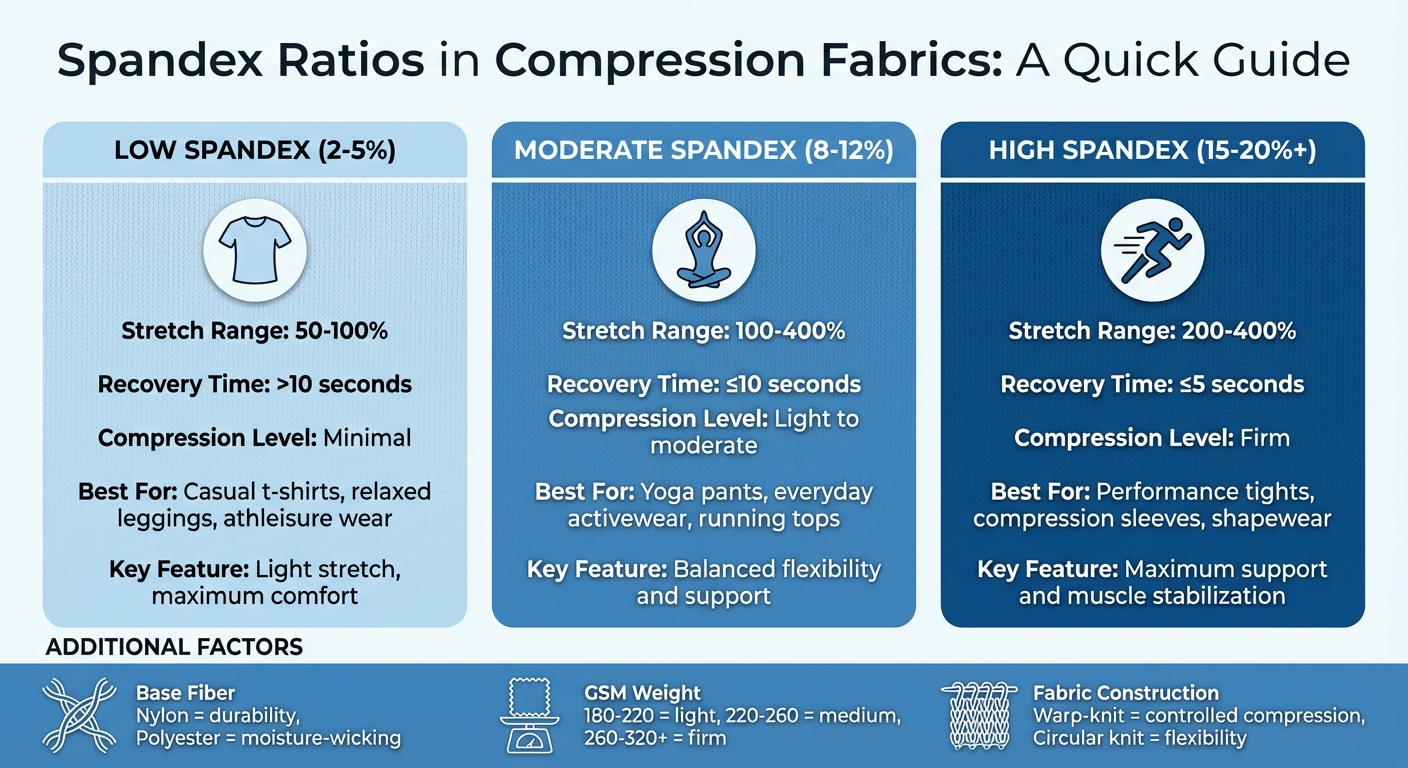

Understanding spandex ratios is key to choosing the right fabric for your needs. Spandex, a stretchable fiber, is blended into fabrics to provide elasticity, recovery, and compression. Here’s the quick takeaway:

- 2–5% Spandex: Adds light stretch; ideal for casual wear like T-shirts or relaxed leggings.

- 8–12% Spandex: Balances flexibility and light compression; perfect for yoga pants and everyday activewear.

- 15–20%+ Spandex: Delivers firm compression and support; used in performance tights, shapewear, and compression sleeves.

The spandex percentage affects how much a fabric stretches, how quickly it recovers, and the level of compression it provides. Higher spandex levels offer more stretch and support but require precise design for comfort and durability. Fabric weight, construction, and base fibers (like nylon or polyester) also play a role in performance. For example, nylon blends provide durability and smoothness, while polyester blends excel at moisture-wicking.

Choosing the right spandex ratio ensures your garment performs as intended, whether for casual comfort or intense athletic support.

Spandex Ratio Comparison Chart: Stretch, Recovery, and Applications

How Spandex Ratios Affect Stretch, Recovery, and Compression

Understanding Stretch and How It’s Measured

Stretch, in fabric terms, refers to how much a material can elongate under tension, measured as a percentage increase from its original length. A typical factory method involves marking a 10-inch segment on the fabric, applying a standard level of tension, and then measuring how far it extends. This ensures consistency in quality control.

