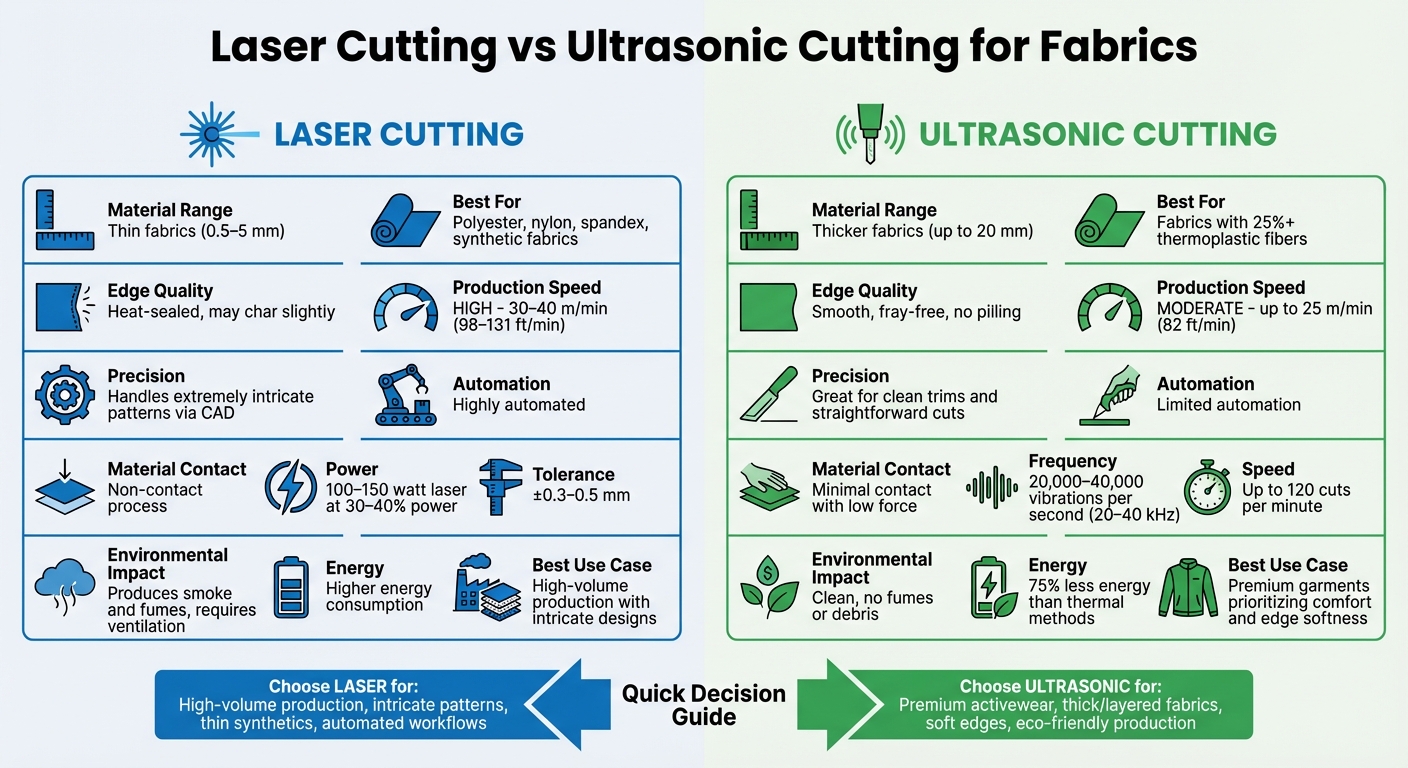

When deciding between laser cutting and ultrasonic cutting for fabric production, the choice boils down to your material, design needs, and production priorities. Here’s a quick breakdown:

- Laser Cutting: Best for thin synthetic fabrics (0.5–5 mm) like polyester and nylon. It seals edges with heat, prevents fraying, and excels at intricate patterns. High-speed automation (30–40 m/min) makes it ideal for large-scale production. However, it can cause minor charring and requires ventilation for fumes.

- Ultrasonic Cutting: Suited for thicker or uneven fabrics (up to 20 mm) with at least 25% thermoplastic fibers. It creates smooth, fray-free edges and is gentler on the fabric, making it perfect for comfort-focused garments. While slower and less automated, it’s cleaner and more energy-efficient.

Quick Comparison

| Feature | Laser Cutting | Ultrasonic Cutting |

|---|---|---|

| Material Range | Thin fabrics (0.5–5 mm) | Thicker fabrics (up to 20 mm) |

| Edge Quality | Heat-sealed, may char slightly | Smooth, fray-free |

| Production Speed | High (30–40 m/min) | Moderate (up to 25 m/min) |

| Precision | Handles detailed designs | Great for clean trims |

| Automation | Highly automated | Limited automation |

| Environmental Impact | Produces smoke and fumes | Clean, no fumes |

For high-volume, intricate designs, laser cutting is the way to go. For premium garments prioritizing comfort and edge softness, ultrasonic cutting is the better fit.

