Tech packs are essential tools for turning garment designs into reality. They act as detailed blueprints that outline every aspect of a design, including measurements, materials, and construction details. Without them, manufacturers are left to guess, leading to costly mistakes, delays, and quality issues.

Key Takeaways:

- A tech pack includes technical sketches, measurements, a Bill of Materials (BOM), and construction instructions.

- Clear and complete tech packs reduce sampling rounds by up to 60%, saving $300–$1,000 per design.

- Tools like Adobe Illustrator and cloud-based PLM platforms streamline the creation and sharing process.

- Common mistakes include missing tolerances, unclear instructions, outdated versions, and ignoring factory capabilities.

How to Make a Tech Pack for Clothing Production

sbb-itb-8dbc09a

What to Include in a Tech Pack

A tech pack isn’t just a document – it’s the blueprint that ensures your design vision becomes a reality. It includes four key components that help manufacturers produce your product exactly as intended.

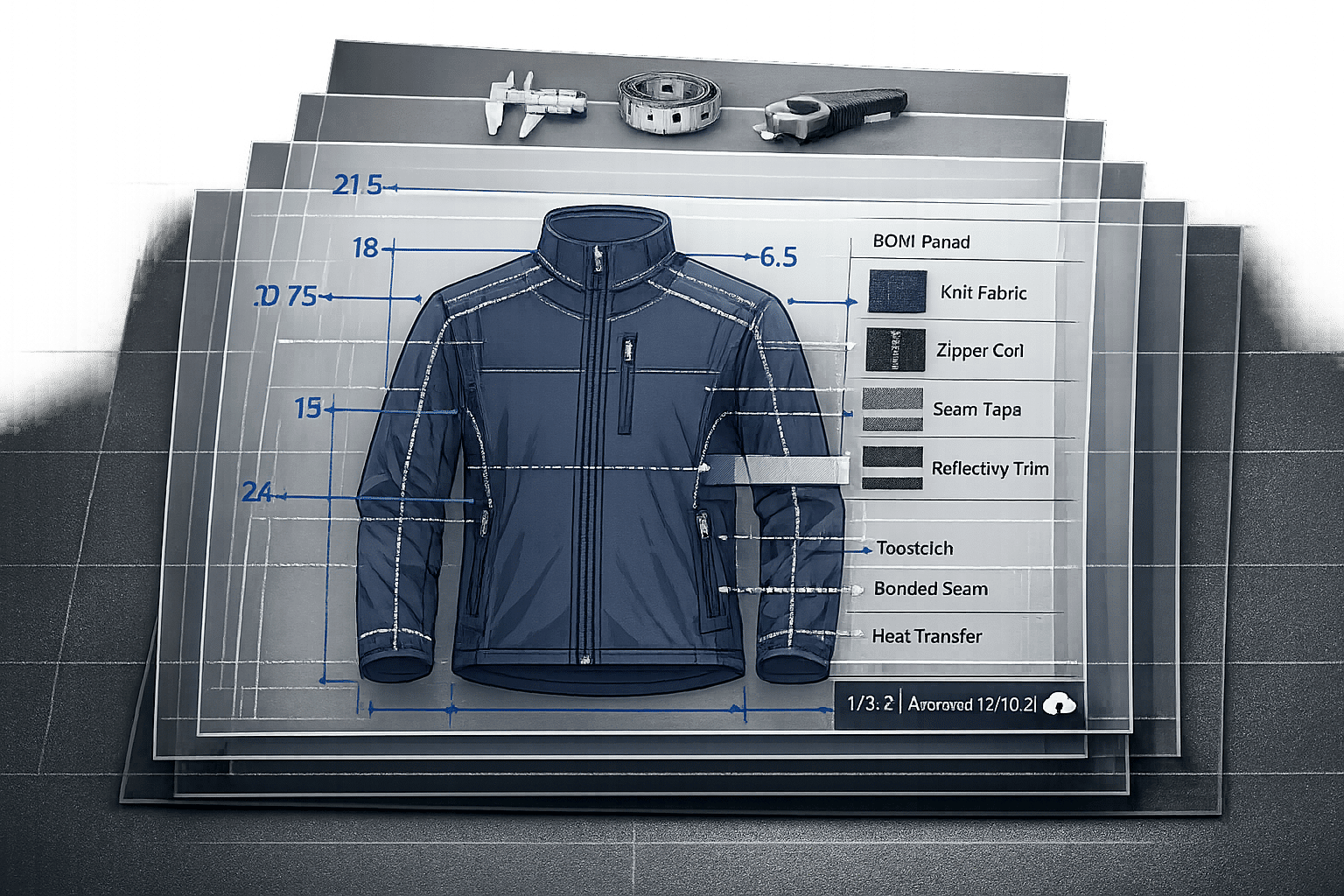

Flat Sketches and Visual Diagrams

Start with detailed, technical sketches that show every angle of your design – front, back, side, and even the inside views. These sketches should be clean and simple, sticking to black-and-white lines without shading or extra styling. Solid lines represent seams, while dashed lines indicate stitching, following industry norms.

"A solid line on a garment typically represents a seam line, while a dashed line represents stitching." – Techpacker

Label every feature clearly with arrows and callouts, especially for intricate details like collars, cuffs, buttons, or zippers. For areas with complex construction, such as pockets or trim, include zoomed-in views for clarity. If you’re using multiple fabrics or textures, add keys or patterns (like stripes or dots) to mark where each material belongs. For prints, embroideries, or logos, note their exact size and placement. Using professional design tools will help you create precise visuals that are easy to update.

Once your sketches are ready, it’s time to focus on measurements to ensure everything fits as planned.

Measurements and Size Specifications

Accurate measurements are the foundation of a tech pack. Start with your base size (usually Medium) and list every critical dimension, like body length, chest width, sleeve opening, and neck size. For more complex designs, include extra details such as pocket placement or collar dimensions. Always specify tolerances (e.g., ±0.5 in.) to define acceptable variations during production.

"Tolerance is one of the most critical aspects inside the tech pack. It’s the plus-or-minus measurement used to assess how well a product follows a specified standard of quality." – Joao, Account Manager, V-Trust

