Quick-dry fabrics are designed to wick moisture and dry faster than traditional materials, making them a staple in activewear. Testing these fabrics ensures they meet performance standards for drying speed, moisture absorption, and wicking efficiency. The three main testing methods – AATCC 201, AATCC 200, and GB/T 21655 – offer different approaches to evaluate quick-dry properties:

- AATCC 201 (Heated Plate): Simulates skin temperature (37°C) with horizontal airflow to measure evaporation rate in mL/h. Ideal for sportswear and base layers.

- AATCC 200 (Air Flow): Uses vertical airflow to measure drying time for saturated fabrics. Best for lightweight, breathable materials like towels.

- GB/T 21655 (Chinese Standard): Includes static and dynamic tests for absorption, wicking height, and evaporation. Focuses on moisture management across multiple metrics.

Key performance benchmarks for quick-dry fabrics include:

- Drying 50% faster than cotton

- Absorbing ≥200% of their weight in water

- Wicking height ≥100 mm

- Evaporation rate ≥0.18 g/h

- Moisture permeability ≥10,000 g/m²/day

Fabric preparation, such as conditioning samples at 21°C and 65% humidity, ensures consistent test results. These methods help manufacturers select and refine materials for high-performance activewear that keeps wearers dry and comfortable.

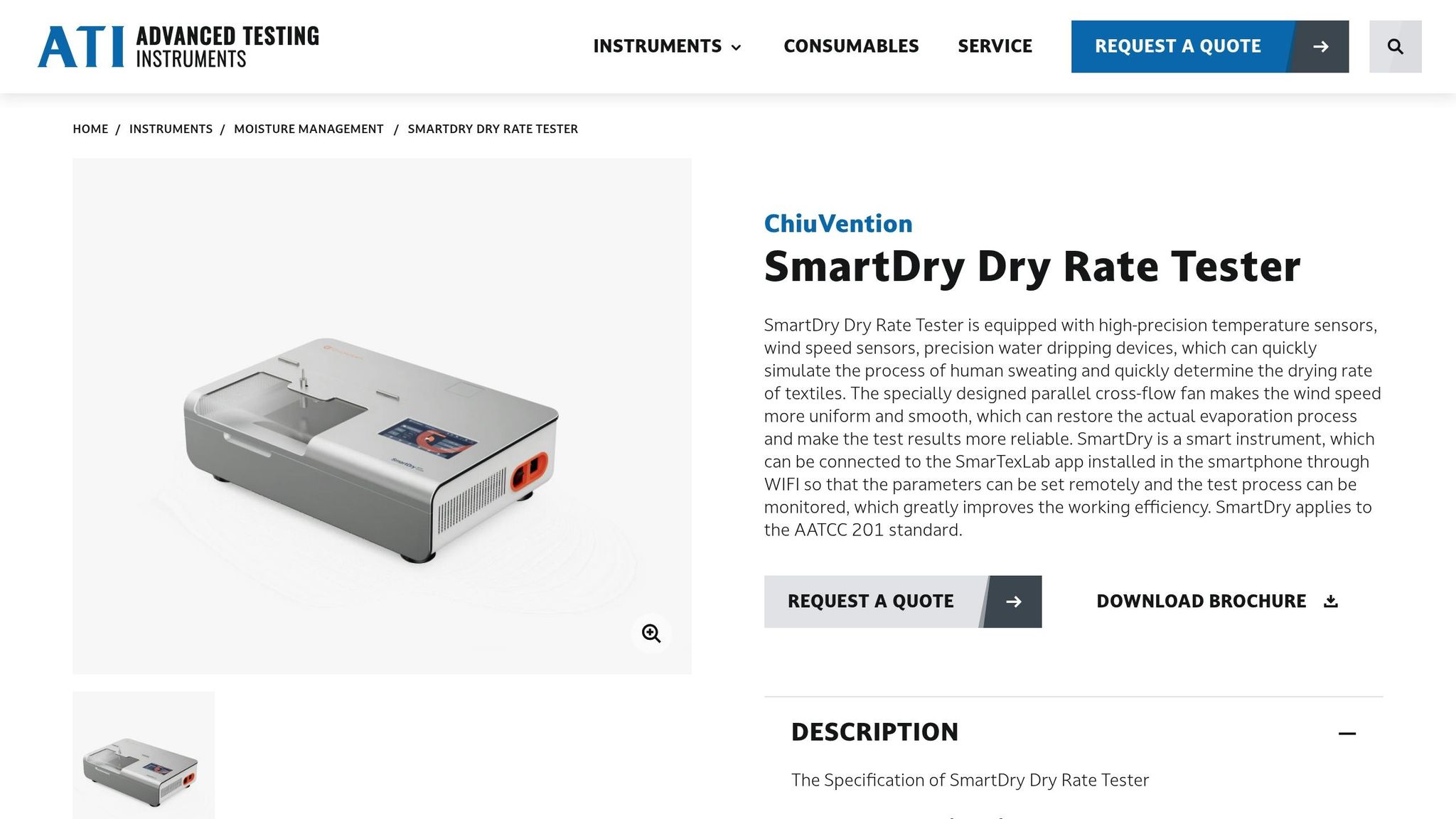

SmartDry Drying Rate Tester-Quick Test for Drying Rate

Industry Standards for Quick-Dry Fabric Testing

When it comes to testing the performance of quick-dry fabrics, several globally recognized standards help ensure these materials meet high expectations, especially for activewear. The most commonly used standards are AATCC 201, AATCC 200, and GB/T 21655. Together, they simulate real-life conditions to evaluate how well a fabric performs. While AATCC 201 and AATCC 200 are American standards, GB/T 21655 represents China’s national standard. These methods collectively provide a thorough way to determine if a fabric lives up to its quick-dry claims. The choice of testing method often depends on the type of garment, its intended use, and the specific performance needs. Below, we explore each method in detail.

AATCC 201 Hot Plate Method

The AATCC 201, also called the Heated Plate Method, measures how fast a fabric dries by observing the evaporation rate of a specific amount of water applied to it. The test uses a heated metal plate set at 37 ± 1°C (99 ± 2°F), mimicking the temperature of human skin during perspiration. A precise amount of water – 0.200 ± 0.003 mL – is applied to the fabric, and an infrared thermocouple probe, positioned 1.0 ± 0.1 cm above the fabric, tracks its surface temperature. As the