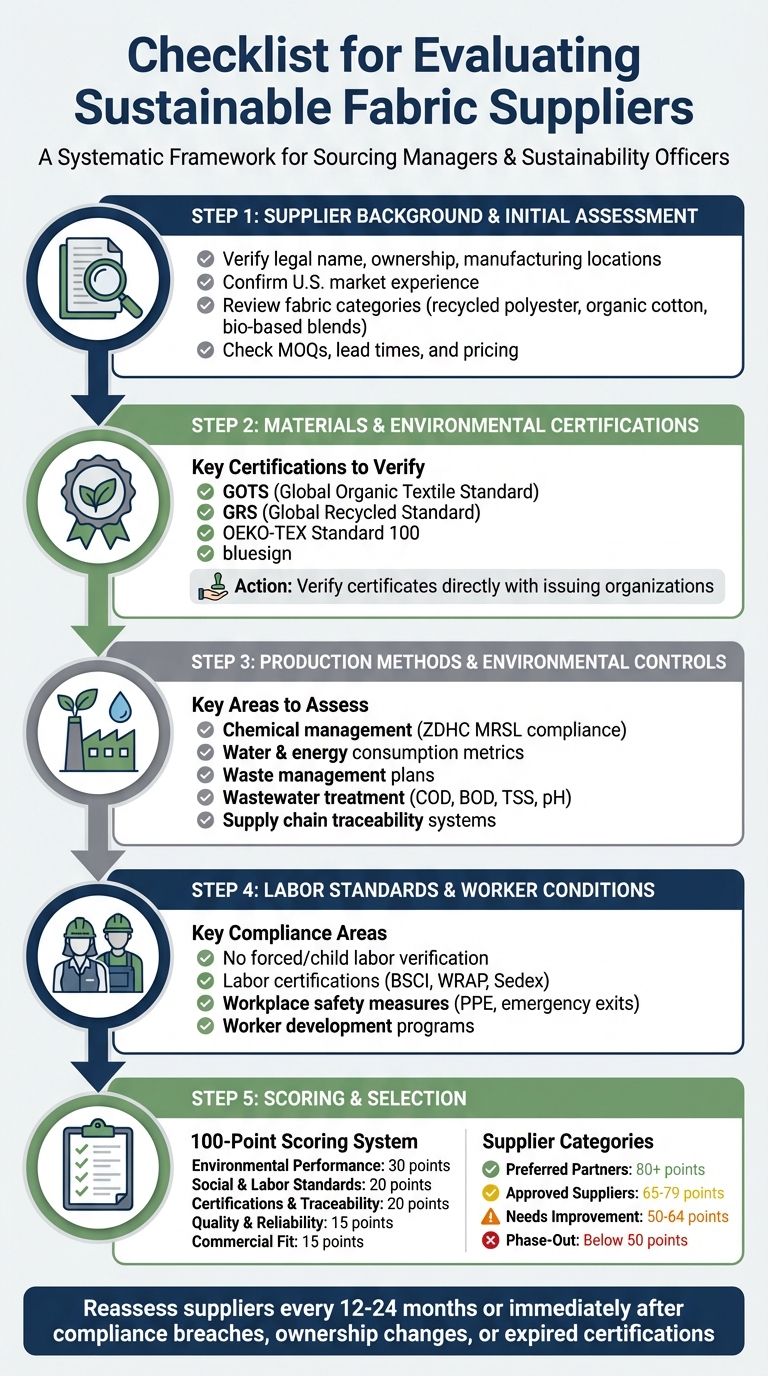

When choosing fabric suppliers, especially for activewear, you need a clear system to evaluate their practices. This checklist helps you assess suppliers based on sustainability, labor practices, and fabric quality. It’s designed for sourcing managers, product developers, and sustainability officers to ensure compliance with U.S. regulations and avoid greenwashing. Here’s how it works:

- Key Criteria: Focus on certifications, recycled content, labor audits, and technical performance.

- Scoring System: Assign weights to priorities like environmental impact (e.g., 50%), labor standards (30%), and quality (20%).

- Verification: Always request credible certifications, test reports, and traceability records.

- Labor Standards: Confirm compliance with local labor laws, safety measures, and ethical practices.

