When deciding how to produce your activewear line, you typically have two options: private label or contract manufacturing. Here’s a quick breakdown of both:

- Private Label: Use pre-designed products from a manufacturer, add your branding, and sell. It’s faster and cheaper upfront but limits customization and design ownership.

- Contract Manufacturing: Create custom products from scratch with full control over design, materials, and features. It requires higher investment and time but allows for unique, original products.

Key Differences:

- Cost: Private label has lower upfront costs; contract manufacturing requires more investment but can lower per-unit costs at scale.

- Customization: Private label limits changes to basic branding; contract manufacturing allows complete design freedom.

- Speed: Private label is quicker to market; contract manufacturing takes longer due to design and development.

- Ownership: Private label products are owned by the manufacturer; contract manufacturing gives you full control over your designs.

Choosing the right model depends on your budget, brand goals, and how much control you want over your products.

Private Label vs Contract Manufacturing Comparison Chart

What Private Label and Contract Manufacturing Mean

Private Label Manufacturing

Private label manufacturing is a straightforward way to launch your activewear brand. Here, you collaborate with a supplier that provides ready-made styles – think leggings, sports bras, joggers, or tank tops. You pick from their existing designs and add your branding touches, such as heat transfer logos, hangtags, or custom packaging. The manufacturer takes care of the production process, using their established patterns and fabrics.

If you need tweaks, like adjusting pocket placement, waistband width, or inseam length, many manufacturers can accommodate those requests. Essentially, you’re customizing a design catalog that’s already been tested and proven, while focusing on building your brand’s identity. This approach lets you tap into the manufacturer’s expertise without starting from scratch.

Contract Manufacturing

Contract manufacturing, on the other hand, is for those who want complete creative control. You’re in charge of designing every detail from the ground up. Working closely with a manufacturer, you can create custom patterns, choose specific performance fabrics, and develop technical features tailored to your vision.

For instance, you could design leggings with a unique waistband structure, a sports bra with a specialized support system, or shorts with custom pocket layouts. Every detail is yours to decide – fabric blends, mesh panel placement, stitching techniques, and overall fit. The manufacturer then brings your blueprint to life, but the intellectual property remains entirely yours. This model is ideal for brands looking to stand out with truly original designs.

How is Contract Manufacturing different from Private Label Manufacturing

Main Differences Between Private Label and Contract Manufacturing

Building on the initial overview, let’s dive deeper into how private label and contract manufacturing differ in production control and market strategy.

Product Ownership and Design Control

One of the most striking differences lies in who owns the product design. With contract manufacturing, you maintain complete ownership of your product’s design, patterns, and intellectual property. You provide the specifications – down to every detail – and the manufacturer simply brings your vision to life. This level of control lets you dictate everything, whether it’s the fit of a pair of leggings or the placement of compression zones in a sports bra.

Private label, on the other hand, flips the script. Here, the manufacturer owns the product design. You choose from their existing catalog of styles, meaning the design, construction, and technical features are pre-determined. While you can add your logo and tweak packaging, you’re limited in making significant changes to the product itself.

As PBZ Manufacturing explains, "The main issue with a private label contract is you do not have control over the product you are putting your name on. You won’t have any say in the production process, you won’t own the formula or design, and you won’t have control over when and how any tweaks are made to the product".

This difference in ownership has a direct impact on brand differentiation. With contract manufacturing, you can create one-of-a-kind products that stand out in a crowded market. Private label, however, often results in multiple brands selling nearly identical items, leaving pricing and marketing as your primary ways to stand out.

Customization and Technical Performance

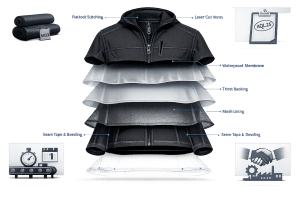

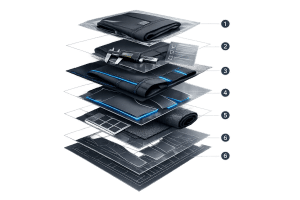

Contract manufacturing gives you the freedom to create products with advanced technical features. Want bonded seams for a seamless finish? Laser-cut ventilation for better airflow? Engineered compression zones for targeted muscle support? All of this is possible. You can even develop proprietary fabric blends or strategically place mesh panels for cooling. Essentially, the possibilities are as broad as your imagination – and budget.

Private label, however, keeps you within the boundaries of what’s already available. You’re limited to the manufacturer’s existing fabric options and production methods. If they don’t offer laser cutting or compression zones, you’re out of luck. Customization is generally restricted to surface-level changes like logo placement, color options, and packaging.