water evaporates, the fabric cools down, and the test ends when the surface temperature returns to its baseline. The drying rate is then calculated in milliliters per hour (mL/h). For accuracy, horizontal airflow at 1.5 ± 0.5 m/s is maintained across the fabric surface. This method is particularly effective for testing base layers, sports shirts, and socks – provided the skin-facing side of the fabric is placed against the heated plate.

AATCC 200 Air Flow Method

The AATCC 200 method evaluates drying performance using airflow rather than direct heat. This test involves saturating the fabric to its full capacity and then measuring how quickly it dries under controlled vertical airflow. This approach is ideal for lightweight, breathable fabrics where air movement, rather than body heat, drives evaporation. However, it’s not suitable for testing socks or hosiery, as the method is tailored for materials designed to perform in outdoor or windy conditions.

GB/T 21655 Testing Methods

The Chinese national standard GB/T 21655 takes a broader approach to fabric testing, classifying materials as "moisture-wicking and quick-drying." Unlike the AATCC methods, which primarily focus on drying rates, GB/T 21655 evaluates multiple performance factors. The standard is divided into two parts:

- GB/T 21655.1 (Static Method): Measures liquid moisture absorption, drip diffusion time, and core absorption height.

- GB/T 21655.2 (Dynamic Method): Tracks moisture transfer speed and direction.

For knitted fabrics to meet this standard, they must achieve specific benchmarks, such as water absorption of ≥200%, drip diffusion time of ≤3 seconds, wicking height of ≥100 mm, evaporation rate of ≥0.18 g/h, and moisture permeability of ≥10,000 g/(m²·d). These criteria must remain consistent even after 5–20 wash cycles.

Fabric Preparation Before Testing

Getting fabric ready for quick-dry testing is all about consistency. By standardizing the preparation process, you can ensure that every sample starts on equal footing. This means paying close attention to environmental conditions, moisture balance, and temperature stabilization. These steps are crucial for producing reliable and comparable results.

Environmental Conditions

Fabric samples need to be conditioned in a controlled atmosphere set to 21°C ± 2°C (70°F ± 4°F) with a relative humidity of 65% ± 5%. These conditions follow ASTM D1776, the standard for conditioning and testing textiles. Testing must also happen in this controlled environment to maintain consistency. Even minor fluctuations in temperature or humidity can throw off drying rate measurements. To achieve this consistency, labs often rely on climate-controlled rooms or chambers.

