Scaling activewear production is challenging but crucial for brands aiming to grow in a market projected to hit $662.56 billion by 2030. Common hurdles include maintaining quality, managing delays, and controlling costs as production scales from small batches to thousands of units. Here’s the key to success:

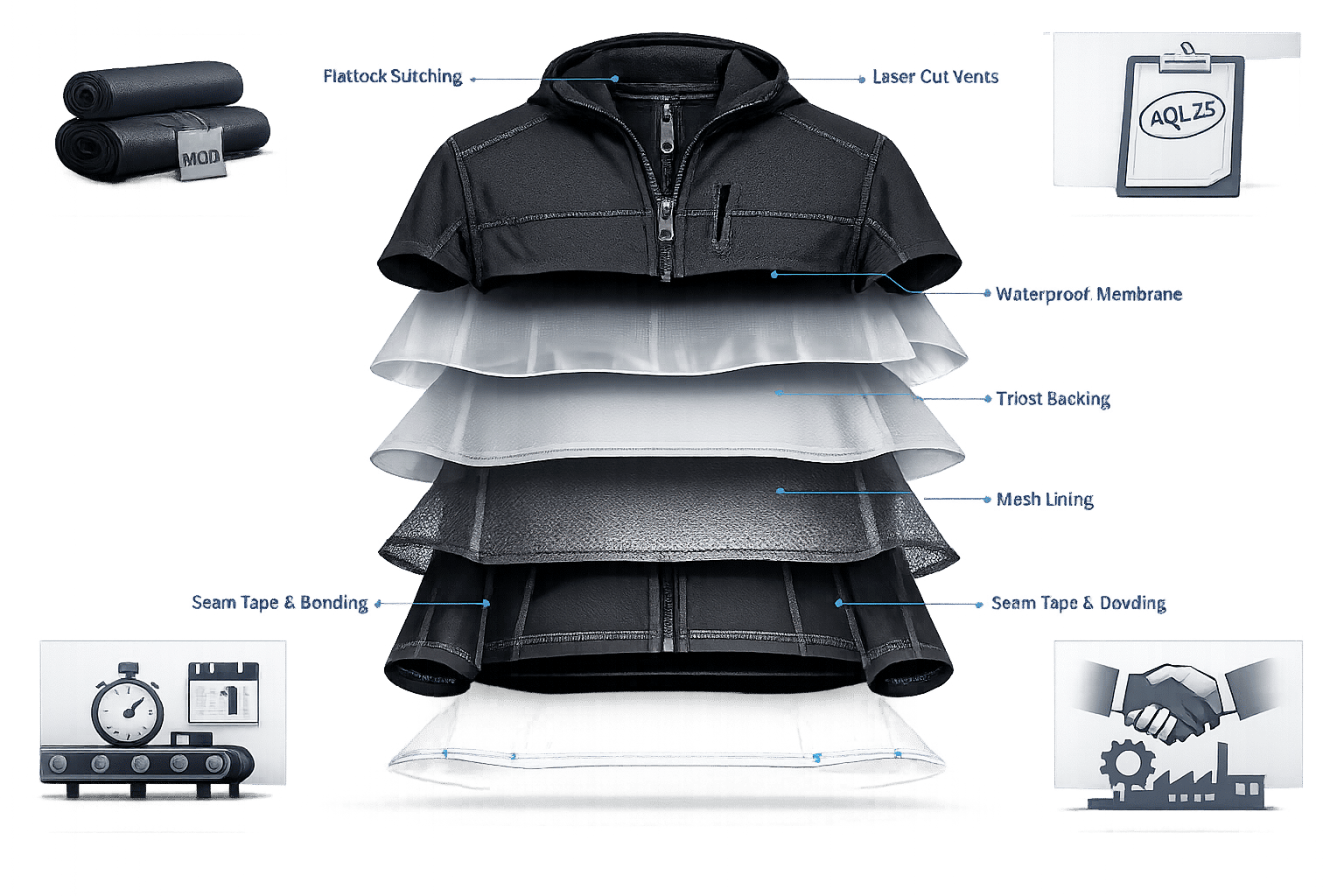

- Quality Control: Prevent issues like stitching errors or fabric inconsistencies with systematic checks and AQL (Acceptable Quality Limit) standards.

- Production Efficiency: Use Lean manufacturing, automation tools (e.g., 3D design software, ERP systems), and parallel production lines to reduce waste and improve speed.

- MOQ Challenges: Negotiate Minimum Order Quantities (MOQs) with strategies like shared fabric markers or pilot surcharges to balance costs and flexibility.

