Seam placement in activewear directly affects how well the garment fits, feels, and lasts. Proper seam design reduces irritation, improves movement, and extends the life of the clothing. Misplaced seams, on the other hand, can cause chafing, restrict flexibility, and lead to faster wear and tear. Here’s what matters most:

- Fit: Seams like princess seams in bras or side seams in leggings enhance support and prevent bunching.

- Comfort: Seams positioned away from high-friction areas (e.g., inner thighs) reduce irritation.

- Durability: Techniques like flatlock stitching and gussets handle stress better, preventing seam failure.

Manufacturers use methods like body mapping, flatlock stitching, and gusset integration to optimize seam placement. This ensures activewear is comfortable, flexible, and built to withstand intense use. For example, a diamond-shaped gusset in leggings prevents splitting during squats, while curved seams in jackets improve mobility.

Key Takeaway: Thoughtfully placed seams make activewear more comfortable, flexible, and long-lasting, while poor placement can lead to discomfort and premature wear.

LIVE: How To Sew Activewear: Tips and Tricks for Professional Results

Seam Types and Their Effects on Fit and Durability

Activewear Seam Types: Uses, Benefits, and Testing Metrics Comparison

When it comes to activewear, seams play a crucial role in addressing challenges like chafing, restricted movement, and premature wear. Choosing the right seam type can make all the difference in creating durable and comfortable garments.

