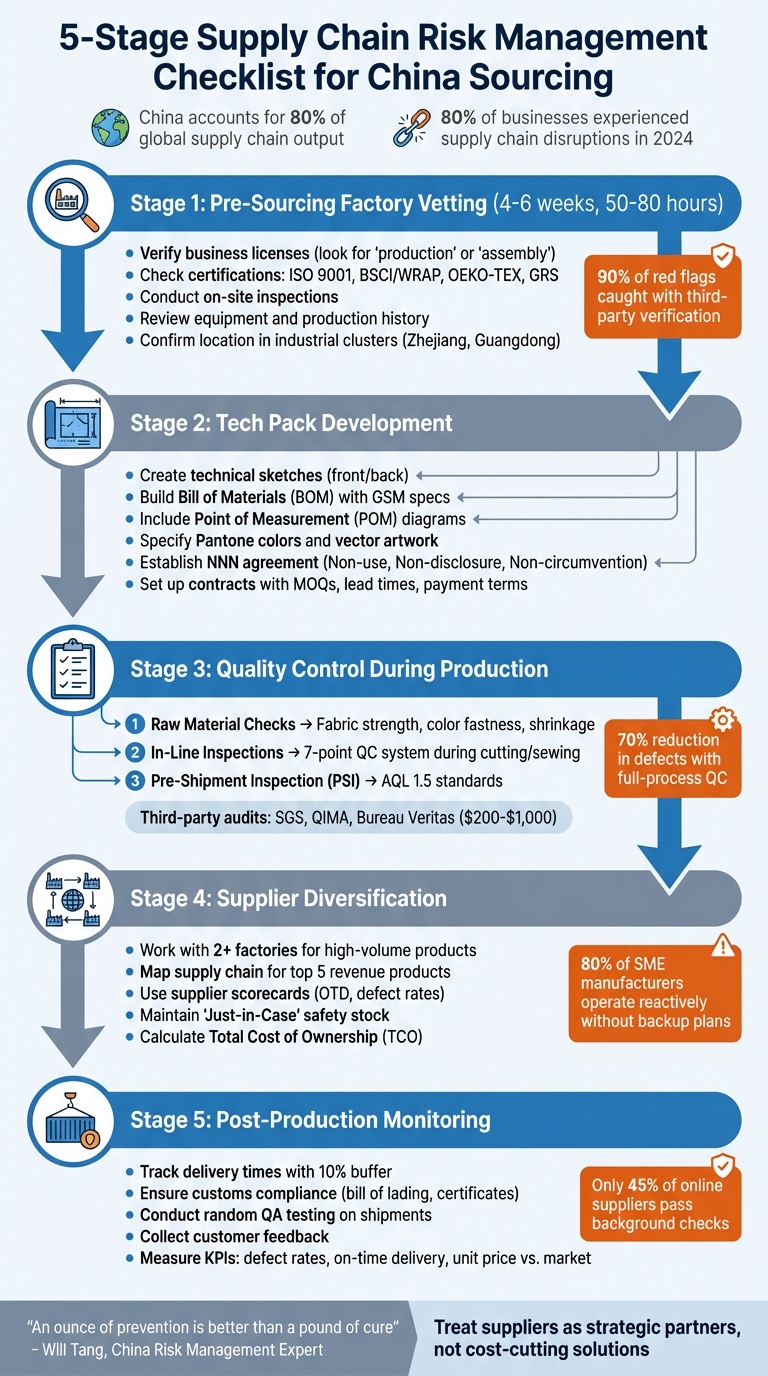

Sourcing from China is crucial for many businesses, with the country accounting for 80% of global supply chain output. However, this reliance brings challenges like quality inconsistencies, production delays, and compliance risks. Here’s a quick guide to reduce these risks:

- Factory Vetting: Verify business licenses, check certifications (e.g., ISO 9001, WRAP), and conduct on-site inspections.

- Tech Pack Preparation: Provide detailed specifications, including materials, measurements, and quality standards.

- Quality Control: Inspect at multiple production stages and use third-party audits for unbiased reviews.

- Supplier Diversification: Work with multiple factories and maintain safety stock to avoid disruptions.

- Post-Production Monitoring: Track delivery timelines, ensure customs compliance, and gather customer feedback.