Laser Cutting vs Ultrasonic Cutting for Fabrics: Complete Comparison Chart

How Laser Cutting Works for Fabrics

Laser Cutting Process and Principles

Laser cutting involves directing a focused, high-power CO₂ laser beam onto a fabric, creating a fine dot about 1–2 mm in diameter. This concentrated energy either vaporizes or melts the material along a programmed path, which is designed using CAD/CAM systems. Since the process is non-contact, there’s no physical tool touching the fabric. This eliminates mechanical stress and avoids tool wear entirely.

To ensure precision, a high-speed coaxial airflow – using gases like nitrogen, helium, or compressed air at 60–70 psi – blows away molten material and smoke. This airflow also helps keep the fabric flat and prevents overburn, especially on delicate pieces. Typically, a 100–150 watt laser operating at about 30–40% power delivers the best results, ensuring clean and efficient cuts.

Fabrics Compatible with Laser Cutting

Laser cutting is particularly effective for synthetic thermoplastic fabrics like polyester, nylon, and spandex. These materials benefit from the heat-sealing effect of the laser, which eliminates the need for additional edge finishing. Technical textiles, including carbon fiber, softshell, microfiber, and synthetic leather, also respond well to laser cutting. The process can handle intricate contours with high precision, achieving tolerances of approximately ±0.3–0.5 mm.

However, natural fibers may scorch during the process, and fabrics containing PVC can release harmful fumes, making them less suitable for laser cutting.

Effects of Laser Cutting on Fabric Performance

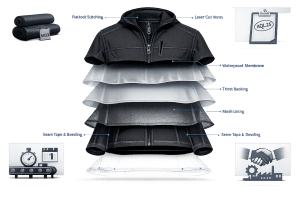

One of the standout benefits of laser cutting is its ability to thermally seal edges, enhancing fabric durability without introducing mechanical stress.

"In synthetic fabrics, laser cutting produces well-finished edges as the laser melts and fuses the edge, which avoids the problem of fraying produced by conventional knife cutters."

- SpringerOpen Review

This edge-sealing feature helps maintain the fabric’s stretch and drape, making it an excellent choice for high-stretch textiles like those used in activewear.

Laser cutting also allows for the creation of intricate patterns and complex shapes that would be challenging or impossible with traditional mechanical tools. It ensures consistent results across large production runs. However, there can be minor trade-offs, such as slight focal edge effects or occasional pilling, when compared to ultrasonic cutting. Still, the speed and automation of laser cutting – reaching up to 30–40 m/min in single-ply operations – make it a highly efficient option for many applications.

How Ultrasonic Cutting Works for Fabrics

Ultrasonic Cutting Process and Principles

Ultrasonic cutting uses high-frequency sound waves (20–40 kHz) to slice fabrics with precision. The process involves three main components: a generator, a transducer, and a sonotrode (a vibrating blade).

The blade vibrates at an astonishing rate of 20,000–40,000 times per second, creating frictional heat at the point of contact. When the blade’s frequency aligns with the fabric’s resonance, it cuts effortlessly while melting the fibers along the edge. This simultaneous cutting and sealing action ensures clean, fray-free edges. The heat is highly localized, affecting only the cutting line, so the surrounding material remains untouched. This eliminates the need for additional finishing steps like hemming or overlocking.

Ultrasonic cutting is capable of handling materials up to 20 mm thick and achieves impressive speeds – up to 120 cuts per minute or 82 feet (25 meters) per minute for continuous rolls. This precision and efficiency make it particularly suitable for synthetic fabrics.

Fabrics Compatible with Ultrasonic Cutting

Ultrasonic cutting works best with fabrics containing at least 25% thermoplastic fibers, such as polyester, nylon, and spandex. Polyester is particularly well-suited for this method, while Nylon 6 and Nylon 6/6 are known for creating strong and durable seams. Other materials like polypropylene and polyethylene also perform well due to their excellent welding properties.

The method is versatile enough to handle technical textiles, including non-wovens, composites, elastic bands, and stretch fabrics. It can manage varying thicknesses and uneven weaves better than laser cutting, making it ideal for layered constructions. However, natural fibers like cotton and wool do not melt, so for blended fabrics, the natural fiber content should be kept below 40% to achieve optimal edge sealing.

Advantages of Ultrasonic Cutting for Activewear

When it comes to activewear, ultrasonic cutting offers several key advantages. The sealed, fray-free edges result in soft finishes, making garments like leggings and sports bras more comfortable to wear. By eliminating traditional stitching, this method reduces seam bulk, minimizing the risk of chafing during intense physical activities.

