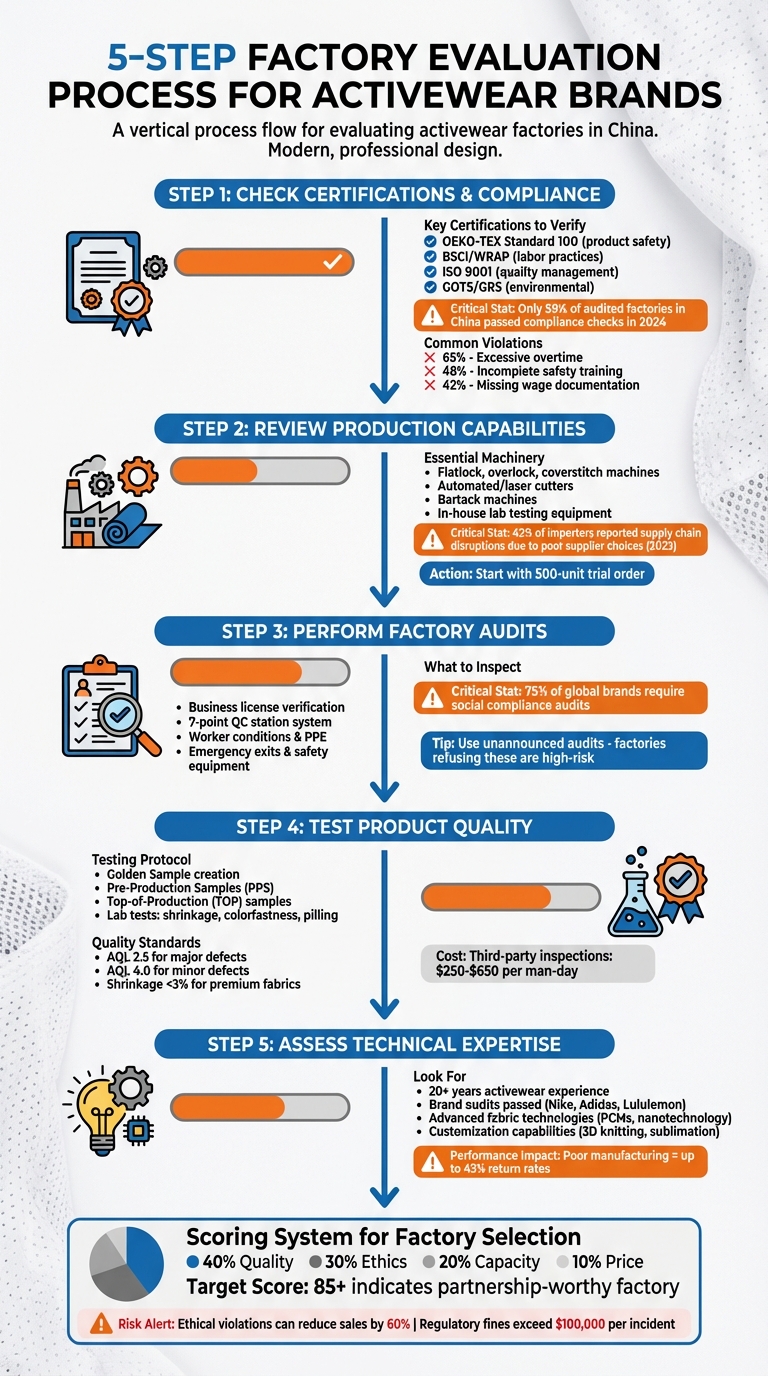

Selecting the right activewear factory in China can make or break your brand. Poor quality, compliance issues, or missed deadlines can cost you revenue and damage your reputation. Here’s what you need to know:

- Certifications Matter: Verify key certifications like OEKO-TEX Standard 100 for safety, BSCI and WRAP for labor practices, and ISO 9001 for quality management. Use official databases to confirm validity.

