Reflective fabrics are a game-changer for safety in activewear, especially for runners and cyclists in low-light conditions. These materials use retro-reflective technology to bounce light back to its source, enhancing visibility and reducing the risk of accidents. Key types include:

- Glass Bead Fabrics: Highly visible, flexible, and durable, with reflectivity up to 700 candelas per lux. Ideal for jackets and leggings.

- Microprismatic Materials: Superior in wet conditions and low-light environments, offering wide-angle reflectivity. Common in cycling gear and safety uniforms.

- Stretch Reflective Fabrics: Elastic and soft, perfect for compression clothing and yoga wear.

- Specialized Fabrics: Includes flame-retardant, perforated, and heat-transfer options tailored for specific needs like breathability, fire resistance, or custom designs.

Each type balances visibility, comfort, and durability differently, making it essential to choose based on your activity and environment. Proper care, like washing at low temperatures and air drying, ensures longevity.

1. Glass Bead Reflective Fabrics

Glass bead reflective fabrics work by embedding countless tiny glass beads into the fabric’s surface. When light from sources like car headlights or streetlamps hits these beads, it bounces back toward the source, a process called retro-reflection.

Visibility and Reflectivity

These fabrics are known for their outstanding visibility. Silver-gray versions typically reflect light at about 500 candelas per lux, while fluorescent yellow and red options can reach up to 700 candelas per lux. Generally, glass bead fabrics used in activewear deliver reflectivity values ranging from 250 to over 420 cd/lux/m², and they maintain this effectiveness even when light hits them from wider angles. This consistent performance ensures both safety and design versatility.

Comfort and Flexibility

Designed with both performance and comfort in mind, these fabrics are bonded to elastic backings – usually made of 86% polyester and 14% spandex – to allow for four-way stretch. This makes them perfect for snug activewear like yoga pants and cycling jerseys. For high-intensity workouts, perforated versions offer better ventilation, helping to keep wearers cool and prevent overheating. Many of these fabrics are also wind-resistant and water-repellent, making them a practical choice for outdoor activities in various weather conditions.

Durability and Care

Top-quality glass bead fabrics are built to last, withstanding 15 to 50 wash cycles at temperatures up to 60°C (140°F) while maintaining their reflective properties. To extend their lifespan, wash these garments at a maximum of 40°C (105°F) using mild detergents, and avoid bleach or fabric softeners, as these can weaken the bond holding the beads. Line drying is recommended because high heat from a dryer can damage the reflective layer. Additionally, avoid washing them with abrasive materials, like jeans, to prevent the beads from wearing off. This durability makes them a reliable option for activewear that demands both performance and longevity.

Best Applications

Glass bead reflective fabrics shine in activewear where visibility and flexibility are critical. They’re ideal for items like running jackets, cycling jerseys, compression leggings, and other outdoor training gear. For a stylish twist, some designs now feature "rainbow" reflective effects – fabrics that appear black during the day but create a dazzling multi-color glow under nighttime illumination. Many of these materials meet international safety standards such as EN ISO 20471 and ANSI/ISEA 107, ensuring dependable protection for athletes in low-light conditions.

2. Microprismatic Reflective Materials

Microprismatic materials take reflective technology to the next level by replacing traditional glass beads with synthetic micro-prisms. These prisms collect, focus, and reflect light directly back to its source, creating a highly effective retro-reflective effect. This technology is especially useful in tough conditions where visibility is critical, such as during heavy rain or in low-light environments.

Visibility and Reflectivity

One of the standout qualities of microprismatic materials is their exceptional performance in wet weather. Unlike glass bead fabrics, which lose much of their reflectivity when soaked by rain, prismatic materials maintain their reflective properties even in downpours. This reliability has made them increasingly popular in professional safety gear, such as police uniforms and high-visibility road-wear, where consistent performance in dark and rainy conditions is essential.