- Material Sourcing: Opt for high-performance fabrics like Nylon/Spandex blends or recycled materials (e.g., rPET) while ensuring consistency through relaxation, GSM checks, and shrinkage tests.

- Cost Management: Track expenses with detailed cost sheets, reduce fabric waste, and calculate break-even points to maintain profitability.

- Manufacturer Partnerships: Choose factories with advanced machinery, clear communication, and scalable capacity to support growth.

Scaling requires detailed planning, reliable partners, and consistent quality. With the right systems in place, brands can reduce costs by up to 35% per unit while meeting growing demand.

Minimum Order Quantities and Economies of Scale

Activewear Production Cost Breakdown: Small vs Large Batch Manufacturing

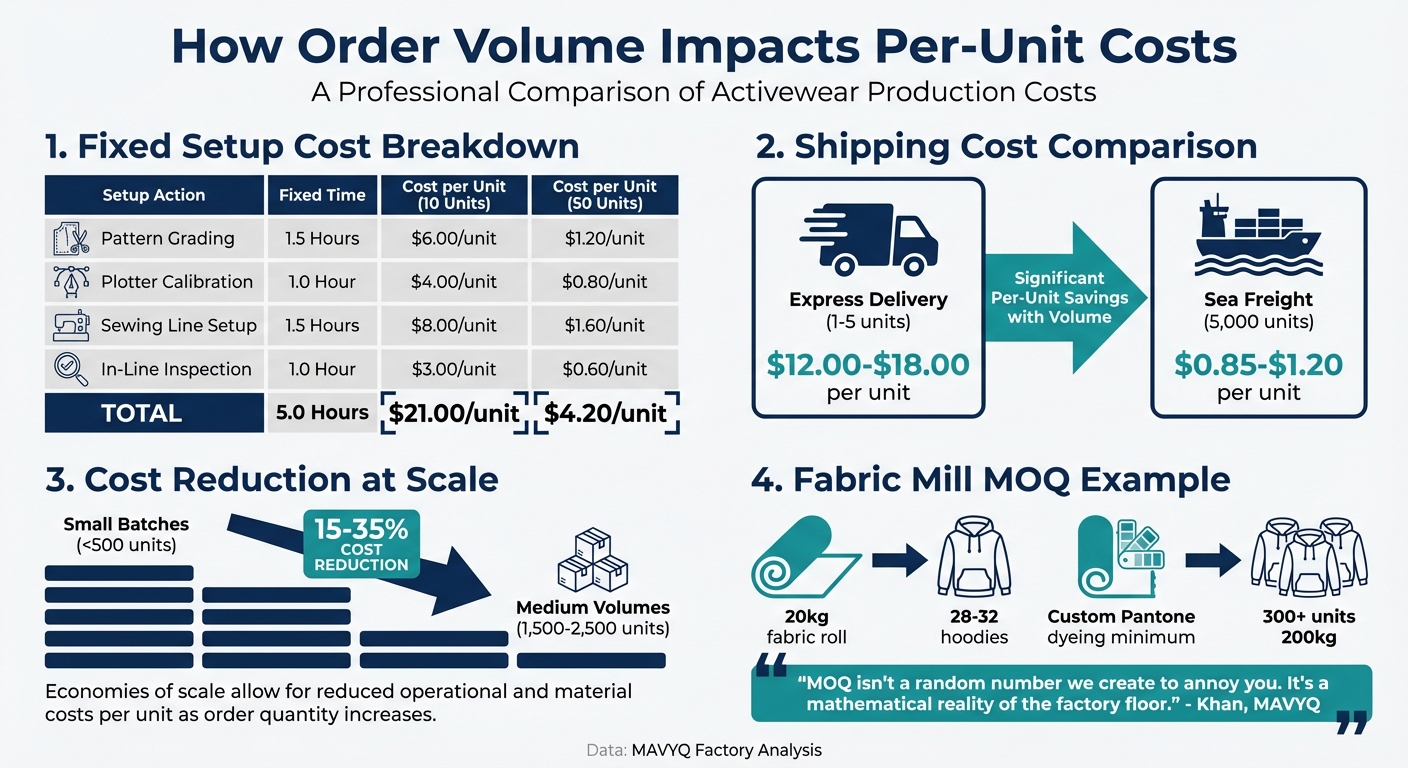

Scaling production comes with its own set of challenges, and managing Minimum Order Quantities (MOQs) is a key part of the equation. These minimums aren’t arbitrary – they’re tied to the fixed costs that factories incur every time they set up a production run. Tasks like pattern grading, machine calibration, sewing line setup, and in-line inspection require about 5 hours of labor, no matter if the batch is 10 units or 500. For smaller runs, these costs can add up quickly – around $21.00 per unit for 10 pieces. But for 50 units, the cost drops significantly to $4.20 per unit.