Common Seam Types in Activewear

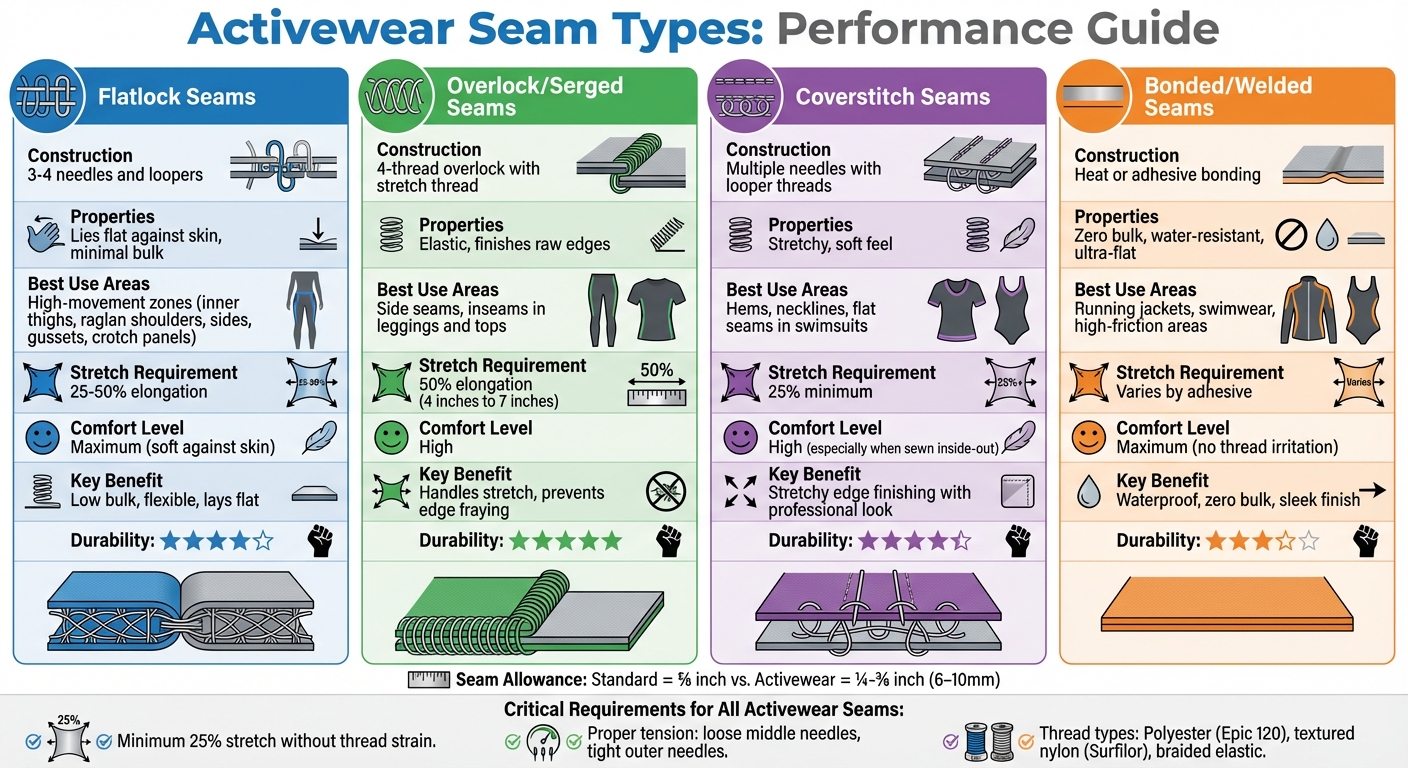

The performance of activewear often hinges on the type of seams used and where they’re placed. Overlock seams are a popular choice for finishing raw edges. Their elasticity makes them ideal for side seams and inseams in leggings and tops, where stretch and flexibility are key.

For areas that demand minimal bulk and maximum comfort, flatlock seams are the go-to option. These seams lie flat against the skin, making them perfect for high-movement zones like inner thighs or raglan shoulders. Often stitched with 3–4 needles and loopers, flatlock seams are gentle on the skin while holding up under stress.

Coverstitch seams are commonly used for hems and flat seams in garments like swimsuits, offering both strength and flexibility. Meanwhile, bonded or welded seams – created using adhesives or heat – provide an ultra-flat, water-resistant finish. These are frequently found in high-end items like running jackets and swimwear, where sleekness and functionality are paramount. Together, these seam types contribute to a balance of fit, comfort, and durability.

How Seam Properties Affect Fit

The way seams are constructed has a direct impact on the fit of stretch fabrics. Narrow seam allowances, typically ¼–⅜ inch (6–10 mm), reduce bulk and improve comfort compared to the standard ⅝-inch seams. For activewear, seams need to stretch at least 25% without straining the thread. This ensures freedom of movement and prevents early wear or failure. Techniques like flatlock or inside-out coverstitching further enhance comfort by keeping looper threads closer to the fabric, reducing the risk of chafing.

Seam Durability Factors

Durability in seams depends on the right combination of seam type, thread, and sewing tension. For high-stress areas, reinforced configurations – such as overlock seams paired with coverstitch topstitching – help prevent slippage. Threads play a critical role too. Polyester threads like Epic 120 and textured nylon options such as Surfilor, or even braided elastic threads, offer a mix of softness and strength. Proper tension is equally important; threads need enough elongation to stretch without snapping, as overly tight tension can cause cracking.

To improve comfort without sacrificing strength, some manufacturers sew coverseam or flatseam seams inside out. This places the softer looper threads against the skin, making the garment more comfortable to wear.

A great example of these principles in action is New Dong Huang Garment Co., Ltd. Their facility, equipped with over 500 advanced sewing and knitting machines as well as bonding, laser cutting, and ultrasonic equipment, ensures precision in seam construction. Their adherence to certifications like BSCI, Sedex, and GRS underscores their commitment to creating seams that prioritize both comfort and longevity. By combining thoughtful seam selection with precise engineering, manufacturers can produce activewear that stands the test of time.

Placing Seams for Comfort and Performance

Body Mapping for Seam Placement

When designing activewear, understanding where the body experiences friction and movement is key. Areas like the inner thighs, crotch, underarms, knees, hips, and shoulders tend to face the most wear and tear. These high-friction zones call for careful seam strategies, such as low-profile stitching, to avoid irritation during extended use. To enhance comfort, designers often shift seams away from these pressure points, incorporate gussets, or use flatlock seams in unavoidable contact areas. This mapping approach ensures that seam placement aligns with the specific needs of different activewear styles.

Seam Placement by Garment Type

Leggings: For performance leggings, designers move the inner leg seam slightly forward or backward to avoid the highest-friction area between the thighs. Side seams along the outer leg not only reduce bulk in sensitive areas but also add visual contouring. A bias-cut diamond gusset at the crotch is a common feature, as it helps distribute stress during movements like squats and lunges, minimizing discomfort and preventing fabric splitting.

