Reflective materials in activewear can save lives by improving visibility in low-light conditions. These materials use retroreflection to bounce light back to its source, making wearers visible from up to 1,000 feet away. However, performance depends on meeting strict international standards like EN ISO 20471, ANSI/ISEA 107, and EN 1150, which test for brightness, durability, and performance after wear and washing.

Key points to know:

- Retroreflection: Ensures light reflects back to drivers, enhancing visibility.

- Standards:

- EN ISO 20471: For professional high-visibility gear (e.g., construction workers).

- ANSI/ISEA 107: U.S. standard for safety apparel in work zones.

- EN 1150: Focused on recreational activewear.

- Testing: Materials are tested for abrasion, washing (50–100+ cycles), cold folding, UV exposure, and rain resistance to ensure long-term effectiveness.

- Performance Requirements: Must maintain a retroreflectivity of at least 100 cd/lux-m² after durability tests.

For activewear brands, these standards guide the placement and durability of reflective elements, ensuring products meet safety needs without compromising comfort or flexibility.

International Standards for Reflective Materials

International Reflective Material Standards Comparison for Activewear

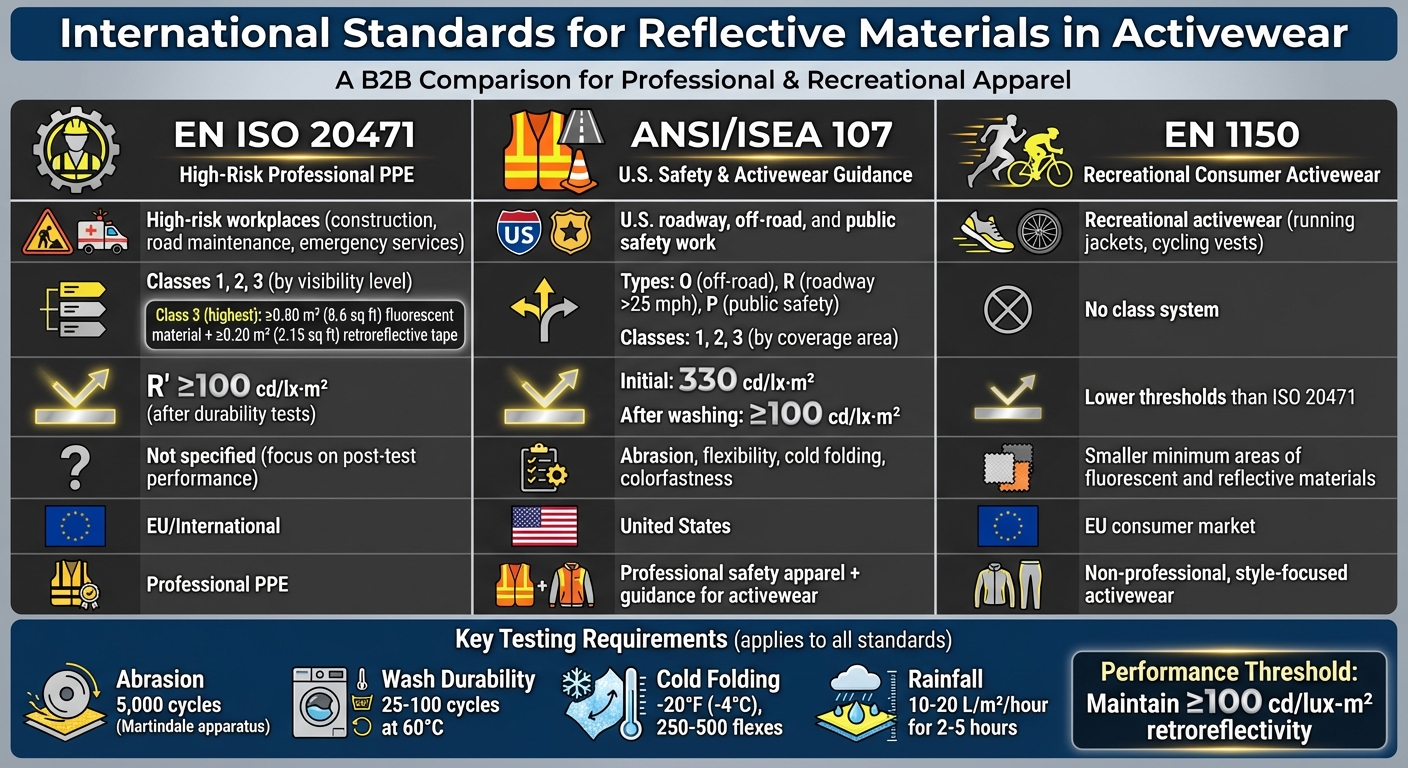

When it comes to reflective materials in activewear, three primary standards set the guidelines: EN ISO 20471, ANSI/ISEA 107, and EN 1150. These standards cater to both professional and consumer needs, providing a foundation for understanding how reflective materials are evaluated and tested.

