- What Are MOQs?

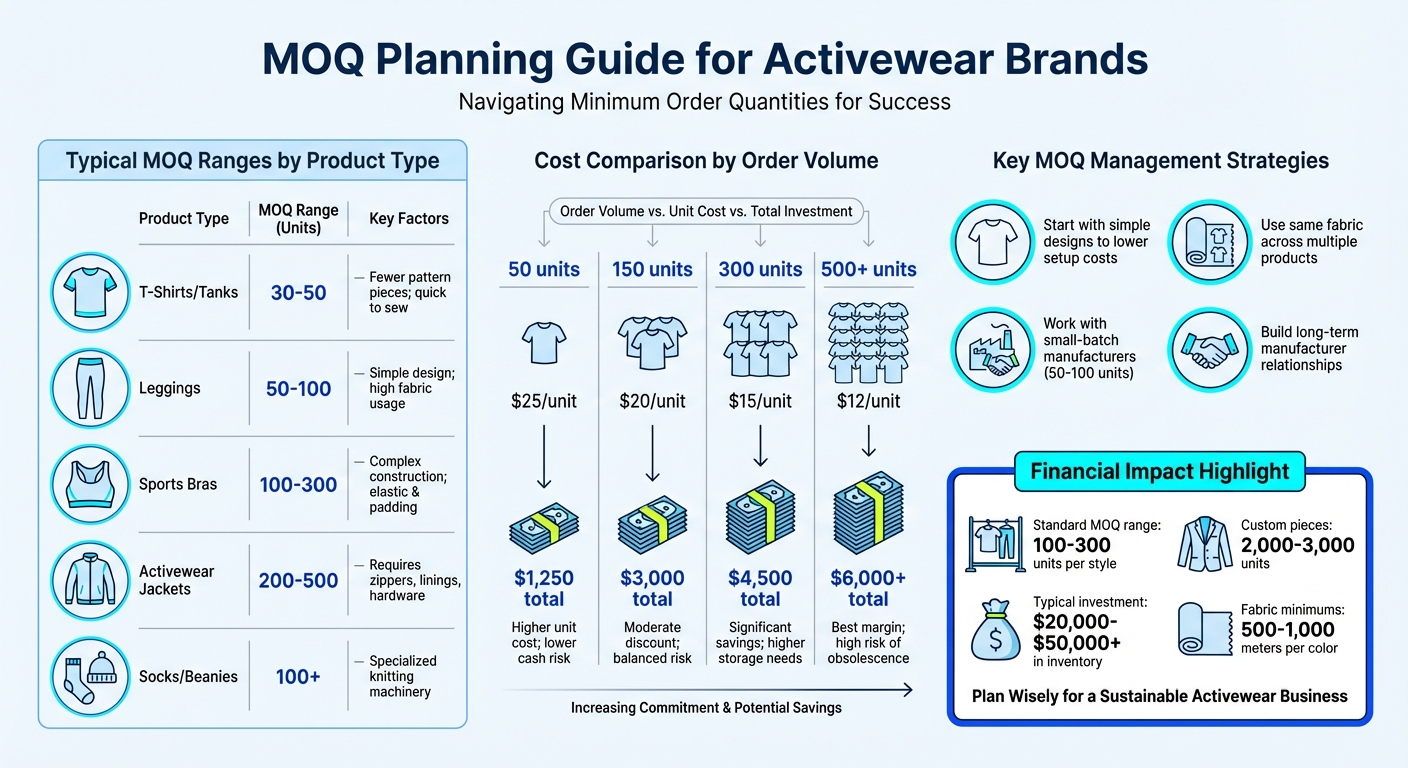

MOQs are the smallest production orders manufacturers accept. For activewear, these range from 100–300 units per style for standard designs, but custom pieces can demand 2,000–3,000 units. - Why Do MOQs Exist?