As Khan from MAVYQ explains:

"MOQ isn’t a random number we create to annoy you. It’s a mathematical reality of the factory floor. If a supplier says ‘No MOQ,’ they aren’t a factory – they are a reseller."

Beyond the sewing process, fabric mills also impose their own MOQs. For example, fabric is typically sold in 20kg rolls, and one roll of 320 GSM fleece can make about 28–32 hoodies. If you’re looking for custom Pantone dyeing, the minimum often starts at 200kg of fabric, which translates to producing 300 or more units. These upstream requirements often dictate the real minimum order size, regardless of what the factory can handle.

How MOQs Impact Costs

Order volume has a direct impact on per-unit costs, following a predictable curve. Moving from small batches (under 500 units) to medium volumes (1,500–2,500 units) can lead to a 15–35% cost reduction. This is due to two factors: spreading fixed setup costs across more units and gaining labor efficiency as workers become faster and more consistent. For example, the first third of a production run is typically the slowest, while the final third delivers the highest efficiency.

Shipping costs also play a role. Express delivery for small batches (1–5 units) can cost $12.00–$18.00 per unit, but sea freight for larger orders (5,000 units) drops dramatically to $0.85–$1.20 per unit. Here’s an example of how setup costs break down across different order sizes:

| Setup Action | Fixed Time | Per-Unit Cost (10 Units) | Per-Unit Cost (50 Units) |

|---|---|---|---|

| Pattern Grading | 1.5 Hours | $6.00/unit | $1.20/unit |

| Plotter Calibration | 1.0 Hour | $4.00/unit | $0.80/unit |

| Sewing Line Setup | 1.5 Hours | $8.00/unit | $1.60/unit |

| In-Line Inspection | 1.0 Hour | $3.00/unit | $0.60/unit |

| Total Fixed Setup Cost | 5.0 Hours | $21.00/unit | $4.20/unit |

Source: MAVYQ Factory Data

Negotiating MOQs with Manufacturers

If meeting standard MOQs feels out of reach, there are ways to work around these constraints. For instance, a "Fabric Shared Marker" strategy allows you to combine different styles – like 25 hoodies and 25 joggers – using the same fabric and color to meet a 50-piece minimum for a fabric run.

Another option is offering a "Pilot Surcharge" (around 25%) for smaller runs, which compensates the factory for their reduced efficiency. Using floor stock – common colors like black or navy in standard fabrics – can also help you avoid custom dye-lot minimums, which often require 300+ units. Additionally, standardizing patterns by using the factory’s pre-existing athletic fit blocks can eliminate pattern grading fees and save setup time.

A phased approach to scaling production is often the most practical. Start with a small batch (300–500 units), transition to a medium run (800–1,500 units), and finally move to larger volumes (2,500+ units). This strategy not only helps identify quality issues early but also optimizes costs as you scale. For example, one menswear brand cut per-unit costs by 28% when scaling from 600 to 2,000 pieces. Similarly, a technical apparel company reduced rejection rates from 8% to 2% by adding in-process quality checks during a scale-up from 1,000 to 4,000 units. These adjustments can make a big difference in both cost efficiency and production quality over time.

sbb-itb-8dbc09a

Material Selection and Fabric Sourcing for Scaled Production

Fabric isn’t just about aesthetics – it’s the backbone of your production costs. In activewear manufacturing, fabric can make up 60% to 70% of a garment’s total cost. When scaling production from hundreds to thousands of units, fabric choice becomes even more critical. It impacts everything from quality to production efficiency. Even minor inconsistencies can disrupt an entire batch.

Performance Fabrics for Activewear

The fabric you choose must align with the garment’s performance needs. For example, premium leggings often use fabrics with a weight of 220–250 GSM (grams per square meter) to ensure they’re "100% squat-proof". Anything lighter can lead to transparency issues, especially under stress. Beyond weight, moisture management is a key factor. The aim isn’t to absorb sweat but to wick it away, as explained by the Maes Group:

"The goal is moisture wicking, not moisture absorption."

