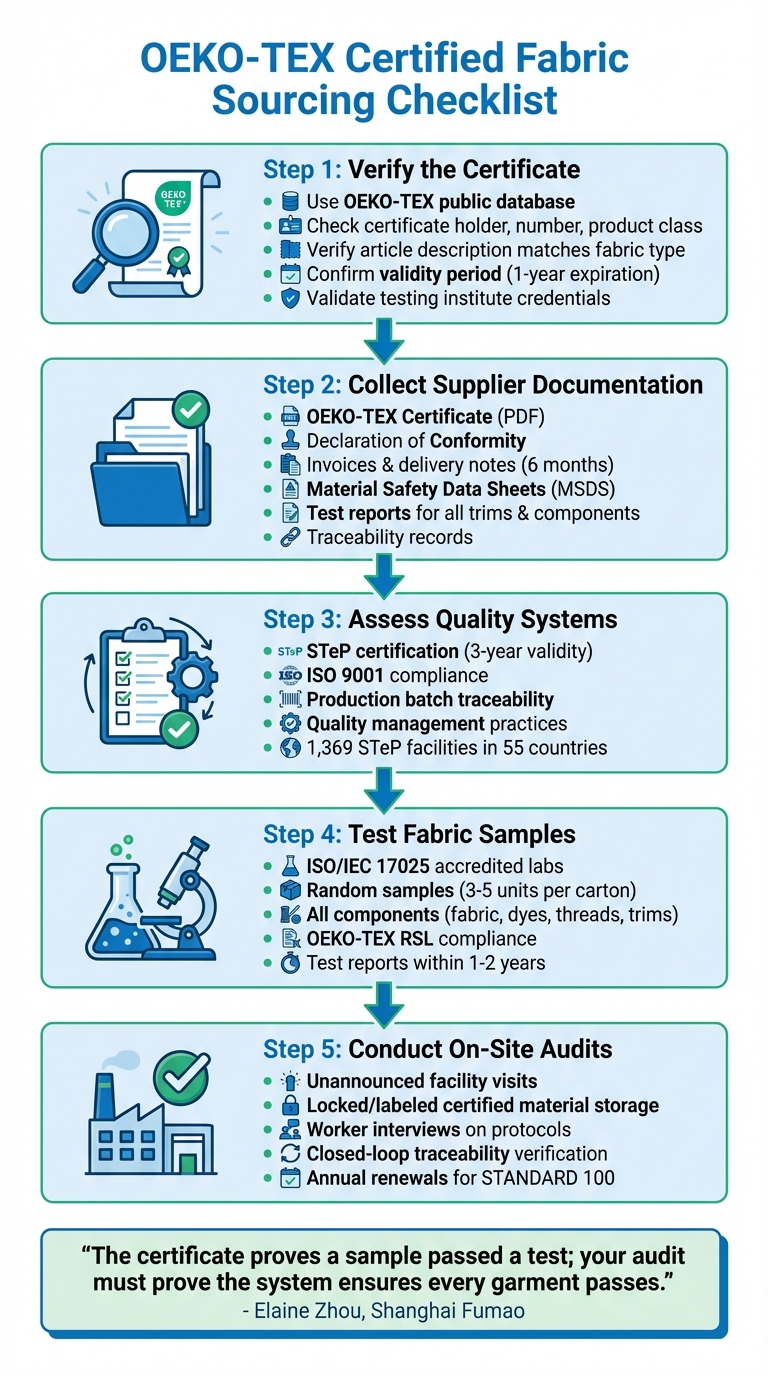

OEKO-TEX certification ensures fabrics are tested for harmful substances and meet strict safety criteria. Whether you’re sourcing activewear or other textiles, following a structured process is essential to ensure compliance and quality. Here’s a quick guide:

1. Verify the Certificate

- Use the OEKO-TEX public database to confirm the certificate’s validity.

- Check critical details like the supplier’s name, certificate number, product class, and expiration date.

- Ensure the certificate matches the specific fabric type you’re ordering.

2. Collect Supplier Documentation

- Request the OEKO-TEX certificate, Declaration of Conformity, and invoices/delivery notes.

