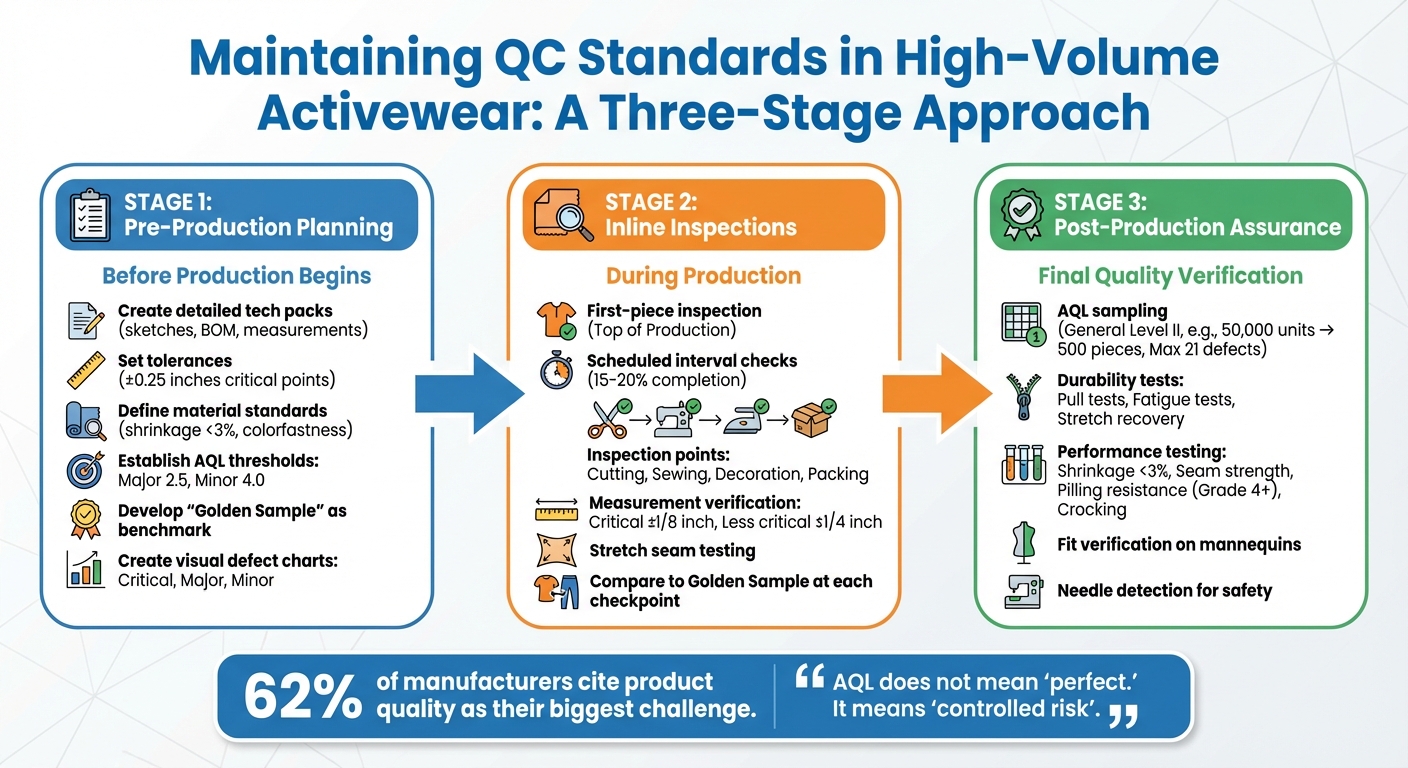

Maintaining quality in high-volume activewear production is challenging but achievable with the right strategies. The key is to implement a structured quality control (QC) process that starts before production, continues during manufacturing, and concludes with post-production checks. Here’s a quick breakdown:

- Pre-Production Planning: Define detailed product specifications, create tech packs, set tolerances, and establish clear quality benchmarks with a pre-production sample.