This is why synthetic blends dominate activewear. Consider this: a 100% cotton shirt can absorb up to 180 grams of sweat and take four hours to dry, while an 80/20 poly-cotton blend absorbs just 110 grams and dries in 90 minutes. For high-performance garments, Nylon 66 stands out for its abrasion resistance and soft texture, making it ideal for compression wear. Meanwhile, spandex (5–20% of the blend) provides the stretch and recovery essential for items like yoga pants and sports bras. High-quality spandex should retain over 95% elasticity after 100 stretches.

Sustainable materials are also gaining popularity. Options like recycled polyester (rPET) from plastic bottles and ECONYL®, made from reclaimed fishing nets, perform similarly to virgin materials while meeting certifications like GRS (Global Recycled Standard) and OEKO-TEX Standard 100. However, there are trade-offs. As Fexwear points out:

"Drape costs durability".

For example, fabrics like Tencel™ or Modal add softness but often require blending with synthetics to meet durability standards for activewear.

Another factor to consider is needle heat sensitivity. Synthetic fibers, such as nylon and spandex, can melt or pucker under high sewing speeds. To avoid this, manufacturers must carefully match needle types and machine settings to the fabric blend.

Once you’ve chosen your performance fabrics, ensuring their consistency during bulk production is the next hurdle.

Ensuring Fabric Consistency in Bulk Orders

When scaling production, fabric consistency can make or break your operation. A 10% variation in GSM – for instance, dropping from 180 to 162 within a single roll – can lead to sizing issues and production failures. To prevent this, apply the "3-Zone Test": check samples from the start, middle, and end of each roll for GSM, stretch, and recovery. If the results don’t align, the roll should be rejected.

Fabric relaxation is another critical step. High-spandex knitted fabrics need to be unrolled and rested flat for 24 hours before cutting. Skipping this step can result in garments that shrink or twist after washing. Always conduct a wash and dry test on a 10 cm (approximately 4 in) fabric sample to measure shrinkage and torque. Use these results to fine-tune your patterns before full production.

Color consistency is equally important. Variations in dye batches can be mitigated through lab dips and shade banding tests, ensuring uniform color throughout production. Additionally, verify that the fabric used in your Pre-Production Sample (PPS) – the so-called "golden sample" – matches the material intended for mass production.

Lastly, certifications matter. Look for standards like OEKO-TEX Standard 100 for chemical safety, GRS for recycled content, and Bluesign for sustainable manufacturing practices. These not only ensure quality but also build trust with your customers.

Production Planning and Workflow Optimization

After selecting materials, the next step in scaling activewear production is detailed production planning. This process outlines every production stage and builds in time buffers to avoid delays. As Ninghow explains:

"Most brands lose time before sewing even starts. Materials and approvals are often the real bottleneck."

When transitioning from small batches (under 500 pieces) to medium volumes of 1,500–2,500 pieces, you’ll need 3–6 months of advance planning, compared to just 4–8 weeks for smaller runs. The reward? A 15–35% reduction in per-unit costs. Achieving these savings requires strict PPS (Pre-Production Sample) validation and adhering to realistic timelines.

Pre-Production Sampling and Validation

The PPS process is critical for finalizing construction, materials, and measurements before mass production begins. Skipping proper validation can result in thousands of units that fail to meet expectations. Approvals should follow a strict sequence: fit → materials → decoration → packaging. Each step must be completed before moving on to the next.

Sampling timelines vary based on location:

- Domestic sampling: 1–2 weeks for prototypes, 3–7 days for PPS.

- International sampling: 2–3 weeks for prototypes, 1–2 weeks for PPS.

To speed up the process, establish 24- to 48-hour decision windows for lab dips, strike-offs, and PPS approvals. Quick approvals can help avoid bottlenecks.

For example, in January 2026, Maes Group avoided a production delay by addressing a shortage of a specific brushed fabric. Their R&D team sourced a 230 GSM alternative and quickly produced samples. The client approved the switch, preventing a halt in production while also improving the product’s abrasion resistance. This highlights the importance of material readiness in keeping production on track.

Once PPS approval is complete, lock all design changes unless absolutely necessary. Kane Chu, Senior Production Engineer at Maes Group, stresses:

"A detailed tech pack is the single source of truth; it prevents costly errors and misinterpretations."