- Gather Material Safety Data Sheets (MSDS), test reports for trims, and traceability records.

- Verify all components, from threads to elastics, meet OEKO-TEX standards.

3. Assess Supplier Quality Systems

- Review the supplier’s quality management practices, including their STeP certification and ISO 9001 compliance.

- Confirm traceability for every production batch, linking raw materials to finished goods.

4. Test Fabric Samples

- Conduct independent lab testing for all garment components.

- Ensure samples represent the actual production batch and comply with OEKO-TEX Restricted Substance List (RSL).

5. Conduct On-Site Audits

- Schedule factory visits to observe production practices and verify compliance.

- Check for proper raw material storage, labeling, and traceability systems.

By following these steps, you can confidently source OEKO-TEX certified fabrics that meet safety and quality standards, ensuring a reliable supply chain for your products.

5-Step OEKO-TEX Fabric Sourcing Checklist for Compliance Verification

How to: STANDARD 100 by OEKO-TEX® Application & Certification Process

sbb-itb-8dbc09a

Step 1: Verify OEKO-TEX Certificate Validity

Before placing an order, make sure the OEKO-TEX certificate is both genuine and current by consulting the public database. Expired or fake certificates can compromise the safety and quality of the fabric. OEKO-TEX offers a public database that allows for real-time verification of certificate details.

Check Certificate Details

When reviewing the certificate, pay attention to these key fields:

- Certificate Holder: This should match the supplier’s legal name exactly.

- Certificate Number: A unique identifier that you can use to verify the certificate in the database.

- Product Class: Ensure the class aligns with the intended fabric use (e.g., Class II for activewear).

- Article Description: The description should be specific, such as "Knitted Polyester Fabric, dyed", rather than a vague "Polyester Fabric."

- Testing Institute: Look for a recognized independent testing body, like Hohenstein or TESTEX, along with their logo.

- Validity Period: Certificates are valid for one year from the issue date, so check the expiration date.

- Standard Type: Confirm the standard listed, such as STANDARD 100 for textiles or LEATHER STANDARD for leather products.

Always request the original scanned PDF of the certificate for clarity and to ensure it hasn’t been tampered with. Then, double-check that the certificate details match the type of fabric you’re ordering.

Match Certificate to Fabric Type

Once the certificate details are verified, confirm that it applies to the specific fabric you’re sourcing. Use the OEKO-TEX Label Check tool to validate the certificate number. Be precise when entering the label, as the system is case-sensitive. The results will show whether the certificate is active, expired, or undergoing renewal.

Pay close attention to the Article Description in the database results. For instance, a supplier might provide a valid certificate, but the database could list "Polyester Woven Fabric" instead of the "Polyester Knit" you ordered. This highlights the importance of ensuring that even a legitimate certificate covers the fabric type you need. For activewear, confirm the product class is correct – typically Class II for materials that come into direct contact with the skin during physical activity.

"The database check provides real-time, independent confirmation from the certification body itself. It is the single most powerful action you can take to protect your order from fraud." – Shanghai Fumao

Step 2: Confirm Supplier Documentation

Once you’ve validated the certificate, the next step is to collect all relevant supplier documents. While the certificate is crucial, it doesn’t guarantee compliance for every production batch. You need additional proof that the supplier has systems in place to consistently meet OEKO-TEX standards. This documentation process connects certificate validation with ongoing compliance, ensuring uniformity across all batches.

Request Required Documents

Start by requesting the original OEKO-TEX certificate (scanned PDF) and a signed Declaration of Conformity. These should be accompanied by other compliance documents. To establish a valid business relationship, include invoices and delivery notes from the past six months, which link specific material lots to the supplier. For finished garments, ask for a detailed list of accessories – like buttons, zippers, labels, and threads – along with relevant compliance documents or test reports.