Sports Bras: Seam placement in sports bras focuses on comfort and functionality. Key areas like the underbust band, the sides of the bust, and shoulder straps are carefully designed to reduce pressure. Curved panel seams are positioned just off high-pressure zones, and underbust seams are finished with soft, brushed elastics and low-profile stitching to prevent chafing. Additionally, flat seams or bindings are used at strap seams and racerback junctions to reduce bulk.

Jackets and Outer Layers: For jackets, ergonomic seam placement prioritizes mobility and comfort. Raglan or articulated sleeve seams follow the natural curve of the shoulder, enabling overhead movements without pulling across the chest. Shoulder seams are often moved away from the top to avoid pressure points caused by backpack straps. Multi-piece sleeves with curved elbow seams enhance mobility and reduce pressure ridges, ensuring these garments perform well in various conditions.

Ergonomic Seam Design

By combining body mapping insights with garment-specific strategies, ergonomic seam designs work harmoniously with the body’s natural contours. Curved seams along the side of the body and princess lines provide a better fit around the bust and waist, while curved yokes and back seams on leggings align with the gluteal shape for improved comfort. At joints, curved seams minimize fabric bunching, allowing for greater freedom of movement.

Vertical seams play a dual role, offering both structural support and aesthetic appeal. In compression leggings, vertical seams along the outer leg and angled seams over the quads and calves anchor compression panels, which support muscles and create a lengthening effect. For tops and jackets, vertical princess seams and paneling contour the bust and torso, delivering zoned compression without adding unnecessary pressure. Manufacturers like New Dong Huang Garment Co., Ltd. have standardized ergonomic features such as gusseted crotches and repositioned inseams in performance leggings. By pairing these designs with high-stretch fabrics and flat seam construction, they strike a balance between durability and comfort.

| Zone | Recommended Placement | Benefit |

|---|---|---|

| Inner thighs/crotch | Bias-cut diamond gusset; avoid inseams | Prevents chafing and splitting during squats |

| Underarms/shoulders | Armhole seams, raglan sleeves, mesh gussets | Maximizes mobility and breathability |

| Knees/elbows | Curved seams following contours | Improves ergonomics and reduces restriction |

sbb-itb-8dbc09a

Engineering Seams for Durability

Aligning Seams with Stress Paths

When it comes to activewear, seams need to move in harmony with the fabric. A key design principle is aligning seams with the fabric’s grainline. By doing this, stress is spread across a larger area rather than being focused on a single spot. For example, in leggings, areas like the crotch endure significant pulling during movements like squats and lunges. Seams that follow the natural curves of these areas help distribute stress more evenly, reducing wear and tear.

Engineers study how fabric stretches and moves under real-life conditions to design seams that align with these natural stress paths. In leggings, the most strain occurs along the crotch curve, inner thighs, and the line running from the seat down to the ankle. Sports bras, on the other hand, see the highest stress at the underbust band, armholes, and where the straps connect to the back panel. For jackets, the shoulders, upper back, and elbows are the primary hotspots for strain during activities like reaching forward or bending. By placing seams around these high-motion areas – rather than directly through them – garments are able to flex naturally with the body. This thoughtful placement also opens the door for additional reinforcements, like gussets and panels, in areas that need extra support.

Using Gussets and Panels

Gussets and panels are a game-changer when it comes to activewear durability. A diamond-shaped gusset, typically 2 to 3 inches wide and 3 to 5 inches long, is a common addition in premium activewear. Positioned at stress-heavy intersections like the crotch, these panels allow the fabric to stretch in multiple directions during movements like deep squats. Because they’re cut on the bias (diagonally across the fabric’s grain), gussets maximize stretch and distribute stress evenly, reducing the chance of seam failure. You’ll also find gussets under the arms of jackets, where they provide similar benefits for movements like reaching or lifting.

Multi-panel construction is another strategy that enhances both fit and durability. By breaking large fabric sections into smaller, shaped pieces, manufacturers create garments that conform better to the body’s contours. This approach also redirects stress away from single, vulnerable seams and spreads it across multiple reinforced joins. The result? Each seam carries less strain, making the garment last longer.