Another advantage is their wide-angle reflectivity, which ensures they remain bright even when light strikes them from extreme angles. However, their performance can vary depending on the orientation of the prisms. In specific conditions, testing shows that microprismatic materials can outperform glass beads by more than 50%. This combination of optical efficiency and adaptability makes them a top choice for demanding applications.

Durability and Care

Microprismatic fabrics are built to withstand tough environments, resisting wind, water, and abrasion. They are rigorously tested to ensure they can handle 7,500 bending cycles and 5,000 abrasion cycles while maintaining their reflectivity. In terms of longevity, they match glass bead fabrics, enduring 15–50 wash cycles under ISO 6330 conditions at temperatures between 105°F and 140°F.

To keep these materials in top condition, wash them with mild detergents and avoid using bleach or fabric softeners. Line drying is recommended, but if you use a dryer, remove the garment immediately to prevent heat damage. For storage, keep them below 80°F (26.7°C) with 30–50% humidity to avoid degradation.

Best Applications

Thanks to their durability and reliable performance, microprismatic materials are perfect for demanding environments where visibility is crucial. They are widely used in professional workwear for industries like construction, mining, oil and gas, and emergency response. For athletes and outdoor enthusiasts, these materials are ideal for cycling gear, running apparel, and other activewear designed for wet or low-visibility conditions.

These materials are particularly effective in "poor sight environments" such as tunnels or low-light areas. Their wide-angle reflectivity ensures visibility from various directions, making them a lifesaver in situations where safety depends on being seen. Strategically placing prismatic elements on moving body parts – like arms, legs, and torsos – helps drivers identify pedestrians or cyclists at night. This is especially important since 75% of pedestrian accidents occur during dawn, dusk, or nighttime hours.

3. Stretch Reflective Fabrics

Stretch reflective fabrics combine high visibility with flexibility, making them perfect for activewear. These fabrics use micro glass beads bonded to an elastic base, typically made of 86% polyester and 14% spandex, allowing the material to move effortlessly with your body. The beads work on a wide-angle principle, reflecting light back to its source even when the fabric is stretched or angled sharply – ideal for activities like running or cycling. Let’s break down how these properties enhance performance.

Visibility and Reflectivity

Stretch reflective fabrics offer reflectivity levels between 250 and 420 cd/lux/m². Thanks to their elastic base, they maintain optimal density even when stretched, ensuring excellent shape retention and tensile recovery. This makes them particularly effective for form-fitting activewear that moves and flexes with the wearer.

Comfort and Flexibility

With four-way stretch capabilities, these fabrics allow unrestricted movement, making them a top choice for compression gear and tight athletic apparel. Unlike traditional reflective materials with rigid backings that can crack or limit motion, stretch reflective fabrics are described as "super-thin" and "ultra-soft", providing superior comfort. Some versions are perforated for better breathability, ensuring you stay cool during intense activities without sacrificing visibility.

Durability and Care

These fabrics are built to last, enduring up to 5,000 abrasion cycles and 7,500 flexing cycles while retaining reflectivity above 100 cd/lux/m². They can handle 25–50 wash cycles at temperatures up to 140°F (60°C), and some specialized types resist cracking even at temperatures as low as -22°F (-30°C). For best results, wash at 105°F (40°C) without presoaking, and avoid bleach or fabric softeners to protect the glass bead coating. Line drying is recommended, but if you use a dryer, remove garments promptly to prevent heat damage to the spandex fibers.

Best Applications

Stretch reflective fabrics are tailored for active lifestyles, excelling in performance wear where flexibility is a priority. They’re ideal for yoga wear, cycling jerseys, running leggings, and compression clothing. Beyond apparel, they’re also a great fit for accessories like hats, shoes, and backpacks. Creative innovations, such as "rainbow" spandex that reflects multi-colored light at night while appearing black during the day, or colored bases like red, blue, and black, allow safety features to integrate seamlessly into brand designs. Double-sided versions ensure 360° visibility for activities like night cycling, while ultra-thin options are perfect for lightweight running vests.

sbb-itb-8dbc09a

4. Specialized Reflective Fabrics (Flame Retardant, Perforated, Heat Transfer)

Specialized reflective fabrics go beyond the basics, offering solutions tailored to unique safety and performance challenges in activewear.