5-Stage Supply Chain Risk Management Checklist for China Sourcing

The China +1 Strategy Explained: Reduce Supply Chain Risk & Cut Costs

Pre-Sourcing: How to Vet and Select Factories

Vetting factories is a critical step to minimize risks. The process can take anywhere from 50 to 80 hours over a span of 4 to 6 weeks. James Kennemer, Founder of Cosmo Sourcing, stresses its importance:

"Your choice of manufacturing partner will determine whether your product succeeds or fails – it’s that simple."

To begin, it’s essential to distinguish between genuine manufacturers and trading companies masquerading as factories. Start by examining the business license for terms like "production" or "assembly", which indicate actual manufacturing rather than distribution. Request a VAT invoice to confirm the factory’s legitimacy, and use satellite imagery to verify the location of the registered address. These steps help ensure you’re dealing with a reliable partner.

Check Certifications and Compliance Standards

Certifications play a key role in confirming that a factory meets U.S. regulatory and ethical requirements. For activewear, specific certifications cover quality, labor practices, chemical safety, and sustainability.

| Certification Type | Specific Standard | Relevance to Activewear |

|---|---|---|

| Quality | ISO 9001 | Ensures consistent production quality and effective management |

| Ethical/Social | BSCI / Sedex / WRAP | Confirms fair labor practices expected by U.S. retailers |

| Chemical Safety | OEKO-TEX Standard 100 | Critical for garments that come into prolonged contact with skin |

| Sustainability | GRS | Verifies recycled content in materials like polyester or nylon |

Always confirm certifications directly with issuing organizations such as ISO, Intertek, or SGS to ensure their validity, scope, and current status. Additionally, for U.S. imports, make sure the factory complies with the Uyghur Forced Labor Prevention Act by meeting U.S. Customs and Border Protection requirements.

Review Factory Background and Production History

A factory’s track record offers valuable insights into its reliability and quality. Use third-party audit reports (e.g., BSCI, Sedex, ISO 9001) and client references, especially from businesses in your industry, to assess consistency.

During on-site visits, gather information such as an equipment list and photos of the production floor. For activewear, check for specialized machinery like flatlock stitching machines. Observe the worker-to-machine ratio and ensure production areas are active during peak times to rule out non-operational facilities. Additionally, review the factory’s internal defect logs and procedures for managing rejected products to evaluate their commitment to quality control.

Pay close attention to Minimum Order Quantities (MOQs). Genuine manufacturers typically set higher MOQs to account for setup costs, while unusually low MOQs may signal that the supplier is a middleman rather than a manufacturer. These steps help secure consistent production and reduce the chances of supply chain disruptions.

Assess Location and Industry-Specific Risks

A factory’s location can reveal potential risks and advantages. In China, manufacturing is often concentrated in industrial clusters, with specific regions specializing in certain products. For example, Zhejiang and Guangdong provinces are known hubs for textiles. Factories in these areas often benefit from strong local supply chains and efficient logistics. On the other hand, if a supplier’s location is far from a recognized industrial cluster for its product type, it might indicate the business is a trading company rather than a direct manufacturer.

Use the National Enterprise Credit Information Publicity System to confirm the factory’s business license and its scope of operations. During site visits, assess factors like lighting, ventilation, and worker safety gear. Ask about employee tenure and turnover rates to gauge labor stability. Also, verify whether the factory handles shipping in-house or relies on reputable third-party logistics providers.

In Chinese business culture, the concept of "saving face" can sometimes lead suppliers to accept orders they aren’t fully equipped to handle. To get a clearer picture of operations, conduct both scheduled and surprise visits to observe daily activities and working conditions firsthand.

Tech Pack Development and Communication Standards

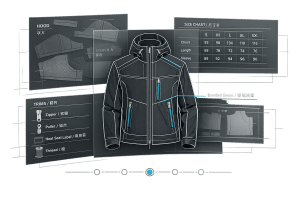

A tech pack serves as the foundation for your entire production process. It’s essentially the guide that ensures your garment is produced exactly as intended. As Techpacker explains, "Consider the tech pack as a ‘blueprint’ for the manufacturer on how to produce your garment". Below, we’ll cover the key elements every tech pack should include and the communication practices essential for smooth collaboration.