Use a Points of Measurement (POM) diagram to show exactly where each measurement starts and ends, labeling each with unique codes for clarity. A fit sheet can also be helpful for tracking sample measurements against your original specs. Once the base size is set, grading rules outline how the dimensions will scale across all sizes.

With measurements locked down, the next step is organizing the materials needed for production.

Bill of Materials (BOM)

The BOM is essentially a shopping list for your garment, covering everything needed to make and package it. This includes:

- Fabrics: Shell, lining, and pocketing materials

- Trims and hardware: Buttons, zippers, threads, snaps, and more

- Labels: Brand tags, care instructions, size labels, and price tickets

- Packaging: Hang tags, polybags, silica packets, tissue paper, and cartons

"The Bill of Materials (BOM) is a list of raw materials to produce a garment and prepare it for shipment… The materials you choose make a huge difference to the quality of your product." – Techpacker

For each item, include specific details like material name, fiber composition, weight (in GSM), color (using Pantone codes), and placement instructions. Add supplier information, including contact details and material codes, along with logistics data like minimum order quantities (MOQ) and lead times. Avoid vague descriptions – be precise, such as "100% organic cotton, 200 GSM, plain weave". Adding photos or swatches of materials like zippers or buttons can also help avoid confusion. Since the BOM ties directly into your cost sheet, keeping a change log for updates is crucial.

Finally, detailed construction instructions ensure that every piece comes together as intended.

Construction Details and Stitching Instructions

This section provides step-by-step guidance for assembling your garment. Specify seam types (e.g., flatlock or overlock), seam allowances, and stitches per inch (SPI) for each section of the design.

"Including ‘stitches per inch’ (SPI) can help define how well a garment is made." – Fashion Delivered

For tricky areas like collars, sleeves, or hems, include annotated diagrams to show exactly how they should be constructed. If your design uses special techniques – like reinforced stress points, decorative stitching, or unique folds – spell these out clearly with close-up visuals. Consistency across all parts of the tech pack is essential to minimize errors during production.

How to Create and Share Tech Packs with Factories

7-Step Tech Pack Creation Process for Garment Manufacturing

Once you’ve gathered all the components for your tech pack, the next step is to assemble them into a production-ready document that’s easy to share with manufacturers. This involves setting up a clear workflow, selecting the best digital tools, and ensuring secure communication with your factory partners.