- Production Capacity: Ensure the factory has the right machinery (e.g., flatlock, overlock) and can meet your volume needs without sacrificing quality. Test with a small trial order.

- On-Site Audits: Visit the factory to confirm operations match claims. Check production lines, quality control measures, and working conditions. Use third-party audits if needed.

- Product Testing: Use "golden samples" and lab tests to confirm fabric performance, durability, and safety. Apply AQL standards for quality control.

- Technical Expertise: Partner with factories experienced in activewear, capable of handling advanced fabrics and designs. Check their track record with brands like Nike or Adidas.

Key Tip: Start with a trial order, verify certifications, and prioritize regular audits to avoid costly mistakes.

5-Step Process for Evaluating Activewear Factories in China

How Sportswear Factories REALLY Make Your Clothes!

sbb-itb-8dbc09a

Step 1: Check Factory Certifications and Compliance

Certifications are your first line of defense when assessing activewear factories. They confirm that a supplier adheres to global standards for labor rights, product safety, and responsible practices. Without the right documentation, you could jeopardize your brand’s reputation or even face legal consequences.

Today, 75% of global brands require social compliance audits from their Chinese suppliers. This isn’t just a suggestion – major retailers often refuse to work with factories that lack compliance. For activewear, certifications like OEKO-TEX Standard 100 are especially important since these products are in prolonged contact with the skin during exercise. This certification ensures that materials like fabrics, threads, and elastics are free from harmful substances that could interact with sweat.

Certifications You Should Look For

Different certifications address different risks, so it’s important to know what to prioritize. Social compliance standards such as BSCI (popular with European brands) and WRAP (preferred in North America) verify ethical labor practices. These include fair wages, legal working hours, and prohibitions against forced labor. While BSCI focuses on continuous improvement, WRAP offers tiered certifications – Silver, Gold, and Platinum.

When it comes to product safety, OEKO-TEX Standard 100 is essential. It tests all components – fabrics, zippers, elastic bands, and even prints – for harmful chemicals. For outdoor wear, you might also need UV Protection (UPF) certification. On the environmental side, GOTS certifies organic fibers, while GRS applies to recycled polyester. ISO 9001 is another important certification, as it demonstrates consistent quality management throughout production.

Always verify certifications through official databases. For example:

- Check BSCI certificates at amfori.org.

- Verify OEKO-TEX certifications at oeko-tex.com.

- Look up GOTS and GRS certifications at global-standard.org.

A 2024 report revealed that only 59% of audited factories in China passed compliance checks. Common violations included excessive overtime (65%), incomplete safety training (48%), and missing wage documentation (42%).

"Verified certifications help you avoid legal risk, satisfy retailer demands, and demonstrate brand integrity to your customers." – Elaine Zhou, Business Director, Shanghai Fumao

These certifications not only confirm production safety but also set the stage for more rigorous compliance measures.

Why Compliance Standards Matter

Certifications are just the beginning – compliance standards are what protect your brand from serious risks. They help prevent legal penalties and customs issues. For instance, under the U.S. Uyghur Forced Labor Prevention Act (UFLPA), you must prove your supply chain is free of forced labor, or your shipments could be detained at the border. Similarly, EU regulations like REACH restrict chemical use in textiles, while California Proposition 65 mandates warnings for certain substances.

Non-compliance can also tarnish your brand’s image. Companies with strong ESG (Environmental, Social, Governance) practices tend to see 25% higher stock returns on average. On the flip side, public backlash can hit hard if ethical sourcing can’t be verified.

To protect your business, include mandatory certification requirements in your purchase agreements. Ensure factories provide updated documents regularly and allow payment delays if certificates are falsified. Also, insist on unannounced audits – factories that refuse surprise visits are often high-risk for compliance violations. Finally, cross-check the factory’s business license through China’s National Enterprise Credit Information Publicity System (NECIPS) to confirm that the registered name matches the certifications.

