Activewear sampling is an essential step in bringing your designs to life, but it can be expensive. Here’s what you need to know:

- Cost Range: Sampling costs vary widely, from $75 to $500+ per sample, depending on design complexity. Full development costs for a style can range from $1,500 to $4,500.

- Key Drivers: Costs are influenced by materials, labor, and design intricacy. High-performance fabrics, advanced machinery, and detailed designs add to expenses.

- Timeframe: Each sample iteration can take 1–4 weeks, and unclear specifications or multiple revisions can double timelines and budgets.

- Cost Breakdown: About 35%–45% of sampling costs go to technical development (tech packs, patterns, grading), with labor and materials comprising the rest.

- Savings Tips: Use stock fabrics for early prototypes, simplify designs, and work with skilled manufacturers to reduce revisions and errors.

Sampling is not a step to skip – it ensures your product meets quality and performance standards before mass production. Proper planning and collaboration with experienced manufacturers can help control costs while avoiding costly mistakes later.

How Much Should You Pay Manufacturers For Samples?

sbb-itb-8dbc09a

What Drives Activewear Sampling Costs

Several factors influence the cost of activewear samples: the materials you choose, the labor and equipment involved, and the intricacy of your design. Each of these elements contributes uniquely to the overall expense.

Material and Fabric Selection

The type of fabric you select can significantly impact costs, especially when it comes to shipping. Freight charges are based on weight, so heavier performance fabrics naturally cost more to ship – this becomes even more noticeable with international shipments.

Performance-enhancing treatments like moisture-wicking, anti-bacterial (anti-odor), and UV protection also add to the base price of materials. Additionally, fabrics with high stretch (85% or more) need extra care during the cutting process. Without proper handling, these materials can stretch out of shape, rendering the sample unusable.

Labor and Manufacturing Processes

Creating samples isn’t a mass-production process – it’s a highly skilled, manual effort. Senior technicians and machinists with expertise in precision work typically handle sampling. As Tris Apparel explains:

"Sampling is typically handled by senior machinists who specialize in precision work. Their attention to detail ensures that the first prototype is technically sound before bulk production begins."

This meticulous approach increases labor costs per unit. Beyond the hands-on assembly, much of the sampling budget goes toward one-time tasks like pattern making, digital grading, and tech pack creation.

Activewear production also requires specialized machinery – such as 4-needle 4-thread machines, flatlock stitching tools, and seamless bonding equipment – that adds to the complexity and cost. Each sample iteration can take anywhere from 1 to 4 weeks, and activewear often requires more rounds of sampling than standard apparel to meet fit and performance standards.

Design Complexity and Revisions

The more intricate your design, the higher the labor and material costs. Each additional pattern piece increases cutting, sewing, and quality control time. For instance, a design with 15 pieces is far more labor-intensive than one with just 8 pieces. Features like bonded seams or ultrasonic welding demand specialized machinery, which further raises setup costs.

Revisions also add to the expense. Every time a design is updated, manufacturers must redo patterns, recalculate fabric requirements, and reassemble the garment. For designs with prints, each additional color in a screen print requires its own screen, which increases both labor and material costs. If your design calls for equipment not typically found in standard factories, production costs can rise by as much as 40%.

These factors collectively shape the cost of activewear sampling, setting the stage for a closer look at how these expenses break down in the next section.