Steps for Creating a Tech Pack

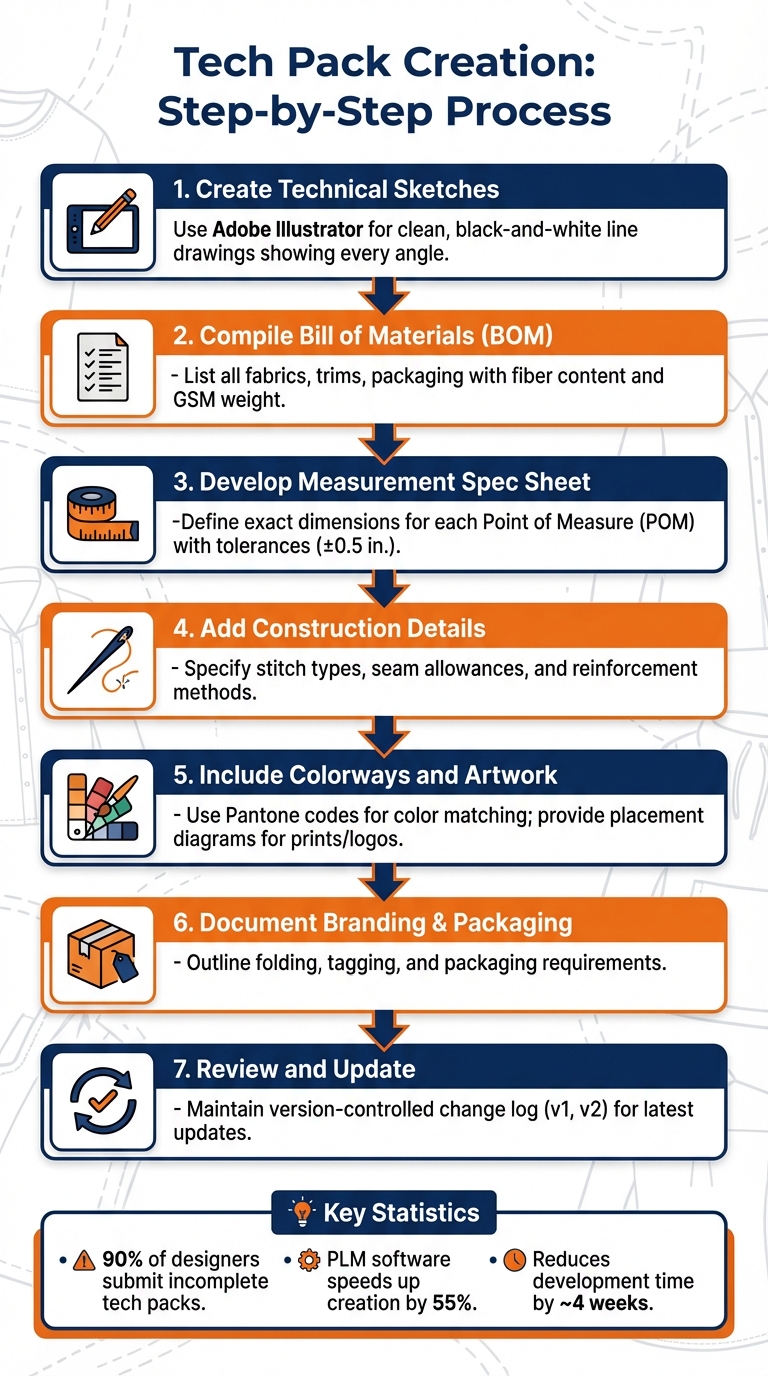

Creating a tech pack is a step-by-step process designed to ensure every detail is accounted for:

- Create technical sketches: Use Adobe Illustrator to produce clean, black-and-white line drawings that showcase every angle of your garment.

- Compile a Bill of Materials (BOM): List all components, from fabrics to trims and packaging, including details like fiber content and fabric weight (GSM).

- Develop a measurement spec sheet: Define exact dimensions for each Point of Measure (POM), including tolerances (e.g., ±0.5 in.).

- Add construction details: Specify stitch types, seam allowances, and reinforcement methods.

- Include colorways and artwork: Use Pantone codes for precise color matching and provide placement diagrams for prints or logos.

- Document branding and packaging requirements: Outline how garments should be folded, tagged, and packaged.