Factories set MOQs to cover costs like fabric (often requiring 500–1,000 meters per color), machine setup, and labor. Complex garments like sports bras or jackets have higher MOQs due to intricate construction. - Challenges for Small Brands:

High MOQs can tie up $20,000–$50,000+ in inventory, risking unsold stock and cash flow issues. Ordering too few units increases per-piece costs, while over-ordering can leave you with deadstock. - How to Manage MOQs:

- Start with simple designs to lower setup costs.

- Use the same fabric across multiple products to meet fabric minimums.

- Work with small-batch manufacturers offering lower MOQs (e.g., 50–100 units).

- Build relationships with manufacturers to negotiate flexibility.

- Cost Breakdown Example:

Ordering 50 units at $25/unit costs $1,250 but reduces risk. Larger orders (e.g., 300 units at $15/unit) save on per-unit costs but require $4,500 upfront.

Bottom Line: Managing MOQs is about balancing costs, inventory risks, and scaling smartly. Start small, test demand, and partner with manufacturers who can support your growth.

Activewear MOQ Ranges and Cost Comparison by Order Volume

how to find a manufacturer for your clothing brand

Why Activewear Manufacturers Set MOQs

Manufacturers don’t decide on MOQs (Minimum Order Quantities) randomly – they’re based on real production requirements that impact every step of the garment-making process. One key factor is fabric roll minimums. Factories typically buy fabric in rolls, with standard minimums starting at 100 meters per color. For specialized activewear fabrics, like moisture-wicking blends or custom-dyed materials, suppliers often require 500 to 1,000 meters. This means that before a single garment is cut, manufacturers need enough orders to make full use of the fabric.

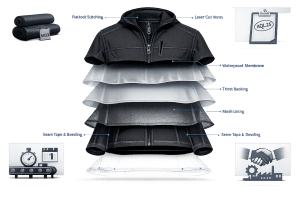

MOQs also help manufacturers balance production costs. Every new design involves stopping production to handle tasks like grading patterns, adjusting machinery, and training workers. Activewear, in particular, requires extra attention – think of the elastic placement in sports bras, flatlock seams in leggings, or the layering and hardware in jackets. By setting MOQs, factories can spread these setup costs across a larger number of units, making each production run more cost-effective.

The complexity of a garment plays a big role in determining the MOQ. A basic tank top, with fewer pattern pieces and quick sewing times, might have a lower MOQ of 30 to 50 units. On the other hand, a sports bra with support panels, elastic trims, and padding involves more labor and preparation, pushing MOQs to 100 to 300 units. These factors shape the MOQ expectations for different types of activewear.

Typical MOQ Ranges by Product Type

MOQs vary depending on the type of activewear, its construction, and how much fabric it uses. Knowing these ranges can help brands decide which products to prioritize and how to allocate their production budget.

| Product Type | Typical MOQ Range (Units) | Key Influencing Factors |

|---|---|---|

| T-Shirts/Tanks | 30–50 | Fewer pattern pieces; quick to sew |

| Leggings | 50–100 | Simple design; high fabric usage per roll |

| Sports Bras | 100–300 | Complex construction; elastic and padding |

| Activewear Jackets | 200–500 | Requires zippers, linings, and hardware |

| Socks/Beanies | 100+ | Needs specialized knitting machinery |

Most manufacturers allow MOQs to be split across sizes. For example, a 50-unit order could include 10 small, 20 medium, 12 large, and 8 extra-large pieces. However, MOQs are generally applied per color, as each colorway requires its own fabric roll. So, ordering one legging design in three colors would mean meeting a 150-unit minimum (50 units per color). These details highlight how volume and variety impact production costs and risks.

How MOQs Affect Production Costs and Risk

Larger orders significantly lower per-unit costs because fixed expenses are spread across more items. For instance, a sports bra that costs $25 per unit at 100 pieces might drop to $18 per unit at 500 pieces – a savings of 28%. But this comes with a trade-off: inventory risk. For smaller brands with limited storage and working capital, ordering 500 units of one style ties up $9,000 upfront, plus an additional 15% to 30% for shipping and import fees.