Sample Cost Breakdown for Activewear

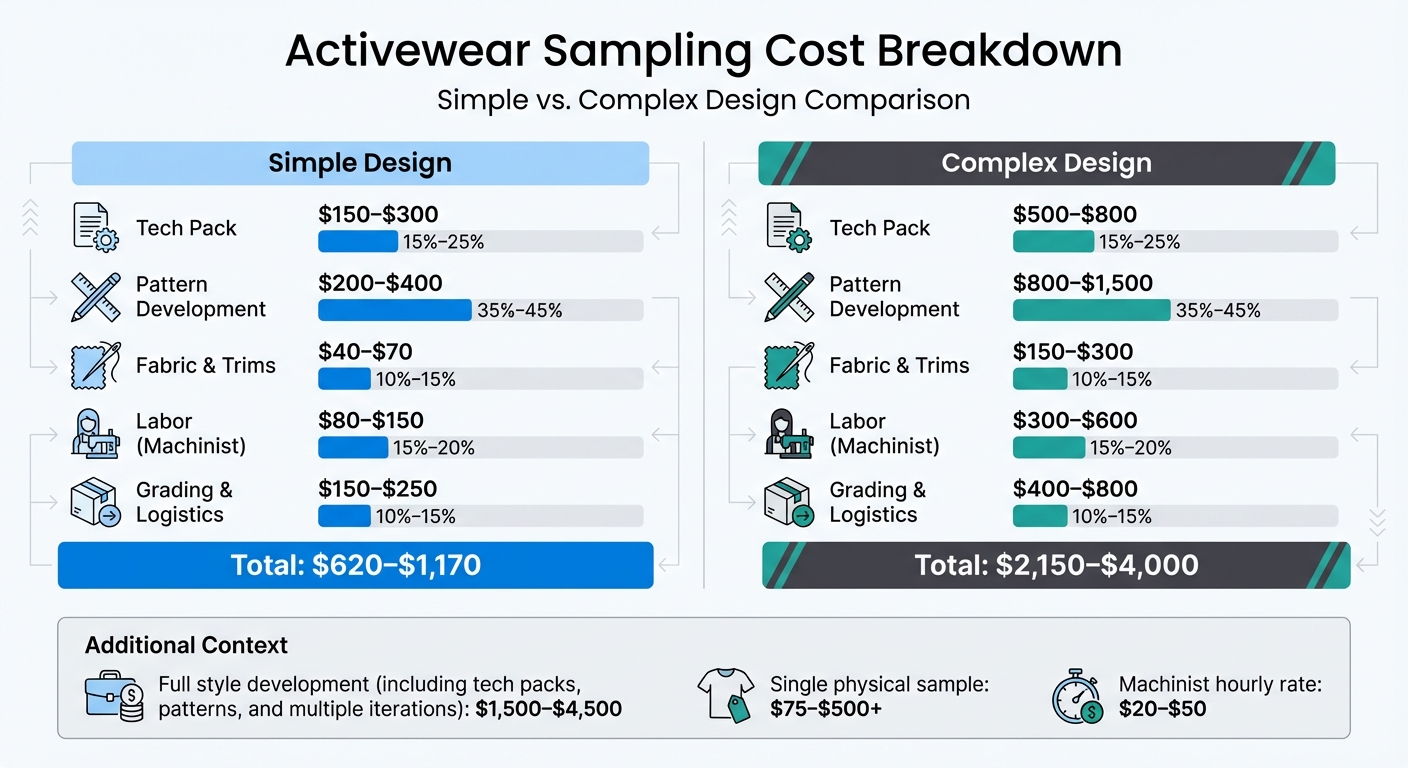

Activewear Sampling Cost Breakdown: Simple vs Complex Designs

When it comes to developing activewear, the costs can add up quickly due to factors like materials, labor, and design complexity. To give you a clearer picture, here’s a detailed breakdown of what goes into sampling expenses. Creating a single style – including tech packs, patterns, and multiple sample iterations – can range from $1,500 to $4,500. For just one physical sample, costs can fall anywhere between $75 and $500+, depending on how intricate the garment is.

Key Cost Drivers

Technical Development

Tech packs, pattern making, and grading make up about 35%–45% of the total sampling budget. These steps are essential but labor-intensive, requiring skilled machinists who charge $20 to $50 per hour. Their expertise ensures the quality and precision needed for activewear.

Material Costs

Small-quantity material purchases for sampling tend to be pricier since they don’t benefit from bulk discounts. Adding a 25% to 50% buffer to your budget is a smart move to account for design tweaks or fit adjustments that may arise during development.

