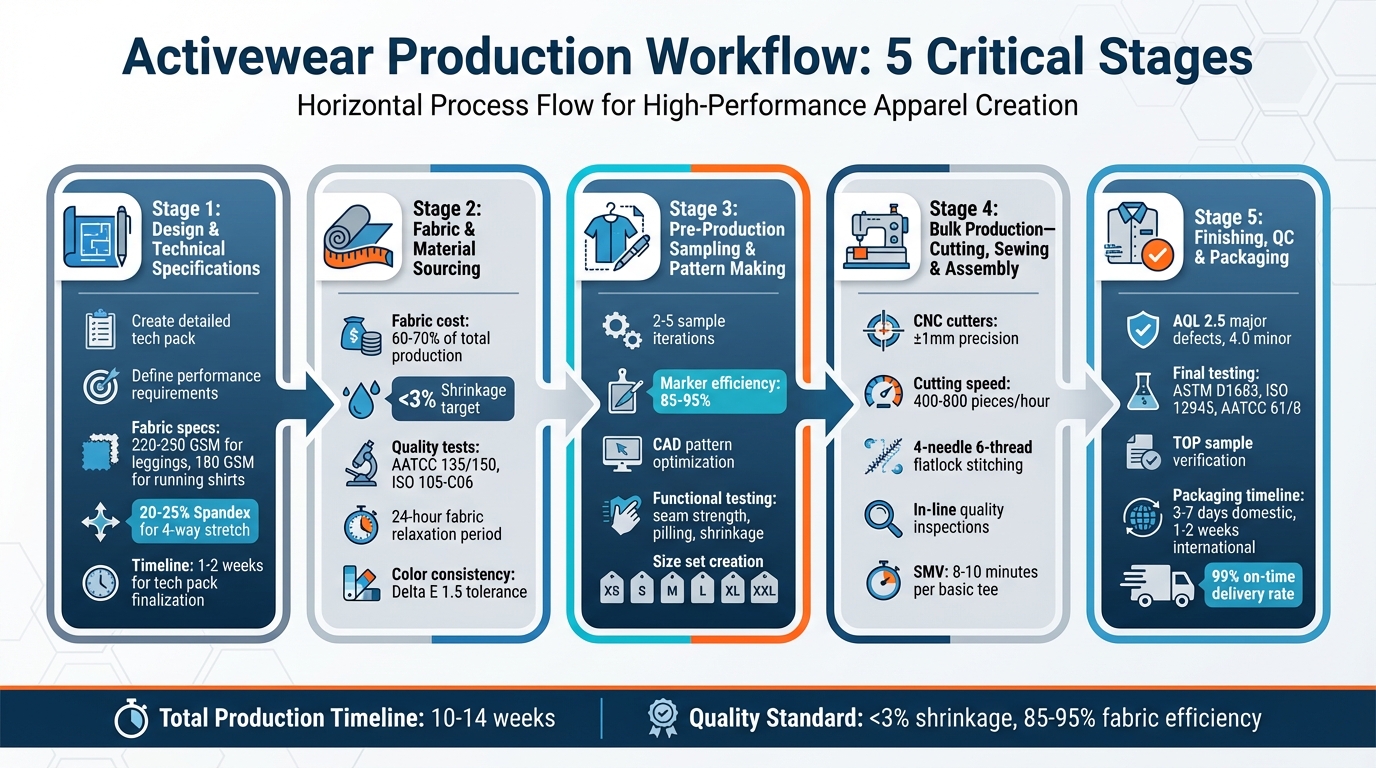

Creating activewear is about precision and performance. From fabric selection to stitching techniques, every step ensures the final product meets high standards for athletic wear. Here’s a quick overview of the process:

- Design & Technical Specifications: Start with a detailed tech pack outlining fabric, fit, and construction details.

- Fabric Sourcing: Choose materials like Nylon 66 or Polyester with Spandex for stretch, durability, and moisture-wicking properties.

- Sampling & Pattern Making: Create and test prototypes to perfect fit and functionality before bulk production.

- Bulk Production: Use advanced tools like CNC cutters and flatlock stitching for consistent, high-quality garments.

- Finishing & Quality Control: Inspect every detail, from seam strength to shrinkage, ensuring garments meet performance standards before packaging.

