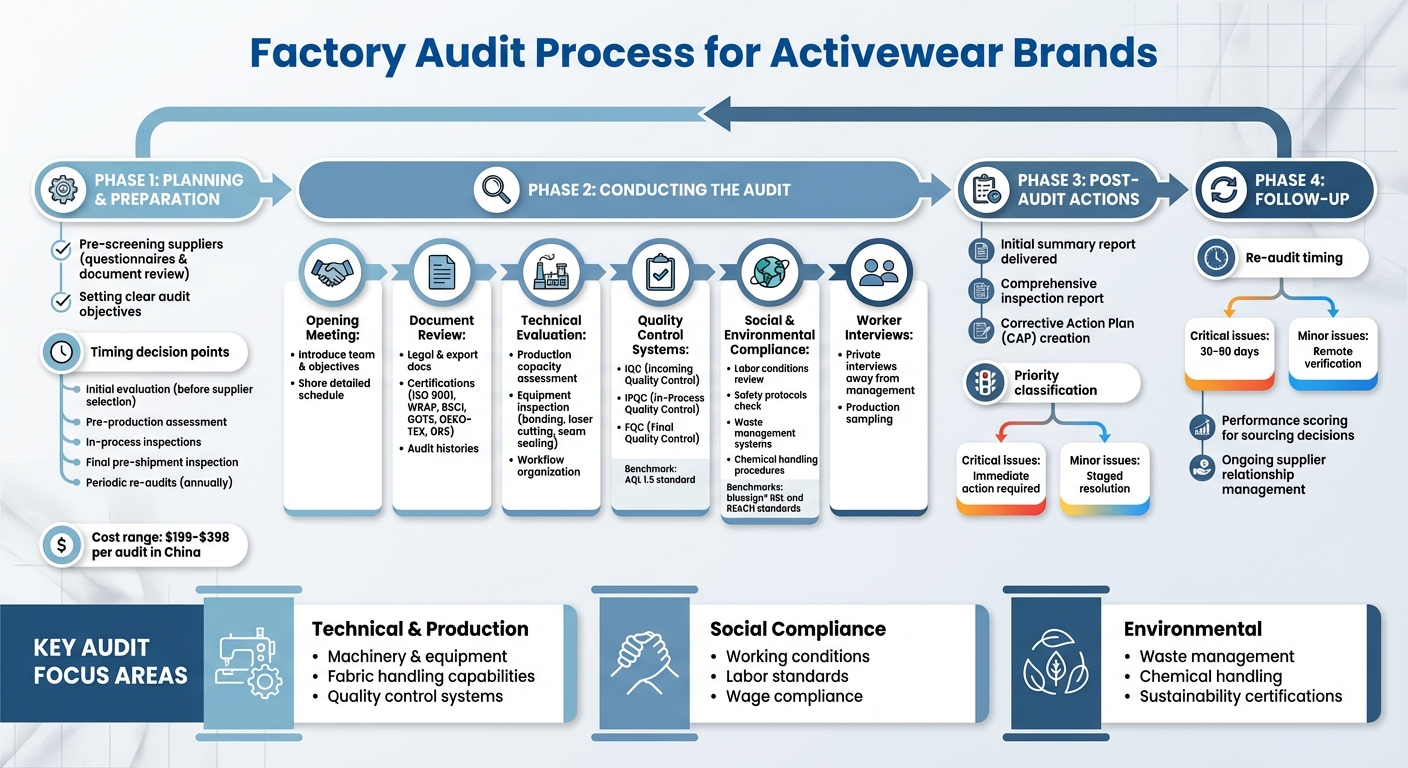

Factory audits are an essential process for activewear brands to ensure their suppliers can consistently produce high-quality products that meet technical, quality, and compliance standards. This involves evaluating production capabilities, ethical practices, and environmental protocols. Here’s what you need to know:

- Purpose: Verify if a factory can handle complex activewear production, including performance fabrics and advanced techniques like bonding or seam sealing.

- Key Areas: Focus on production capacity, quality systems, sustainability claims, and ethical labor practices.