Flame-Retardant (FR) Reflective Fabrics

FR reflective fabrics combine high visibility with fire resistance, making them indispensable in environments where safety is paramount. Unlike standard reflective materials that often use polyester, these fabrics feature flame-resistant backings like Aramid (Nomex) or specially treated cotton. These materials not only resist flames but also provide thermal insulation, offering extra protection in high-risk settings. Laboratory tests show that advanced FR additives can increase the limiting oxygen index to 28.4% – a 53.5% improvement – and reduce peak heat release rates by 37.6%.

Perforated Reflective Fabrics

Designed for breathability without compromising visibility, perforated reflective fabrics include laser-cut holes or mesh patterns. These features enhance airflow, making them ideal for high-intensity activities in warmer conditions. Despite the added ventilation, the retroreflectivity remains impressive, often exceeding 330 cd/(lx·m²). Manufacturers can fine-tune the size and spacing of the perforations to strike the perfect balance between reflectivity and comfort.

Heat Transfer Reflective Films

Heat transfer reflective films offer a flexible and customizable option for adding reflective elements to garments. Using hot pressing, these films can incorporate intricate logos, graphics, or patterns, precisely cut with lasers or knives. Built on TPU or PES backings, they maintain flexibility and can even be segmented to improve ventilation and stretch. This makes them a great choice for garments that prioritize both style and functionality.

Durability and Care

These specialized fabrics are built to last, retaining their reflective properties through 25–100 wash cycles at 140°F (60°C). For FR fabrics, ensure compliance with safety standards like NFPA 2112 for fire protection or ANSI 107 for high visibility. To extend the life of any reflective fabric, wash at 105°F (40°C) or lower using mild detergent. Avoid bleach, high-alkaline, or solvent-based products, as they can dull the reflective finish. Air drying is ideal, but if using a dryer, stick to a low-heat setting and remove garments promptly.

Best Applications

Each type of fabric shines in specific scenarios:

- FR reflective fabrics are perfect for industrial safety gear and uniforms for first responders, where fire resistance is crucial.

- Perforated reflective fabrics excel in activewear like running gear, cycling jerseys, and lightweight jackets, where ventilation and moisture management are just as important as visibility.

- Heat transfer reflective films stand out in branded items such as T-shirts, caps, and bags, offering a way to combine custom graphics with safety features.

Designers are also pushing the creative boundaries by incorporating these materials into floral or geometric patterns, with some even featuring "rainbow" finishes that reflect multi-colored light. These innovative touches make the fabrics suitable for both functional sportswear and entertainment-focused designs, enhancing both visibility and aesthetic appeal in activewear.