Build Complete Tech Packs

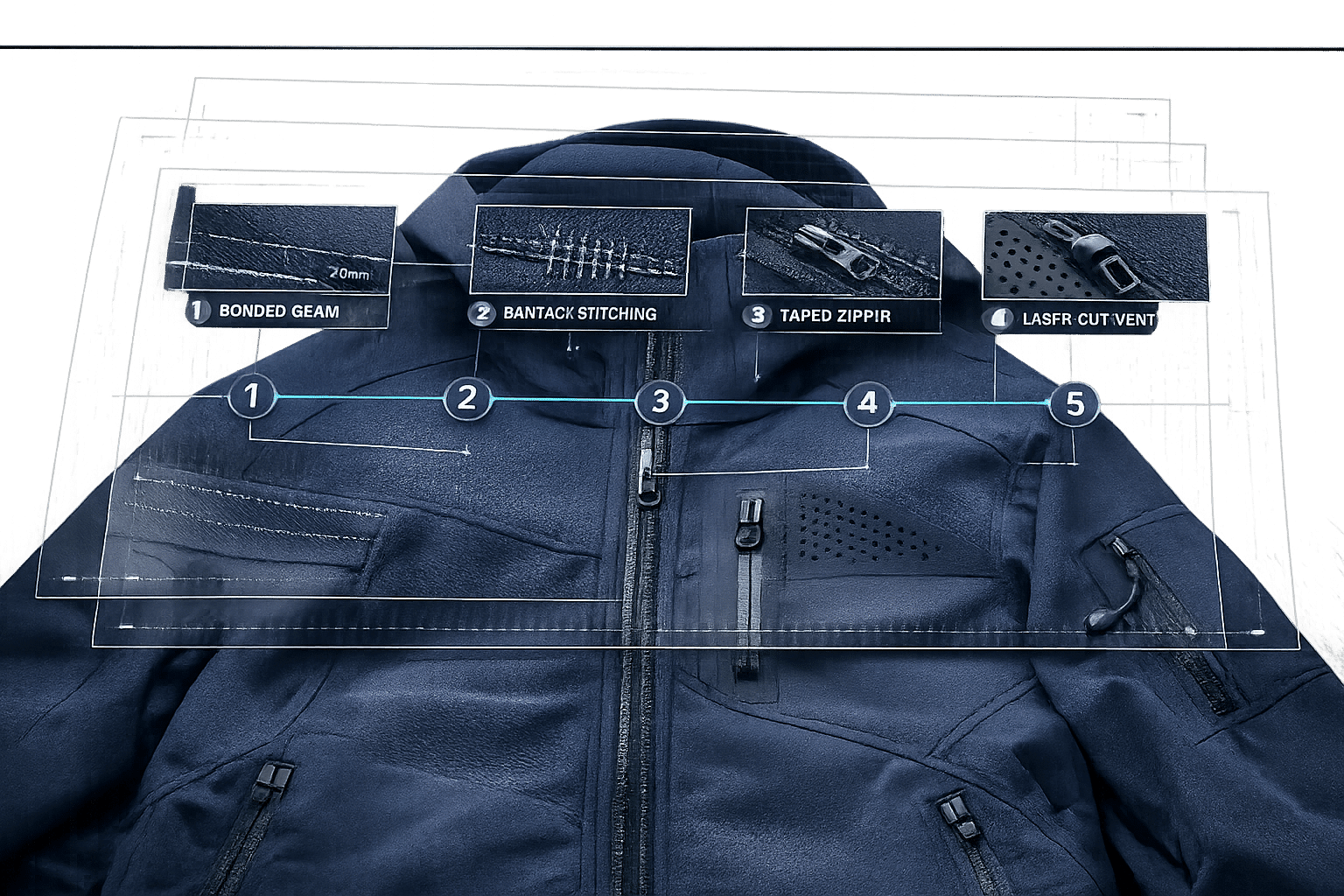

A complete tech pack includes everything your manufacturer needs to know. Start with front and back technical sketches, clearly marking construction details like seam lines and hardware placement. For activewear, highlight specific stitching methods, such as flatlock seams, which are crucial for comfort and durability.

Add a Bill of Materials (BOM) that lists every component: fabrics (with GSM specifications), linings, threads, zippers, buttons, and labels. Precise measurement sheets are a must, detailing dimensions for all sizes. Include Point of Measurement (POM) diagrams, with arrows showing exactly where each measurement should be taken to avoid any misunderstandings. For artwork – whether it’s prints, embroidery, or labels – provide vector files for accuracy.