- Types of Audits:

- Technical and Production: Assess machinery, fabric handling, and quality control.

- Social Compliance: Review working conditions and labor standards.

- Environmental: Check waste management, chemical handling, and certifications.

- Timing: Conduct audits before supplier selection, pre-production, during production, and periodically for ongoing suppliers.

- Preparation: Pre-screen suppliers with questionnaires and document reviews to save time.

- Follow-Up: Use audit findings to create corrective action plans and schedule re-audits to ensure compliance.

Factory Audit Process for Activewear Brands: Complete Timeline and Steps

What is the Role of Factory Audits in Supply Chain Visibility and Mapping?

Planning Your Factory Audit Program

A well-structured factory audit program begins with clear, targeted objectives. Start by pinpointing exactly what you need to verify – whether it’s the factory’s ability to handle advanced performance fabrics, the effectiveness of their quality management systems (like incoming and in-process quality control), or their adherence to ethical and environmental standards. Pay attention to both standard production methods and any advanced capabilities required for your products.

Setting Clear Audit Objectives

Your audit goals should align with the specific needs of activewear production. Focus on verifying production capacity for technical fabrics, ensuring quality control processes meet your standards, and checking compliance with ethical and sustainability certifications. Many manufacturers hold multiple certifications such as WRAP, BSCI, GOTS, OEKO-TEX, and GRS, often backed by up-to-date audit reports. Tailor your audit checklists to reflect the technical and sustainability requirements of your activewear line.

For instance, if you’re producing seamless activewear, you’ll want to assess the factory’s research and development capabilities and their testing procedures. For sustainable collections, place a stronger emphasis on their environmental policies and waste management systems. Additionally, review the factory’s human resources – understanding the experience and availability of quality control inspectors and engineers is crucial to determining whether the factory can consistently meet your expectations.

When to Schedule Factory Audits

Strategically timing your audits can help you avoid expensive production setbacks. Begin with an initial factory evaluation before committing to a supplier or placing your first order. This pre-sourcing audit evaluates the factory’s capabilities, production capacity, and overall suitability, potentially saving you from financial risks. In key manufacturing regions like China, a comprehensive audit typically costs between $199 and $398.

Once you’ve selected a supplier, conduct a pre-production assessment before large-scale manufacturing begins. At this stage, review fabric swatches, trims, and perform small-scale tests to confirm quality and efficiency. As production progresses, schedule in-process inspections at critical points – such as after fabric inspection, post-cutting, or post-sewing – to catch and address problems early. Wrap up with a final pre-shipment inspection to ensure fabric quality, stitching, labeling, and packaging meet your standards.

For ongoing suppliers, periodic re-audits, usually conducted annually, are essential for maintaining consistent quality. Many global brands conduct thorough site visits to monitor capacity, remediation plans, and transparency, ensuring high performance. Follow-up audits within six months are particularly useful for addressing high-risk concerns like wage compliance or factory transparency.

Pre-Audit Preparation and Factory Screening

Pre-screening manufacturers can save both time and resources by eliminating unsuitable options before an on-site audit. Start by identifying potential suppliers through trade shows or directories, then narrow your list using targeted questionnaires. Request key documentation, such as business and export licenses, ISO certifications, social compliance reports (e.g., BSCI, Sedex, or WRAP), and records of past audits. Additional documents, like product or raw material warranty certificates, can also provide valuable insights.

Verify the factory’s profile and confirm that essential documentation is in order. It’s also helpful to evaluate the factory’s human resources structure, including the number of senior managers, engineers, and quality control staff. Understanding the factory’s export focus can also offer clues about their quality expectations. For example, a factory primarily serving Western Europe may have different standards compared to one focused on other markets.

Before scheduling an audit, ensure the factory is accessible and that the supplier is willing to participate. Some factories may decline a full audit for smaller orders or during peak production periods. In such cases, a factory visit can still provide useful insights to determine whether their operations align with your activewear production needs. These preparatory steps set the stage for the detailed on-site evaluations discussed in the next section.