This structured process ensures activewear that performs under stress, aligns with brand goals, and delivers reliable quality for athletes.

5-Stage Activewear Production Workflow from Design to Delivery

How Sportswear Factories REALLY Make Your Clothes!

Stage 1: Design and Technical Specifications

The journey of creating activewear starts by identifying the needs of athletes. This stage, the first in a five-step workflow, ensures that every piece of activewear is designed to meet high standards for both performance and fit. It’s where creative ideas are transformed into detailed engineering guidelines, setting the stage for manufacturing garments that perform flawlessly during athletic activities. This phase bridges the gap between creative design and precise technical requirements.

Defining Performance Requirements

The foundation of any activewear design lies in its performance requirements. First and foremost, the fabric must manage moisture effectively. Activewear achieves this by using materials with specific fiber structures and hydrophilic finishes, which wick sweat away from the body and allow it to evaporate quickly.

Stretch and recovery are also key. These qualities ensure the garment moves effortlessly with the wearer and retains its shape. High-performance fabrics often combine Nylon 66 or Polyester with 20–25% Spandex to achieve true 4-way stretch. Nylon 66 is particularly favored for premium activewear due to its durability, soft texture, and excellent abrasion resistance.

Fabric weight, measured in GSM (Grams per Square Meter), plays a crucial role in both performance and coverage. For example, a lightweight running shirt might use 180 GSM for breathability, while leggings designed for intense workouts typically require 220–250 GSM to remain opaque during movement. Seam construction is another critical factor. Flatlock stitching, which uses a four-needle six-thread method, creates strong, flat seams that reduce chafing.

Different sports demand tailored features. Running gear often includes reflective elements for visibility and lightweight materials for speed. Yoga apparel might focus on high-waisted designs for support and hidden pockets for convenience. Meanwhile, team sports often rely on dye sublimation techniques for vibrant, durable graphics.

Creating a Complete Tech Pack

All these details are compiled into a tech pack – a document that serves as the blueprint for manufacturing. Kane Chu, Senior Production Engineer at Maes Group, emphasizes its importance:

"A tech pack is the single most critical document in the entire sportswear manufacturing process. It is a comprehensive blueprint that leaves no room for error".

A thorough tech pack includes several key components:

- Technical sketches: Front and back views with detailed seam placements.

- Bill of Materials (BOM): A complete list of materials, including fabric composition, GSM, zippers, and thread types.

- Measurement chart: Graded specifications for each size, along with tolerances (e.g., ±0.5 inches) to guide quality control.

- Construction notes: Stitch types and assembly instructions.

- Artwork files: Vector formats (AI, EPS, PDF) for logos and prints.

The tech pack acts as the product’s DNA, ensuring consistency whether the production run is 30 or 3,000 units. It also defines the garment’s intended fit – slim, regular, or relaxed – providing clear guidance for pattern makers. Investing 1–2 weeks to finalize a professional tech pack can save time and money by reducing errors and minimizing revisions during the sampling phase.

At New Dong Huang Garment Co., Ltd. (https://leggingsupplier.com), creating and executing detailed tech packs is a critical step in producing high-quality activewear that meets stringent performance demands.

Stage 2: Fabric and Material Sourcing

After finalizing the tech pack, the focus shifts to sourcing materials that meet the performance goals set during the design phase. This step ensures that the chosen fabrics align with the functionality and comfort required for the intended activity. Fabric selection plays a key role in determining breathability, sweat management, compression, and overall durability. As a Fabriclore textile expert explains:

"Performance fabrics show how well sportswear works in real life… choosing a fabric is a science and strategic process".

Choosing High-Performance Fabrics

Selecting the right material starts with understanding the activity the garment is designed for. For high-intensity activities like running, fabrics with strong moisture-wicking properties are essential. These fabrics, often made from polyester, feature specific fiber structures and finishes that pull sweat away from the skin, allowing for quick evaporation. Polyester is a popular choice – it’s lightweight, durable, and budget-friendly. On the other hand, yoga and other low-impact activities benefit from softer, more breathable options like bamboo or modal blends.

Stretch and recovery are critical for activewear. High-quality sportswear requires true 4-way stretch, enabling unrestricted movement without the fabric losing its shape. This is typically achieved by incorporating 10–30% elastane (spandex).