Sample Conditioning

After stabilizing the testing environment, the next step is conditioning the fabric samples to balance their moisture levels. Each sample should be conditioned for at least 4 hours to reach moisture equilibrium. To ensure even air circulation, suspend the samples individually on a perforated rack. This prevents variations in initial moisture content, which could skew drying rate results since textiles naturally adjust to their surroundings.

Once conditioned, place the sample on the drying tester’s heated plate for 5 minutes to match the instrument’s surface temperature of 37°C (99°F). This thermal soak ensures the sample is ready for accurate readings from the infrared thermocouple and produces a consistent evaporation curve. These careful steps in preparation are the foundation for accurate quick-dry testing results.

sbb-itb-8dbc09a

Comparing Testing Methods

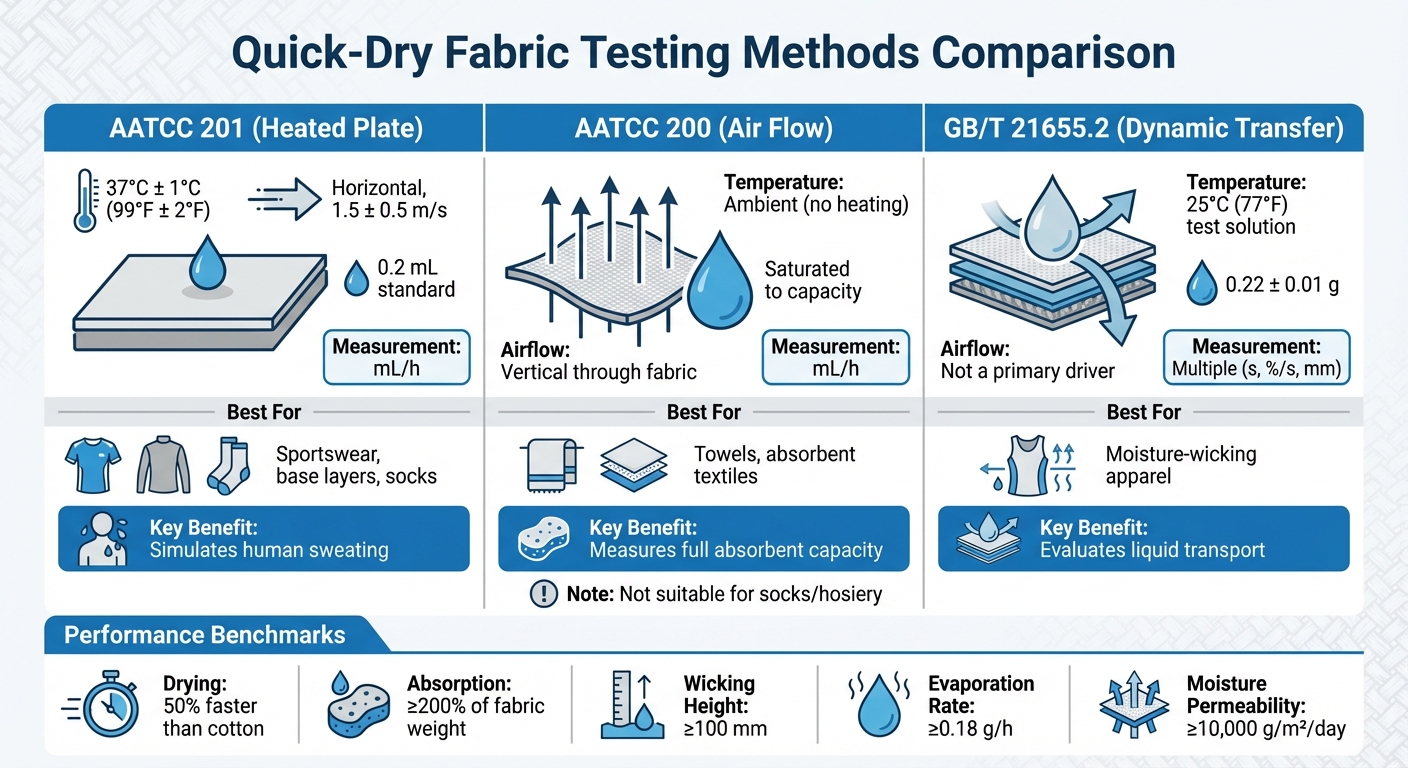

Quick-Dry Fabric Testing Methods Comparison: AATCC 201 vs AATCC 200 vs GB/T 21655

This section dives into how the testing methods differ, offering clarity on their specific uses. AATCC 201 mimics perspiration during exercise by using a heated plate set at 37°C (99°F) and horizontal airflow of 1.5 ± 0.5 m/s. AATCC 200, on the other hand, fully saturates the fabric and measures drying under vertical airflow without any added heat. Meanwhile, GB/T 21655.2 relies on electrical resistance sensors to monitor how moisture moves from the fabric’s inner surface to its outer layer.