How to Conduct Factory Audits for Activewear

Conducting a factory audit for activewear involves a series of steps designed to ensure the factory meets your quality, technical, and compliance standards. Here’s how to approach this process effectively.

Opening Meeting and Document Review

Kick off the audit with an opening meeting to introduce your team and explain the purpose, scope, and objectives of the audit. Share a detailed plan that outlines the schedule, key activities, and milestones so the factory knows what to expect throughout the day.

The next step is to review essential documents. This includes legal, export, and quality-related paperwork, such as audit histories and certifications. Once the document review is complete, shift your attention to how these documented processes are being implemented on the factory floor.

Evaluating Technical and Production Capabilities

Take a close look at the factory’s production setup, capacity, and expertise in activewear manufacturing. Observe the production floor to assess equipment maintenance, process control, and workflow organization. Pay special attention to whether the factory can handle the unique challenges of activewear production, such as working with technical fabrics and advanced construction methods.

For example, ensure the factory is equipped for specialized processes like bonding, laser cutting, and seam sealing. These techniques require precise machinery and temperature control to meet the demands of activewear production.

Inspecting Quality Control and Testing Systems

A robust quality control system is critical for ensuring consistent product standards. Verify that the factory’s quality control processes cover every stage, from raw materials to finished products. Check for detailed records of Incoming Quality Control (IQC), In-Process Quality Control (IPQC), and Final Quality Control (FQC). Inspect the quality control equipment – state-of-the-art tools can signal stronger quality management systems.

Additionally, confirm that the factory can internally test pre-production samples and assess the performance of new products. Review product and warranty certificates for raw materials to ensure compliance with chemical safety standards. For instance, Helly Hansen requires its Tier 1 and Tier 2 suppliers to sign a chemical compliance agreement based on bluesign®’s RSL and REACH standards. Such disciplined systems are vital for maintaining consistent quality.

Checking Social and Environmental Compliance

Auditing a factory’s ethical and environmental practices is just as important as evaluating its production capabilities. Conduct social compliance checks to assess labor conditions, health and safety measures, and adherence to environmental policies. Inspect worker areas for proper lighting, ventilation, emergency exits, and fire safety equipment. Review wage records, working hour logs, and employment contracts to ensure compliance with local labor laws and global standards like BSCI or Sedex.

On the environmental front, examine waste management systems, water treatment processes, and energy use. If sustainability is a priority, check for certifications such as GOTS or GRS and evaluate how the factory handles fabric scraps and chemical waste. Confirm that the factory has documented procedures for managing hazardous materials and that workers are trained in environmental safety protocols.

Worker Interviews and Production Sampling

Interview workers privately, away from management, to get an honest understanding of their working conditions. Ask about their hours, wage payments, break schedules, and safety training. These interviews often reveal discrepancies between official records and everyday practices, especially concerning overtime and working conditions.

Observe production processes in action and collect samples at various stages. Watch how workers handle technical fabrics and whether they follow standard operating procedures, including quality checks. These real-time observations provide a practical layer of verification, complementing the document reviews and technical assessments. This hands-on approach ensures that the factory’s processes consistently deliver high-quality activewear.

sbb-itb-8dbc09a

Building Factory Audit Checklists

Following the audit procedures discussed earlier, using tailored checklists ensures every audit step aligns with specific criteria. A well-structured checklist transforms your audit into a thorough and systematic evaluation. The aim is to create a repeatable and efficient process that captures all critical details. These checklists should outline clear product specifications and objective inspection criteria to ensure they meet both customer expectations and regulatory requirements.

Before crafting your checklist, define the objectives of your evaluation – whether it’s an initial supplier assessment, ongoing monitoring, or addressing specific production concerns. Build your checklist around recognized standards such as ISO 9001 for quality management systems. These checklists should consolidate technical, quality, and compliance insights into a cohesive audit strategy.

Technical and Equipment Checklist

The technical checklist should focus on the factory’s ability and capacity to handle your specific activewear production needs. Start by evaluating the specialized machinery required for activewear manufacturing: flatlock machines for smooth seams, bonding equipment for seamless construction, laser cutting tools for precision, and heat-sealing machines for waterproof applications. Document the condition and maintenance history of each machine, as well-maintained equipment often reflects a stronger quality management system.