Colorways should be specified using Pantone references, and digital or physical swatches for trims should accompany them. Your tech pack will also serve as the reference for quality control, with inspectors comparing finished garments directly against these specifications. To protect your designs, establish a China-specific NNN agreement (Non-use, Non-disclosure, and Non-circumvention) before sharing the tech pack.

Set Up Contracts and Communication Systems

Once your tech pack is ready, ensure your contracts align with its specifications. These agreements should detail MOQs, lead times, payment terms, penalties for delays or quality issues, and tolerances (e.g., ±0.4 inches) based on the tech pack. Verify that the supplier’s bank account beneficiary name matches their business license to avoid any financial discrepancies.

Establish clear communication channels early on. In China, WeChat is the go-to platform for real-time updates, but keep formal email records for critical decisions. Set a consistent check-in schedule – weekly production updates and monthly video calls typically work well. Assign dedicated points of contact on both sides to streamline communication. Use short sentences, bullet points, and visuals in written communication to overcome language barriers. For more technical discussions, partnering with bilingual sourcing agents can be invaluable.

Finally, the "golden sample" (pre-production sample) approved from your tech pack becomes the standard for the entire production run. Make sure all parties agree on it before moving forward with mass production.

Quality Control During Production

Ensuring quality during production is essential to prevent expensive mistakes. By building on detailed tech packs, you can implement a system of thorough, step-by-step inspections. Catching defects early can save significant costs. Instead of waiting until the end, inspect products at various stages of production to minimize surprises.

Inspections at Key Production Stages

Quality control works best when applied at three critical points:

- Raw Material Checks: Inspect materials as they arrive to assess fabric strength, color fastness, and shrinkage.

- In-Line Inspections: During cutting, sewing, and finishing, use a 7-point quality control system to identify issues like misaligned seams or broken stitches as they occur. Addressing problems immediately prevents them from escalating.

- Pre-Shipment Inspections (PSI): Before shipping, conduct inspections using AQL 1.5 standards to evaluate visual quality, functionality, labeling, and packaging. Additionally, oversee container loading to confirm the correct quantities and ensure packaging (e.g., hang tags, polybags, and boxes) meets your requirements.

These steps create a foundation for unbiased testing by external parties.

Third-Party Testing and Audits

While internal inspections are vital, external audits provide an extra layer of assurance. Factory teams may overlook or even conceal issues, but hiring independent auditors from trusted firms like SGS, QIMA, or Bureau Veritas ensures an impartial review. These audits can uncover up to 90% of supplier red flags before committing to large orders.

"Third-party verification via ISO 9001 or WRAP certification… catches 90% of red flags before you commit."

- Elaine Zhou, Business Director, Shanghai Fumao

Third-party audits cover several critical areas:

- Technical Capabilities: This includes equipment maintenance and employee training.

- Social Compliance: Auditors check for adherence to labor policies, fair working hours, and ethical practices.

- Environmental Standards: Reviews focus on chemical safety, waste management, and certifications like OEKO-TEX.

Costs for factory audits in major Chinese manufacturing hubs range from $200 to $398 per man-day, while more detailed audits by SGS may exceed $1,000. For long-term partnerships, consider performing quarterly surprise audits to prevent "quality fade", where suppliers may gradually reduce standards after initial orders.

sbb-itb-8dbc09a

Reduce Risks Through Supplier Diversification and Backup Plans

Relying on a single factory for production can be risky. Did you know that 80% of small to medium-sized manufacturers operate reactively, without proactive contingency plans in place?. The key to mitigating these risks lies in diversifying your suppliers and maintaining inventory buffers.

Work with Multiple Suppliers

A multi-sourcing strategy is a smart way to shield your business from production interruptions. For high-volume products like leggings or sports bras, it’s wise to partner with at least two factories capable of meeting your specifications. For lower-volume specialty items, you can work with fewer suppliers, as long as they’re flexible and quick to adapt.

Start by mapping your supply chain. Use a bill of materials for your top five revenue-generating products to identify all component and raw material suppliers. This will help you uncover hidden dependencies. For instance, if three different factories rely on the same mill for moisture-wicking fabric, your supply chain isn’t as diversified as it might seem.

