When sourcing activewear fabrics from China, testing standards are non-negotiable. They ensure fabrics meet performance promises like moisture-wicking and breathability, safeguarding your brand and customer trust. Without proper testing, you risk poor-quality materials that fail to regulate temperature, cause discomfort, or lead to shipment disputes over fabric weight.

Key takeaways:

- Testing Standards: Updated Chinese standard GB/T 21655.1-2023 evaluates moisture absorption, wicking, drying, and spreading. Ensure suppliers use this version.

- Testing Risks: Skipping tests can lead to thermoregulation issues, wet fabrics, and customer dissatisfaction.

- Verification: Inspect supplier facilities, confirm adherence to standards, and demand detailed test reports.

- Methods: Key tests include vertical wicking for sweat movement, liquid moisture management for dynamic transfer, and vapor permeability for breathability.

Testing ensures fabrics meet performance needs like quick drying and comfort, making it a critical step in sourcing quality activewear.

Webinar: Measuring the Effects of Moisture Wicking Fabrics and Thermal Effusivity

Fabric Testing Standards in China

Chinese manufacturers follow strict national testing protocols, with GB/T 21655.1-2023 being the latest standard, effective from December 1, 2023. It’s important to confirm that suppliers are using this updated version instead of the older 2008 standard.

The GB/T system is divided into two parts. Part 1 (GB/T 21655.1-2023) employs a composite testing method to evaluate moisture absorption, wicking height, drying rate, and spreading speed. Part 2 (GB/T 21655.2-2019) focuses on dynamic moisture transfer. Knowing which method your supplier uses is crucial to ensure the fabric meets your specific requirements. These two parts provide a comprehensive framework for analyzing various fabric performance metrics.

GB/T 21655.1-2023 Testing Parameters

The GB/T 21655.1-2023 standard takes a composite approach, combining several measurements into a single performance grade. It evaluates fabrics based on moisture absorption, wicking height, drying rate, and spreading speed. Unlike some international standards, this method offers a more holistic view of how a fabric will perform under active conditions.

The testing process looks at how quickly moisture rises through the fabric (wicking height), how fast it spreads across the surface (spreading speed), and how efficiently it evaporates (drying rate). To earn the "moisture absorption and quick-drying" classification, a fabric must perform well across all these parameters – not just excel in one while underperforming in others.

Chinese vs. International Standards

While Chinese standards often align with international ones, there are notable differences. For example, both GB/T 21655.1 and AATCC 197 measure vertical wicking, but they interpret the data differently. GB/T 21655.1 integrates wicking height into a broader multi-metric grade, whereas AATCC 197 evaluates wicking height as a standalone measurement.

When it comes to dynamic moisture testing, GB/T 21655.2-2019 parallels AATCC TM195 by using a Moisture Management Tester (MMT). However, the Chinese standard includes specific technical requirements, such as applying a test solution of 0.22 ± 0.01 g within 20 ± 1 seconds and fixing the upper sensor assembly at 1,000 ± 15 g. These precise conditions can lead to different results compared to other methods, making it essential to understand the nuances of each standard before comparing GB/T data with AATCC or ISO results.

If you’re targeting the U.S. market, it’s a good idea to request both GB/T and AATCC test results to ensure compliance with local standards.

Moisture-Wicking Testing Methods

Testing methods are crucial for verifying how fabrics perform in real-world conditions. In Chinese manufacturing, three primary methods are used to assess how well activewear handles sweat.

Vertical Wicking Tests

Vertical wicking tests measure how far moisture travels up a fabric strip over time. To perform this test, the fabric is suspended vertically with its lower edge in contact with a colored water solution. The distance the liquid rises through capillary action is recorded. This method gauges a garment’s ability to pull sweat away from the skin during physical activity. While it’s part of the GB/T 21655 standards, it only measures upward liquid movement and doesn’t account for how moisture spreads or dries across the fabric. Though limited in scope, this test serves as a starting point for more comprehensive evaluations.

Liquid Moisture Management Testing

Liquid moisture management testing takes a more dynamic approach by using sensors to track how moisture moves. This test involves an upper sensor (1,000 ± 15 grams) and a water module that delivers 0.22 ± 0.01 grams of liquid in 20 ± 1 seconds. Sensors on both sides of the fabric measure key factors like wetting time, absorption speed, maximum wetting radius, spreading speed, and overall one-way transport capacity. These metrics show how effectively sweat moves from the inner layer to the outer layer, where it can evaporate. The data is captured at a frequency of at least 10 Hz, ensuring precise tracking of moisture dynamics.