The biggest risk is "deadstock" – unsold inventory that takes up space and drains cash flow. Smaller brands constantly juggle this dilemma: order too few units and face higher costs per piece, or order too many and risk being stuck with unsold products.

Customization adds another layer of complexity. Choosing custom-dyed colors or exclusive prints can raise MOQs significantly because fabric mills require dedicated dye batches. A brand using stock materials might secure a lower MOQ, but a custom color could push the minimum to 1,000 units or more. This is why many newer brands stick to stock fabrics initially – it avoids the high minimums of custom textiles and allows them to test their market with smaller production runs.

How to Manage and Negotiate MOQs

Activewear brands can navigate and negotiate Minimum Order Quantities (MOQs) by understanding the factors that influence these requirements. For growing brands, balancing budget constraints with quality production is essential. The trick lies in identifying what drives these minimums and exploring ways to improve efficiency for both the brand and the manufacturer. This opens the door to making design and production adjustments that help reduce costs.

Start with Simple Product Designs

Simpler designs are a great way to keep MOQs low. Why? They require less setup time and effort, which means manufacturers can produce smaller batches without losing profitability. For instance, designs that avoid intricate details or specialized components allow manufacturers to streamline production. By focusing on core products that use readily available fabrics and minimal hardware, brands can keep their initial orders more manageable. Once you’ve established demand for your product, it becomes easier to justify adding more complex features.

Another smart move is using the same fabric across multiple products. Let’s say you’re producing leggings, sports bras, and tank tops – all made from the same moisture-wicking fabric. By using a single type of material, you not only meet supplier minimums but also reduce fabric waste. This strategy helps you stretch your resources further.

Build Long-Term Relationships with Manufacturers

Your relationship with the manufacturer can significantly impact MOQ flexibility. Manufacturers are more likely to lower their minimums when they see you as a long-term partner rather than a one-time client. Sharing a clear growth plan – complete with projected sales, reorder timelines, and plans for expanding your product line – shows them that your business has staying power. A brand ordering 100 units today might grow to 1,000 units in the future, and manufacturers value that potential.

Consistency and trust go a long way. Paying invoices on time, providing accurate product specifications, and keeping your manufacturer in the loop about your sales performance can lead to perks like better payment terms, priority production slots, and more flexible MOQs. Some brands even negotiate "growth-based" deals, where they start with smaller MOQs but commit to increasing volume as sales targets are met. Offering partial or full upfront payments can also ease the manufacturer’s financial risk, making them more open to smaller initial orders.

Partner with Small-Batch Production Specialists

If you’re just starting out, working with small-batch production specialists can be a game-changer. While large factories often require orders of 1,000 units or more, small-batch specialists are designed to cater to smaller brands. They typically accept orders as low as 50–100 pieces per style and can deliver samples quickly – often within 5–7 days.

Of course, smaller batches come with a higher cost per unit. For instance, the price of a sports bra might jump from $18 at 500 pieces to $25 at 100 pieces. But for a brand with limited funds, the total upfront cost is much more manageable – $2,500 for 100 pieces compared to $9,000 for 500 pieces. This lower financial commitment reduces risk and helps you avoid being stuck with excess inventory. As your brand grows and sales patterns become clearer, you can scale up to larger orders to take advantage of lower per-unit costs.

sbb-itb-8dbc09a

Planning Inventory and Collections Around MOQs

Once you’ve finalized MOQs and selected your manufacturing partners, the next step is to align your inventory strategy. The goal? Meet those minimums without running into cash flow problems or ending up with unsold stock.

Use Demand Forecasting and Size Distribution

Accurate demand forecasting is your best friend when it comes to determining the right unit quantities and size distribution. By analyzing historical sales data, you can pinpoint which sizes are most popular with your customers. When you combine this insight with MOQ planning, every production run is better tailored to market demand.

Forecasting also helps identify your Economic Order Quantity (EOQ), which minimizes inventory costs. For example, if your EOQ is 200 units but your supplier’s MOQ is 300, you’ll need to either negotiate terms or adjust your product mix to make the larger order worthwhile. Don’t forget to factor in lead times: raw material sourcing might take 2–4 weeks, and quality control could add another week. Building in a time buffer can help you avoid stockouts.