This distinction is especially important in industries requiring specialized capabilities. For instance, medical device companies rely on contract manufacturing to meet strict FDA and ISO standards for products like blood pressure monitors. Similarly, activewear brands aiming for high-performance features often need the precision and flexibility that contract manufacturing provides.

Cost Structure and Financial Risk

Private label manufacturing is easier on the wallet upfront. Since the designs, patterns, and production processes are already in place, you’re not paying for research and development. You simply buy finished products with your branding, making this approach ideal for startups or brands with limited budgets.

Contract manufacturing, on the other hand, demands a larger initial investment. Costs include custom design work, pattern development, sample creation, and possibly specialized tooling. If you’re creating a proprietary fabric blend or a unique waistband design, these expenses can pile up before production even begins.

That said, the long-term financial picture can shift. While private label often comes with fixed minimum order quantities (MOQs) and standard per-unit pricing, contract manufacturing can offer better unit costs at scale. Plus, you’re building equity in your own designs rather than paying to use someone else’s.

Time to Market and Flexibility

If speed is your priority, private label is the faster option. The products are already designed, tested, and ready for production. You can go from concept to market in just weeks, making this approach ideal for testing new markets or jumping on fast-moving trends in athleisure.

Contract manufacturing, by contrast, is a slower process. Starting from scratch means designing, prototyping, testing, and refining – all of which take time. Depending on the complexity of your product, it could take several months to move from idea to finished product. A basic tank top might move quickly, but technical leggings with advanced features could take much longer.

However, contract manufacturing offers more flexibility in the long run. Since you own the designs, you can tweak them as needed, switch manufacturers, or update products based on customer feedback. Private label ties you to the manufacturer’s catalog and their timeline for updates.

Quality Control and Supply Chain Involvement

Contract manufacturing requires a hands-on approach. You’re responsible for overseeing every step of the production process, from fabric testing to fit approvals and quality checks. This level of involvement means more travel, more communication, and a need for technical expertise on your team.

Private label manufacturing shifts much of this responsibility to the manufacturer. They’ve already tested their designs and refined their processes. Your role is mainly to inspect the final product and ensure your branding meets standards. This requires less technical know-how and fewer resources dedicated to production oversight.

The same dynamic applies to supply chain management. With contract manufacturing, you often need to source specific fabrics, trims, or components yourself, working directly with suppliers to meet your design requirements. Private label simplifies this by keeping everything within the manufacturer’s established supply chain, though this limits your control over material choices.

sbb-itb-8dbc09a

How to Choose the Right Model for Your Activewear Brand

Aligning with Your Brand’s Stage and Goals

The stage your brand is in plays a key role in determining the best manufacturing approach, especially when factoring in production control and costs.

For early-stage brands, private label manufacturing is often the way to go. Why? It offers lower upfront costs and faster entry into the market. This allows you to focus on building brand awareness instead of diving deep into product development. This approach works particularly well in the lifestyle athleisure space, where customers often care more about style and branding than intricate technical features.

On the other hand, growth-stage brands can benefit from contract manufacturing. This option supports the creation of unique, technically advanced products that help your brand stand out. If your target audience includes performance athletes who demand top-notch technical capabilities, contract manufacturing gives you the control needed to meet those expectations.

Evaluating Your Team’s Skills and Resources

Contract manufacturing isn’t for everyone – it requires a solid foundation in design and technical expertise. You’ll need to handle tasks like creating detailed tech packs, reviewing samples, and ensuring quality control. If your team lacks these skills, you may need to bring in specialists or consultants, which can increase your overall costs.

Private label manufacturing, by contrast, is much more straightforward. It doesn’t require deep technical knowledge. Instead, your focus shifts to branding and sales. This includes choosing product styles that fit your brand’s aesthetic, deciding on logo placement, and managing packaging. The manufacturer takes care of the technical side, making this a great option for teams with limited garment production experience.

Whichever route you choose, it’s essential to also consider your financial planning to ensure your brand grows sustainably.

Budgeting for Costs, Order Sizes, and Future Growth

Think beyond your first order. Private label manufacturing typically comes with fixed minimum order quantities, which can make it harder to adjust your product line as your business expands.

Contract manufacturing, while requiring a larger upfront investment, offers more long-term flexibility. You’ll need to budget for design, sampling, and tooling, but the payoff can be significant. Owning your designs gives you better control over unit costs as your order volumes grow. Plus, this model allows you to negotiate better pricing, switch manufacturers if needed, or tweak products to align with market trends. For brands aiming to scale in the competitive U.S. activewear market, this initial investment often proves worth it in the long run.