Fabric weight, measured in GSM (grams per square meter), is another key factor. It affects both performance and coverage. For bottoms, a GSM of at least 250–260 ensures the material isn’t see-through when stretched.

Durability is also a major consideration. Nylon 66 is often preferred for premium activewear due to its superior abrasion resistance compared to polyester. It’s stronger, softer, and offers better recovery, making it ideal for compression and yoga wear. However, polyester remains the go-to for many activewear items, thanks to its balance of durability, breathability, and affordability.

A simple water test can help verify moisture-wicking properties before committing to bulk orders. Flick water onto the back of a fabric sample – if the water travels through to the front while leaving the back relatively dry, the fabric passes the test.

Once fabrics meeting these performance criteria are selected, they undergo rigorous inspection to ensure quality before moving into production.

Inspection and Pre-Treatment Processes

Quality control begins as soon as the fabric arrives. Each roll is visually inspected for defects like stains, holes, snags, or color inconsistencies before any cutting takes place. Since fabric typically accounts for 60–70% of a garment’s production cost, identifying issues early can save significant time and money.

Physical checks verify the fabric’s GSM, width, and handfeel against the approved tech pack. To ensure color consistency, spectrophotometry is used, with any variations exceeding Delta E 1.5 flagged for rejection. Grouping fabric by dye lot also helps maintain uniformity across all garment panels.

Pre-production lab testing is a must. Common tests include shrinkage (AATCC 135/150), colorfastness (ISO 105-C06), and pilling resistance (ISO 12945). High-quality activewear fabrics aim for a shrinkage rate below 3%. For materials prone to shrinking, especially those with high spandex content, it’s crucial to let them rest flat for at least 24 hours after unrolling. This relaxation process minimizes shrinkage after cutting.

Shrinkage allowance can be calculated by washing and drying a small fabric swatch, then adjusting patterns accordingly before bulk cutting. For performance garments, it’s also important to test the fabric’s 4-way stretch and its ability to return to its original shape, ensuring the final product maintains its fit over time.

As Ninghow emphasizes:

"Tight QC and clear specs – even on labels and trims – help brands catch costly mistakes before stock reaches retail".

At New Dong Huang Garment Co., Ltd. (https://leggingsupplier.com), fabric innovation includes options like eco-friendly, quick-dry, anti-odor, and anti-UV materials. Each fabric undergoes thorough quality control to meet the performance standards outlined in the tech pack.

Stage 3: Pre-Production Sampling and Pattern Making

Once high-performance fabrics pass inspection, the focus shifts to creating prototypes that connect the design vision with actual production. These prototypes serve as a critical step to validate fit, functionality, and durability before moving into bulk manufacturing. As Maria Rodriguez, a seasoned fashion industry expert, explains:

"A prototype is your insurance policy against costly mistakes. It’s much more economical to identify and fix issues at the prototype stage than after you’ve produced hundreds or thousands of garments."

Designers typically go through 2–5 sample iterations, including proto, fit, size set, and final pre-production samples (PPS), to resolve construction, fit, and grading challenges. Skipping the PPS phase – especially when working with a new supplier – can result in expensive inconsistencies during mass production.

Pattern Grading and Fabric Optimization

Pattern grading involves scaling an approved base pattern to create a full size range, from XS to XXL, while preserving the garment’s fit and functionality. Using CAD software, tech pack specifications are translated into digital patterns, which are then nested to maximize fabric efficiency and maintain consistent grainline control – a critical factor for ensuring proper stretch and recovery, particularly in activewear.

Professional factories aim for a marker efficiency of 85% to 95%, meaning only 5% to 15% of fabric is wasted. Considering that fabric accounts for 60% to 70% of production costs in activewear, this level of precision is essential. Computer-guided cutting machines ensure millimeter-level accuracy, which is especially important for high-stretch materials that require exact alignment.

Before bulk production begins, manufacturers create a size set – prototypes for every size in the range – to confirm the success of the grading process. This step helps identify sizing issues early, reducing the risk of returns caused by inconsistent fits. Maintaining fabric consistency across all sizes ensures uniform performance throughout the entire range. Once finalized, these digitally optimized patterns undergo rigorous functional testing.