Additionally, collect Material Safety Data Sheets (MSDS) for dyes, chemicals, and auxiliaries. If you’re sourcing recycled materials, request a Certificate of Origin; for organic materials, ask for traceability certificates, such as IFOAM. Also, gather Quality Management Records that cover Standard Operating Procedures (SOPs) for purchasing, production traceability, incoming quality control (IQC), and methods for handling non-conformities.

| Document Category | Specific Documents to Request | Purpose |

|---|---|---|

| Primary Certification | OEKO-TEX Certificate, Declaration of Conformity | Confirms compliance with OEKO-TEX standards. |

| Transaction Proof | Invoices, Delivery Slips (last 6 months) | Links certified suppliers to purchased materials. |

| Component Testing | Lab Test Reports for dyes, threads, trims | Ensures all garment parts meet safety standards. |

| Traceability | Production Batch Records, IQC Records | Tracks raw materials to finished products. |

| Chemical Safety | Material Safety Data Sheets (MSDS) | Confirms the safety of chemical inputs during production. |

| Specialty Claims | Certificate of Origin (Recycled), IFOAM | Verifies claims about material origin or sustainability. |

It’s important to go beyond primary documentation. For example, a certificate for the main fabric won’t cover trims or elastics. Ensure validation extends to all components by cross-referencing lot numbers on fabric rolls or trim boxes with test reports and internal material receiving records. Make sure test reports are recent – ideally within one to two years – and were issued before the production date of your current order.

Verify Supplier Pre-Certifications

To strengthen compliance, check if the supplier uses pre-certified materials or OEKO-TEX compliant chemicals during production. This approach can lower testing costs for finished products if individual components – like fabrics, buttons, or threads – are already certified under STANDARD 100 or ECO PASSPORT. Ask for documentation confirming that raw materials and chemical inputs meet these standards.

To evaluate the supplier’s traceability system, request a "closed-loop" dossier for a specific production lot. This dossier should include all records for every component in that batch, from incoming quality control logs to material issuance records. A supplier who can quickly provide this dossier demonstrates strong internal traceability.

"The certificate proves a sample passed a test; your audit must prove the system ensures every garment passes." – Elaine Zhou, Business Director at Shanghai Fumao

Step 3: Review Quality Management Systems

Once you’ve secured the necessary documentation, the next step is to assess the supplier’s quality management systems. A certificate may confirm that a sample passed testing at one point, but what truly matters is whether the supplier can consistently deliver compliant fabrics across all production batches. This means taking a closer look at their internal processes, standard procedures, and facility certifications.

Required Quality Assurance Documents

To evaluate a supplier’s quality management practices, ask for their OEKO-TEX STeP (Sustainable Textile & Leather Production) certification. This certification focuses on six modules, one of which specifically addresses Quality Management, including documentation, traceability, and risk management. Currently, there are 1,369 STeP-certified facilities across 55 countries, employing over a million people.

Request the STeP Final Report, which breaks down the supplier’s performance across all modules using a three-level rating system: Level 1 (Entry), Level 2 (Good implementation), and Level 3 (Exemplary implementation). A Level 3 rating indicates that the supplier not only meets basic requirements but has also achieved at least 67% of advanced criteria, showcasing strong quality management practices. Additionally, gather supporting documents such as the ISO 9001 Certificate, which is integrated into the STeP assessment, and the Declaration of Conformity, where the supplier formally confirms compliance with OEKO-TEX standards.

| Document Type | Purpose | Relevant Standard |

|---|---|---|

| STeP Certificate | Verifies facility-wide quality and sustainability | OEKO-TEX STeP |

| STANDARD 100 Certificate | Confirms product safety and absence of harmful substances | OEKO-TEX STANDARD 100 |

| Declaration of Conformity | Formal supplier pledge of compliance | All OEKO-TEX Product Standards |

| ISO 9001 Certificate | Validates general quality management systems | Recognized by STeP |

To earn STeP certification, suppliers must complete a self-assessment, undergo an on-site audit, and participate in periodic unannounced inspections during the certification’s three-year validity period. The entire process typically takes three to six months from application to completion, and facilities must meet stringent criteria – there are around 50 exclusion points that can disqualify a facility outright. These certifications ensure that suppliers maintain consistent and compliant production processes over time.

Confirm Production Traceability

While documentation is essential, production traceability is equally important. Every fabric batch should be traceable back to its raw materials. Suppliers with STeP certification are required to demonstrate full traceability, covering everything from raw materials (like wood, cellulose, or leather) to the finished fabric. On-site audits help confirm material handling, production volumes, and traceability practices.