Water Vapor Permeability Testing

Water vapor permeability testing focuses on breathability, assessing how easily moisture escapes as vapor under controlled conditions. This test complements liquid-based methods by ensuring that fabrics not only wick liquid sweat but also allow water vapor to pass through. Without good vapor permeability, wearers may experience a damp, clammy sensation, even if the fabric manages liquid sweat well. For activewear targeting the U.S. market, combining tests for absorbency, wicking, quick-drying, and breathability provides a complete understanding of fabric performance and comfort.

How to Verify Manufacturer Testing Capabilities

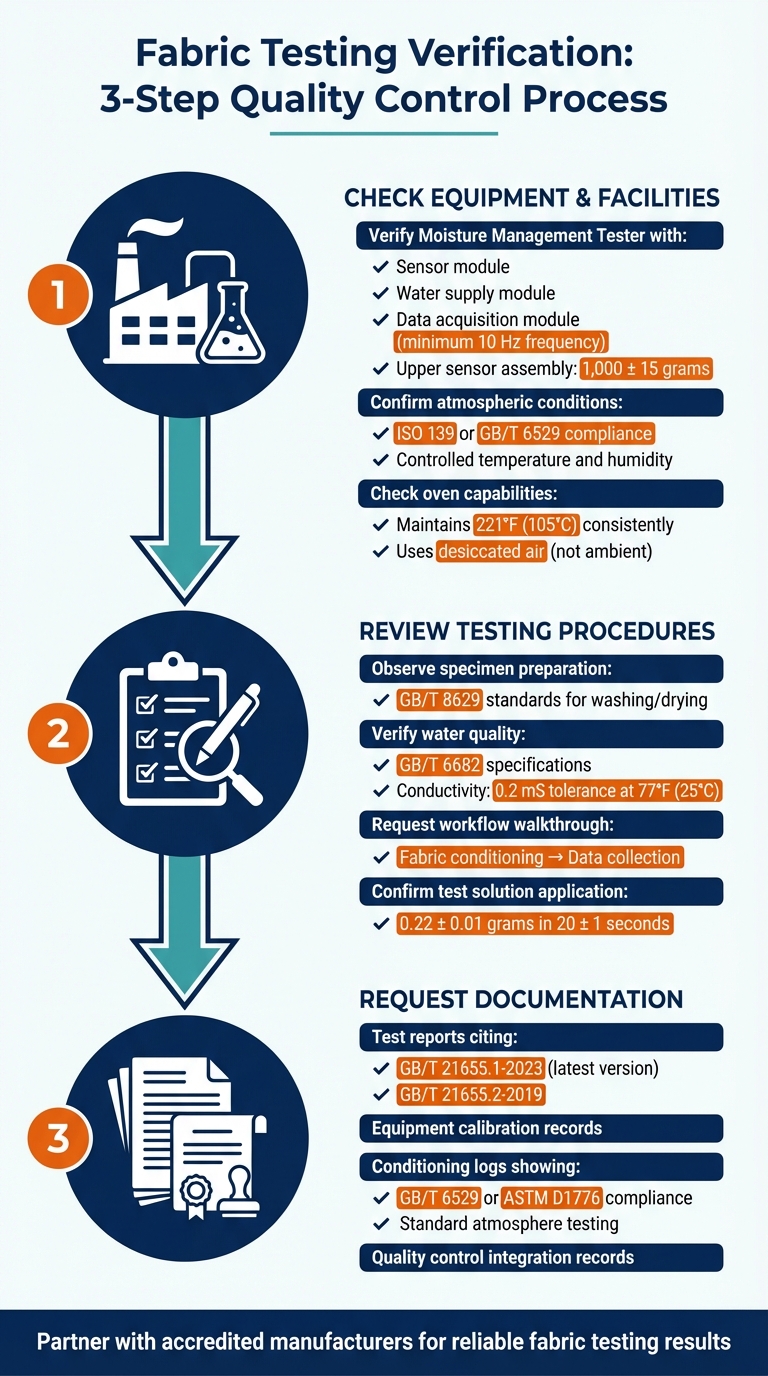

Complete Fabric Testing Verification Process for China Sourcing

Ensuring that your supplier has the right equipment and expertise for accurate testing is crucial. This process guarantees you receive dependable data and maintain the high standards expected in the U.S. market. Here’s a step-by-step guide to help you verify your supplier’s testing capabilities.

Check Equipment and Facilities

Start by inspecting the testing equipment during a visit to the manufacturer’s facility. The machinery should meet the technical requirements outlined in GB/T 21655.2-2019. Additionally, confirm that the facility adheres to standard atmospheric conditions as per ISO 139 or GB/T 6529 standards. Proper temperature and humidity control are critical to ensure fibers reach moisture equilibrium before testing begins. For moisture content tests, verify that the ovens can consistently maintain a temperature of 221°F (105°C). Using ambient air instead of desiccated air can result in residual moisture errors of 1% or more, so this detail is essential.