Functional Testing of Prototypes

Prototypes are subjected to lab tests to confirm their performance in real-world conditions. Key tests include:

- Seam strength (ASTM D1683)

- Dimensional stability to measure shrinkage (AATCC 135/150, aiming for less than 3% shrinkage)

- Pilling resistance (ISO 12945, graded on a 1 to 5 scale)

Testing also evaluates specialized construction techniques. For example, the 4-needle 6-thread flatlock stitch is considered the gold standard for activewear due to its ability to create strong, flat, and chafe-free seams – essential for compression gear and yoga wear. Bartack reinforcements at high-stress points, like waistbands and pocket openings, are tested to ensure they can withstand repeated strain.

Field testing complements lab tests by having fit models perform activities like running, squatting, and stretching to identify issues that static tests might overlook.

"The prototype stage is where a designer’s creativity meets reality. It’s the critical bridge between imagination and production that determines whether a design will succeed in the marketplace." – Thomas Chen, Production Director at Fashionline Studios

These thorough validations ensure a smooth transition to bulk manufacturing while upholding the high-performance standards set earlier in the process.

At New Dong Huang Garment Co., Ltd. (https://leggingsupplier.com), the sampling process includes custom design services, pattern making, and functional testing to meet the performance requirements outlined in the tech pack. With over 27 years of experience, the company uses advanced CAD tools and precision manufacturing equipment to optimize fabric usage while ensuring the fit and durability demanded by high-performance activewear.

sbb-itb-8dbc09a

Stage 4: Bulk Production – Cutting, Sewing, and Assembly

After the optimized patterns and prototypes from Stage 3 are finalized, the process shifts to bulk manufacturing. This stage transforms approved samples into mass-produced garments, using automated cutting, specialized sewing methods, and systematic assembly. Throughout, strict adherence to prototype specifications ensures consistency.

Precision Cutting Technologies

Modern factories depend on Computer-Numerical-Control (CNC) cutters, which use digital markers to achieve millimeter-level precision. This technology guarantees that every piece in a production run is identical. Before cutting begins, fabric is carefully prepped. Automated systems stack the fabric, known as plies, in uniform layers to keep it flat and tension-free. For materials like spandex, which are common in activewear, the fabric is left unrolled for at least 24 hours to prevent shrinkage or sizing issues post-cutting.

Digital marker planning plays a key role in maximizing fabric use, achieving efficiency rates of 85–95%. Factories use specialized cutting tools tailored to different design needs:

- Straight knives handle sharp angles and corners.

- Rotary knives make long, straight cuts with continuous motion.

- Hot notchers seal fabric edges to prevent fraying.

- Drills mark internal points like pocket placements across all fabric layers.

"Modern factories in the USA use computer-numerical-control (CNC) cutters, which follow the digital marker with extreme precision, ensuring every component is identical." – MFG Merch

After cutting, pieces are sorted and bundled by size, color, and dye lot, ensuring uniformity as the process moves to sewing.

Specialized Sewing Techniques for Activewear

In assembly lines, a progressive bundle system is often used. Here, each worker focuses on a specific task – like attaching waistbands or sewing sleeves – streamlining production and maintaining consistency. For example, the Standard Minute Value (SMV) for a basic t-shirt is 8–10 minutes. This metric helps managers estimate labor costs, balance workflows, and predict daily output.

Activewear demands unique stitching techniques to meet performance and durability standards:

- Flatlock stitching (ISO 607): This method creates flat, chafe-free seams, essential for compression wear and yoga gear. Flatlock seams maintain elasticity even after 50 wash cycles and provide over 30% more stretch compared to industry norms.

- Overlock stitching: Also known as serging, this technique trims, sews, and finishes edges in one step, offering high elasticity for areas like underarms and side seams.

- Coverstitching: Featuring parallel top stitches with a looper thread underneath, this method allows hems to stretch without breaking, making it ideal for leggings and performance tees.

- Bartack stitching: A dense zigzag pattern reinforces stress points like pocket edges and zipper ends.

Thread selection is equally critical. High-tenacity or microfilament polyester threads ensure seams are both durable and soft. Additionally, ballpoint or stretch needles (sizes 75/11 or 80/12) are used to glide between knit fibers, reducing the risk of runs or skipped stitches.