In early 2026, Chu’s team resolved a waistband issue during production when a client raised concerns about a drawstring affecting the garment’s silhouette. Instead of making a quick fix, they created new samples to ensure the problem was fully addressed before moving forward with mass production. This level of precision minimizes costly rework.

| Sample Type | Purpose | Timing |

|---|---|---|

| Prototype (PROTO) | Test silhouette, stitching, and initial fit | First physical sample |

| Fit Sample | Validate measurements on body/form; adjust pattern | After proto feedback |

| Size Set | Confirm grading across all sizes (S–XL) | After base size approval |

| PPS (Pre-Production) | Final sign-off in bulk materials; "Golden Sample" | Before cutting bulk |

| TOP (Top of Production) | Confirms bulk matches the PPS | Early in production |

Validated samples ensure smoother production timelines and faster bulk order turnarounds.

Optimizing Lead Times for Scaled Production

From concept to delivery, activewear production typically takes 12 to 20 weeks. Key phases include:

- Material sourcing: 3–4 weeks.

- Bulk production: 4–6 weeks.

- Custom fabric development: Adds 12–16 weeks.

To save time, pre-book core fabrics for repeat seasonal items and rely on in-stock materials for initial orders.

For large-scale orders, parallel production lines improve speed and consistency. In June 2025, Ninghow produced 30,000 moisture-wicking jerseys in under 25 days for a Southeast Asian sports league by leveraging streamlined systems. Similarly, a startup fashion label scaled its first collection from 800 T-shirts to 12,000 units in just three months using scalable production systems.

When orders exceed 1,200 pieces, shift from inspecting each piece to statistical quality control (AQL 2.5). This approach maintains speed while ensuring quality. Adding quality control checkpoints after fabric cutting and during assembly – rather than only at the end – can dramatically reduce rejection rates, from 8% to 2%.

Audara, a Fashion Tech Specialist at Audaces, emphasizes:

"Effective production planning hinges on continuous monitoring. To ensure adherence to schedules, regular assessments are vital, enabling the early detection of potential issues."

Use ERP systems to track material availability and machine allocation in real time. For international orders, adopting Delivered Duty Paid (DDP) terms can minimize risks related to customs delays and unexpected tariffs. Always set start and end dates with built-in time buffers to handle unforeseen issues like machine maintenance or material shortages.

| Production Phase | Typical Duration | Key Strategy to Optimize |

|---|---|---|

| Sampling & PPS | 2–8 weeks | Approve in strict order; freeze changes after PPS |

| Material Sourcing | 3–4 weeks | Pre-book core fabrics; use in-stock materials |

| Bulk Production | 3–8 weeks | Use parallel lines and automated cutting |

| Shipping | 3 days–6 weeks | Use DDP terms to avoid customs delays |

Careful planning and monitoring at each stage are key to scaling production while maintaining quality and meeting deadlines.

Maintaining Quality Control at Scale

As production scales up, the challenges of maintaining consistent quality and avoiding delays grow significantly. When moving from hundreds to thousands of units, quality control needs a systematic approach, shifting from inspecting each garment to introducing checkpoints at key stages. This method catches defects early – when they’re simpler and cheaper to address – and prevents recurring issues from impacting entire batches.

In-Line and Final Quality Checks

Key checkpoints should be established at critical production stages: after cutting (to ensure panel accuracy), after initial sewing lines (to confirm seam strength), and post-decoration (to test logo durability). For larger orders exceeding 1,200 pieces, adopting AQL 2.5 for major defects and 4.0 for minor defects is recommended. This approach, widely used in activewear, balances speed with effective oversight.

To ensure consistency, approve a Pre-Production Sample (PPS) as the quality benchmark and lock it in to avoid deviations over time. Additionally, define clear tolerance ranges in your tech pack (e.g., ±0.5 inches for key measurements) to eliminate subjective judgments during inspections.

| QC Stage | Key Objective | Critical Deliverables |

|---|---|---|

| Pre-Production | Engineering the blueprint | Confirmed Tech Pack, Graded Patterns, Approved PPS |

| Fabric Prep | Material stability | GSM Verification, 24-hour Relaxation, Shrinkage Test |

| Cutting | Precision & waste reduction | Marker Efficiency (85–95%), Cut Piece Accuracy |

| Sewing | Assembly consistency | In-Line QC Reports, SPI (Stitches Per Inch) Check |

| Finishing | Retail readiness | AQL Audit Results, Packaging Compliance, Final Measurements |

These checkpoints not only streamline quality control but also set the stage for incorporating advanced manufacturing technologies to maintain consistency at scale.

Using Advanced Manufacturing Technology

Automation plays a crucial role in ensuring consistent quality during large-scale production. Tools like CAD software, CNC cutters, flatlock machines, and spectrophotometry help minimize human error, optimize fabric usage (targeting 85–95% marker efficiency), strengthen seams, and monitor color consistency – flagging deviations exceeding a Delta E of 1.5.