To ensure the reliability of your suppliers, revisit earlier vetting guidelines. Double-check that the beneficiary name on bank accounts matches the company name on the business license to avoid payment fraud. Use supplier scorecards to track Key Performance Indicators (KPIs) like On-Time Delivery (OTD) and quality defect rates. This data will help you decide which suppliers are worth continuing to work with.

Once you’ve built a diversified supplier network, the next step is to strengthen your supply chain with effective inventory planning.

Maintain Safety Stock Levels

The traditional Just-in-Time (JIT) inventory model focuses on cutting costs but can leave your business vulnerable during global disruptions. A more resilient approach is "Just-in-Case" inventory management. This doesn’t mean stockpiling excessive inventory – it’s about finding the right balance.

For predictable, lower-cost items like basic tank tops or accessories, decentralize inventory by keeping stock closer to production or distribution points. For high-value, less predictable items like technical jackets with specialized fabrics, centralize inventory in a controlled primary location and maintain adequate buffers. When setting safety stock levels, consider factors like shipping delays, sample approval timelines, and unexpected production hiccups.

"Resilience means being proactive about understanding and anticipating all kinds of inevitable change and putting in place the strategies and tactics that allow a company to be both stable and agile at the same time."

- Jennifer Rosa, NIST

When making inventory decisions, focus on the Total Cost of Ownership (TCO) instead of just looking at per-unit pricing. Factor in freight costs, tariffs, and the potential expenses tied to stockouts or production delays. Conduct regular stock audits to catch discrepancies early and keep your inventory on track.

Post-Production Risk Management

Getting products manufactured is just one part of the equation; ensuring they arrive on time and meet compliance standards is the other. The steps outlined here build on earlier factory evaluations and in-production quality checks, forming a comprehensive approach to risk management.

Track Delivery Times and Customs Requirements

Timely deliveries hinge on accurate customs documentation. For shipments originating from China, you’ll need standard paperwork like a bill of lading, invoice, shipping list, customs declaration, insurance policy, and sales contract. Depending on the type of product, additional certifications – such as import quota certificates, import licenses, or inspection certificates – may be required.

Make sure to confirm facility registration ahead of time, particularly if you’re sourcing technical fabrics or materials subject to regulatory scrutiny. According to the General Administration of Customs of China (GACC), certain industries require facilities to be registered before shipping. The International Trade Administration emphasizes this point:

"Facilities and establishments are strongly encouraged to verify that all facility and product registration information is complete and correct prior to shipping product to China".

To stay on top of logistics, create a tracking sheet that records shipment dates, locations, and handlers. Incorporate this information into a development calendar, allowing for a 10% buffer to account for potential delays. This proactive approach helps identify bottlenecks early. Just as technical specifications are crucial during production, monitoring delays and customs documentation is equally critical in the post-production phase.

Before shipments leave the warehouse, conduct an audit to ensure accurate labeling and compliance with packaging standards. Also, verify whether logistics are handled internally or through third-party providers, as this can impact accountability.

Once logistical standards are confirmed, attention should shift to gathering customer insights post-delivery.

Collect and Review Customer Feedback

Customer feedback acts as an early detection system for production flaws. Ask your manufacturer upfront about their process for handling quality issues discovered after delivery. Their response will reveal whether they take responsibility for their work or avoid accountability when problems arise.

To establish a quality baseline, conduct random QA testing on initial shipments. This allows you to compare customer complaints – such as defects or material failures – against your own shipment samples and production records.

Keep a close eye on how responsive your supplier is during the post-production phase. If they go silent or take days to respond after a shipment, that could indicate deeper issues. Poor communication at this stage often signals broader problems that could affect future orders.

The next step is to quantify this feedback to evaluate your supplier’s reliability.

Measure Supply Chain Performance After Implementation

To assess performance, track key metrics like defect rates, lead times, and delivery adherence. Compare the unit prices you’re paying with market prices in China to identify potential cost-saving opportunities.

| Metric Category | Specific KPI to Track | Purpose |

|---|---|---|

| Quality | Defect Rate / Rejection Log | Pinpoint production flaws and material issues |

| Cost | Unit Price vs. Market Price | Evaluate vendor pricing competitiveness |

| Reliability | On-Time Delivery Rate | Ensure supply chain stability |

| Responsiveness | Communication Lead Time | Measure factory support efficiency |

Assuming that a supplier will maintain consistent standards after approval can be risky. As China risk management expert Will Tang warns:

"If you assume that once a Chinese vendor has been approved they will continue to deliver to the same standard, you are asking for trouble".