The choice of method hinges on the type of fabric and its intended use. For instance, AATCC 201 is ideal for sportswear and base layers that are worn close to the skin. AATCC 200 is better suited for absorbent fabrics like towels and linens but isn’t recommended for items like socks or hosiery. GB/T 21655.2 provides a more detailed picture of moisture management by analyzing wicking speed and the fabric’s ability to transport moisture in one direction.

When it comes to reporting results, AATCC 201 and AATCC 200 both measure drying rates in milliliters per hour (mL/h), while GB/T 21655.2 offers a broader range of metrics, including wetting time (in seconds), absorption speed (in %/s), and spreading distance (in millimeters). Quick-drying fabrics, for example, tend to dry about 50% faster than regular cotton under the same conditions.

Testing Method Comparison Table

| Feature | AATCC 201 (Heated Plate) | AATCC 200 (Air Flow) | GB/T 21655.2 (Dynamic Transfer) |

|---|---|---|---|

| Temperature Setting | 37°C ± 1°C (99°F ± 2°F) | Ambient (no heating) | 25°C (77°F) test solution |

| Airflow Mechanism | Horizontal, 1.5 ± 0.5 m/s | Vertical through fabric | Not a primary driver |

| Water Volume | 0.2 mL standard | Saturated to capacity | 0.22 ± 0.01 g |

| Measurement Units | mL/h | mL/h | Multiple (s, %/s, mm) |

| Best Application | Sportswear, base layers, socks | Towels, absorbent textiles | Moisture-wicking apparel |

| Key Benefit | Simulates human sweating | Measures full absorbent capacity | Evaluates liquid transport |

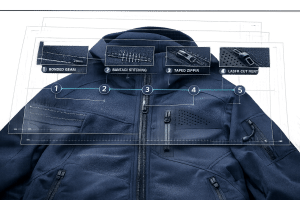

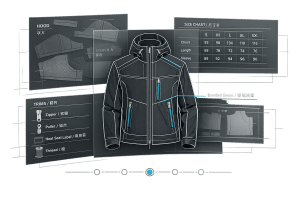

This comparison underscores the importance of matching the testing method to the fabric’s intended use, especially when developing performance apparel. For garments with multiple panels, such as athletic shirts, it’s a good idea to test samples from different sections, as drying rates can vary based on construction. Recognizing these variations is crucial for interpreting performance data accurately and setting practical standards for apparel.

Understanding Test Results and Performance Standards

When evaluating fabric performance, three key metrics come into play: drying rate, absorption, and wicking height. The drying rate measures how much liquid evaporates from the fabric in an hour (expressed in mL/h or g/h), providing insight into how quickly moisture leaves the material. Absorption, on the other hand, determines how much water weight the fabric can hold compared to its original weight. Lastly, wicking height gauges how effectively the fabric moves moisture along its fibers through capillary action. Together, these factors form the foundation for assessing fabric performance across various tests.

For activewear to perform well, it must meet specific benchmarks: water absorption should be at least 200%, evaporation rates must reach or exceed 0.18 g/h, wicking height should surpass 100 mm within 30 minutes, drip spreading needs to occur in under three seconds, and moisture permeability should exceed 10,000 g/m²/day. These standards guide the selection of fabrics and construction methods that ensure high-performance activewear.

Fabric construction plays a pivotal role in meeting these standards. Knitted fabrics, for instance, tend to absorb moisture more effectively than woven ones due to their looped structure, which increases porosity and reduces yarn twist. Fiber choice is equally important: synthetic materials like polyester and nylon excel at moisture evaporation, whereas cotton absorbs water but releases it slowly, often leaving wearers with a damp and uncomfortable sensation. For garments with multiple panels, such as athletic shirts, testing individual sections is crucial since drying rates can vary based on construction details.