- Inline Inspections: Conduct frequent checks during production, including first-piece inspections, scheduled interval reviews, and measurement verifications, to catch defects early.

- Post-Production Assurance: Use AQL sampling to inspect finished goods, perform durability and performance tests, and ensure compliance with safety and design standards.

Three-Stage QC Process for High-Volume Activewear Production

Quality in High Volume Manufacturing

Pre-Production QC Planning

When you’re dealing with high-volume production, even small mistakes can lead to expensive setbacks. That’s why pre-production planning is so important – it lays the groundwork for consistency by locking in all the necessary specifications and standards before the first cut. This early attention to detail sets the stage for effective quality control throughout the process.

Setting Product Specifications and Tolerances

Think of a tech pack as your production roadmap. It’s not just a list of instructions – it’s a comprehensive guide that includes flat sketches, a Bill of Materials (BOM), measurement details, seam and stitching guidelines, color and fabric print specifications, and labeling diagrams. Without this level of detail, you risk leaving too much room for error.

"A tech pack is essentially a blueprint created by your designer, with instructions for the manufacturer to use during production." – Belinda Jacobs, Techpacks.co

Every measurement in the tech pack needs a tolerance – for example, a chest width of ±0.25 inches. For activewear, you’ll also need to set material standards, such as fiber type, fabric weight, thickness, and performance criteria like shrinkage (premium fabrics typically shrink less than 3%) and colorfastness.

Before mass production begins, create a pre-production sample based on the tech pack. This sample serves as the gold standard for fabric, color, construction, and fit during the entire run. You’ll also need to define Acceptable Quality Levels (AQL) from the start. Common AQL thresholds are 2.5 for major defects (like broken zippers or misaligned seams) and 4.0 for minor ones (such as loose threads or slight color variations). As Ninghow puts it, "AQL indicates controlled risk, not perfection".

Creating Standardized Work Instructions

Clear, visual instructions are essential to minimizing production errors. Standard Operating Procedures (SOPs) should outline every step of the QC process to ensure consistency, no matter who’s on the production floor or what shift they’re working. Details like stitch density, seam types, and placement rules for prints or embroidery should all be covered.

Translate these instructions into the local language to avoid miscommunication. Include visual guides that show exactly how to measure dimensions – this helps prevent errors in reporting. Specify who is responsible for providing testing tools, like GSM cutters or metal detectors, and update the instructions immediately if any changes are made. For instance, switching from single-needle to chain stitching should be reflected in the SOPs right away. By addressing these details upfront, you can avoid costly mistakes further down the line.

Establishing Visual Quality Standards

Clarity is key when defining pass/fail criteria. Use defect classification charts to outline what counts as Critical (e.g., safety hazards like sharp needles), Major (e.g., usability issues like incorrect sizing), or Minor (e.g., cosmetic flaws like small inconsistencies) defects. This ensures everyone is on the same page, speeding up decision-making on the production floor and reducing disputes.

For color consistency, rely on Pantone color swatches and create "shade bands" to manage variations across fabric batches. In professional garment QC, color mismatches exceeding Delta E 1.5 are usually flagged as failures. Beyond measurements, conduct visual fit tests on mannequins to confirm the garment looks and fits as intended. Lastly, share the QC checklist and tech pack with the manufacturer before making any payments. This ensures they fully understand and can meet your requirements before production begins.

Raw Material and Fabric Testing

Testing raw materials based on established specifications is crucial to avoid production issues down the line. Once specifications are finalized, raw materials should be tested to prevent expensive fixes after production. As Eurofins Assurance states, "If the quality of the raw materials is poor, the finished products will very likely be of poor quality". This is particularly important for large-scale production, where fabric batches must maintain consistency in shade, weight, and performance characteristics. These tests help uphold pre-production standards and ensure smooth, high-volume manufacturing.

Testing Fabric Performance

Activewear fabrics require thorough performance evaluations to meet demanding use cases. Start with dimensional stability and shrinkage tests, following AATCC 135/150 standards. High-quality fabrics should shrink less than 3%. Next, conduct colorfastness tests to ensure durability against washing, perspiration, and rubbing. Use ISO 105-C06 for washing resistance, AATCC 15 for perspiration, and AATCC 8 for crocking. For crocking, a white test fabric is rubbed against the colored material ten times to check for color transfer.