- Production Methods: Evaluate chemical use, waste management, and energy efficiency.

- Traceability: Ensure suppliers track materials back to their origins with proper documentation.

This approach simplifies decision-making, minimizes risks, and ensures alignment with your brand’s goals. Use it to compare suppliers during onboarding, contract renewals, or periodic reviews.

Sustainable Fabric Supplier Evaluation Framework: 5-Step Assessment Process

Sourcing ethical & sustainable fabrics from overseas

Supplier Background and Initial Assessment

Start by gathering key details about the supplier, including their legal name, ownership structure, manufacturing locations, years of operation, and production focus. This information helps you understand the labor laws, environmental rules, and potential U.S. import duties that may apply. It also sets the stage for deciding if further technical and environmental evaluations are necessary.

Basic Supplier Information

To assess the supplier’s experience with U.S. markets, request sample technical data sheets and restricted substances reports. Find out if they already export to the U.S. or to regions with similar compliance standards, like the EU or UK. Ask for examples of brands or product categories they currently serve. Having a U.S.-based agent or representative can be a big advantage, as it streamlines communication, contract negotiations, and issue resolution.

Create a list of fabric categories relevant to your brand – such as recycled polyester knits, organic cotton wovens, bio-based blends, or performance stretch fabrics. Include details like fiber compositions, fabric weights (in both oz/yd² and g/m²), and intended applications. Identify which product lines are marketed as sustainable, such as GRS-certified recycled polyester, GOTS-certified organic cotton, or bio-based fibers. Check if the supplier can provide documentation and certifications for each product lot. Also, note any claimed environmental practices, like reduced-water dyeing, dope dyeing, solvent-free laminations, or renewable energy usage.

Finally, compare all this information against your brand’s technical and sustainability standards.

Match with Your Brand Requirements

Ensure the supplier’s fabric specifications meet your performance needs, such as stretch, moisture-wicking, breathability, abrasion resistance, or UPF ratings. Check their test reports to confirm compliance with your restricted substances list (RSL), including requirements for recycled or organic content and the absence of PFAS, formaldehyde, and heavy metals. Confirm that the supplier aligns with your minimum order quantities (MOQs), lead times, and pricing in U.S. dollars. Also, verify their willingness to collaborate on fabric development to meet evolving sustainability goals.

Example: New Dong Huang Garment Co., Ltd.

New Dong Huang Garment Co., Ltd. stands out for its stability and specialization in technical activewear. As a manufacturer of yoga wear, leggings, sports bras, and performance layers, their expertise matches the high-stretch, moisture-managing, and durable fabrics needed by activewear brands. They provide certifications and audit records that demonstrate compliance with stringent U.S. standards. For a U.S.-based brand, this profile typically warrants moving forward with deeper evaluations, including requests for detailed fabric data, product-specific certifications, and comprehensive environmental and social audits.

Materials and Environmental Certifications

Material Composition and Recycled Content

When sourcing fabrics, request a detailed fiber breakdown by percentage. This breakdown should specify the proportions of virgin, recycled (whether post- or pre-consumer), and bio-based components. Ensure this information is backed by test reports or bills of materials. If possible, dig deeper into the fiber origin – such as the country or region – to better understand upstream impacts and confirm claims like "organic", "traceable", or "closed-loop."

For U.S. buyers, this data must comply with FTC textile labeling rules, ensuring that hangtags and care labels provide accurate information to consumers. Double-check that this information aligns across tech packs, invoices, and product labels. This consistency is essential for verifying a supplier’s material claims.

Required Environmental Certifications

Once you have material details, confirm that your suppliers hold credible third-party certifications for sustainability. U.S. apparel brands often prioritize certifications that address specific environmental and social factors:

- GOTS (Global Organic Textile Standard): Focuses on organic fibers like organic cotton, covering criteria for organic content, chemical use, processing, and some social standards throughout the supply chain.

- GRS (Global Recycled Standard): Verifies recycled content (both pre- and post-consumer) and includes chain-of-custody requirements, chemical restrictions, and social and environmental practices.

- OEKO-TEX Standard 100: Tests finished textile products for harmful substances, ensuring they meet stringent safety standards for human health.