Kane Chu, Senior Production Engineer at Maes Group, highlights the importance of technology and expertise:

"The technology and skilled seamstresses your factory uses directly impact your garments’ durability and comfort."

For scaled production, lab testing becomes essential. Tests for pilling resistance (ISO 12945), colorfastness (ISO 105-C06), and seam strength (ASTM D1683) should be mandatory. Premium activewear fabrics should also maintain shrinkage rates below 3% after washing. By combining advanced tools with rigorous testing protocols, manufacturers can uphold quality standards even as production volumes grow.

Cost Management and Margin Optimization

Keeping costs under control is essential for maintaining profitability, especially as production scales. The challenge? Scaling up can quickly eat into your profit margins. Fabric alone makes up 60% to 70% of total raw material costs, with raw materials accounting for about 50% of production expenses. Add to that factory costs like salaries, wages, and overtime, which take up another 24%. With such slim margins, even small inefficiencies can snowball when you’re producing thousands of units instead of hundreds.

Tracking Material and Labor Costs

A detailed cost sheet is your best friend when it comes to managing expenses. Include a Bill of Materials (BOM) in your Tech Pack to track every material and labor-related charge. This should cover everything from the main body fabric (e.g., 230 GSM Nylon/Spandex) and lining to trims, CMT charges, wastage allowances, and shipping/duties. This level of detail helps you stay on top of costs, especially when suppliers make mid-production changes to materials or specifications.

To keep labor costs in check, use Standard Allowed Minute (SAM) tracking. By setting time-based benchmarks for tasks in cutting, sewing, and finishing, Industrial Engineering (IE) can help you pinpoint non-essential activities that inflate costs. Pair this with Activity-Based Costing (ABC) to get a clearer picture of indirect expenses and uncover hidden inefficiencies as production scales. Since fabric waste can directly impact your margins, monitor offcuts and rejects closely. Even improving fabric utilization by 2% to 3% can make a noticeable difference.

Rebeca Bichachi, Product Marketing Specialist at NetSuite, sums it up perfectly:

"Apparel costing is a strategic tool that informs pricing, product design, and sourcing choices and affects overall profitability."

For better oversight, consider integrating ERP or PLM software. These tools centralize production data, giving you real-time updates on material deliveries and labor productivity. This way, you can catch issues early instead of dealing with costly surprises later. With accurate cost tracking, calculating break-even points becomes much simpler.

Break-Even Analysis for Scaled Orders

Once you’ve got your costs nailed down, the next step is figuring out your break-even point. This tells you the minimum quantity you need to produce and sell to cover fixed costs and start turning a profit. The formula is straightforward:

Unit sales required = (Fixed costs + Target profit) / Contribution per unit.

Your contribution per unit – calculated as your selling price minus variable costs (materials, labor, packaging) – reveals how much each sale helps cover overhead and generate profit.

Scaling up, however, comes with its own set of challenges. When production exceeds 1,200 units, factories often see a 25% drop in efficiency due to machine breakdowns, line rebalancing, and the learning curve. To account for defective goods that won’t pass quality control, use the formula 1/(1 – Reject %) to adjust production. For instance, with a 3% reject rate, you’d need to produce roughly 3% more units to hit your target order quantity.

Profit margins for retail clothing typically range from 4% to 20%. Wholesale pricing is usually set at 2× the Cost of Goods Sold (COGS), while retail pricing often lands at 3× to 4× COGS. To stay ahead, review cost factors like fabric prices, shipping rates, and exchange rates weekly – not just once per season. This regular monitoring lets you tweak production volumes or pricing strategies before your margins take a hit.

Building a Partnership with Your Manufacturer

Your manufacturer plays a key role in scaling your activewear production. The right partner not only understands your growth goals but also communicates clearly and uses their technical know-how to grow alongside your brand.

What to Look for in a Manufacturing Partner

Start with technical capabilities. Look for manufacturers equipped with specialized machinery, like 4-needle-6-thread flatlock machines for seamless, chafe-free stitching, and automated cutting tools to ensure precision. These tools are essential for maintaining quality as production scales.

Next, assess how they handle your Tech Pack. A reliable partner treats this document as the ultimate guide for production and keeps communication open and consistent. Pay attention to how responsive they are during early interactions, especially if there are potential challenges like language differences or time zone gaps.

Quality control is another critical factor. Top-tier manufacturers rely on standardized benchmarks, such as an AQL (Acceptable Quality Limit) of 2.5, and conduct thorough inspections at multiple stages. These processes ensure consistent quality, which is vital when scaling production.