To avoid this, conduct regular audits that are independent of your purchasing department. This helps detect any decline in quality before it impacts your customers.

Conclusion: Main Points for Managing Supply Chain Risks

Effectively managing supply chain risks in China requires careful attention at every stage – from pre-order evaluations to post-delivery assessments. The steps outlined here – ranging from initial vetting to ongoing performance monitoring – serve as a protective framework against disruptions, quality issues, and financial setbacks.

In 2024, more than 80% of global businesses experienced supply chain disruptions, and only 45% of suppliers sourced online passed background checks. Additionally, implementing full-process quality control measures can reduce defects by as much as 70%. As Will Tang, a China risk management expert, wisely notes:

"An ounce of prevention is better than a pound of cure".

These statistics underscore the importance of maintaining rigorous standards throughout every stage of production. For activewear brands, this means prioritizing technical accuracy with detailed tech packs and stringent quality controls. Suppliers must have specialized equipment, like flatlock stitching machines, and expertise in performance fabric testing for factors such as shrinkage, colorfastness, and seam strength. Generic manufacturers often fall short of meeting the high standards required for activewear production.

A partnership with New Dong Huang Garment Co., Ltd. addresses these challenges head-on. With 27 years of experience in activewear manufacturing, advanced technologies like bonding and laser cutting, and certifications such as BSCI, Sedex, and GRS, they bring reliability and expertise to the table. Their commitment to precision and quality makes them a valuable sourcing partner for brands aiming to mitigate risks and maintain high standards.

The key takeaway? Treat your suppliers as strategic partners, not just cost-cutting solutions. Build trust through on-site visits, maintain backup options to diversify risk, and remember that initial vetting is only the beginning. Regular audits, clear communication, and consistent performance tracking transform reactive risk management into a proactive strategy. By following these practices, your brand can secure a stronger, more competitive position in the market.

FAQs

What steps should I follow to evaluate a factory in China?

Evaluating a factory in China takes careful preparation to ensure you’re working with a reliable and compliant manufacturer. The first step is to verify the factory’s business license and legal registration. This ensures you’re dealing with an actual manufacturer and not a middleman. Take the time to review official documents, and if possible, conduct a site visit to confirm their legitimacy.

The next step is to assess the factory’s manufacturing capabilities and quality control processes. A factory audit is a great way to get a closer look at their facilities, equipment, and whether they follow international standards. Don’t skip the step of reviewing product samples and testing for production consistency – this is critical to making sure their output aligns with your specific needs.

Lastly, perform thorough due diligence. Check references from other clients and set up ongoing quality assessments to monitor their performance over time. This well-rounded approach helps reduce risks and lays the foundation for a reliable partnership in your supply chain.

What are the benefits of using a tech pack when working with Chinese manufacturers?

A tech pack is a crucial document when working with Chinese manufacturers. Think of it as a comprehensive blueprint that lays out every detail of your product’s design and production requirements. It includes everything from specifications and materials to measurements and construction details. By consolidating all this information into one place, a tech pack helps eliminate confusion and significantly reduces the chances of mistakes.

Beyond just clarity, a tech pack simplifies the production process by setting clear expectations right from the start. This means fewer back-and-forth questions, saving you time and ensuring the manufacturer can meet your quality standards. In short, it’s a vital tool for smoother, more efficient collaboration.

Why is it important to work with multiple suppliers to reduce supply chain risks?

Relying on just one supplier or region can put your business at serious risk. Unexpected issues like factory shutdowns, shipping delays, or geopolitical problems can throw a wrench in your operations. But by partnering with multiple suppliers spread across different regions, you can safeguard your business against these disruptions and keep things running smoothly, even if one supplier faces challenges.

Expanding your supplier network doesn’t just reduce risks – it also opens the door to more flexibility, stronger negotiating power, and better quality control. It prevents over-reliance on a single source and shields your supply chain from economic or political issues in a specific region. To keep your supply chain dependable and strong, make it a priority to regularly audit and monitor your suppliers.