Review Testing Procedures

Observe the manufacturer’s testing procedures to ensure accuracy and adherence to proper protocols. Pay attention to how specimens are prepared and sampled, ensuring the process aligns with the GB/T 8629 standards for domestic washing and drying. Confirm that the facility uses laboratory-grade water that meets GB/T 6682 specifications, with the test solution’s conductivity held within a tolerance of 0.2 mS at 77°F (25°C). Request a detailed walkthrough of the entire testing workflow – from fabric conditioning to data collection – to identify any procedural gaps. Following proper procedures ensures reliable test results and supports the overall quality of the fabric.

Request Documentation

Thorough documentation is a hallmark of professional testing. Ask for test reports that reference current standards and request equipment calibration records to verify that all apparatus meet the required tolerances. Conditioning logs should confirm that samples were tested in controlled environments, following GB/T 6529 or ASTM D1776 standards. These records are vital for integrating testing into broader quality control measures for activewear sourcing.

Manufacturers that prioritize advanced equipment, precise testing protocols, and comprehensive documentation set the benchmark for fabric quality. For instance, New Dong Huang Garment Co., Ltd. (https://leggingsupplier.com) is well-regarded for its rigorous testing capabilities and strong commitment to quality control, making it an excellent example to follow when verifying fabric testing standards.

sbb-itb-8dbc09a

How to Interpret Test Results

Understanding Fabric Performance Grades

Once you’ve received the test results from your manufacturer, the next step is figuring out what the data actually means. The GB/T 21655.1-2023 standard evaluates fabrics using a grading system focused on three key areas: absorption rate (for both inner and outer surfaces), one-way transportation capability (how well moisture moves from the skin-side to the outer-side), and spreading/drying rate. Together, these metrics paint a clear picture of how effectively a fabric manages moisture during physical activity.

A critical component of this analysis is the Overall Moisture Management Capability (OMMC) index, which includes the Accumulative One-Way Transport Capacity (O). This composite score measures how efficiently a fabric moves moisture away from the skin. For high-performance activewear like running gear or HIIT clothing, a high "O" value is essential – it helps prevent that unpleasant "cold and clammy" feeling caused by sweat lingering on the skin.

When reviewing your test reports, make sure all five core metrics are included: Wetting Time (T), Absorption Speed (A), Maximum Wetting Radius (R), Spreading Speed (S), and One-Way Transport (O). If any of these are missing, it’s a red flag that the testing might be incomplete. Also, confirm that the report cites the latest standards – GB/T 21655.1-2023 for comprehensive testing or GB/T 21655.2-2019 for dynamic moisture transfer – rather than outdated versions from 2008 or 2009. Additionally, check that the samples were conditioned according to GB/T 6529 standards to ensure moisture equilibrium before testing. With a solid understanding of these performance grades, you’ll be better equipped to compare fabrics and choose the right one for your product.

Comparing Fabrics

Once you’ve got the performance data, the next step is comparing fabrics to see how they stack up against your product’s needs. For high-intensity activities, fabrics with shorter Wetting Times and higher One-Way Transport scores are the clear winners – they do a better job of keeping sweat off the skin compared to materials that simply absorb moisture. A fabric that absorbs well but lacks strong one-way transport can leave sweat trapped, leading to discomfort during prolonged wear.

Focus on fabrics with higher One-Way Transport and Spreading Speed values, as these ensure faster evaporation and better overall moisture management. Synthetic blends like polyester or nylon are great options – they’re naturally hydrophobic and resist saturation much better than untreated cotton. Keep in mind, though, effective moisture management isn’t just about excelling in one area. You’ll want a fabric that balances absorption, wicking, and quick-dry properties to perform well in real-world conditions.

Even small deviations in testing protocols can undermine the reliability of the results, which could lead to poor sourcing decisions. These technical details might seem minor, but they play a big role in ensuring your fabric comparisons are accurate and aligned with your product’s goals.

Quality Control Checklist for Fabric Testing

Pre-Sourcing Preparations

Before choosing a supplier, make sure to outline your technical requirements clearly. These might include details like fiber type, mass per unit area, and specific design features. It’s also a good idea to request preliminary test reports from potential suppliers. These reports should cover key metrics such as wetting time, absorption speed, and one-way transport capacity, helping you verify their claims before committing to an order.