EN ISO 20471: High-Visibility Clothing

EN ISO 20471 is the go-to standard for high-visibility clothing used in high-risk workplaces like construction zones, road maintenance, and emergency services. It categorizes garments into three classes, with Class 3 offering the highest level of visibility. To meet Class 3 requirements, garments must include at least 0.80 m² (8.6 sq ft) of fluorescent material and 0.20 m² (2.15 sq ft) of retroreflective tape. These materials must cover both the torso and limbs to ensure visibility from all angles.

The standard enforces strict performance criteria for reflective materials. Retroreflective tape, for example, must maintain a coefficient of retroreflection (R’) of at least 100 cd/lx·m² even after undergoing various conditioning tests. These tests simulate wear and tear to ensure the tape doesn’t crack, peel, or lose its reflective properties in real-world conditions.

ANSI/ISEA 107: U.S. High-Visibility Standards

ANSI/ISEA 107 serves as the U.S. standard for high-visibility safety apparel, organizing garments by Type (work environment) and Class (coverage level). Type O applies to off-road worksites, Type R is for roadway environments where traffic exceeds 25 mph, and Type P is tailored for public safety personnel like police and firefighters. The Classes – 1, 2, and 3 – define the minimum required areas of fluorescent and reflective material, with Class 3 offering the most comprehensive coverage for 360-degree visibility.

Reflective materials under this standard must achieve a minimum retroreflection of 330 cd/lx·m² and retain at least 100 cd/lx·m² after multiple washes. Additional tests for abrasion, flexibility, cold folding, and colorfastness ensure that garments maintain their brightness and durability over time. For activewear brands targeting U.S. runners and cyclists, mimicking the coverage patterns of Type R/Class 2 or 3 garments can provide excellent visibility for nighttime activities, even if the apparel isn’t officially classified as personal protective equipment (PPE).

EN 1150: Visibility for Non-Professional Use

EN 1150 focuses on consumer-grade activewear, such as running jackets and cycling vests, designed for recreational use. Unlike EN ISO 20471, this standard allows for smaller minimum areas of fluorescent and reflective materials, offering more flexibility in design. It’s tailored for lower-risk settings and emphasizes basic retroreflective performance and fluorescent coloring rather than the rugged durability required for professional PPE.

For activewear manufacturers, EN 1150 is a practical guideline for creating products that balance visibility with style. While the standard ensures garments enhance visibility in low-light conditions, it doesn’t impose the same stringent requirements as professional-use standards. This makes it ideal for lightweight and stylish options like running tops, cycling vests, and casual outdoor gear aimed at European consumers.

| Standard | Target Use | Classification | Min. Retroreflection | Key Market |

|---|---|---|---|---|

| EN ISO 20471 | High-risk work | Classes 1, 2, 3 (visibility levels) | R’ ≥100 cd/lx·m² (post-tests) | EU/International |

| ANSI/ISEA 107 | Roadway/off-road/public safety | Types O/R/P; Classes 1, 2, 3 | 330 cd/lx·m²; retain 100 cd/lx·m² | United States |

| EN 1150 | Recreational/non-professional | No class system | Lower thresholds than ISO 20471 | EU consumer market |

Testing Procedures for Reflective Materials

Reflective materials used in activewear face constant exposure to wear and environmental factors. Testing ensures these materials maintain their visibility over time. Key evaluations focus on abrasion resistance, wash durability, and performance under extreme weather. Standards require that reflective materials retain a retroreflectivity of at least 100 cd/lux-m² after undergoing these tests. Together, these procedures confirm the reliability of reflective materials in real-world scenarios.

Abrasion and Flexing Resistance

Abrasion tests simulate everyday wear and tear. Using a Martindale apparatus, materials are subjected to 5,000 cycles. To pass, they must limit reflectivity loss to 50% and meet the retroreflectivity standards outlined in ANSI/ISEA 107.

Flexing resistance is also critical. Samples are folded and unfolded between 10,000 and 25,000 times following ISO 7854 or ANSI/ISEA 107 Section 7.2 guidelines. Any cracking, peeling, or loss of adhesion during these tests indicates potential durability issues in practical use.

Wash Durability and Maintenance

Frequent laundering is another challenge for reflective materials. Tests based on protocols like AATCC 61 or ISO 6330 subject materials to 5–100 wash cycles at 60°C with detergent. Afterward, photometric tests (e.g., ASTM E810) measure retroreflectivity. Standards such as EN ISO 20471 and ANSI/ISEA 107 require materials to maintain their retroreflectivity after 25 to 50 washes. Manufacturers often go further, testing up to 100 cycles to ensure reflectivity remains above 80% of the original value. For example, materials starting at 330 cd/lux-m² might decrease to around 100 cd/lux-m² after 50 washes.