To maintain quality, in-line inspections are conducted throughout the sewing process. Supervisors, or "rovers", check for issues like skipped stitches or seam puckering in real time, preventing small errors from escalating. Before full-scale assembly begins, a first-line sewing check ensures that stress points meet construction standards.

At New Dong Huang Garment Co., Ltd. (https://leggingsupplier.com), bulk production combines advanced tools like automated cutters and specialized sewing machines with over 27 years of expertise in activewear manufacturing. The company achieves a 99% on-time delivery rate by using techniques such as flatlock stitching, in-line quality checks, and efficient workflow management. This meticulous approach ensures garments meet the durability and performance needs of activewear, paving the way for the final quality checks and packaging phase.

Stage 5: Finishing, Quality Control, and Packaging

Once production wraps up, garments go through a finishing process to get them ready for retail. This starts with trimming loose threads and removing any stains or debris that might have appeared during assembly. Each piece is then pressed or steamed to refine its shape and give it a polished look. At this stage, branding elements like hangtags, care labels (with ISO 3758 symbols), buttons, and drawcords are also added. These steps lead into the critical quality control phase.

Some factories take a TOP (Top of Production) sample from the first batch of completed garments. This sample is compared to the golden sample to ensure consistency in materials, fit, and overall craftsmanship. For high-quality activewear, fabrics are generally expected to have a shrinkage rate of less than 3% after washing.

Final Quality Inspections

Randomly selected garments go through a final quality audit based on Acceptable Quality Limits (AQL). Most manufacturers use an AQL of 2.5 for major defects, such as broken seams or incorrect sizing, and 4.0 for minor issues like loose threads or slight color inconsistencies. Inspectors also test for seam strength (ASTM D1683), pilling resistance (ISO 12945), and colorfastness (AATCC 61/8). Wash tests are performed on these samples to detect any shrinkage or measurement changes, allowing adjustments before mass distribution. For activewear with graphics, additional tests ensure that heat transfers and screen prints adhere well and can endure athletic movements. Since fabric accounts for 60–70% of a garment’s total cost, these inspections are essential to safeguard the production investment.

"A single bad batch of finished garments, plagued by poor stitching or fabric that fails under stress, can compromise your brand’s standards and erode customer trust." – Kane Chu, Senior Production Engineer, Maes Group

Packaging for Delivery

Once garments pass quality control, they are folded according to the specifications in the tech pack and placed in polyethylene bags to protect them from dirt and moisture. Inspectors check that the size ratios in each carton match the buyer’s forecast and confirm the accuracy of barcodes and labels to prevent shipping errors. For activewear, TPU (Thermoplastic Polyurethane) care labels are often used because they resist chlorine, saltwater, and UV exposure, ensuring durability even after repeated use. Finally, corrugated boxes are sealed with water-activated tape to create a strong, tamper-evident closure. The same precision applied throughout production is carried into the packaging process, with final inspections ensuring everything meets high standards. This stage typically takes 3 to 7 days for domestic production and 1 to 2 weeks for international orders.

At New Dong Huang Garment Co., Ltd., the finishing process integrates thorough quality checks with efficient packaging. With over 27 years of expertise, the company adheres to AQL standards, conducts in-depth performance testing, and uses TOP sample verification to ensure every garment meets durability and performance expectations before it’s shipped to global clients.

Improving Production Workflows with Advanced Technologies

Automation and AI tools are transforming the way activewear is produced, speeding up processes while ensuring precision and consistency. These technologies are woven into every stage of production, from design to cutting to final inspection.

3D virtual design platforms like CLO 3D and Optitex are game-changers. They allow brands to create digital simulations of fit and drape, eliminating the need for physical prototypes. This shift reduces development timelines from weeks to just days, letting designers finalize changes before production even begins.

On the cutting floor, AI-powered vision systems are making a noticeable difference. These systems deliver cutting accuracy within ±1.0 mm, compared to the ±2.5 mm accuracy of manual methods. Automated cutters can handle 400–800 pieces per hour – up to seven times faster than manual cutting – and reduce fabric waste by 3–5% thanks to optimized layouts.

Handling limp fabrics has always been a challenge, but robotic fabric handling is catching up. Using advanced grippers and vacuum conveyors, these robots can manage delicate textiles with precision. For example, researchers have developed robotic sewing systems that adjust seam allowances in real-time using camera feedback, even if fabric shifts or stretches. Softwear Automation‘s SEWBOT system takes this further, producing a finished T-shirt in just four minutes. With minimal human involvement, this setup can churn out 800,000 shirts annually.