For fabrics prone to friction, perform pilling and abrasion tests using ISO 12945/12947 standards. Moisture management testing is essential for performance fabrics to confirm they wick sweat effectively during workouts. Elastic fabrics should undergo stretch and recovery tests to ensure they return to their original shape without exposing fibers or damaging stitches. Additionally, measure fabric weight (GSM) and conduct chemical safety tests to detect harmful substances, including azo dyes, lead, phthalates, and formaldehyde.

Inspecting Trims and Accessories

Trims and accessories demand the same level of scrutiny as fabrics. As QIMA highlights, "Unreliable accessories can destroy the consumer’s overall impression of your product and brand". Inspect bulk trims before production begins, as manufacturers typically won’t accept returns for trims already sewn into garments.

Conduct pull tests on zippers and snaps by applying a set amount of force for 10 seconds to ensure they won’t detach or break. Perform fatigue tests by operating each accessory 50 times to confirm durability. Elastic bands and straps should undergo stretch tests to verify they maintain elasticity and stitching integrity under tension. Use Pantone charts to confirm trims match approved color standards, and check dimensions against your tech pack using dial calipers or a measuring tape.

In-Line Quality Inspections

Performing quality checks during production helps catch defects before they escalate. Instead of relying on a single inspection, these checks happen at multiple stages throughout the manufacturing process. As Ninghow puts it, "Inline QC is not one check. It is checkpoints". This method allows for immediate issue identification and correction, saving time and money compared to fixing problems after an entire batch is completed. Start with a first-piece inspection to establish the standard for the production run.

First-Piece Inspections

Examining the first finished garment from each batch helps prevent widespread issues. A Top of Production inspection ensures machines are properly set up and that the garment matches the tech pack. Pay close attention to critical measurements to confirm they meet specifications. Also, check bartacks at high-stress points for durability. Boaz David from Human B cautions, "If there are signs of issues in the sampling stage, they will be a nightmare during production". Additionally, conducting a size set review – inspecting one piece from each size – verifies that grading has been applied correctly before mass production begins.

Scheduled Interval Inspections

Once the initial setups are approved, regular inspections throughout production help maintain quality. Plan checks at 15%–20% completion to detect defects early. Key checkpoints include:

- After cutting: Ensure panel accuracy and proper shade grouping.

- After initial sewing: Evaluate seam quality and stitch density.

- After decoration: Confirm print placement and adhesion.

- Before packing: Conduct a final review.

At each stage, stretch seams to check for cracking stitches, count stitches per inch to verify density, and ensure elastic bands maintain stretch and conceal fibers. Reference your Golden Sample and tech pack at every checkpoint to ensure consistency.

Measurement Checks

Inline QC also involves consistent measurement checks to confirm every garment meets approved specifications. Lay garments flat and apply tight tolerances – ±1/8 inch for critical dimensions and ±1/4 inch for less critical areas – to ensure a consistent fit. For activewear made from high-stretch fabrics, measure both static and stretched dimensions to verify the garments maintain their intended fit during wear. Additionally, check for symmetry between the left and right sides of each garment and confirm that all sizes match the graded measurements outlined in the tech pack.

sbb-itb-8dbc09a

Post-Production Quality Assurance

Once in-line checks are completed, post-production quality assurance steps in to confirm the overall consistency and durability of the garments. This phase ensures that every finished product meets both performance and design standards. By combining statistical sampling with hands-on performance testing, manufacturers can verify that the entire batch is ready for shipment. For 62% of manufacturers and importers, maintaining product quality is the biggest challenge, making these final checks absolutely critical before the goods leave the factory.

Companies like New Dong Huang Garment Co., Ltd. (https://leggingsupplier.com) emphasize thorough post-production procedures to deliver high-performance, consistent activewear.