To verify this, request flow of goods documentation that tracks the journey of raw inputs to the final product. For specialty materials, confirm their origins through appropriate certificates. If the fabric has a MADE IN GREEN label, it’s an added advantage. This label combines process certification (STeP) with product safety (STANDARD 100) and includes a unique product ID or QR code for full supply chain transparency.

"STeP is NOT a product certification or label. STeP is company-related… The OEKO-TEX® STeP label can NOT be used for product labeling. It is only for B2B communications." – Hohenstein

Keep in mind that STeP certification is valid for three years, during which facilities must undergo regular compliance audits to maintain their certification.

Step 4: Validate Fabric Samples and Testing

To ensure your fabrics meet OEKO-TEX standards, it’s crucial to physically test samples and confirm production quality through laboratory analysis. This step builds on your earlier review of quality systems by verifying the actual materials used in production.

Request Representative Fabric Samples

One of the biggest challenges is ensuring that the fabric samples you test truly reflect what will be delivered in bulk. Suppliers may sometimes provide pre-approved samples but use uncertified components, such as elastics or threads from different vendors, during actual production runs. To counter this, randomly select 3-5 units from each packed carton of your final production batch instead of relying on supplier-provided samples. For instance, in a 5,000-piece order, this method gives you a clearer picture of the overall batch quality.

Before collecting samples, confirm that your supplier has locked and clearly labeled storage areas for certified raw materials to avoid any mix-ups with uncertified inventory. Each fabric roll should have identification tags that match test reports or Certificates of Conformity (CoC). This step strengthens traceability by ensuring that every production batch aligns with safety standards. During site visits, look for visual evidence like color-coded bins reserved for certified materials or digital job tickets specifying certified components.

When preparing samples for testing, follow strict guidelines. Include all fabric colors and finishes, and double-wrap samples in polyethylene film to prevent contamination. OEKO-TEX requires samples to represent a full color range – red, yellow, green, blue, black, white, orange, and purple – limited to five dyestuffs per sample. For printed fabrics, submit 12" x 12" (30 x 30 cm) swatches that show complete pattern coverage.

Perform Laboratory Testing

Send your samples to an ISO/IEC 17025 accredited lab, such as SGS, Bureau Veritas, or Intertek. While supplier in-house labs can be helpful for process monitoring, they lack the independence required for final compliance checks. Random pre-shipment testing usually costs a few hundred dollars – a small price compared to the potential expense of recalls.

Testing should cover every component of the garment, not just the main fabric. This includes dyes, sewing threads, zippers, elastics, and labels, all of which must comply with the OEKO-TEX Restricted Substance List (RSL). Pay special attention to trims and elastics, as these are common sources of restricted phthalates. The lab report should confirm compliance with OEKO-TEX STANDARD 100 for the appropriate product class for your activewear.

Ensure that fabric roll lot numbers correspond with test reports from the mill. Verify that all component test reports are current – ideally no older than 1-2 years – and predate your production order.

"A test report from 2018 for a fabric produced in 2024 is worthless." – Shanghai Garment/Fumao

Request a complete order dossier that includes all component test reports and Material Safety Data Sheets (MSDS) for processing chemicals. This ensures closed-loop traceability, allowing you to link any finished garment back to the documentation for every material used in its creation. These test results should also be added to your full compliance dossier for final review and verification.

Step 5: Conduct On-Site Audits and Monitoring

Documentation and factory testing might confirm compliance on paper, but on-site audits ensure those standards are actively upheld during production. Visiting supplier facilities allows you to see if OEKO-TEX practices are genuinely implemented, turning written policies into real-world actions.

Schedule Regular Audits

How often you audit depends on the specific OEKO-TEX certification your supplier holds. For example:

- STANDARD 100 certificates expire annually, requiring yearly retesting and renewal.

- STeP certified facilities maintain three-year certifications but undergo periodic, often unannounced, compliance audits during that time.

- RESPONSIBLE BUSINESS certificates are valid for three years but require annual compliance audits.

Currently, there are 1,369 STeP certified facilities across 55 countries, employing over a million people.