- bluesign: Emphasizes chemical management and cleaner production processes at the mill level, approving inputs and methods that reduce environmental and health impacts.

Match these certifications with your brand’s priorities. For example, a U.S. activewear brand marketed as "recycled and non-toxic" might require GRS for recycled content and OEKO-TEX Standard 100 for chemical safety, with a preference for bluesign or ZDHC-compliant chemistry. Suppliers like New Dong Huang Garment Co., Ltd., which holds GRS certification, demonstrate their commitment to sustainability and recycled materials. They also comply with ethical standards such as BSCI, WRAP, Sedex, and audits from major brands like Nike, New Balance, and Under Armor as of December 2025.

Certificate Verification

To ensure credibility, verify each certification directly with the issuing organization or its public database. Check that the certificate’s legal name, address, scope number, covered sites, product categories, issue date, and expiration date match your purchase details.

For specific orders, require transaction certificates from the certifying body. These certificates should link the certified recycled input to the exact shipment and quantity. They must include the buyer’s name (or their agent), a clear fabric description, quantities, and the same scope number as the original certification. Be alert for warning signs like blurry documents, mismatched company details, or reluctance to share original PDFs. In such cases, contact the certification body directly or consider a brief third-party audit to confirm authenticity.

sbb-itb-8dbc09a

Production Methods and Environmental Controls

Chemical and Resource Use

When working with suppliers, it’s essential to ensure they have a chemical management policy in place that aligns with recognized standards like ZDHC MRSL, bluesign, or OEKO-TEX STeP. This policy should outline how chemicals are purchased, stored, used, and disposed of during production. Always request a complete chemical inventory along with Safety Data Sheets (SDS) for transparency.

For compliance, require a signed Restricted Substances List (RSL) conformance statement for each production batch, ensuring it meets U.S. and EU REACH standards. Include RSL and MRSL clauses in contracts and conduct random spot tests through accredited labs to check for restricted substances such as heavy metals or formaldehyde – especially critical for children’s apparel in the U.S.

To monitor resource usage, ask for quantitative data on water and energy consumption, such as gallons per pound of fabric and kWh per yard. This allows for fair comparisons across mills of different sizes. Additionally, inquire whether the supplier uses renewable energy sources like solar or wind, or has implemented energy-saving measures such as heat recovery systems, low-liquor-ratio dyeing equipment, or LED lighting upgrades.

For waste management, request a written plan detailing how the supplier handles textile scraps, packaging, chemical containers, and sludge. Look for metrics showing waste generation per 1,000 yards of fabric and the percentage diverted from landfills through recycling or reuse. Examples of waste reduction initiatives include reusing selvage for lower-grade products, closed-loop recycling of polyester scraps, or returning chemical containers for reuse.

Lastly, verify that wastewater and air quality management systems are in place to handle emissions and discharges responsibly.

Wastewater and Air Quality Management

Ensure your supplier operates an on-site effluent treatment plant (ETP) or connects to a certified common treatment facility capable of handling their production volume. Request third-party lab reports from the past 6–12 months to confirm that discharge parameters – such as COD, BOD, TSS, pH, color, and heavy metals – comply with both local laws and industry benchmarks.

Ask for operating logs that document flow rates, chemical dosing, sludge handling, and maintenance activities. During site visits or virtual walkthroughs, pay attention to key indicators like clear discharge water without noticeable color or odor, properly dewatered and securely stored sludge, and secondary containment around chemical tanks. Suppliers participating in programs like the ZDHC Wastewater Guidelines often meet structured performance benchmarks.

For air quality, request government permits and recent stack test reports for equipment like boilers, generators, and stenters. These reports should include measurements for pollutants such as NOx, SOx, particulate matter, and volatile organic compounds (VOCs). Confirm the type of fuel used – natural gas typically results in cleaner emissions compared to coal or high-sulfur alternatives – and check for pollution-control equipment like scrubbers, bag filters, or after-burners. Additionally, verify that production areas have proper indoor air quality controls, such as local exhaust systems for printing and coating or dust extraction systems for cutting rooms.

To maintain ongoing accountability, U.S. brands can require independent wastewater and air testing as part of their contracts and request annual data sharing for supplier comparisons.