Step 2: Review Production Capabilities and Capacity

After confirming certifications, the next step is to assess whether the factory’s production capabilities align with your activewear requirements. Just having the right paperwork doesn’t guarantee smooth operations – outdated machinery or overburdened production lines can lead to delays and quality problems. In fact, in 2023, nearly 43% of importers reported significant supply chain disruptions due to poor supplier choices.

The goal here is to ensure the factory’s equipment, workforce skills, and production capacity meet your business needs. For activewear, this means focusing on machinery and techniques suited for technical fabrics and complex constructions like leggings, sports bras, and jackets.

Check Machinery and Equipment

Producing activewear requires specialized machinery that many standard garment factories don’t have. Look for machines like flatlock, overlock (ISO 504), and coverstitch (ISO 602), which are essential for creating seamless, elastic, and durable garments.

Precision cutting tools are just as important. Automated and laser cutters help achieve tight tolerances in intricate designs, such as mesh panels or color-blocked patterns, ensuring proper alignment. Additionally, bartack machines are vital for reinforcing stress points like pocket edges and side seams.

High-performing factories often have in-house lab testing equipment to maintain consistent quality. Examples include tensile testers for seam strength, pilling testers (ISO 12945), and spectrophotometers for color accuracy. A cautionary tale: in 2021, AuraVita, a Berlin-based wellness brand, lost $18,000 after a factory in Dongguan failed to meet agreed thickness tolerances on bamboo-fiber yoga mats due to the lack of in-house testing.

When visiting a factory, check maintenance records to ensure machines are regularly serviced and calibrated for consistent output. Also, confirm that fabric rolls are given time to relax before cutting – this prevents shrinkage later in the process. Factories should have at least seven distinct quality control stations, including in-line checks and a final inspection before packing.

"Trust is earned in manufacturing – not assumed. The most reliable factories don’t hide behind glossy brochures. They welcome scrutiny because their systems are built to withstand it." – Li Wei, Senior Sourcing Director, LeapGlobal Procurement Advisors

These equipment checks are critical for evaluating the factory’s overall production capability.

Measure Production Capacity and Delivery Performance

Once you’ve verified the machinery, shift your focus to the factory’s ability to meet your production needs. Capacity isn’t just about how many units a factory can produce; it’s about whether they can scale to meet your brand’s growth and handle tight deadlines without sacrificing quality. Request detailed data on monthly output and peak capacity to confirm they can handle seasonal demand spikes.

Inspect production lines, either in person or via live video, to observe active workflows and review WIP (Work in Progress) boards. Time how long it takes to produce a single style to get a realistic idea of throughput. Also, check that workers are using proper personal protective equipment (PPE) and that the facility follows organized 5S standards for efficiency.

Determine which parts of production are outsourced, such as embroidery, printing, or dyeing, as these steps can introduce delays from third-party vendors. Verify that the factory is a direct manufacturer rather than a trading company, as direct control over production schedules is crucial.

Finally, consider placing a small trial order – around 500 units – to test both capacity and quality. By thoroughly reviewing machinery and production capacity, you’ll be better prepared for the next steps in assessing quality and technical performance.

Step 3: Perform Factory Audits and Site Visits

Once you’ve verified production capacity, the next step is conducting an on-site audit. While email and video calls are helpful, they simply can’t replace physically inspecting a facility. In fact, more than 75% of global brands now require social compliance audits from their Chinese suppliers. A thorough 3-step audit process can identify around 90% of potential issues before you commit to a manufacturer. This step not only confirms certifications but also uncovers problems that paperwork alone might miss.

Take this example: In late 2024, a Florida swimwear brand audited a factory that claimed to operate 10 production lines. During their visit, they discovered the factory had only 3 lines. They ultimately chose a facility with 8 verified lines, leading to inventory turning 40% faster thanks to timely deliveries. This highlights why physical verification is absolutely crucial.

What to Look for During On-Site Audits

Start by verifying the factory’s identity. Check that the business license matches the factory’s name and address to ensure you’re dealing with a direct manufacturer and not a trading company. For instance, in Spring 2025, a California activewear brand identified a fake business license at one facility during a site visit. By choosing a factory with authentic documentation, they successfully placed a 2,000-unit order.