Cold Folding and Rainfall Exposure

Cold Folding tests examine how materials handle freezing conditions. Samples are exposed to 32°F (0°C) for 1–3 hours, followed by 250–500 flexes at -4°F (-20°C). Afterward, microscopic inspections check for cracking, and retroreflectivity is reassessed. This test is particularly important for winter activewear designed for cold environments.

Rainfall simulation tests, outlined in EN ISO 20471 or ASTM D751, involve spraying water at a rate of 10 to 20 liters per square meter per hour for 2 to 5 hours. After drying, materials are retested for reflectivity. To pass, they must retain over 90% of their initial reflectivity, with no separation between fluorescent and retroreflective layers. These tests ensure that reflective materials meet the demands of low-light and harsh weather conditions, making them reliable for activewear in challenging environments.

Visibility Performance and Measurement Standards

Visibility performance is assessed using retroreflection and chromaticity tests. These methods evaluate how light interacts with materials – whether it’s light bouncing back, like from vehicle headlights, or maintaining vibrant fluorescent colors for daytime visibility. These tests form the foundation for the detailed protocols outlined below.

Retroreflection and Photometric Tests

Retroreflection tests focus on measuring visibility under low-light conditions. Specifically, they calculate the coefficient of retroreflection (R′) in candelas per lux per square meter (cd/lux-m²) using a photometer. Standards like ASTM E809 and ASTM E810 provide guidelines for the testing geometry and performance benchmarks. These tests replicate what drivers see under controlled lighting angles.

To meet the requirements of EN ISO 20471 and ANSI/ISEA 107, reflective materials must achieve an initial brightness of at least 330 cd/lux-m² and maintain a minimum of 100 cd/lux-m² after durability tests. This ensures garments provide 360° visibility when reflective tape is properly positioned around them.

Manufacturers sometimes perform quick field tests with tools like the 3M Confirm test set. This device uses LED-equipped glasses to compare a material’s reflectivity against reference cards at arm’s length. For more thorough evaluations, laboratory tests employ calibrated photometers to simulate various angles of light, ensuring the materials meet real-world performance needs. Failing to meet these standards can compromise the safety of runners and outdoor enthusiasts.

Fluorescent Color and Chromaticity Testing

While retroreflection tests handle nighttime visibility, chromaticity testing ensures fluorescent colors remain effective during the day. Fluorescent materials work by absorbing UV light and re-emitting it as visible light, which enhances brightness. Spectrophotometry is used to verify that the color coordinates fall within the designated ranges set by EN ISO 20471 for professional gear and EN 1150 for non-professional activewear.

Testing procedures often involve exposing materials to Xenon light to mimic extended UV exposure. Afterward, the materials are evaluated for color retention. Even after 50 to over 100 wash cycles, fluorescent colors must stay within their chromaticity range to ensure they remain bright enough for daytime visibility.

sbb-itb-8dbc09a

Integrating Reflective Materials into Activewear Manufacturing

Manufacturers are now emphasizing the use of reflective materials in activewear, ensuring these materials meet rigorous testing standards and compliance requirements.

Material Selection and Compliance Labeling

Reflective materials used in activewear must meet the ANSI/ISEA 107 standard for brightness: an initial minimum of 330 cd/lux-m² and at least 100 cd/lux-m² after multiple washes. These materials should pass photometric tests for retroreflection and chromaticity tests for fluorescent colors. Additionally, they need to endure wear and tear, including abrasion, flexing, and cold folding at temperatures as low as -20°F without showing signs of cracking.

For products sold in the EU, the CE mark must be included, along with the appropriate EN ISO 20471 class and care instructions. In the U.S., ANSI/ISEA 107 compliance is demonstrated through performance data rather than a specific mark. Manufacturers must maintain detailed documentation, including lab test results for retroreflection (using methods like ASTM E809/E1809), wash durability records, and certifications such as Oeko-Tex for chemical safety. Garment-specific requirements are also critical – for example, Class 3 garments must include at least 0.80 m² (8.6 sq ft) of fluorescent material and 0.20 m² (2.15 sq ft) of reflective tape. These measures guide how reflective materials are incorporated into activewear designs.

Applications in Activewear Products

Activewear designers use these standards to strategically place reflective elements across various products. For running gear, reflective strips are often added to high-movement areas like cuffs, hems, and seams on leggings and jackets. This ensures 360° visibility while meeting ANSI/ISEA 107 Type R roadway class requirements. Curved seams and high-visibility zones, such as calves and arms, are ideal for reflective placement, offering nighttime safety without compromising fabric stretch or breathability.