Supply Chain Traceability

Traceability is a key component of responsible production, ensuring that every stage of fabric manufacturing is transparent. Suppliers should be able to track each fabric lot back to its raw materials, including details about the spinning mill, ginner, or recycler. At a minimum, require unique batch or lot IDs on purchase orders, packing lists, and production records to connect finished fabric to its yarn and fiber sources.

Suppliers should also provide the names and locations of yarn and fiber suppliers along with supporting certificates, such as GOTS transaction certificates or GRS scope and transaction certificates, to validate any sustainability claims. For example, if a fabric is labeled as "50% recycled polyester", request mass-balance or physical traceability records to confirm this composition. Document blending and substitution rules to ensure claims are accurate.

Many mills now use digital systems like ERP platforms, PLM integrations, or blockchain-based tools to manage traceability. Ask which system your supplier uses to track batch numbers, process parameters, and quality data across spinning, weaving or knitting, dyeing, and finishing. Request a demonstration to see how a specific order is traced from raw fiber to finished fabric. Confirm that the system includes features like user access controls, audit trails for edits, and integration with scanning or RFID technology to minimize manual errors.

For example, New Dong Huang Garment Co., Ltd. holds GRS certification and has passed audits from major brands like Nike, New Balance, and Under Armor, showcasing compliance with strict chemical management and traceability standards. To ensure consistency, use standardized traceability questionnaires with all suppliers and reserve the right to conduct chain-of-custody audits to verify that documentation aligns with physical material flows.

Labor Standards and Worker Conditions

When evaluating suppliers, it’s crucial to assess not just their production methods but also their commitment to ethical labor practices.

Labor Law Compliance

Start by ensuring the supplier adheres to local labor laws and international standards. These include bans on forced labor, child labor, and discrimination, as well as protections for freedom of association, legal working hours, and payment of at least the minimum wage plus overtime premiums.

Look for third-party labor compliance certifications as proof of adherence to core labor principles. For instance, New Dong Huang Garment Co., Ltd. holds certifications such as BSCI, Sedex, and WRAP and has passed audits from major global brands, demonstrating their alignment with strict labor and ethical standards.

Request documentation that confirms the absence of forced or child labor. This might include age-verification procedures, anonymized employee records, anti-trafficking policies, and due diligence reports on labor agents. Social audit reports (e.g., SMETA or SA8000), grievance logs, and records of corrective actions for past violations can provide additional assurance. In higher-risk regions, consider unannounced third-party audits or off-site worker interviews to ensure transparency.

To reinforce these standards, include specific labor clauses in contracts and supplier codes of conduct. Require corrective action for any non-compliance found during audits. Positive indicators, such as stable workforce tenure, low absenteeism, and favorable feedback from confidential worker interviews, can signal that policies are being effectively implemented.

Workplace Safety Measures

Conduct on-site evaluations or request video walkthroughs to verify safety measures. Essential elements include clearly marked and accessible emergency exits, evacuation maps, fire detection systems, and proper personal protective equipment (PPE).

Review records of fire drills, emergency training, incident logs, and corrective actions. A comprehensive safety program should address hazard communication, fire safety, first aid, PPE upkeep, and heat stress management. Training should be provided during onboarding and refreshed annually in languages workers understand.

Certifications like BSCI, Sedex, and WRAP – held by companies such as New Dong Huang Garment Co., Ltd. – require compliance with occupational health and safety standards. Look for consistent enforcement, demonstrated by declining injury rates, prompt resolution of audit issues, and active health and safety committees with worker involvement.

Worker Development Programs

Evaluate whether the supplier invests in worker development through structured training programs. These should cover both technical and soft skills, with clear pathways for promotions and pay increases tied to demonstrated competencies.

Effective programs often include training during paid hours, tracked participation, and measurable outcomes such as higher internal promotions, reduced turnover, or improved productivity. Suppliers going beyond basic compliance may also provide worker committees for safety and welfare, anonymous grievance channels with clear resolution tracking, and benefits like on-site meals, transportation, or basic healthcare access.

While specific worker development initiatives at New Dong Huang Garment Co., Ltd. aren’t outlined, their certifications confirm compliance with international labor standards, ensuring worker welfare and fair pay practices.