Next, inspect the quality control (QC) systems in place. Look for dedicated QC stations at various stages, including inline checks during production and final inspections at the end of the line. In Summer 2024, an Ohio uniform manufacturer opted for a facility with a 7-point QC station system after an on-site audit. This robust setup gave them confidence to sign a contract immediately, especially since another factory had skipped final inspections. Also, review defect logs, AQL (Acceptable Quality Level) tables, and tools like needle detection machines, which are critical for ensuring product safety in activewear production.

Pay close attention to social compliance and labor conditions. Assess the work environment for proper lighting, ventilation, and cleanliness. Confirm that emergency exits are accessible and unlocked, fire extinguishers are available, and workers are using the required Personal Protective Equipment (PPE). Common violations in Chinese factories include excessive overtime (65%), insufficient safety training (48%), and incomplete wage records (42%).

It’s also a good idea to privately interview random workers away from management. This can help you uncover issues like coached responses or wage withholding. Be cautious of "perfect" time logs showing exactly 8-hour shifts with no variation – this could indicate falsified records.

"The most effective way to detect compliance fraud is through unannounced audits. Factories that refuse unannounced visits or require weeks of advance notice are high-risk." – FactoryFollow Compliance Guide

When to Use Third-Party Auditors

If you’re unable to travel or need specific expertise, third-party audits are a practical solution. Firms like SGS, QIMA, and Bureau Veritas offer objective, globally recognized reports that can catch issues your own team might overlook. These audits can cost over $1,000 per visit but are often worth the investment.

Third-party auditors are particularly skilled at document verification. They authenticate business licenses and certifications (like BSCI, GOTS, and ISO) against official registries, ensuring you avoid fake or expired documents. They’re also adept at spotting audit fraud, such as rehearsed answers, fabricated records, or temporary fixes made just to pass the inspection.

Beyond identifying problems, these auditors provide Corrective Action Plans (CAPs), which outline steps for factories to address non-compliance before production starts. For buyers unable to visit in person, some firms even offer virtual audits using mobile streaming tools and geo-tagging for real-time facility walkthroughs.

Rather than relying on a single visit, schedule surprise audits annually or quarterly to ensure long-term compliance. Companies that prioritize strong ESG (Environmental, Social, Governance) performance often see tangible benefits, including up to 25% higher stock returns on average.

Step 4: Test Product Quality with Samples and Inspections

Once audits are done, it’s time to put the actual products to the test. Certifications might look good on paper, but they don’t guarantee performance. This step ensures you avoid costly surprises, like garments with excessive shrinkage or weak seams. Think of it as the final quality checkpoint after verifying production capacity.

One key tool here is the "Golden Sample" – a pre-approved prototype that sets the standard for fabric, color, measurements, and construction details. Every item in your order should match this benchmark. Without it, you’re left with vague expectations and no clear reference point.

How to Request and Test Prototypes

Request samples at different stages of production. Start with Pre-Production Samples (PPS) to confirm construction details, followed by Top-of-Production (TOP) samples to review the first items from the production line. Compare these prototypes against your tech pack, checking tolerances (e.g., ±0.5 cm for seams), stitch density, alignment, and symmetry.

Lab testing is another crucial step. Test for shrinkage (AATCC 135/150), colorfastness (ISO 105-C06), and pilling resistance (ISO 12945). For premium fabrics, shrinkage should stay below 3%. If your product includes performance features, evaluate moisture-wicking, seam strength (ASTM D1683), and UV protection (using UPF ratings per AS/NZS 4399 or AATCC 183). Designs with screen prints or heat transfers should undergo adhesion and elasticity tests to ensure they won’t crack or peel after washing.

Don’t forget to clarify the factory’s revision policy, including the number of sample rounds they’ll provide and the timeline for adjustments.