Additionally, evaluate production processes from raw material input to final packaging. Check the status of machinery, workflow organization, and the factory’s internal quality control systems, such as Incoming Quality Control (IQC), In-Process Quality Control (IPQC), and Final Quality Control (FQC). These systems are essential for maintaining production consistency.

Quality and Product Performance Checklist

This checklist should include all garment specifications – such as weight, dimensions, materials, Pantone color codes, and labels – along with performance criteria like stretch recovery, moisture-wicking, breathability, fade resistance, and UPF ratings.

Assess seam strength, seam types (e.g., flatlock), and bonding techniques that improve garment comfort. Define clear pass/fail criteria for each product feature and specify the measurement tools and personnel responsible for verifying consistency. You may also apply Acceptable Quality Limit (AQL) standards, like AQL 1.5, to maintain quality across all orders. Share this checklist with suppliers before production begins so they can review the requirements, confirm their capabilities, or suggest adjustments.

Social and Environmental Compliance Checklist

The social and environmental checklist should address key areas such as labor documentation, wage records (ensuring compliance with minimum and living wage standards), working hours, and safety protocols. Verify payroll records to ensure fair wages and proper working hours, confirm the absence of forced or child labor, and check for the availability and use of Personal Protective Equipment (PPE). Additionally, ensure there are functioning employee grievance mechanisms in place. Assess safety measures like fire safety equipment, machine guarding, and electrical systems to guarantee a safe working environment.

For environmental compliance, examine waste management systems, water treatment processes, energy usage, and chemical handling practices. Verify certifications and licenses, such as ISO 9001, Oeko-Tex, or BSCI/Sedex, to confirm compliance. Beyond document reviews, conduct worker interviews in their native language to understand actual working conditions and their awareness of workplace rights. This hands-on approach ensures that documented policies are being implemented effectively on the factory floor.

Post-Audit Actions and Follow-Up

After completing an audit, the next step is to take meaningful follow-up actions. Typically, the auditor provides an initial summary report highlighting key issues, followed by a comprehensive inspection report. This marks the beginning of a process to determine whether the factory can be considered a reliable partner or requires further evaluation.

Creating Corrective Action Plans

Start by holding a meeting with key stakeholders to review the audit findings and address any non-conformances. The factory should then be tasked with preparing a corrective and preventive action report. It’s important to prioritize issues based on their severity – critical violations like child labor or forced labor must be addressed immediately, while less urgent matters can be resolved in stages.

The factory is provided with a detailed Corrective Action Plan (CAP) that outlines specific recommendations to improve its quality systems. Clear instructions and deadlines should accompany these suggestions, tailored to the complexity of each issue. Regular monitoring ensures that emerging problems are managed effectively. Once the corrective measures are implemented, re-audits are conducted to confirm their success.

Re-Audits and Follow-Up Verification

Re-audits play a crucial role in verifying the effectiveness of corrective actions. The timing and scope of these follow-ups depend on the severity of the issues and client requirements. For critical problems, on-site re-audits should be scheduled within 30 to 90 days. Minor issues, however, may be verified remotely. If problems persist, additional audits may be necessary until compliance is consistently achieved. This structured approach not only ensures the CAP’s success but also promotes continuous improvements in the factory’s systems and processes.

Using Audit Data for Sourcing Decisions

Audit data is a powerful tool for enhancing supply chain management. It helps ensure quality, reduce risks, and guide decisions about supplier selection. Developing a scoring system based on audit results allows for strategic order allocation. Factories with strong technical capabilities, reliable quality systems, and solid social compliance records are better positioned for larger order volumes and longer partnerships. Regular audits and follow-ups encourage ongoing improvements, ultimately strengthening sourcing relationships.

Tracking performance across multiple audits can reveal important trends. Factories that show consistent improvement demonstrate a commitment to partnership, while those with recurring issues may require a reassessment of their role in the supply chain or even a reallocation of orders.

