing their dedication to precision and quality control. Once a Pre-Production (PP) sample is approved through model fittings, it becomes the benchmark for bulk production, ensuring every garment matches the approved specifications. This thorough quality control process helps safeguard your brand’s reputation and minimizes costly production errors.

Support for Custom Design Projects

NDH offers end-to-end solutions for activewear brands, guiding projects from the initial concept to final production. Their fabric sourcing capabilities are bolstered by an extensive library of Nylon Spandex blends tailored for varying athletic needs. For instance:

- High-compression fabrics for weightlifting

- Soft, high-stretch materials for yoga

- Breathable, 4-way stretch fabrics for running

During the sourcing phase, NDH’s team ensures fabric properties align with your garment’s intended purpose, resulting in optimized performance. This attention to detail allows for accurate pattern printing and precise sample cutting, bringing your tech pack designs to life.

Conclusion

Producing activewear in China requires a well-crafted tech pack that bridges the gap between a brand’s vision and the factory’s execution. As Techpacker aptly states:

"The quality of a finished product completely depends on the ‘quality’ of this communication".

A comprehensive tech pack – complete with detailed flat sketches, accurate size charts with tolerances, and thorough BOMs – can significantly reduce misunderstandings and cut down on costly sample revisions. Brands that prioritize this level of preparation often see a 60% or higher improvement in sampling success rates, while also minimizing corrections and shipping delays.

But it’s not just about specifications. Clear communication goes hand in hand with efficiency. Using annotated visuals, setting realistic timelines, and respecting cultural nuances can help build a strong foundation for collaboration. Detailed diagrams and labeled photos play a critical role in conveying instructions clearly. When paired with a solid tech pack, this type of communication ensures a smoother path to finding the right manufacturing partner.

A well-prepared tech pack doesn’t just reduce errors – it’s the cornerstone of a successful, long-term relationship with skilled manufacturers. The right partner can take this foundation and elevate it. For instance, New Dong Huang Garment Co., Ltd. brings 27 years of activewear manufacturing experience, advanced equipment, and the expertise to bring your designs to life with precision. With their R&D capabilities, quality certifications, and end-to-end support, they ensure your vision is executed seamlessly from the first sample to full-scale production.

FAQs

What should I include in a tech pack to ensure successful activewear manufacturing in China?

A well-prepared tech pack is the backbone of transforming your activewear designs into finished products when collaborating with Chinese manufacturers like New Dong Huang Garment Co., Ltd. To start, include key details such as the style name, season, sample size, target price (in USD), and important dates to ensure everyone is on the same page. Add flat sketches or CAD drawings that clearly show all seams, stitch types, and construction details. Alongside these, provide a bill of materials (BOM), listing fabrics, trims, and accessories with specifics like fabric composition (e.g., 70% polyester/30% spandex), weight, stretch percentage, and any performance features like moisture-wicking or compression. Don’t forget to include color codes (Pantone or RAL) and a size-grade table with measurements in inches for all sizes.

For activewear, it’s crucial to detail construction methods such as flat-lock seams, along with hardware placements for zippers or drawstrings. Include care instructions tailored to the garment’s intended use. If your design requires special finishes like UV protection or reflective prints, specify the application process and testing criteria to ensure quality. Providing reference samples, material swatches, and compliance requirements will give the factory everything they need to meet your expectations. A thorough tech pack minimizes miscommunication, speeds up the sampling process, and ensures a smoother path to production.

What are the best ways to communicate effectively with Chinese manufacturers during production?

To ensure smooth communication with Chinese manufacturers, start by preparing a clear and detailed tech pack. This should include exact measurements in both inches and centimeters, detailed sketches, material specifications, trim details, color codes (such as Pantone), and reference images. To avoid confusion, consider providing the tech pack in both English and Chinese, which can significantly reduce the chances of miscommunication.

Maintain regular updates through weekly emails, video calls, or messaging apps like WeChat. These consistent check-ins are crucial for addressing any potential issues early, ensuring samples meet your specifications, and keeping production timelines on track.

Lastly, use a Sample Order Terms document to clearly define key details. This document should cover required attachments (like CAD files), revision protocols, and approval milestones. By setting clear expectations in writing, you can minimize misunderstandings and keep both parties aligned throughout the process.

What are the most common mistakes to avoid when creating a tech pack for Chinese manufacturers?

Creating a tech pack for Chinese manufacturers is a key step in ensuring accurate samples and a smooth production process. However, there are some common mistakes that can lead to delays and errors along the way.

One major issue is incomplete or unclear specifications. Forgetting to include measurements, stitch details, or material descriptions often results in inaccurate samples. Another frequent problem is sending disorganized files – mixing PDFs, images, and spreadsheets without proper labels can confuse manufacturers and slow things down. On top of that, missing critical details like CAD drawings, color codes, trim samples, or a bill of materials can create sourcing and production delays.

Communication is another area where problems arise. Poor communication practices, such as failing to confirm that documents were received or using vague language, can lead to unnecessary misunderstandings. Additionally, skipping over essential elements like clear sizing charts, fit tolerances, or packaging instructions can create inconsistencies in the final product.

To avoid these pitfalls, always provide a well-structured, detailed tech pack that includes all required information. Pair that with clear, consistent communication with your factory to ensure a smoother production process.