Apply Quality Control Standards

Once prototypes pass testing, layer in quality control measures to catch issues early. Start with inline QC during production to spot defects in cutting, sewing, and decoration before they spread across the entire batch. This approach saves time, reduces waste, and keeps your delivery schedule on track. After at least 80% of the products are packed, conduct a Final Random Inspection to verify size accuracy, labeling, and packaging.

Use AQL (Acceptable Quality Limit) standards to set defect thresholds. For activewear, an AQL of 2.5 is typical for major defects (e.g., open seams), while 4.0 is used for minor ones (e.g., loose threads). Keep in mind, AQL isn’t about perfection – it’s about managing risk.

"Tight QC and clear specs – even on labels and trims – help brands catch costly mistakes before stock reaches retail." – Ninghow

Consider hiring third-party inspectors, such as QIMA or SGS, to validate the quality of your products. Pre-shipment inspections usually cost between $250 and $650 per man-day but can drastically reduce major defect rates. To protect yourself financially, structure payments strategically: pay 30% upfront, 40% against the Bill of Lading, and hold the final 30% until a third-party inspection confirms the quality.

Step 5: Assess Technical Expertise and Innovation

Once you’ve ensured product quality, it’s time to evaluate the factory’s technical expertise and ability to push the boundaries of activewear performance. This step is crucial for distinguishing manufacturers that simply execute instructions from those capable of improving and refining your product. A factory with advanced knowledge of performance fabrics and a forward-thinking approach can help you stay ahead in a market where consumer demands are constantly evolving.

The sportswear industry is projected to grow substantially by 2026, driven by the increasing demand for versatile garments. Today’s consumers want clothing that transitions effortlessly from a morning workout to the office and even to social gatherings in the evening. Factories that understand these expectations can deliver fabrics with exceptional odor control, thermal regulation, and durability for prolonged use.

Fabric Technologies and Customization Options

Seek out factories that work with cutting-edge performance materials, moving beyond basic moisture-wicking polyester. For instance, Phase-Change Materials (PCMs) can absorb and release heat, while hydro-functional polymers like HeiQ Smart Temp activate cooling based on sweat levels. Nanotechnology applications offer enhancements like stain resistance and anti-odor properties. Factories utilizing bio-based spandex, such as Lycra EcoMade, which replaces up to 70% of petroleum-based content with industrial corn-based ingredients, demonstrate a commitment to both performance and eco-conscious manufacturing.

Customization capabilities are another key indicator of technical sophistication. Does the factory offer advanced solutions like 3D body scanning for personalized fits or WHOLEGARMENT 3D knitting for seamless, complex "body mapping" designs? Investigate their decoration techniques – options like sublimation for all-over prints, 3D embroidery, or reflective elements can elevate your designs. Pay attention to their sampling process; a facility that smoothly transitions from digital patterns to physical prototypes and maintains a library of 68+ colors for small-order customization (as low as 400 pieces) demonstrates flexibility and readiness to support emerging brands.

To verify performance claims, request lab tests for UPF ratings, moisture management, water vapor transmission, and durability. Sustainability claims also matter – organic cotton uses about 90% less water than conventional cotton, and one recycled polyester garment can be made from roughly seven recycled plastic bottles. These details help you assess both the factory’s technical capabilities and its environmental impact.

Experience and Track Record in Activewear

Factories with 20+ years of activewear experience should be at the top of your list. This level of expertise minimizes costly errors like crooked seams, uneven shrinkage, or labels that fall off – issues that can lead to return rates as high as 45%. Activewear manufacturing requires precision, from flatlock stitching to consistent performance in compression fabrics and moisture-wicking materials. Only seasoned factories can consistently meet these standards across bulk production.

Look for factories that have passed Independent External Assessments (IEAs) for major brands such as Nike, Adidas, Lululemon, or New Balance. These audits confirm the factory’s ability to meet stringent compliance standards, protecting your brand from potential legal risks. Take New Dong Huang Garment Co., Ltd. as an example: with over 27 years of experience, they have passed brand audits for Nike and New Balance. Their certifications (BSCI, Sedex, GRS) and advanced machinery (bonding machines, laser cutters) underscore their technical depth. Their fabric innovations, including eco-friendly, quick-dry, anti-odor, and anti-UV properties, set a high benchmark for quality and performance.