The 30-minute benchmark is commonly used in testing because it mirrors the demands of athletic performance. Within this timeframe, effective fabrics demonstrate noticeable wicking through vertical capillary action, efficiently moving sweat away from the body.

Durability is another critical factor revealed through test results, especially after repeated washing. Chemical finishes that enhance moisture management often degrade with laundering, while fabrics made with permanent moisture-wicking yarns maintain their performance over time. This information helps manufacturers weigh the pros and cons of using structural fiber modifications versus chemical treatments, depending on the garment’s intended lifespan and price point.

Conclusion

Standardized testing methods give manufacturers a reliable way to verify that quick-dry fabrics live up to their claims. These tests show that such fabrics dry about 50% faster than cotton. Without these protocols, it becomes much harder to ensure consistency in moisture management performance across different production batches.

These methods are fundamental to advancing activewear design. They help manufacturers choose the best materials – whether it’s modified polyester, polypropylene, or specialized fibers like COOLMAX – and determine whether chemical treatments or moisture-wicking yarns are better suited to their performance goals. The AATCC 201 test replicates real-world sweating conditions, ensuring the results align with how the fabric performs during athletic activity. Thanks to standards like AATCC, ISO, and GB/T, factories worldwide can generate consistent data, enabling brands to compare results no matter the location. This uniformity allows designers to confidently select fabrics that meet the benchmark evaporation rate of at least 0.18 g/h, ensuring dependable moisture management.

"The advantage of TM201 is the more application-realistic heating/airflow configuration and how the water is delivered as a finite volume source at the fabric center also incorporates wicking performance into the measurement." – Chiuvention

These insights reflect the importance of the detailed methodologies discussed earlier. By following these rigorous testing standards, manufacturers can consistently produce high-performance activewear that keeps athletes dry and performing at their best.

FAQs

What’s the difference between AATCC 201 and AATCC 200 fabric drying tests?

When it comes to testing how fabrics dry, AATCC 201 and AATCC 200 offer two distinct approaches, each tailored for specific scenarios and fabric types.

AATCC 201: The Heated-Plate Method

This method involves placing a small droplet of water (0.2 mL) on a fabric sample that’s set on a plate heated to 98.6°F – essentially skin temperature. Controlled airflow is applied to help evaporate the water, and the drying rate is carefully measured. The heated-plate method is versatile, making it suitable for testing a wide range of materials, including knits, wovens, and even finished garments.

AATCC 200: The Airflow Method

In contrast, AATCC 200 uses a different approach. The fabric is fully saturated with water, and its drying time is measured as air flows across the material. This method is designed to mimic real-world moisture conditions, making it particularly effective for evaluating performance fabrics. However, it’s not suitable for certain items like socks or hosiery.

Key Differences

- AATCC 201 focuses on evaporation from a small, fixed water droplet on a heated surface.

- AATCC 200 measures drying from full saturation under airflow conditions.

Each method serves a unique purpose, allowing manufacturers to assess fabric performance based on specific drying scenarios.

Why is fabric preparation important for accurate quick-dry testing results?

Proper preparation of fabric samples is crucial to obtaining accurate and trustworthy quick-dry testing results. Any inconsistencies in the sample – like size, moisture levels, or surface conditions – can skew the results and fail to reflect the fabric’s actual drying capabilities.

To begin, the fabric should be cut to precise dimensions and conditioned in a controlled environment. Typically, this means maintaining conditions of 70°F ± 2°F and 65% ± 2% relative humidity to stabilize the fabric’s moisture content. Next, the sample is saturated with a measured amount of deionized or distilled water, such as 0.2 mL per test area, to ensure uniform wetting. It’s also important to eliminate wrinkles, finishes, or contaminants, as these can disrupt heat transfer or airflow during testing. Testing multiple samples and calculating the average results can help reduce random variations and improve reliability.

By adhering to these steps, manufacturers like New Dong Huang Garment Co., Ltd. can ensure accurate evaluations of quick-dry performance, delivering high-quality fabrics that meet consumer expectations with confidence.

Why is it necessary to test different parts of a garment for quick-dry performance?

When testing garments, examining multiple sections of the fabric is key to ensuring that variations in thickness, weave, or exposure don’t result in uneven drying. This attention to detail ensures consistent quick-dry capabilities, better comfort, and reliable temperature control throughout the entire garment.

By thoroughly analyzing each part, manufacturers can identify and fix any irregularities, delivering apparel that performs well in active or outdoor settings.