In yoga wear, subtle reflective details on areas like hips and shoulders enhance visibility for low-light conditions, whether in studios or during outdoor evening sessions. These designs maintain the flexibility of the fabric. Outdoor performance clothing often combines fluorescent and reflective elements, such as chest and back strips on base layers or sports bras. These elements are rigorously tested to ensure they can withstand flexing and extreme cold. Designers also avoid placing reflective materials in dirt-prone areas and prioritize materials that retain their properties after washing.

New Dong Huang Garment Co., Ltd.’s Manufacturing Capabilities

New Dong Huang Garment Co., Ltd. has been a leader in activewear manufacturing for over 27 years, specializing in integrating reflective materials. The company uses reflective tapes that meet both EN ISO 20471 and ANSI/ISEA 107 standards, pairing them with stretch fabrics that pass stringent washing and durability tests. With over 500 sewing and knitting machines, their facility ensures precise placement of reflective elements, achieving comprehensive 360° visibility while maintaining garment flexibility.

Their advanced equipment, including bonding, laser cutting, and ultrasonic machines, allows seamless integration of reflective features without sacrificing comfort. A dedicated quality-control team ensures compliance at every stage of production. The company holds certifications such as BSCI, Sedex, and GRS and has passed audits from major brands. With a 99% on-time delivery rate and a management team averaging 18 years of experience, New Dong Huang Garment Co., Ltd. consistently delivers custom designs that prioritize both safety and functionality. This expertise ensures that reflective materials are not just an add-on but a key element in creating high-performance activewear.

Conclusion

Reflective materials play a crucial role in enhancing safety by reducing collision risks in low-light conditions. Standards like ANSI/ISEA 107, EN ISO 20471, and EN 1150 set specific requirements for brightness, color, and surface area to ensure visibility at distances that allow drivers enough time to react safely. Rigorous testing – covering abrasion resistance, wash durability, cold-weather performance, and photometric evaluations – ensures these materials maintain their effectiveness throughout the lifespan of a garment, even under tough conditions.

Certified reflective materials stand out by retaining their brightness and functionality after extensive testing, unlike cheaper alternatives that lose their effectiveness after just a few washes. Brands that adhere to strict retroreflective standards and invest in thorough pre-production and bulk testing ensure their products deliver real visibility benefits. Lab-tested performance directly translates into better detection distances and faster driver reactions in real-world scenarios.

Taking these performance benchmarks further, New Dong Huang Garment Co., Ltd. employs advanced manufacturing techniques to meet these demanding standards. By strategically placing reflective tapes and films along seams and articulation points, they achieve 360° visibility without compromising on stretch or breathability. Their use of cutting-edge bonding and laser-cutting technologies, coupled with a dedicated quality-control team, ensures compliance at every stage of production. With certifications like BSCI, Sedex, and GRS, and a 99% on-time delivery rate, the company delivers reliable quality from raw materials to finished garments.

For both U.S. and global brands, working with a manufacturer that prioritizes these rigorous standards not only enhances product safety but also strengthens consumer trust. Combining robust testing with expert manufacturing ensures reflective materials perform consistently across seasons, helping brands stand out in the competitive activewear market while building long-term customer confidence.

FAQs

What are the main differences between EN ISO 20471, ANSI/ISEA 107, and EN 1150 reflective material standards?

EN ISO 20471 outlines the standards for high-visibility clothing designed for workers, emphasizing visibility performance and durability in demanding work environments. In the U.S., the ANSI/ISEA 107 standard governs high-visibility apparel, classifying garments into Class 1, 2, and 3 based on their reflectivity and the visibility needs of various job settings. Meanwhile, EN 1150 targets non-workwear uses, focusing on reflective properties for low-light conditions, such as those needed for recreational or personal activities, rather than adhering to stricter visibility requirements.

How do reflective materials stay effective after repeated washing?

Reflective materials are built to withstand the test of time, even when subjected to repeated washing machine cycles. Rigorous wash durability testing ensures these materials keep their reflective properties intact, maintaining their ability to provide visibility and safety.

To achieve this level of durability, manufacturers rely on top-tier reflective fabrics and advanced production methods. These efforts ensure the material remains dependable for visibility and performance over an extended period. Following the recommended care and washing instructions is also crucial in preserving their effectiveness.

Why is reflective material essential for activewear safety?

Reflective material plays an important role in keeping activewear safe, particularly in low-light or nighttime situations. It boosts visibility, making it easier for others – like drivers – to spot the wearer, which helps lower the risk of accidents.

The way it works is simple yet effective: reflective materials bounce light back toward its source. This makes them a smart addition to activewear for activities such as running, cycling, or walking in poorly lit areas. For outdoor enthusiasts and commuters, this feature becomes a key factor in staying visible and safe while on the move.