Determine which standards apply to your product. For moisture management, refer to GB/T 21655.2. Also, ensure that conditioning requirements are explicitly defined – testing should be conducted in a standard atmosphere as specified by GB/T 6529. If you plan to conduct acceptance testing, set up laboratory bias protocols in advance. According to ASTM D2654:

the purchaser and the supplier shall conduct comparative tests to determine if there is a statistical bias between their laboratories.

This step can help avoid disagreements later if test results differ.

On-Site Inspections

Once your technical specifications are in place, visit the supplier’s facility to confirm their testing capabilities. An on-site inspection allows you to evaluate whether their equipment and processes meet your requirements. Specifically, check for a Tester for liquid moisture transfer properties equipped with a sensor module, water supply module, and data acquisition module. The upper sensor assembly should weigh 1,000 ± 15 grams, and the data acquisition frequency must be at least 10 Hz to ensure accurate measurement of moisture transfer dynamics.

Ask for a live demonstration of the GB/T 21655.2 test. Pay attention to how they calculate wetting time and ensure that the test solution’s conductivity stays within a tolerance of 0.2 mS at 77°F (25°C). Review calibration logs to confirm compliance with GB/T 21655.2 standards. Additionally, verify that the water used for testing adheres to GB/T 6682 specifications for analytical laboratory use. Environmental conditions are equally important – testing must occur in a controlled atmosphere to prevent inaccurate results caused by fluctuations in humidity or temperature.

Post-Sourcing Verification

After confirming the supplier’s capabilities and receiving the shipment, conduct thorough testing to ensure the fabric meets your standards. Never assume that everything is in order just because the shipment has arrived. Request detailed test reports that cover all key performance metrics. These reports should also include technical details like fiber content and mass per unit area. If you’re working with finished products, ask for measurement tables tailored to fit testing to guarantee size consistency.

If discrepancies arise in test results, compare data from different labs. ASTM D2654 recommends using a student’s t-test for unpaired data to identify any statistical bias between laboratories. Also, confirm that test reports specify the testing atmosphere. For example, Procedure 2 of ASTM D2654-22 requires using air from a standard atmosphere for textile testing at 221°F (105°C). To further ensure quality and safety, look for third-party certifications like OEKO-TEX or Intertek High-Performance Marks.

Conclusion

A well-structured approach to fabric testing is essential for ensuring quality control, safeguarding your brand, and meeting customer expectations. By incorporating the updated GB/T 21655.2-2019 standard, you can effectively evaluate key factors like absorption, one-way moisture transport, and drying rates. Comparing these results with international benchmarks such as AATCC 195 adds another layer of reliability.

Thorough testing ensures critical performance features like heat balance, efficient moisture transfer, and quick drying. These attributes not only enhance comfort but also help prevent issues like skin irritation and discomfort during intense physical activities.

To achieve accurate and trustworthy results, partner with accredited third-party labs such as Intertek. Request detailed test reports that include metrics like wetting time (T), absorption speed (A), maximum wetting radius (R), spreading speed (S), and accumulative one-way transport capacity (O). It’s also important to confirm that manufacturers follow the latest standards and conduct tests under controlled conditions, as outlined in GB/T 6529.

FAQs

How does China’s GB/T 21655.1-2023 fabric testing standard compare to international standards like ISO or ASTM?

GB/T 21655.1-2023 serves as China’s national standard for assessing fabric absorption and quick-drying capabilities. While it aligns in some ways with international standards like ISO and ASTM, it’s specifically designed to fit the needs of the Chinese market and local manufacturing processes.

This standard provides guidelines for evaluating moisture-wicking and quick-drying properties. However, the exact differences in testing methods, criteria, or parameters compared to ISO or ASTM standards aren’t widely documented. If your brand sources fabrics from China, it’s crucial to ensure the test results align with the performance expectations of your target market.

How can I confirm my supplier is following the latest GB/T 21655.1-2023 fabric testing standard?

To confirm your supplier is adhering to the GB/T 21655.1-2023 standard, ask for a detailed test report that specifically mentions this version. Cross-check the details in the report against the official 2023 standard to ensure everything aligns. If you’re uncertain, reach out to a reliable testing organization or certification body for additional verification.

Why should GB/T and AATCC test results be used together for fabrics in the U.S. market?

Combining GB/T and AATCC test results ensures your fabric meets both Chinese standards and U.S. market expectations for moisture management and breathability. GB/T tests focus on moisture-wicking properties as outlined by Chinese guidelines, while AATCC results reflect testing methods widely recognized in the United States.

Using both approaches helps you build a comprehensive performance profile, ensuring compliance, boosting product quality, and increasing acceptance in the U.S. market.