Preventing Seam Failure

Durable seams are essential for activewear, and several construction methods help prevent failures. Flatlock seams are a popular choice because they lie flat against the fabric, creating strong, low-bulk joins that stretch easily. This makes them ideal for high-movement areas like inner thighs and crotch panels, where flexibility and comfort are crucial. For even greater durability, some manufacturers combine a straight stitch with stretch thread and a four-thread overlock. This combination allows seams to stretch from 4 inches to 7 inches – a 50% elongation – without breaking.

Thread selection and machine settings also play a critical role. Seams should be able to stretch between 25% and 50% without resistance. If needle tension is too tight, it restricts elongation and increases the risk of thread breakage. Adjusting the tension – loosening the middle needles while keeping the outer ones tighter – strikes the right balance between softness and structural integrity. Companies like New Dong Huang Garment Co., Ltd. are pushing the boundaries by incorporating bonding and laser-cutting techniques alongside traditional stitching. These methods reinforce high-stress areas and reduce reliance on thread alone, resulting in more resilient garments.

By combining strategic seam placement with robust construction techniques, manufacturers ensure that activewear can withstand the toughest movements and last through countless workouts.

| Seam Type | Durability Benefit | Best Use Areas |

|---|---|---|

| Flatlock | Low bulk, flexible, lays flat | High-movement zones, crotch panels |

| Overlock/Serged | Handles stretch, finishes edges | Side seams, with stretch thread |

| Bonded/Welded | Zero bulk, waterproof | Swimwear, high-friction areas |

| Coverstitch | Stretchy edge finishing, soft feel | Hems, necklines |

Best Practices for Seam Placement in Activewear Design

Analyzing Fit and Performance Requirements

Before cutting the first piece of fabric, designers must understand how the garment will function in action. The primary activity – whether running, yoga, weightlifting, or cycling – shapes the movement patterns and determines seam placement. For example, runners need seams that reduce chafing during repetitive leg motions, while yoga practitioners benefit from seams that accommodate deep stretches and twists.

It’s essential to pinpoint high-stress zones where fabric stretches the most and align seam design with the garment’s intended fit. Compression garments need seams that hold their shape under tension, while looser designs prioritize freedom of movement. In leggings, key stress points include the crotch, inner thighs, and the seam running from the seat to the ankle. For sports bras, the underbust band and the strap-to-back panel connections endure the most strain. Seams in these areas must stretch adequately to prevent discomfort or chafing during movement.

The target audience also plays a role in seam design. Curvier patterns may require additional gusset support to handle shape changes, while endurance athletes often prefer seams finished with soft threads, like Surfilor, to minimize irritation on skin-facing areas. Addressing these factors early in the process helps avoid revisions later. These insights set the stage for incorporating strategic seam placement into the design process.

Integrating Seam Placement into Pattern Design

Using body mapping insights, designers can translate these requirements into precise pattern adjustments. Once high-stress points are identified, seam strategies can be incorporated directly into the pattern blocks. For activewear, narrower seam allowances are often specified to ensure smooth integration during construction. Seam types are chosen based on the garment’s needs: flatlock seams for high-stretch areas like leg openings, coverstitches for necklines, and bonded seams for sleek, bulk-free finishes.

Strategic paneling is another crucial element. Dividing larger fabric sections into smaller, contoured pieces not only enhances fit but also distributes stress across multiple seams. For example, diamond-shaped gussets at stress points like the crotch provide maximum stretch and durability.

When grading patterns across sizes, proportional scaling ensures that seam placements remain consistent. Testing size ranges from XS to XXL ensures that details like side seam curves in leggings maintain proper alignment relative to body measurements. For instance, New Dong Huang Garment Co., Ltd., a leading activewear manufacturer with over 27 years of expertise, employs advanced techniques like bonding, laser cutting, and seamless construction to produce performance gear. Their design teams in Australia and China focus on translating global trends into precise, high-quality samples.