Using AQL Sampling Standards

The Acceptable Quality Limit (AQL) method provides a reliable way to inspect large batches without needing to check every single item. To start, determine the size of your lot and choose an inspection level – General Inspection Level II is the standard for apparel. For example, if you’re producing 50,000 units with a 2.5 AQL, you would inspect 500 pieces, allowing for a maximum of 21 defects before rejecting the entire batch.

Defects are classified into three categories:

- Critical defects: Safety hazards like sharp needles (0% acceptable).

- Major defects: Issues like open seams that could cause product failure (2.5% limit).

- Minor defects: Cosmetic flaws that don’t affect functionality (4.0% limit).

"AQL does not mean ‘perfect.’ It means ‘controlled risk’".

Randomly select master cartons using a standard formula, then compare each garment to the Golden Sample and tech pack specifications. If the number of defects exceeds the acceptable limit, the entire batch will need either a full inspection or rework.

Durability and Performance Testing

Durability tests ensure that activewear can withstand everyday use. For example:

- Perform 10-second pull tests on zippers and buttons to check their strength.

- Conduct fatigue tests by operating snaps or buttons 50 times to see if they fail.

- Test elastic bands and straps for stretch recovery, ensuring stitching doesn’t break under tension.

Fabric performance is equally important. High-quality activewear fabrics should shrink less than 3% after washing, which can be verified using AATCC 135/150 protocols. Seam strength should meet ASTM D1683 standards, especially in stress-prone areas like the crotch and underarms. Additional tests include crocking (AATCC 8) to ensure dyes don’t transfer during exercise and pilling resistance, which should score at least Grade 4 on a 1–5 scale.

Fit and Wear Testing

Proper fit is about more than just measurements. Completed garments should be placed on mannequins to visually confirm they align with reference images and sit correctly. For accuracy, measure key points like the chest, waist, and sleeve length for all sizes, comparing them against tech pack dimensions with tolerances of ±0.25 inches for seams.

Other critical checks include odor tests to identify potential issues like moisture, mold, or chemical contamination. Finally, run all garments through needle detection equipment to ensure no broken needle fragments remain – a vital safety step before packaging.

Scaling QC Teams and Documentation

As production ramps up, ensuring consistent quality becomes a challenge. Standardized protocols and digital traceability systems are essential to maintain objective QC evaluations. By building on earlier QC checkpoints, scaling both teams and systems becomes a necessity. Without a solid structure, even skilled QC teams risk inconsistent results across different production lines or factories. These measures extend controls seamlessly from pre-production and in-line checks to the post-production phase, creating a complete quality framework.

Training QC Staff for Activewear

Scaling QC teams starts with thorough training that goes beyond basic garment inspection. QC personnel need a solid grasp of Acceptance Quality Limit (AQL) tables, standardized via ANSI/ASQ Z1.4, to determine statistically significant sample sizes instead of relying on 100% inspection. When it comes to activewear, training must include performance-specific checks such as seam strength (ASTM D1683), elastic stretch recovery, and 50-cycle fatigue tests for fasteners.

"Never forget to train the QC personnel and properly aligned so they will be aligned with the expectations laid out in the inspection protocol." – Eurofins Consumer Products Assurance

Inspectors must consistently use the approved reference garment, which serves as the definitive quality benchmark during bulk production. Training should also cover activewear-specific decoration checks, including screen print elasticity, heat transfer peel strength, and sublimation clarity. To ensure consistent measurements, staff should be trained to measure garments on flat surfaces without stretching the fabric.

Setting Up Documentation Systems

In addition to comprehensive training, robust documentation strengthens the quality process. Start with detailed tech packs that include flat sketches, a Bill of Materials (BOM), measurement specifications with defined tolerances (usually ±0.25 inches for critical points), and seam/stitching details. These tech packs act as a universal guide when working with multiple factories.

Inspection Criteria Sheets (ICS) play a key role in standardizing evaluations. These checklists, complete with digital photos of defects, provide clear, objective evidence, improving accountability and speeding up corrective actions. For traceability, every Purchase Order should link to specific fabric roll codes, inspection lot numbers, and test summary sheets – critical documentation if defects are found post-shipment.