To ensure transparency, include the right to conduct unannounced inspections in your supplier agreements. Avoid pre-arranged showroom tours and instead visit during active production shifts to observe real operations. During these audits, check for locked and labeled storage areas for certified raw materials and confirm the use of color-coded containers (e.g., green bins) for certified production lines. Additionally, verify that all inventory is labeled and traceable to internal records. These on-site checks serve as a practical extension of earlier lab tests and document reviews.

Monitor Compliance Over Time

After completing physical audits, ongoing monitoring is essential to maintain supplier accountability. Implement a system for closed-loop traceability checks. For instance, randomly select a finished garment and ask your supplier to trace its serial number back to the documentation for every component – fabric, dye, thread, zipper, and elastic – used in its production. Facilities with strong internal controls can usually complete this process in minutes using ERP or MES systems. Delays or incomplete responses might indicate weak processes.

Take advantage of tools like the myOEKO-TEX customer portal and the OEKO-TEX Label Check tool for routine compliance validation. Additionally, conduct random pre-shipment testing by sending three to five units from each production batch to accredited laboratories like SGS, Bureau Veritas, or Intertek.

Speak directly with workers during your visits to confirm adherence to OEKO-TEX standards. Interview employees from various departments and shifts about their understanding of safety protocols, wages, complaint mechanisms, and OEKO-TEX labels. Review non-conformance logs and corrective action reports – be cautious of facilities with no documented issues, as this could indicate a lack of transparency rather than flawless operations.

"The certificate proves a sample passed a test; your audit must prove the system ensures every garment passes." – Elaine Zhou, Business Director, Shanghai Fumao

Conclusion: Sourcing Certified Fabrics with Confidence

This checklist shifts the approach from simply accepting certifications to actively verifying that every part of your supply chain aligns with OEKO-TEX standards. Sourcing OEKO-TEX certified fabrics isn’t just about gathering documents – it’s about creating a transparent supply chain where every element meets stringent safety and sustainability requirements. The five-step process outlined earlier ensures that you move beyond passive acceptance to actively confirming your supplier’s quality control, from initial certificate checks to ongoing compliance monitoring.

For activewear, which often comes into direct contact with skin during intense activities, ensuring product safety is non-negotiable. Certifications like STeP and MADE IN GREEN highlight your dedication to sustainable production and social responsibility. With access to a network of over 35,000 certified companies and more than 10,000 listed in the free OEKO-TEX Buying Guide, you can confidently partner with suppliers who uphold these high standards.

"STeP certification drives progress and empowers supply chain actors to embrace sustainability, strengthen their competitiveness and improve their economic position." – OEKO-TEX

This certification framework sets the stage for the ongoing vigilance required in sourcing. Since STANDARD 100 certificates expire annually, trustworthy suppliers maintain a "living compliance culture." This means workers are well-versed in protocols, materials are carefully segregated, and systems are in place to trace any finished garment back to its original documentation within minutes – ensuring genuine compliance rather than superficial certification.

FAQs

What should I do if a supplier’s OEKO-TEX certificate is valid but doesn’t match my exact fabric?

If a supplier’s OEKO-TEX certificate is valid but doesn’t align with your exact fabric, take extra steps to verify it. Start by reviewing the certificate details carefully and cross-checking the unique certificate number in the official OEKO-TEX database. Make sure the certificate explicitly covers the fabric you’re sourcing.

It’s also a good idea to conduct on-site inspections and physical checks to confirm everything matches up. If you notice any inconsistencies, ask the supplier for updated documentation or reach out to the certification body directly. This ensures compliance and helps you sidestep any potential complications.

Do trims, threads, elastics, and labels need their own OEKO-TEX proof too?

To meet OEKO-TEX standards, every component of a product must have its own certification. This includes trims, threads, elastics, and labels. Each piece undergoes testing to ensure it is free from harmful substances and aligns with the required safety standards.

How often should I retest and audit to keep OEKO-TEX compliance on every batch?

OEKO-TEX® certificates remain valid for one year. To keep certification active, materials typically undergo annual retesting and auditing. This routine testing ensures that every batch continues to meet the necessary standards and aligns with the latest certification criteria.