- Review and update: Maintain a version-controlled change log (e.g., "v1", "v2") to ensure factories always work with the latest version.

"A tech pack is a blueprint of a final garment… the quality of a finished product completely depends on the ‘quality’ of this communication."

– Saral Kochar, Founder, Techpacker

It’s worth noting that around 90% of designers submit incomplete or incorrect tech packs when requesting manufacturing quotes, leading to delays and costly revisions. Utilizing Product Lifecycle Management (PLM) software can speed up tech pack creation by as much as 55% and shorten product development timelines by about four weeks.

Digital Tools and File Formats for Tech Packs

The tools you use can make or break the efficiency of your tech pack creation process. Adobe Illustrator is a top choice for technical sketches, offering the precision needed for details like seam placements. For BOMs and measurement specs, Microsoft Excel and Google Sheets are reliable, though they lack real-time collaboration features. Cloud-based PLM platforms, such as Techpacker, centralize all components – sketches, BOMs, and comments – into a dynamic, always-updated document.

When it comes to file formats, PDFs are the go-to for sharing final tech packs, as they preserve formatting across devices. Factories may also request Adobe Illustrator (AI) files for artwork and logos to ensure high-quality reproduction. Additionally, exporting raw BOM and measurement data as CSV files can help integrate smoothly with factory systems.

| Tool Type | Common Examples | Primary Use |

|---|---|---|

| Graphic Design | Adobe Illustrator, CorelDRAW | Technical sketches, fashion flats, artwork placement |

| Spreadsheets | Microsoft Excel, Google Sheets | BOM, measurement specs, costing |

| PLM Platforms | Techpacker, Onbrand | Centralized collaboration, version control, live tech packs |

Onbrand, for instance, claims their platform can get teams up and running with real data in just 2 to 4 weeks, compared to the 6 to 24 months often required by older PLM systems. Their Core Plan starts at $89 per user per month.

With the right tools and formats in place, the next step is ensuring these tech packs are shared securely with your manufacturing partners.

Secure File Sharing Methods

How you share your tech pack is just as important as the content itself. Sharing files via traditional email can lead to version control problems, with multiple versions floating between teams. Cloud-based PLM systems eliminate this issue by creating a single source of truth. These platforms allow teams to send tech packs directly to factories in minutes and update them in real time. For email sharing, compress large files to avoid confusion caused by multiple versions.

"The speed and accuracy in which development teams can organize and share flexible tech packs ensure final products arrive as envisioned with no room for interpretation."

– Elizabeth Damioli, Bamboo Rose

For manufacturers like New Dong Huang Garment Co., Ltd., providing artwork in AI files ensures designs are accurately reproduced during mass production. Aligning tech pack details with factory capabilities can significantly reduce production errors and sampling rounds. Brands using detailed tech packs report a reduction in sampling rounds by up to 60%, cutting the average rounds from 4.5 to 1.8. This can save $300–$750 per design by minimizing the need for multiple physical samples.

Common Mistakes to Avoid When Sharing Tech Packs

When it comes to tech packs, clear communication is non-negotiable. Even seasoned design teams can stumble into mistakes that disrupt the manufacturing process. Let’s break down some frequent errors and how to steer clear of them.

Incomplete or Unclear Information

Leaving out critical details forces factories to guess – and guessing rarely ends well. For example, if you skip over specifics like seam allowances, tolerances, or stitch types (think lockstitch vs. overlock), manufacturers might make their own assumptions. The outcome? Garments, such as custom workout leggings, that stray far from your original vision.

Be precise. Define tolerances for every measurement – like ±0.5 in. for a waistline – and spell out construction details clearly. For instance, “lockstitch at 12 SPI with bartack reinforcement” leaves no room for interpretation.

Don’t overlook administrative details either. Typos in labels, incorrect Pantone codes, or sloppy shipping marks can lead to misbranded products or customs headaches. Similarly, avoid using artistic sketches with shading and unnecessary embellishments. Factories need clean, black-and-white technical flats that clearly outline seams and stitching. Solid lines for seams and dashed lines for stitching work best.

Next, let’s tackle the issue of outdated files and how they can derail production.

Poor Version Control

Emailing tech packs as attachments might seem convenient, but it’s a recipe for confusion. If one team member sends version 2 while another forwards version 1, factories could end up working with outdated specs. This misstep often leads to wasted materials, delays, and extra sampling rounds.