The following table breaks down typical cost components for both simple and complex designs:

Cost Components Table

| Component | Simple Design Cost | Complex Design Cost | Percentage of Total |

|---|---|---|---|

| Tech Pack | $150–$300 | $500–$800 | 15%–25% |

| Pattern Development | $200–$400 | $800–$1,500 | 35%–45% |

| Fabric & Trims | $40–$70 | $150–$300 | 10%–15% |

| Labor (Machinist) | $80–$150 | $300–$600 | 15%–20% |

| Grading & Logistics | $150–$250 | $400–$800 | 10%–15% |

| Total Estimated Cost | $620–$1,170 | $2,150–$4,000 | 100% |

Simple vs. Complex Designs

The cost difference between simple and complex designs is striking. A straightforward activewear top with basic seams and standard trims will typically fall on the lower end of the cost spectrum. On the other hand, more advanced pieces – like technical leggings with bonded seams, multiple panels, and performance-focused features – can easily surpass $4,000.

While these initial development costs might seem steep, they are distributed across your first production run, which helps lower the per-unit cost as your order volume grows.

How to Reduce Sampling Costs

Sampling costs can add up quickly, but smart decisions at each step – from selecting materials to working with the right manufacturers – can help keep expenses under control.

Choose Budget-Friendly Materials for Prototypes

For early prototypes, stick to stock fabrics. These are ideal for refining fit and design before committing to higher-cost specialty materials. Polyester blends are a great choice for activewear prototypes since they are generally more affordable than nylon or natural fibers. A common polyester-spandex blend is often the most economical option.

You can also cut costs by using lower GSM (grams per square meter) fabrics in the initial stages. For instance, opting for a 180 GSM jersey instead of a heavier 320 GSM French terry can save on both material and shipping expenses. Additionally, lighter colors like pastels are cheaper to dye and process – pastel shades might take 24 hours to dye, while darker shades could require up to 48 hours.

Hold off on adding specialized treatments like organic cotton until the final stages of production. For example, organic cotton T-shirts can cost 30% to 50% more than those made from regular cotton, so save premium materials for when the design is finalized.

Streamline the Design Process

The number of sample rounds is one of the biggest contributors to costs. Clear and detailed specifications can reduce the need for multiple iterations, making it more effective than simply negotiating lower prices per sample. Detailed tech packs that outline stretch, recovery, and tension can eliminate guesswork and cut down on revisions.

Simplify your designs to save time and money. For example, redesigning a legging from 11 pattern pieces to just 6 can lower production costs by 22% while keeping the overall look intact. Using standardized seam types – like flatlock seams across your entire collection – also helps factories optimize their processes. Brands that reduced their seam types from five to two saw defect rates drop from 8% to 3%, with production speeds increasing by 15%.

Providing a fit reference garment can help ensure accurate sizing on the first try, avoiding the need for costly revisions. Lock in core design elements like fabric weight, fit standards, and neckline shape early on, as changes to these features later can lead to starting over. Simplifying complex features, such as replacing fly-front zippers and 3D patch pockets with elastic waistbands, can also trim both sampling and production costs.

Lastly, working with skilled manufacturers can further streamline the process by reducing errors and speeding up approvals.

Collaborate with Experienced Manufacturers

Experienced manufacturers bring technical expertise and efficient workflows that can significantly lower sampling costs. For instance, New Dong Huang Garment Co., Ltd. (NDH), which has over 27 years of activewear production experience, evaluates design feasibility and cost efficiency right from the concept stage. This ensures your designs are scalable and realistic.

"A professional custom activewear manufacturer is not just a supplier – it is a strategic production partner." – Ohsurewear

These manufacturers offer valuable support, including pattern making, tech pack creation, and digital grading, which helps minimize costly mistakes caused by unclear design specs. They can also recommend simpler construction methods, like replacing intricate paneling with piping, to reduce labor costs without affecting the final design. Brands that consistently use pre-production (PP) samples report 60% fewer quality issues in bulk production.

NDH’s advanced tools, such as bonding machines and laser cutters, further streamline the sampling process. Their structured workflows act as built-in quality control, identifying material or construction issues early to prevent costly mistakes in bulk production. This expertise leads to fewer sample rounds, faster turnaround times, and lower overall development costs.