Testing and Refining Seam Placement

After refining the patterns, thorough testing ensures the seams perform as intended. Prototyping uncovers issues that static patterns might miss. Wear trials – such as 30-minute runs, yoga sessions, or weightlifting routines – help identify problems like chafing, binding, or discomfort. Machines like coverseam or flatseam place softer looper threads against the skin, reducing irritation without compromising stretch.

Stretch tests are equally important, verifying that seams can elongate between 25% and 50% without thread breakage. Techniques like overlock or zigzag stitching with stretch thread, combined with cycle testing (at least 100 bends or stretches), ensure durability in high-stress areas. Washing prototypes multiple times checks that seams maintain integrity after repeated laundering. Adjusting needle tension – loosening the middle needles while keeping the outer ones tight – balances softness with structural strength.

Feedback from wear trials provides invaluable insights. Users can highlight friction zones, restriction points, and overall comfort. This feedback can lead to refinements, such as shifting a seam, adding a gusset, or selecting a different seam type. The goal is to create a garment that moves effortlessly with the body, regardless of activity intensity. These tests validate the design’s durability and comfort, ensuring it meets the demands of real-world use.

| Seam Type | Best Use in Activewear | Key Testing Metric |

|---|---|---|

| Flatlock | High-movement areas (sides, gussets) | 25–50% stretch with minimal bulk |

| Coverseam | Necklines, hems | Softness against skin and sufficient elongation |

| Bonded/Welded | Waterproof, zero-bulk finishes | Precise edge alignment and no thread breakage |

Conclusion

Seam placement plays a crucial role in the performance of activewear. Every seam line and panel curve directly impacts how the garment performs under demanding conditions, ensuring both comfort and dependable support during intense activities. Thoughtful seam positioning helps minimize friction in sensitive areas and evenly distributes stress across panels, contributing to the garment’s durability and longevity.

The integration of techniques like body mapping and gusset design elevates these garments to move naturally with the body. This level of precision is achieved using advanced tools such as bonding machines and laser cutters, alongside meticulous attention to details like thread tension and seam allowances. These technical skills are hallmarks of leaders in the industry.

One standout example is New Dong Huang Garment Co., Ltd.. With over 27 years of experience in activewear manufacturing, they specialize in precision seam engineering and cutting-edge design techniques. By employing methods like seamless construction and body-mapped paneling, they create garments that deliver exceptional fit, comfort, and durability. Their global design teams and state-of-the-art production facilities ensure every garment meets rigorous quality standards, from the initial prototype to final production. For brands, collaborating with a manufacturer that prioritizes functional seam engineering is essential to producing activewear that performs as promised.

FAQs

How does seam placement improve the comfort and durability of activewear?

Seam placement is a key factor in making activewear more comfortable and long-lasting. By positioning seams thoughtfully, manufacturers can cut down on chafing and irritation in high-movement areas, giving you a smoother, more enjoyable experience during wear.

On top of that, smart seam placement enhances the fit by eliminating unnecessary bulk and reducing pressure points. This allows the clothing to move effortlessly with your body. The result? Not only a boost in comfort but also a longer-lasting garment, as it helps reduce wear and tear in areas that typically endure the most strain.

What types of seams are best for improving durability and comfort in activewear?

When it comes to balancing durability and comfort in activewear, bonded seams, laser-cut seams, and ultrasonic seams stand out as top choices. These modern techniques deliver strong, flat finishes that help reduce bulk and significantly lower the chances of chafing during physical activity.

By skipping excessive stitching and fortifying areas prone to wear and tear, these seam styles not only extend the life of the garment but also ensure a smoother, more comfortable fit – perfect for those with active routines.

Why is body mapping crucial for placing seams in activewear?

Body mapping plays a crucial role in seam placement, ensuring seams align with the body’s natural contours and movements. This thoughtful design reduces friction, lowers the chance of chafing, and provides a more comfortable fit – especially important during intense physical activities.

Strategically placed seams don’t just enhance comfort; they also boost durability. By distributing stress evenly across the garment, they help prevent wear and tear in high-impact areas, ultimately increasing the product’s longevity. Seam placement, guided by body mapping, is a cornerstone of creating activewear that performs well and stands the test of time.