"Ultrasonic technology allows for the creation of seamless garments by bonding fabrics together without the need for stitches or seams."

Another benefit is that ultrasonic cutting preserves the fabric’s breathability. Unlike needle punctures, which can compromise moisture-wicking properties, this method maintains the structural integrity of the fabric. Additionally, ultrasonic bonds are often stronger and more durable in high-stress areas compared to traditional stitched seams.

From a production standpoint, ultrasonic cutting is highly efficient – four times faster than sewing machines and ten times faster than gluing. It also uses up to 75% less energy than traditional thermal methods. By eliminating the need for thread, needles, and adhesives, it reduces waste and enhances garment recyclability, making it a more sustainable choice.

Laser Cutting vs Ultrasonic Cutting: Performance Comparison

Comparison Table: Key Differences

When deciding between laser and ultrasonic cutting for activewear production, it’s essential to weigh how each method performs across critical factors.

| Feature | Laser Cutting | Ultrasonic Cutting |

|---|---|---|

| Precision Mechanism | Uses a focused high-power density laser beam (thermal) | Relies on high-frequency microscopic blade vibrations (mechanical) |

| Pattern Complexity | Handles extremely intricate shapes via CAD | Excellent for clean trims and straightforward incisions |

| Edge Quality | Fused/sealed edges; may experience charring or "focal edges" | Smooth cuts with no warping, fluffing, or pilling |

| Material Thickness | Best for 0.02–0.20 in (0.5–5 mm) | Handles up to 0.8 in (20 mm) |

| Speed | Achieves 98–131 ft/min (30–40 m/min) for single ply | Slower by comparison; less suited to automation |

| Material Contact | Non-contact process (no pressure) | Minimal contact with low force |

| Automation Level | High; integrates seamlessly with computer systems | More challenging to automate compared to laser systems |

| Environmental Impact | Produces smoke, fumes, and noise | Clean process with no fumes, noise, or debris |

The table outlines the primary distinctions, which are further explored below, focusing on precision and user comfort.

Precision and Pattern Complexity

Let’s delve deeper into how each technology manages intricate patterns and fine details.

Laser cutting is ideal for creating detailed patterns in activewear. Its collimated laser beam focuses to an incredibly fine point, allowing it to carve out complex designs with precision. Because it’s a non-contact process, the laser avoids applying any force that might distort delicate fabrics, making it perfect for intricate contours and shapes. Additionally, laser systems pair effortlessly with CAD software, enabling virtually unlimited design possibilities without physical pressure.

Ultrasonic cutting also delivers excellent precision, thanks to its high-frequency vibrations that cut with minimal force. This approach prevents material distortion or warping, which is particularly beneficial for softer fabrics. However, when it comes to automating complex geometric patterns, ultrasonic cutting falls short compared to laser technology. It does, however, shine in handling thicker materials, accommodating layers up to 0.8 in (20 mm).

For activewear that demands intricate patterns or ventilation perforations, laser cutting stands out. It manages fine details efficiently and operates at production speeds of 98–131 ft/min.

Edge Quality and Garment Comfort

Beyond precision, the quality of cut edges plays a big role in how comfortable activewear feels against the skin.

Laser cutting seals fabric edges through heat, which can sometimes result in burning or pilling. This may leave edges feeling slightly rough, especially in areas that come into direct contact with the skin.

"The edge-sealing effect of ultrasonic cutting cannot be surpassed by laser cutting… ultrasonic can also make perfect edge-sealing dust-free cloth."

Ultrasonic cutting, on the other hand, creates clean, smooth incisions without distorting the fabric or causing pilling. This makes it an excellent choice for high-end activewear fabrics where soft, flawless edges are essential for comfort. For garments like performance leggings or sports bras, ultrasonic cutting ensures smooth edges that feel gentle against the skin.

Both methods reduce seam bulk compared to traditional stitching. Laser welding, in particular, offers more flexible seams, making it ideal for designs requiring stretch. While laser cutting excels in producing intricate designs at high speeds, ultrasonic cutting prioritizes edge softness and overall comfort. The choice ultimately depends on whether production speed or edge quality is the top priority. Laser cutting delivers speed and precision, while ultrasonic cutting ensures superior comfort at a slower pace.

sbb-itb-8dbc09a

Choosing the Right Cutting Method for Your Production

Factors to Consider When Choosing

The choice of cutting method largely depends on the fabric you’re working with. For synthetic textiles like polyester or nylon, laser cutting is a top choice. It seals the edges as it cuts, preventing fraying. However, steer clear of using it on PVC-based synthetics due to the release of toxic fumes. If you’re dealing with thicker or uneven fabrics (up to 0.8 inches or 20 mm), ultrasonic cutting is a better option. For thinner materials (ranging from 0.02 to 0.20 inches), laser cutting remains the more suitable method.