"MOQs provide a structured approach to planning and forecasting… essentially locking in a baseline for your production run." – JOOR

Test Market Demand with Small Production Runs

Before diving into a large MOQ, consider testing the waters with a smaller production batch. Producing 50–100 units of a new style allows you to gauge market demand without tying up too much capital. Sure, the per-unit cost may be higher – $25 instead of $15, for example – but the overall investment is far less risky. Once you validate demand and refine your product, scaling production becomes a safer bet.

Take a page from Everlane’s playbook. In 2024, the brand used automated replenishment and real-time sales data to manage reorder points for its staple denim collection. The result? A 30% reduction in stockouts within six months, along with less excess inventory. These kinds of strategies help you weigh the financial trade-offs of different production volumes.

Compare Unit Costs at Different Order Volumes

Understanding how costs shift at various MOQ levels is critical for making smart decisions. Larger orders often come with better pricing, but they also bring the risk of unsold inventory. Here’s a quick breakdown:

| Order Volume | Estimated Unit Cost | Total Investment | Financial Trade-off |

|---|---|---|---|

| 50 units (Low MOQ) | $25.00 | $1,250 | Higher unit cost; lower cash risk |

| 150 units | $20.00 | $3,000 | Moderate discount; balanced risk |

| 300 units (Standard) | $15.00 | $4,500 | Significant savings; higher storage needs |

| 500+ units (Bulk) | $12.00 | $6,000+ | Best margin; high risk of obsolescence |

For new brands with limited resources, starting with 50–150 units is often the wisest choice. As you establish reliable sales data and improve cash flow, you can gradually scale up to orders of 300 or 500 units, capturing better margins along the way. Keep in mind, though, that inventory distortion – the cost of being either understocked or overstocked – hit $1.7 trillion globally in 2025. Up next, we’ll look at how flexible manufacturing partnerships can help you grow strategically.

Working with Flexible Manufacturers for Growth

Finding the right manufacturing partner can make or break your ability to scale. Large factories often require minimum orders of 1,000 units or more to maintain efficiency, which can be a tough hurdle for growing activewear brands. That’s where specialized manufacturers come in – they provide the flexibility needed for smaller, sustainable growth. A standout example in this space is New Dong Huang, a company that understands the evolving needs of emerging brands.

New Dong Huang Garment Co., Ltd. Capabilities

With 27 years of experience, New Dong Huang Garment Co., Ltd. has built a reputation for producing high-quality activewear. They specialize in yoga wear, running gear, and outdoor performance clothing, leveraging advanced equipment to deliver retail-grade products, even for smaller production runs.

This expertise is critical because activewear isn’t just about aesthetics – it’s about functionality. Features like flatlock seams, gussets, and four-way stretch fabrics require specialized machinery that many general apparel factories simply don’t have. On top of that, New Dong Huang offers eco-conscious fabric options certified by organizations like OEKO-TEX and GRS. Their materials meet modern performance standards while supporting sustainability goals. The company also boasts a 99% on-time delivery rate and holds compliance certifications from major brands like Nike and New Balance.

What sets New Dong Huang apart is their ability to adapt to the unique needs of growing brands, offering tailored solutions that evolve alongside their clients.

Custom Production Options for Growing Brands

For smaller brands, New Dong Huang’s flexibility is a game-changer. They offer a minimum order quantity (MOQ) of just 100 pieces per style, with mixed sizing (S–XL) included. This allows brands to test the waters without overcommitting to large orders. For those venturing into organic cotton designs, they even offer no-MOQ production, making it easier for startups to experiment with small-batch collections.

Customization is another key strength. Their services include custom fabric sourcing, multiple printing options, and full private-label branding. Need samples? They’re ready in 5–7 days. Small-batch production wraps up in 15–25 days, giving brands a quick turnaround. Plus, submitting your designs is straightforward – they accept sketches, tech packs, photos, or even physical samples, so you don’t need a technical background to get started.