How New Dong Huang Garment Co., Ltd. Supports Both Models

Private Label Capabilities

New Dong Huang (NDH) offers a ready-to-go portfolio of activewear designed for quick market entry. Their collection includes leggings, sports bras, jackets, and base layers, catering to both performance and lifestyle needs. These pieces are crafted with built-in performance features, giving brands access to high-quality fabrics without the expense or time commitment of custom development.

For those looking to align with the growing demand for eco-conscious products, NDH provides options made from sustainable fabrics. The private label process is straightforward: choose your styles, add your branding, and proceed with production. This low-barrier approach is ideal for brands focused on establishing their presence without diving into the complexities of product design from scratch.

Contract Manufacturing Expertise

In addition to private label offerings, NDH excels in custom contract manufacturing for brands that want unique, tailored products. With over 27 years of experience, NDH’s advanced production capabilities include specialized machinery like bonding machines and laser cutting equipment. These tools allow for precise construction techniques, such as seamless bonding, clean-finished edges, and intricate design elements – features that set premium activewear apart.

NDH’s contract manufacturing services cover every step of the development process. From trend research and tech pack creation to pattern making and fabric selection, they provide end-to-end support. The company is certified by BSCI, Sedex, and GRS and has passed audits for major athletic brands. With a 99% on-time delivery rate, they ensure reliability for brands that depend on consistent production schedules.

Supporting Long-Term Brand Growth

NDH’s dual service model is designed to grow with your brand. By combining private label and custom manufacturing options, they offer a seamless transition as your needs evolve. Brands can start with private label products to test the market and establish a foothold, then shift to custom manufacturing as sales grow and product differentiation becomes a priority.

This progression helps brands build technical expertise and expand their design capabilities while maintaining stable production. NDH’s approach supports the natural development of activewear brands in the competitive U.S. market, where both speed and innovation are critical for success.

Conclusion

Choosing between private label and contract manufacturing comes down to where your brand stands today and where you want it to go. Private label is a faster, more cost-effective option, perfect for brands focused on building their presence through strong branding and marketing efforts. On the other hand, contract manufacturing offers complete control over design and product uniqueness, making it ideal for brands ready to invest in standout, performance-focused products. The right choice depends on your budget, internal resources, and long-term growth plans, aligning your strengths – whether in design or marketing – with the model that best fits your vision.

Finding a partner that grows with your brand is just as important. The U.S. activewear market thrives on both speed and innovation, and New Dong Huang Garment Co., Ltd. (NDH) is equipped to support brands at every stage. Offering both private label collections and custom contract manufacturing, NDH provides the flexibility to pivot between ready-made styles and fully customized designs, depending on your strategy. Whether you’re testing the waters with pre-designed options or creating proprietary pieces with advanced techniques, NDH’s dual approach ensures your business can adapt and evolve.

Many brands start with private label to establish cash flow and validate their market before transitioning to custom manufacturing as they scale. NDH’s 27 years of experience, 99% on-time delivery rate, and certifications from BSCI, Sedex, and GRS make it a reliable partner no matter which path you choose – or when you decide to change course.

FAQs

What are the benefits of choosing contract manufacturing for activewear production?

Contract manufacturing offers more control over the design and customization of your activewear, enabling you to create products that align perfectly with your brand’s identity. It also provides greater flexibility in production volumes, so you can easily adjust output to match market demand.

On top of that, contract manufacturing connects you with industry expertise and cutting-edge technologies, which can improve product quality and drive innovation. By outsourcing production, you can cut down on infrastructure and labor expenses, making it an efficient option for brands looking to deliver high-quality, tailored activewear without the burden of running their own manufacturing facilities.

What’s the difference in product ownership between private label and contract manufacturing?

In private label manufacturing, the manufacturer creates a product and retains ownership of its design and production. However, the purchasing company takes charge of the branding and marketing, selling the product under its own label. This setup allows businesses to quickly introduce products without managing the production process.

On the other hand, contract manufacturing gives the company complete ownership of the product, including its design and specifications. This approach offers businesses the flexibility to fully customize and develop their products, making it ideal for those aiming to deliver something distinct to the market.

What should brands think about when choosing between private label and contract manufacturing?

When choosing between private label and contract manufacturing, it’s essential to weigh your business goals, budget, and how much control you want over the production process. If your priority is to launch quickly while keeping costs down, private label might be the way to go. This approach offers pre-designed products that you can brand with your logo, making it a faster and more affordable option.

On the flip side, contract manufacturing works well for businesses aiming to create customized products, maintain strict quality control, and plan for scalability. This route lets you develop unique products tailored to your vision, but it often requires a larger investment and a more hands-on role in production. Consider your long-term strategy carefully – does speed or customization better suit your business objectives?