Production volume is another key consideration. Laser systems are highly automated and operate at impressive speeds (98–131 ft/min), making them ideal for large-scale production. On the other hand, ultrasonic cutting, with its limited automation capabilities, is better suited for smaller production runs or premium product lines.

Budget and environmental impact are also important. While laser cutting involves higher upfront costs and requires fume extraction systems, it reduces labor expenses in the long run. Ultrasonic cutting, by contrast, is a cleaner option and more budget-friendly, featuring re-sharpenable blades that extend its cost-effectiveness.

By weighing these factors, you can determine the most efficient and practical cutting method for your production needs.

Use Cases and Method Recommendations

For high-volume activewear made from synthetic fabrics, laser cutting is a standout choice. It handles intricate designs – like laser-perforated ventilation zones or detailed branding engravings – with both speed and precision. This method is particularly advantageous for delicate fabrics, as it avoids the mechanical pressure that could distort or damage them.

Meanwhile, ultrasonic cutting shines in applications requiring smooth, seamless edges, such as hems on leggings or sports bras. It’s also the go-to method for high-end activewear where comfort is paramount. This technique is especially effective for thicker, multi-layered materials or fabrics prone to charring or pilling under laser heat.

Working with Experienced Manufacturing Partners

Technical considerations aside, teaming up with experienced manufacturers is crucial for achieving the best results. A seasoned manufacturer can tailor cutting methods to your specific fabrics and designs. For instance, New Dong Huang Garment Co., Ltd. brings over 27 years of expertise in activewear production. They combine laser and ultrasonic cutting technologies to provide precision cuts for high-performance fabrics like 70/30 nylon-spandex blends – a popular choice for yoga wear and running apparel.

RANDIX flatbed cutter – laser cutting, ultrasonic cutting, marking, modular cutting solutions

Conclusion

Deciding between laser cutting and ultrasonic cutting comes down to the type of fabric you’re working with and your production priorities. Laser cutting shines when it comes to automation and creating intricate patterns. It also seals edges effectively on synthetic fabrics like polyester and nylon, helping to prevent fraying. That said, it can generate smoke and fumes, which means proper ventilation is a must. Plus, certain materials might end up with slightly charred or rough edges.

On the other hand, ultrasonic cutting provides a cleaner, quieter option with excellent edge quality. Using high-frequency vibrations (20,000–40,000 per second), it creates smooth, fray-free seams that are soft to the touch – perfect for premium activewear where comfort is key. Ultrasonic cutting also handles thicker materials better than laser cutting and doesn’t produce harmful emissions.

"The edge-sealing effect of ultrasonic cutting cannot be surpassed by laser cutting, which is determined by the machine itself." – SUNTECH

Ultimately, the choice involves weighing speed against seam quality, helping you make the right decision for your production needs.

FAQs

How does the environmental impact of laser cutting compare to ultrasonic cutting for fabrics?

Laser cutting offers a highly accurate, non-contact way to cut materials, which helps reduce waste and seals fabric edges in the process. This often eliminates the need for extra finishing steps. However, it’s worth noting that this method relies on a thermal process that uses a significant amount of energy, produces fumes, and demands proper ventilation. Additionally, the electricity required for high-power lasers adds to its overall environmental impact.

Ultrasonic cutting takes a different approach by using high-frequency vibrations to slice through fabrics. Unlike laser cutting, it avoids melting the material, generating less heat and fewer airborne particles. While comprehensive data on its energy use and emissions is scarce, ultrasonic cutting is generally seen as a cleaner alternative, producing less heat and fewer particulates compared to laser methods.

How do laser cutting and ultrasonic cutting impact fabric comfort and durability?

Laser cutting improves fabric comfort and durability through a contact-free, heat-based technique that melts and seals the fabric edges. This approach prevents fraying, keeps the material soft, and preserves its natural drape. By minimizing wear and tear, it also helps extend the garment’s lifespan. Plus, since the laser beam doesn’t exert any mechanical pressure, the fabric’s texture and feel remain unaffected.

On the other hand, ultrasonic cutting is known for delivering precise, clean cuts. While its effects on fabric comfort and long-term durability are less documented, it’s widely used for delicate materials. This pressure-free cutting process ensures the fabric isn’t damaged during handling, making it a reliable option for sensitive textiles.

What is the most cost-effective cutting method for small-scale fabric production?

For small-scale fabric production, laser cutting offers a budget-friendly solution. It eliminates the need for physical tools, cuts down on labor costs thanks to its quick setup and changeover process, and operates with relatively low energy use. Plus, laser cutting delivers precise, clean edges, reducing material waste while maintaining excellent quality.