New Dong Huang Garment Co., Ltd.: Cost-Effective Sampling Services

New Dong Huang Garment Co., Ltd. (NDH) brings 27 years of expertise in activewear manufacturing to the table, focusing on controlling costs and maintaining quality throughout the sampling process. Their approach begins right at the concept stage, where they assess design feasibility and suggest cost-saving alternatives before cutting any fabric. This early technical review helps avoid expensive reworks, laying the groundwork for NDH’s detailed design support.

Their custom design services include tech pack creation, pattern development, and grading. Experienced technicians manually cut and sew the first prototypes to ensure every sample is accurate from the start. By prioritizing precision, NDH minimizes revisions, cutting sample costs from $80 to just $10–$15 per mass production unit.

NDH also uses advanced tools like bonding machines and laser cutters to improve production efficiency and spot potential issues early. Their fabric sourcing spans high-performance materials (like moisture-wicking nylon/spandex blends) and eco-friendly options (such as bamboo fiber and organic cotton). Fabric typically makes up 60% to 70% of a garment’s total cost, so careful material selection plays a crucial role in keeping sampling expenses in check.

The company holds global certifications (BSCI, Sedex, GRS) and has passed audits for major brands like Nike and New Balance. Their robust quality control measures reduce defects and rework. With a 99% on-time delivery rate and a monthly production capacity of 800,000 pieces, NDH combines speed with top-notch sampling precision.

"Sampling is not an optional expense – it’s insurance for your production success." – Tris Apparel

NDH’s streamlined processes not only help cut sampling costs but also pave the way for smooth and successful mass production.

Conclusion

Activewear sampling costs are primarily influenced by three key factors: the choice of materials (which can make up 60% to 70% of total garment costs), the complexity of the design (like detailed seams or multi-piece construction), and the expertise required for labor. Understanding these elements helps brands allocate budgets wisely and steer clear of expensive mistakes.

The best way to reduce costs is by eliminating confusion, not cutting corners. Clear and detailed tech packs prevent miscommunication, using stock fabrics allows brands to perfect fit before committing to custom materials, and simplifying construction helps lower costs during both the sampling and production phases.

Collaborating with experienced manufacturers, like New Dong Huang Garment Co., Ltd., can turn sampling into a strategic advantage. With over 27 years of industry experience, they offer early design feasibility reviews and a precision-driven process that can significantly reduce costs in large-scale production. Their use of advanced equipment and adherence to global certifications ensures consistent quality while keeping expenses in check.

Sampling is more than just a step in development – it’s an investment in production success. Accurate samples help avoid costly issues like bulk order rejections, color inconsistencies, and fit problems that could harm a brand’s reputation. The goal isn’t to achieve the cheapest sample, but to minimize errors and ensure smooth, high-quality production.

FAQs

How many sample rounds should I budget for?

It’s a good idea to set aside funds for multiple sample rounds, particularly if your design is complex. Detailed or intricate designs often need extra tweaks and development, which can drive up sampling costs. Budgeting for several rounds helps ensure your design is polished and fully ready for production.

What should I include in a tech pack to avoid rework?

To cut down on rework, it’s essential to include clear, detailed information in your tech pack. Here’s what to focus on:

- Technical sketches: Include front, back, and side views to give a complete visual guide.

- Fabric, material, and color details: Specify exact materials and color codes to avoid confusion.

- Stitching, seam placement, and trims: Provide precise details on how these should look and where they belong.

- Accurate size specs and measurements: Ensure all dimensions are exact and easy to follow.

- Print, graphic, and branding placements: Indicate where logos, patterns, or graphics should go.

When your instructions are clear and thorough, manufacturers are less likely to make mistakes, keeping production on track.

When should I switch from stock fabric to custom fabric?

When your brand has reached a solid footing, it might be time to consider custom fabric. This option allows you to create materials that align perfectly with your design vision, branding, or performance needs. On the other hand, stock fabric is a great choice for smaller projects, quick turnarounds, or testing new ideas.

While custom fabric does come with higher upfront costs and longer production timelines, it offers unmatched consistency and exclusivity. This makes it an excellent fit for brands aiming to deliver a cohesive and distinctive product line. Stock fabric, meanwhile, is ideal for flexibility and speed in smaller-scale operations.