"Finding low MOQ clothing manufacturers that still offer quality and customization is rare. Ninghow delivered everything we needed." – Fay, Boutique Brand Owner (Australia)

To streamline production, brands can use New Dong Huang’s stock fabric library, which helps reduce lead times. Consolidating styles with the same fabric and trims can also improve efficiency. Sample fees are typically around $100 per style and are often refunded once you place a bulk MOQ order.

Conclusion

Effectively managing MOQs requires a focused strategy: opt for simple designs to keep setup costs low, consolidate materials across styles to meet fabric minimums, and build long-term relationships with manufacturers who align with your growth goals. Testing new styles through small production runs is a smart way to reduce risk and manage costs effectively. This approach directly tackles the financial hurdles that many emerging brands face.

High MOQs can strain cash flow, which is critical for the growth of new brands. With activewear MOQs often ranging from 500 to 3,000 units per style, smaller brands frequently find themselves in a tough spot. This is why partnering with manufacturers who offer flexibility is so important – they allow you to scale production at a pace that aligns with your financial capacity, avoiding the pitfalls of overproduction.

Take New Dong Huang Garment Co., Ltd., for example. With 27 years of industry experience and MOQs starting as low as 100 pieces per style, they provide growing brands the flexibility to test, refine, and scale their offerings. Their custom production services also allow brands to adapt quickly to shifts in market demand.

The right manufacturing partner grows with your brand. A manufacturer who understands your technical needs and financial challenges can play a key role in your success. Use tools like data-driven forecasting, set reorder points that account for lead times (typically 12–20 weeks), and aim for inventory turnover rates of 4–6 times per year for your core styles. These steps help ensure a sustainable path to growth.

FAQs

How can small activewear brands work with manufacturers to lower MOQs?

Small activewear brands can work toward negotiating lower minimum order quantities (MOQs) by keeping production requirements straightforward and showing potential for future growth. MOQs are often set to cover costs like materials, labor, and setup, so simplifying production can make smaller orders more practical. For instance, opting for fabrics already in stock, minimizing design extras like zippers or drawstrings, or selecting multi-purpose materials can help reduce manufacturing complexity.

Another approach is to offer a slightly higher price per unit or contribute to setup costs, helping factories offset their expenses. Additionally, presenting a solid growth strategy – like plans for larger future orders or running pre-order campaigns – can build trust and encourage manufacturers to take on smaller initial orders.

Take New Dong Huang Garment Co., Ltd., for example. They support new brands by offering flexible production options, including pilot batches starting as low as 100 pieces. By using stocked performance fabrics and aligning MOQs with startup budgets, they help create high-quality activewear that meets U.S. market standards.

How can activewear brands minimize financial risks when dealing with high MOQs?

Minimizing financial risks when dealing with high minimum order quantities (MOQs) requires careful planning and smart decisions. Working with manufacturers like New Dong Huang Garment Co., Ltd., known for their flexible MOQs and advanced production capabilities, can make it easier to match your orders with actual demand rather than relying on uncertain forecasts. Opting for versatile fabrics with lower minimum requirements and simplifying designs – like reducing the number of colors or trims – can also cut down upfront costs and make smaller production runs more manageable.

Another smart tactic is launching pre-sale or limited-edition campaigns. These allow you to gauge market interest and generate revenue before committing to larger production runs, ensuring your working capital is available for other priorities like marketing or product development. You might also consider bundling multiple styles into a single order or exploring on-demand production for less critical items. By starting with smaller quantities and scaling up based on proven demand, brands can protect cash flow and use MOQs strategically to support growth.

How can using the same fabric across multiple products help with MOQs?

Using the same fabric across multiple products lets manufacturers consolidate material orders, cutting down on production setup costs and minimizing fabric waste. This strategy can also reduce the minimum order quantity (MOQ) for each product, which simplifies inventory management and keeps costs in check as you expand your collection. By optimizing fabric usage, brands can create a more efficient and adaptable production process.