Advantages and Disadvantages

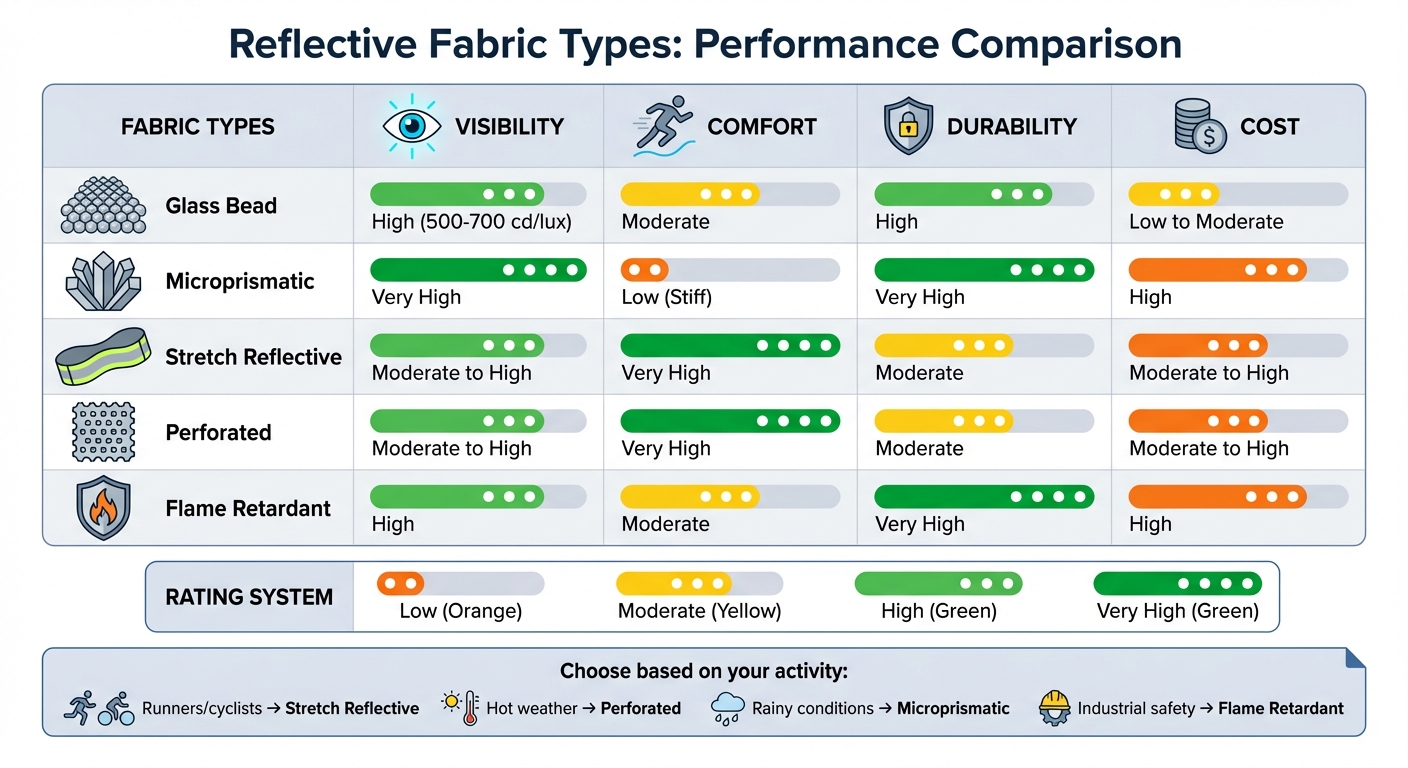

Reflective Fabric Types Comparison: Visibility, Comfort, Durability and Cost

Choosing the right reflective fabric for activewear is all about striking a balance between safety and performance. Each type of reflective material has its own strengths and weaknesses, making it essential to weigh these factors carefully during the design process. Here’s a breakdown of the key features of different reflective fabrics to help guide your choices.

Glass Bead Fabrics

Glass bead fabrics are a solid option for high visibility and durability, all at a relatively affordable cost. Modern designs often incorporate polyester taffeta or spandex backings, which improve comfort. However, they’re still less flexible compared to non-reflective fabrics and may show wear along the edges over time.

Microprismatic Materials

Microprismatic materials stand out for their exceptional brightness, reflecting light directly back to the source . They’re made from PET or PVC, which gives them their durability but also makes them thicker and stiffer – less ideal for activities like running or cycling. While they come with a higher price tag, their longevity makes them worth considering for long-term use.

Stretch Reflective Fabrics

For those prioritizing comfort, stretch reflective fabrics are a great choice. These fabrics, built on spandex backings, flex and move with the body, maintaining their shape even after repeated use. However, they trade off some durability for comfort and fall into the mid-to-high price range.