Conclusion

Factory audits play a critical role in ensuring technical, quality, and social compliance, helping to safeguard both your supply chain and your brand’s reputation. By conducting detailed audits, you can feel confident that your factory partner is capable of consistently delivering products that align with your specifications and uphold ethical standards.

These audits don’t just verify compliance – they encourage ongoing improvements in quality, safety, and efficiency. Even in cases where factory owners initially resist change, active coaching and follow-through often lead to safer and more efficient operations over time.

A transparent supply chain strengthens consumer trust and boosts worker confidence, making audits far more than a box-ticking exercise. They serve as a strategic tool for building better partnerships and ensuring long-term success.

Follow-up actions and re-audits are where audits truly show their value. Factories that demonstrate consistent improvement often secure larger orders and deepen their partnerships. On the other hand, recurring issues highlight the need for reassessment and careful decision-making.

While audits require an upfront investment, the cost is small compared to the risks of working with unreliable suppliers. A well-designed audit program not only protects your supply chain and ensures product quality but also sets the stage for sustainable growth in the competitive activewear market.

FAQs

What are the main benefits of factory audits for activewear brands?

Factory audits play a crucial role for activewear brands, ensuring manufacturing practices are both ethical and efficient. These audits help confirm that suppliers meet quality requirements and follow ethical labor practices, such as providing safe working conditions and fair wages. By doing so, brands safeguard their reputation and avoid serious issues like unsafe work environments or labor violations.

Beyond ethics, audits serve as a risk-management tool. They help identify potential problems – like faulty machinery or limited production capacity – before committing to large orders. Catching these issues early minimizes waste, prevents costly delays, and ensures compliance with both U.S. and international regulations, keeping products ready for market.

Audits also promote transparency and encourage ongoing improvement. By addressing factors such as health and safety, overtime pay, and waste management, factories can enhance their operations and build stronger relationships with brands. This transparency resonates with consumers, who increasingly prioritize ethical and high-quality supply chains when making purchasing decisions.

What steps can activewear brands take to ensure ethical and environmental compliance during factory audits?

To uphold ethical practices and meet environmental standards, activewear brands should take a structured approach to factory audits. Start with a comprehensive checklist that addresses key areas such as labor rights – covering fair wages, safe working conditions, and reasonable hours – alongside environmental factors like energy usage, water consumption, and waste management. Including globally recognized standards like ISO 9001 and social responsibility frameworks ensures that evaluations are thorough and aligned with industry best practices.

A mix of announced and unannounced audits is essential to verify compliance over time. Announced visits give factories the opportunity to meet your Code of Conduct, while unannounced inspections help confirm that improvements are sustained. If your internal team lacks capacity, consider partnering with accredited third-party auditors who adhere to established ethical and environmental guidelines.

Continuous monitoring is just as important. Require suppliers – such as New Dong Huang Garment Co., Ltd. – to regularly submit environmental data and certifications like Oeko-Tex or Bluesign. Combining detailed audits with ongoing oversight enables brands to confidently support ethical labor practices and sustainable production.

What should activewear brands include in a factory audit checklist?

Activewear brands need a thorough factory audit checklist to ensure product quality, ethical labor practices, and environmental standards are upheld.

For product quality, pay close attention to fabric performance – think stretch, resistance to pilling, and durability. Evaluate stitching and seam strength, color fastness, and the functionality of details like zippers and fasteners. Measurements should be accurate to guarantee proper fit, alignment, and garment symmetry. Additionally, review labeling and packaging for accuracy and conduct performance tests, such as moisture-wicking capabilities or compression retention.

On the ethical and environmental fronts, confirm that factories adhere to fair labor practices. This includes paying fair wages, providing personal protective equipment (PPE), and maintaining a safe workplace where employees can voice concerns without fear. Environmental checks should cover waste management practices, water conservation efforts, and the use of eco-friendly chemicals during production.

By addressing these critical areas, activewear brands can build trustworthy manufacturing partnerships while aligning with U.S. standards for quality, sustainability, and social responsibility.