Computer vision systems are also redefining quality control. These systems continuously monitor for defects like micro-tears, color inconsistencies, and fiber disruptions – issues that might escape human inspectors. Tools like HKPU’s WiseEye and EasyODM‘s automated inspection systems can identify up to 40 common defects, cutting defective fabric output by 90% and achieving an impressive 99% accuracy rate.

A great example of these advancements in action is New Dong Huang Garment Co., Ltd.. With 27 years of experience in activewear production, the company incorporates cutting-edge equipment like bonding machines and laser cutters. By combining automated cutting, inline quality checks, and precise assembly methods, they consistently deliver high-performance garments that meet the rigorous demands of global brands.

Conclusion

Producing activewear isn’t just about stitching fabric together – it’s a meticulous process where each phase builds upon the last. Starting with the tech pack, often referred to as the product’s blueprint, every detail matters. The AQL 2.5 inspection at the end ensures that your brand’s reputation stays intact. That 10-to-14-week production timeline? It’s not random – it’s the result of thorough checks and balances at every step.

"A detailed tech pack is the single source of truth; it prevents costly errors and misinterpretations."

- Kane Chu, Senior Production Engineer, Maes Group

The numbers paint a clear picture: fabric alone makes up 60–70% of the total cost of a garment. Efficient cutting, with 85–95% marker efficiency, can make a noticeable difference to your bottom line. And keeping shrinkage below 3%? That guarantees garments perform as they should, even after repeated washing.

Processes like fabric relaxation (letting knit rolls rest for 24+ hours), 4-needle 6-thread Flatlock stitching, and in-line quality control aren’t optional – they’re essential for creating activewear that can handle the demands of athletic movement. Locking in design decisions after approving the Pre-Production Sample and sticking to rigorous testing protocols helps safeguard your timeline and your brand’s integrity.

Take New Dong Huang Garment Co., Ltd., for example. With 27 years of expertise, they combine advanced tools like bonding machines and laser cutters with time-tested processes to deliver the precision global brands rely on. When every stage of production is fine-tuned, you’re not just making apparel – you’re creating performance gear that athletes can trust.

FAQs

What is a tech pack, and why is it important in activewear production?

A tech pack is like a blueprint for creating a garment. It’s a detailed document that breaks down every aspect of a design, including measurements, materials, colors, trims, and construction details. Essentially, it’s the bridge between the designer’s vision and the manufacturer’s execution.

When it comes to activewear, precision is everything. A well-crafted tech pack ensures manufacturers fully understand the design, reducing errors and avoiding costly production delays. It keeps the process organized and efficient, helping to deliver a product that matches expectations. Think of it as a step-by-step guide that’s crucial for producing high-performing activewear.

How are AI and 3D design technologies changing the way activewear is manufactured?

AI and 3D design technologies are reshaping the way activewear is manufactured, making production faster, more efficient, and less wasteful. AI tools handle tasks like creating patterns, virtual prototyping, and forecasting trends, cutting down the need for physical samples and speeding up the entire process. Meanwhile, 3D design software lets designers digitally create and test garments, ensuring they get the fit and style right while reducing material waste.

These advancements also help manufacturers react quickly to market demands, avoid producing excess inventory, and lessen their environmental footprint. On top of that, they make remote collaboration easier, allowing teams across the globe to work together without needing physical prototypes. By integrating AI and 3D design into their processes, activewear brands can deliver higher-quality products, offer better customization, and stay in tune with what consumers want.

What should I consider when choosing fabrics for high-performance activewear?

When choosing fabrics for high-performance activewear, focus on four key features: moisture-wicking, breathability, durability, and comfort. The best fabrics will keep you dry by pulling sweat away from your skin, ensuring you stay comfortable even during intense workouts. Materials that allow airflow and help regulate body temperature are a must, especially for high-energy activities.

Durability is just as critical since activewear faces frequent washing and heavy use. Look for fabrics that maintain their shape and performance over time. Depending on your activity, you might also need specific features like stretchability for better flexibility or antibacterial properties to help control odors. Plus, many brands are now offering eco-conscious options, blending environmentally friendly materials with the performance you need.