To further evaluate a factory, request export logs or customs data to confirm shipments to your target market (e.g., the US or EU). Use resources like the National Enterprise Credit Information Publicity System (NECIPS) to verify their legal standing via their Unified Social Credit Code. Before committing to large-scale production, start with a trial order of 500 units to test their systems. Finally, consider using a weighted scoring system: allocate 40% to quality, 30% to ethics, 20% to capacity, and 10% to price. A total score of 85+ indicates a factory worth partnering with.

Conclusion

Evaluating activewear factories in China requires a methodical approach to protect your brand from potential pitfalls. This process involves checking certifications, assessing production capabilities, conducting on-site audits, testing for quality, and reviewing technical expertise. A structured, multi-step vetting process can help identify most red flags before entering into a partnership.

The stakes are high: poor manufacturing can lead to product returns, potentially slashing revenue by up to 45%, while ethical violations can spark media scandals that reduce sales by as much as 60%. With 67% of consumers now factoring in sustainability and ethical practices when purchasing apparel, ensuring a factory meets these standards is essential – not just for quality but for maintaining your brand’s reputation and customer trust.

To make better decisions, consider using a weighted scoring system to minimize bias, and always verify certifications through official databases instead of relying on PDFs alone. Starting with a smaller trial order, such as 500 units, is a practical way to evaluate a factory’s capabilities before committing to larger-scale production.

Investing in third-party audits is a smart move. The cost of such audits is minor compared to the financial risks posed by defective products or compliance violations. Regulatory fines for non-compliance can exceed $100,000 per incident, making thorough due diligence a critical step for financial and legal protection.

Partnering with the right factory ensures consistent product quality, dependable delivery schedules, and ongoing support. At New Dong Huang Garment Co., Ltd. (https://leggingsupplier.com), we prioritize these high standards in activewear manufacturing, delivering reliable quality and long-term value to our brand partners.

FAQs

Which certifications are must-haves for activewear factories in China?

When sourcing activewear from factories in China, certifications play a critical role in ensuring product safety, quality, and ethical practices. Some of the most important certifications to look for include:

- OEKO-TEX Standard 100: This certification guarantees that the materials used are free from harmful substances, ensuring product safety for consumers.

- ISO 9001: Focused on quality management, this standard ensures that the factory maintains consistent production processes and meets customer expectations.

- BSCI and WRAP: These certifications address social compliance, ensuring that the factory adheres to ethical labor practices and operates responsibly.

To avoid potential issues with fake or expired certifications, always verify their authenticity. You can do this through online certification databases or by arranging third-party audits. This step is crucial for maintaining trust and ensuring compliance with industry standards.

How can I spot fake factory certificates or business licenses?

To spot fake factory certificates or licenses, pay attention to warning signs like inconsistent formatting, low-quality printing, or the absence of official seals and signatures. Double-check company information, dates, and the language used to ensure everything aligns correctly. Use official channels or trusted third-party services to verify authenticity. Additionally, arranging for third-party audits can provide extra reassurance. Carefully reviewing these elements can help you steer clear of fraudulent documents.

What should I test in a “golden sample” before bulk production?

Before diving into bulk production, it’s crucial to carefully examine the "golden sample" to ensure it aligns with your quality expectations. Here are the key areas to focus on:

- Workmanship: Check the stitching, seams, and overall construction for any flaws or inconsistencies.

- Materials and colorfastness: Assess the fabric quality, durability, and whether the colors remain consistent and resist fading.

- Fit and measurements: Verify that the sizing is accurate and falls within acceptable tolerances.

- Labeling: Make sure labels provide correct care instructions and content details.

Conducting these evaluations early can help you avoid potential quality issues and unwanted delays in production.