Switch to cloud-based platforms to avoid this chaos. A shared, real-time document ensures everyone – designers, factories, and vendors – is always on the same page. With a single source of truth, you eliminate guesswork and keep production running smoothly.

Finally, don’t ignore what your factory can actually deliver.

Ignoring Factory Capabilities

Not all factories are equipped to handle every design detail or material. Specifying techniques or fabrics that your manufacturer can’t work with only sets the stage for problems. Before you finalize your tech pack, confirm that your factory can meet your specifications.

Use simple, direct language, especially if your factory has limited English proficiency. Diagrams with labeled arrows can also help clarify complex construction details. This reduces back-and-forth questions and keeps the process efficient. Additionally, ensure your factory follows an Acceptable Quality Level (AQL) process that aligns with your brand’s standards. When your tech pack reflects what the factory can realistically produce, you’ll see fewer errors and smoother production overall.

| Common Mistake | Impact on Production | Prevention Strategy |

|---|---|---|

| Missing Tolerances | Inconsistent fit across sizes and runs | Define precise ± measurements for all key points |

| Shaded Sketches | Misinterpreted construction and proportions | Use clean, black-and-white technical flats |

| Outdated Versions | Incorrect samples and wasted materials | Use cloud-based platforms for real-time updates |

| Vague Stitching Info | Weak seams or durability issues | Specify SPI and seam types clearly |

| Incorrect Labeling | Compliance problems and customs delays | Provide detailed artwork and placement diagrams |

Conclusion

Tech Pack Best Practices Summary

A tech pack acts as the production roadmap, ensuring manufacturers can bring your designs to life exactly as envisioned. Yet, around 90% of designers submit incomplete tech packs. This often results in wasted materials, more sampling rounds, and missed deadlines.

To avoid these pitfalls, include key elements such as detailed technical flats, accurate measurements with tolerances, a thorough Bill of Materials, and clear construction details. Using cloud-based platforms for sharing files helps maintain version control, ensuring factories always work from the most up-to-date instructions. Additionally, verify that your chosen factory can handle the fabrics and techniques you specify.

"Without a complete and accurate tech pack, even the best manufacturers can’t deliver your vision as intended." – SupplyScope

By following these practices, you can streamline production and ensure your designs are executed with precision, as seen with top industry brands.

How New Dong Huang Garment Co., Ltd. Supports Tech Pack Collaboration

New Dong Huang Garment Co., Ltd. exemplifies how strong manufacturing partnerships can elevate your production process by turning detailed tech packs into exceptional products.

With over 27 years of experience in activewear manufacturing, a management team averaging 18 years in the field, and a 99% on-time delivery rate, NDH has established itself as a trusted partner. Their facilities house more than 500 sewing and knitting machines, and they utilize advanced techniques like 4-needle 6-thread stitching and flatlock seams to meet high-quality standards.

NDH holds certifications such as BSCI, Sedex, and GRS and meets the compliance requirements of major brands like Nike and New Balance. Whether your designs call for features like gussets for flexibility, breathable mesh panels, or eco-friendly recycled materials, NDH’s capabilities and their "Ask Our Expert" consultation service ensure your vision is seamlessly translated into production.

FAQs

What’s the minimum info a factory needs in a tech pack?

Factories rely on a tech pack’s key details to produce garments with precision. These details include measurements, construction methods, materials, trims, and other essential specifications. By supplying clear and thorough information, you minimize mistakes and help ensure a seamless production process.

How do I prevent factories from using the wrong tech pack version?

To prevent factories from working with outdated tech pack versions, it’s crucial to establish clear version control and communication practices. Start by using a digital system to distribute updated tech packs. Make sure each document includes revision dates and version numbers for easy tracking.

Additionally, maintain regular communication about any changes. Confirm that updates have been received and understood by the factory. This extra step ensures everyone is on the same page, reducing the risk of errors.

When should I confirm a factory can meet my materials and construction specs?

Before production kicks off, it’s crucial to confirm that the factory can meet your material and construction specifications. This should ideally happen during your initial communication and the review of the tech pack. Taking this step ensures that all requirements are clearly understood and that the factory has the capability to deliver what you need. It’s a simple way to avoid potential misunderstandings and ensure your expectations are met.