Scalability and flexibility should also be priorities. Can they manage a smooth transition from small test orders (e.g., 300–500 pieces) to large-scale production? As Jiya Choudhary of Maker’s Row explains:

"Your manufacturer is more than a service provider; they are an integral part of the journey towards the success of your brand".

By focusing on these aspects, you can identify a manufacturing partner capable of supporting your brand’s growth and long-term success.

How New Dong Huang Garment Co., Ltd. Supports Scaling

New Dong Huang Garment Co., Ltd. is a great example of how a strategic manufacturing partner can help scale production effectively. With 27 years of experience, they provide full-package (FOB) services that cover every stage of the supply chain, from sourcing materials and developing patterns to sampling and quality control.

Their advanced technology includes bonding machines, laser cutting equipment, and 3D design tools that minimize the need for physical samples, speeding up production timelines. They also maintain a 99% on-time delivery rate and hold certifications such as BSCI, Sedex, and GRS, ensuring compliance with major brand standards.

Flexibility is another strength. Their low MOQs make it easier to test new designs without taking on significant financial risk. Additionally, they offer innovative fabric options – like eco-friendly, quick-dry, anti-odor, and anti-UV materials – that meet the rising demand for sustainable products. With 67% of consumers considering sustainability when purchasing activewear and 73% willing to pay more for it, these options align perfectly with market trends.

On top of that, New Dong Huang offers custom design services, covering everything from trend research and tech pack creation to pattern making and fabric selection. This eliminates the need to juggle multiple freelancers or agencies, which often charge between $1,500 and $3,000 for design work. Their comprehensive approach simplifies the process, allowing brands to focus on scaling with confidence.

Compliance and Eco-Friendly Practices in Large-Scale Manufacturing

Expanding activewear production means taking on greater responsibility – not just for quality, but also for the social and environmental impact of your operations. With the sustainable athleisure market projected to surpass $88 billion in 2024, ignoring compliance and eco-conscious standards risks damaging both consumer trust and your access to key markets.

Eco-Friendly Material Options

When it comes to sustainable materials, recycled polyester stands out as a practical choice for large-scale activewear production. Sourced from post-consumer plastic bottles or discarded fishing nets, it offers the same lightweight and crease-resistant qualities as virgin polyester, but with a much smaller environmental footprint. By incorporating recycled fabrics, manufacturers can reduce water usage by 20%, energy consumption by 50%, and CO2 emissions by 60%.

Another option is organic cotton, though it tends to come with higher costs. Conventional cotton production consumes approximately 2,700 liters of water for a single T-shirt, whereas organic cotton requires only 243 liters.

These materials don’t compromise on performance. Recycled polyester and polyamide replicate the texture and durability of virgin plastics, ensuring your activewear retains the stretch, moisture-wicking properties, and abrasion resistance that customers expect. For high-performance leggings, aim for fabrics in the 220-250 GSM range with 20-25% Spandex to deliver the "squat-proof" coverage that’s become a non-negotiable feature.

Meeting Compliance and Certification Standards

While sustainable materials are a key part of the equation, securing global certifications is essential for building credibility and ensuring compliance across your supply chain.

Certifications demonstrate that your manufacturing partners adhere to ethical labor practices, environmental standards, and safety protocols. These credentials not only protect your brand’s reputation but also make it easier to enter premium retail markets.

- BSCI (Business Social Compliance Initiative) and WRAP (Worldwide Responsible Accredited Production) ensure ethical labor and humane working conditions.

- Sedex (Supplier Ethical Data Exchange) offers a platform to share audit data, helping you monitor and manage risks across your supply chain.

As the OECD highlights:

"Due diligence is a process that helps businesses understand their impact on society and the environment".

For material-specific certifications, GRS (Global Recycled Standard) verifies recycled content in fabrics like recycled polyester, while GOTS (Global Organic Textile Standard) ensures that textiles made from organic fibers meet rigorous environmental and social standards. Additionally, OEKO-TEX Standard 100 tests finished products for harmful substances, which is particularly important for garments designed to be worn close to the skin.