Specialized Options

Specialized reflective fabrics cater to specific needs. For example, perforated fabrics improve breathability without sacrificing much visibility, making them perfect for hot-weather activities. Flame-retardant (FR) fabrics combine safety and durability, thanks to specialized backings like Aramid, though they come with a higher price point .

| Fabric Type | Visibility | Comfort | Durability | Cost |

|---|---|---|---|---|

| Glass Bead | High (500–700 cd/lux) | Moderate | High | Low to Moderate |

| Microprismatic | Very High | Low (Stiff) | Very High | High |

| Stretch Reflective | Moderate to High | Very High | Moderate | Moderate to High |

| Perforated | Moderate to High | Very High | Moderate | Moderate to High |

| Flame Retardant | High | Moderate | Very High | High |

This comparison highlights how different materials serve different purposes, making it critical to match your fabric choice with the specific safety and performance needs of your activewear design.

Conclusion

Reflective fabrics play an essential role in activewear, ensuring both performance and safety. The key to selecting the right fabric lies in aligning it with your activity and environment. For runners and cyclists, stretch reflective fabrics with a spandex backing are a great choice – they move seamlessly with your body, allowing for unrestricted motion while you stride or pedal. When working out in warmer conditions, perforated reflective fabrics are a smart option. They promote breathability, helping to keep you cool during intense sessions.

For activities like yoga, where flexibility is key, four-way stretch fabrics maintain their shape even after repeated use, offering durability and comfort. Weather also heavily influences fabric choice. If you’re active in rainy conditions, look for materials certified under EN ISO 20471 or ANSI/ISEA 107 for "Wet Reflectivity" to ensure visibility even when wet. For cold-weather athletes, it’s important to choose reflective materials that stay durable in extreme temperatures, down to -22°F (-30°C), so the reflective layer doesn’t crack or lose effectiveness during winter workouts.

To maintain your reflective gear, machine wash at 105°F without using bleach or fabric softeners, and air-dry to preserve its functionality. For maximum visibility, place reflective elements on moving parts of the body, like your arms and legs, to catch the light effectively.

FAQs

What are the main differences between glass bead and microprismatic reflective fabrics used in activewear?

Reflective fabrics come in two main types – glass bead and microprismatic – each with unique characteristics that make them suitable for different activewear purposes.

Glass bead fabrics use tiny aluminum-coated glass spheres to reflect light back toward its source. They provide solid visibility but tend to lose their reflective quality at wider angles. Additionally, frequent washing can wear them down over time. These fabrics are a budget-friendly choice and work well for casual wear or activities at moderate speeds.

Microprismatic fabrics, in contrast, use microscopic prisms to redirect light, delivering much brighter and more consistent reflection, even at shallow angles. They are built to last, maintaining their reflective properties through repeated use and washing. While they come with a higher production cost, their durability and brightness make them perfect for high-performance activewear like running gear or outdoor sports apparel.

Brands like New Dong Huang Garment Co., Ltd. offer both types, giving designers the flexibility to balance visibility, longevity, and cost to meet the diverse needs of activewear users.

What’s the best way to care for reflective activewear to make it last?

To keep your reflective activewear in great shape, here are some practical care tips to follow:

- Check before washing: Look for any tears, loose reflective elements, or stains. Repair small damages or spot-clean stains before tossing your gear in the wash.

- Use cold water and a gentle wash: Stick to a mild, bleach-free detergent and opt for a delicate or hand-wash cycle. Steer clear of fabric softeners or harsh chemicals, as they can harm the reflective material.

- Handle drying with care: Whenever you can, line-dry your activewear in the shade. If you need to use a dryer, select a low-heat setting to protect the reflective surface.

- Store smartly: Keep your garments in a cool, dry spot, away from direct sunlight or anything sharp that could cause damage.

Make it a habit to inspect the reflective areas regularly for signs of wear or dullness, and replace any pieces that no longer perform effectively. By sticking to these steps, you’ll keep your activewear durable and visible for longer.

What type of reflective fabric is best for outdoor activities in rainy or wet conditions?

When it comes to outdoor activities in wet or rainy weather, waterproof reflective fabrics stand out as the go-to option. Take Cordura-nylon, for example – this material combines water resistance with reflective features, making it both practical and long-lasting. Perfect for activewear like jackets and outdoor performance gear, these fabrics keep you dry, visible, and comfortable, even when the weather takes a turn.