To maintain high standards, establish multi-year monitoring plans that combine scheduled and unannounced audits, annual self-assessments, and periodic worker surveys. Insist on time-bound corrective action plans supported by evidence such as updated policies, photos, or training records to address any major issues. Incorporate these findings into your ongoing supplier evaluation process.

Supplier Scoring and Selection Process

Building a Scoring System

Transforming your supplier checklist into a 100-point scoring system allows for an objective comparison of suppliers. For instance, you might assign 30 points to environmental performance, 20 to social and labor standards, 20 to certifications and traceability, 15 to quality and reliability, and 15 to commercial fit. To calculate scores, rate each item on a scale of 0–5, multiply by its assigned weight, and sum the results for a total out of 100.

Take this example: a U.S.-based activewear brand evaluates New Dong Huang Garment Co., Ltd., a supplier known for strong certifications, compliance with GRS, and a 99% on-time delivery rate. Using the scoring system, this brand can objectively assess the supplier’s overall performance. Once scores are calculated, the next step is to categorize suppliers for final selection.

Making Your Final Decision

Establish minimum score thresholds to classify suppliers into categories. For example:

- Preferred partners: Scores of 80 or higher

- Approved suppliers: Scores between 65 and 79

- Needs improvement: Scores between 50 and 64

- Phase-out: Scores below 50

Additionally, set clear "red lines" for automatic rejection, such as falsified certifications or serious safety violations.

When finalizing supplier choices, consider both sustainability scores and production capabilities. For instance, a supplier with slightly lower environmental metrics might still be selected if their technical expertise is essential, provided improvement benchmarks are set. U.S. buyers should also weigh factors like total landed costs, shipping times to U.S. ports, and compliance with domestic regulations.

It’s equally important to apply these thresholds for ongoing evaluations. Rescoring suppliers annually – or every 12–24 months – aligns with contract renewals and audit schedules. Immediate reassessment should be triggered by significant events such as compliance breaches, changes in ownership, expired certifications, or major quality issues. To ensure accuracy and guard against greenwashing, back up all scores with verifiable documentation, including certifications, audit results, test reports, and delivery records. Regular reviews keep suppliers aligned with evolving production and sustainability standards.

Summary

A well-structured scoring system turns your checklist into actionable supplier decisions. By assigning weighted points to factors like environmental practices, labor standards, certifications, and operational fit, you can objectively rank suppliers and identify the best partners for your business. Regular reassessments ensure that suppliers continue to meet your performance criteria, while clear thresholds and red lines help minimize risks. This method strikes a balance between sustainability goals and practical production needs, supporting a resilient and ethical supply chain.

FAQs

How can I confirm that a supplier’s sustainability certifications are legitimate?

To confirm the legitimacy of a supplier’s sustainability certifications, start by verifying their credentials with trusted third-party organizations like BSCI, Sedex, GRS, or WRAP. Reach out directly to these certification bodies to validate the supplier’s audit reports and certificates.

You should also ask the supplier for relevant documentation and carefully cross-check details like certification numbers and expiration dates with the issuing organization. This extra step ensures accuracy and reinforces confidence in their sustainability efforts.

What should I look for to ensure a fabric supplier follows ethical labor practices?

To verify that a fabric supplier follows ethical labor practices, check for certifications such as BSCI, Sedex, WRAP, or GRS. These certifications indicate that the supplier meets standards for fair wages, safe working conditions, and respect for workers’ rights.

It’s also worth assessing whether the supplier is transparent about their labor policies and actively works to prevent exploitation. You can gain a deeper understanding of their ethical stance by asking about their worker safety initiatives and employment conditions.

How can I confirm that a fabric supplier follows environmentally friendly practices?

To ensure a fabric supplier operates with environmentally friendly practices, begin by looking for established certifications such as BSCI, Sedex, GRS, or WRAP. These certifications signal that the supplier meets recognized standards for sustainability and ethical practices. You should also inquire about their use of sustainable materials, energy-saving production techniques, and efforts to minimize waste. Don’t hesitate to ask for documentation or audit reports to confirm their compliance with environmental standards. Open and transparent communication with the supplier is key to making sure their practices align with your sustainability objectives.