Always request physical copies of certifications from your manufacturers and verify their credentials. Look for certifications like ISO 9001, which ensures quality management systems are in place to maintain consistent production standards and avoid costly compliance issues as you scale.

| Certification | Focus Area | Key Benefit for Scaling |

|---|---|---|

| BSCI / WRAP | Social & Labor Standards | Safeguards reputation against labor violations |

| GRS | Recycled Content | Validates sustainability claims for eco-conscious products |

| OEKO-TEX 100 | Chemical Safety | Ensures product safety for global distribution |

| Sedex | Supply Chain Visibility | Enhances transparency and risk management |

| ISO 9001 | Quality Management | Guarantees consistent production quality |

Incorporating these eco-conscious materials and certifications not only aligns with consumer expectations but also strengthens your production processes, ensuring your brand remains competitive as you scale.

Conclusion

Scaling activewear manufacturing isn’t just about producing more units; it’s about creating a system that keeps quality high, manages costs effectively, and responds to market needs. Successful brands approach scaling as a step-by-step process, starting with small batches of 300–500 pieces, moving to medium runs of 800–1,500, and eventually reaching large-scale production of 2,500 units or more. This method helps pinpoint quality issues and production inefficiencies before they impact thousands of items.

The backbone of this success lies in three critical components: detailed tech packs, pre-production samples that confirm every aspect of the product, and statistical quality control (AQL 2.5), which ensures consistency as production scales. Without these systems, even the best-designed products can falter when production ramps up.

As production volumes grow, managing costs becomes increasingly important. Brands often achieve a 15–35% reduction in per-unit costs when transitioning from small to medium production runs, but this requires careful planning and the right partnerships. These savings are only possible with manufacturers who meet stringent technical and operational standards.

Selecting the right manufacturing partner is essential for smooth scaling. New Dong Huang Garment Co., Ltd. offers the expertise, supply chain integration, and quality assurance systems that brands need to grow confidently. With services ranging from tech pack creation to Full Package (FOB) solutions that handle everything from material sourcing to DDP shipping, NDH eliminates the operational hurdles that can stall growth.

The activewear market is projected to reach $662.56 billion by 2030, presenting a massive opportunity for brands ready to scale. Achieving success in this space requires more than just ambition – it demands a structured approach, reliable systems, and strong partnerships. By focusing on phased scaling, rigorous quality processes, and dependable manufacturing support, your brand can confidently position itself for growth in this booming market.

FAQs

How can I effectively negotiate minimum order quantities (MOQs) with manufacturers?

Negotiating MOQs (Minimum Order Quantities) with manufacturers can feel like a tricky process, but a thoughtful approach can help you strike a deal that benefits both sides. First, it’s important to understand why MOQs exist in the first place. They allow manufacturers to cover setup costs and keep production running efficiently. Acknowledging this upfront can set the tone for a productive conversation. From there, consider proposing alternatives like phased orders or smaller, flexible quantities that align better with your budget.

Another strategy is to emphasize your potential as a long-term customer. Manufacturers are often more open to adjusting MOQs if they see the possibility of consistent orders or a growing partnership. Clearly outline your business plans and show how they align with the manufacturer’s production capabilities – it’s all about demonstrating mutual value.

Lastly, focus on building a strong working relationship. Open communication and a willingness to compromise – like agreeing to a slightly larger initial batch – can go a long way in earning trust. Over time, this trust can lead to more favorable terms. By using these approaches, you can navigate MOQ negotiations while laying the foundation for a successful partnership.

What steps can brands take to maintain fabric consistency when scaling activewear production?

Maintaining fabric consistency as you scale up production requires a solid quality assurance process. The first step? Partnering with reliable fabric suppliers who can deliver materials that match your exact specifications – whether it’s color, weight, or stretch. Always validate pre-production samples to ensure everything aligns before moving into full-scale manufacturing.

Once production is underway, inline quality checks at various stages are crucial. These checks help identify and address inconsistencies early in the process. Using precise cutting techniques, like standardized templates, ensures garment shapes and fabric cuts remain uniform across the board. To wrap things up, pre-shipment inspections and random batch sampling are key to confirming that the final products meet your quality expectations before they reach your customers. By following these steps, you can cut down on waste, avoid costly rework, and deliver dependable quality every time.

Why are certifications important in sustainable activewear manufacturing?

Certifications play a key role in the world of sustainable activewear manufacturing. They serve as proof that products adhere to strict environmental, social, and ethical guidelines. This includes practices like using recycled materials, sourcing organic fibers, or ensuring fair labor conditions – elements that help build trust between brands and their customers.

Certifications such as the Global Recycled Standard (GRS) and the Organic Content Standard (OCS) allow manufacturers to showcase their dedication to sustainability and compliance with industry standards. Beyond that, they bring transparency to the process, guarantee the authenticity of materials throughout the supply chain, and help brands cater to the rising consumer demand for ethically made activewear.