"Tight QC and clear specs – even on labels and trims – help brands catch costly mistakes before stock reaches retail." – Expert Takeaway, Ninghow

Consolidating QC data helps identify recurring defects and refine training protocols. For instance, companies like New Dong Huang Garment Co., Ltd. (https://leggingsupplier.com) use structured documentation systems to maintain consistent quality across decades of activewear production. Their approach ensures that large-scale runs meet the same performance standards as smaller batches. This documentation system complements earlier QC checkpoints, ensuring a consistent quality process from pre-production to final inspection.

Conclusion

Achieving consistent quality in high-volume production depends on a structured, three-step process: pre-production planning, inline inspections, and final audits. It all starts with detailed preparation, including a precise tech pack and a "Golden Sample" to establish clear quality benchmarks. Without these initial guidelines, quality becomes subjective and harder to measure.

Inline inspections play a crucial role by identifying defects early in the cutting, sewing, and decoration phases. Addressing problems at this stage is far less expensive than dealing with them later. Solely relying on final inspections often means catching issues too late, leading to costly rework or even the rejection of entire batches. As Boaz David, a Fashion Production Consultant, explains:

"The myth is that QC is done only at the end, a second before it leaves the factory floor. But by then, it’s too late to address anything".

Final audits, conducted after production, provide an additional layer of assurance. Using AQL sampling methods ensures a statistically sound approach to quality control, balancing the need for rigorous standards with the impracticality of inspecting every single unit in large production runs. Additional lab tests, such as those for shrinkage (aiming for less than 3%), pilling resistance, and chemical safety, further guarantee product durability and compliance with regulations.

FAQs

What is a tech pack, and why is it important in activewear production?

A tech pack serves as a comprehensive blueprint that turns a designer’s idea into a garment ready for production. When it comes to activewear, this document ensures that every detail affecting performance, fit, and durability is clearly communicated.

The essential elements of a tech pack include flat sketches or CAD drawings that display all angles of the garment, a bill of materials (BOM) listing fabrics, trims, and other components, and measurement charts detailing size specifications and grading rules. It also specifies construction details such as stitch types, seam allowances, and finishing methods. Additional sections cover colorways, artwork files, and packaging instructions, as well as tolerances for dimensions, seam strength, and fabric weight to uphold quality standards.

At New Dong Huang Garment Co., Ltd., our tech packs are meticulously organized, combining US measurement units (inches) with metric fabric specifications (gsm). Each pack undergoes a thorough review with the production team to ensure the final product meets the original design vision, even in high-volume manufacturing.

What is AQL sampling, and how does it help maintain quality in high-volume production?

AQL (Acceptable Quality Limit) sampling is a statistical approach used to assess the quality of a production batch by examining a designated sample size. It establishes clear defect limits, allowing manufacturers to spot and address any unacceptable units before they make their way to customers.

By identifying defects early in the process, AQL sampling helps keep bulk production within acceptable quality standards. This method is particularly useful for high-volume manufacturing, where even small issues can snowball into significant problems if not caught in time.

Why are inline inspections important for high-volume production?

Inline inspections play a key role in maintaining quality during high-volume production by catching defects early in the process. By evaluating garments at each stage of production, manufacturers can address issues immediately, preventing the same mistakes from being repeated across thousands of items. This approach saves time, reduces expensive rework, and helps maintain consistent quality standards.

For activewear producers like New Dong Huang Garment Co., these inspections are even more critical. Performance fabrics demand precise standards, such as proper stretch recovery, strong seams, and effective moisture-wicking properties. Inline checks provide real-time feedback, enabling quick adjustments to machine settings or materials, which keeps production running smoothly and efficiently.

Beyond quality control, inline inspections help cut waste and safeguard brand reputation by identifying problems before they escalate. This not only lowers material expenses but also supports sustainability efforts by reducing defective inventory and the need for reprocessing. In short, incorporating these inspections leads to more efficient production, happier customers, and a stronger, more dependable supply chain.