Two-way stretch fabrics stretch in either the lengthwise or crosswise direction, while four-way stretch fabrics move in both directions. This makes four-way stretch the go-to choice for compression knits designed to move seamlessly with the body. Even a small amount of spandex can significantly impact stretch. For instance, fabrics with 8–12% spandex can stretch by 50–100% or more, while those with 15–20%+ spandex in a dense knit can stretch up to 200%. This higher stretch capacity is essential for garments providing firm compression. Understanding stretch is the first step toward evaluating how well a fabric performs in recovery.

Recovery: How Fabric Returns to Shape

Recovery refers to a fabric’s ability to return to its original shape after being stretched. It’s a critical factor in ensuring garments maintain their fit over time. Testing recovery involves stretching a marked length of fabric to a specific elongation – like 50% or 100% – holding it there, releasing it, and measuring how close it comes to its original length. Fabrics with higher spandex content tend to excel in both short-term recovery (snapping back quickly after movement) and long-term recovery (maintaining shape through repeated wear and washes).

Well-designed blends, such as 85/15 or 90/10 (base fiber to spandex), show minimal shrinkage – typically around 1.5–4% after 20 washes – and maintain their surface quality. This translates to garments that retain their compression and don’t sag at areas like the knees or elbows. On the flip side, fabrics with only 2–3% spandex may lose their shape and bag out over time, compromising their fit and appearance.

Compression Levels and Spandex Content

Compression, the gentle pressure a fabric applies to the body, is directly influenced by the spandex ratio. While spandex content determines elasticity, other factors like base fibers, fabric density, and garment cut play a role in the final compression level.

- 2–5% spandex: Offers light stretch with minimal compression, ideal for casual wear that prioritizes comfort.

- 8–12% spandex: Delivers light compression when paired with medium-density knits, making it suitable for everyday leggings and lightly supportive tops.

- 15–20%+ spandex: Found in tight, power knits, this ratio provides firm compression – perfect for performance tights, shapewear, and sleeves designed to reduce muscle vibration and enhance support.

The choice of base fibers also matters. Nylon and polyester, when blended with spandex, create stable fabrics that maintain consistent compression around muscles. Additionally, denser constructions with higher GSM (grams per square meter) and tighter knits produce greater compression than lighter or more open designs, even with the same spandex percentage. Manufacturers like New Dong Huang Garment Co., Ltd. can fine-tune compression levels by adjusting spandex content, yarn type, and knit structure to target specific needs. This intricate balance between stretch, recovery, and compression is what makes spandex engineering so vital in crafting high-performance activewear.

Compression Fabrics – Everything You Wanted To Know

Common Spandex Ratios and Their Performance Characteristics

Different spandex ratios play a key role in determining how fabrics perform, offering varied levels of stretch, compression, and durability. Here’s a closer look at how these ratios affect fabric characteristics.

Low Spandex (2–5%) for Comfort Stretch

Blends with 2–5% spandex provide a gentle stretch and minimal compression, perfect for casual activewear. When mixed with cotton or polyester, they create soft, breathable fabrics suitable for relaxed t-shirts, everyday leggings, and athleisure wear. These blends typically stretch between 50–100% and take over 10 seconds to return to their original shape. While they recover well from minor stretching, they aren’t built to handle repeated, high-intensity movements and may lose their shape under prolonged stress.

Moderate Spandex (8–12%) for Light Compression

Fabrics with 8–12% spandex offer a balance of flexibility and light support, making them ideal for everyday activewear. With a stretch range of 100–400% and recovery times under 10 seconds, these blends are commonly used in yoga pants and running tops. They provide consistent durability and shape retention, even under moderate strain. Additionally, these fabrics excel at wicking moisture and maintaining vibrant colors (rated 4–5 on industry scales). They also help reduce muscle vibration during movement, offering gentle stabilization that may ease post-workout soreness.

High Spandex (15–20%+) for Firm Compression

Blends with 15–20% or more spandex deliver firm compression and targeted support. Capable of stretching 200–400% and recovering in five seconds or less, these fabrics conform closely to the body’s contours. They are frequently used in performance gear like running tights, compression sleeves, and shapewear. Typically made with 80–85% nylon or polyester and 15–30% spandex, these blends reduce muscle oscillation, improve blood flow, and enhance body awareness during intense activities. While high spandex ratios improve support, careful design is crucial to avoid overly restrictive fits.

Here’s a quick summary of these spandex ratios and their key characteristics:

| Spandex Ratio | Stretch Range | Recovery Time | Best Applications |

|---|---|---|---|

| 2–5% | 50–100% | >10 seconds | Casual t-shirts, relaxed leggings, athleisure |

| 8–12% | 100–400% | ≤10 seconds | Yoga pants, everyday activewear, running tops |

| 15–20%+ | 200–400% | ≤5 seconds | Performance tights, compression gear, shapewear |

sbb-itb-8dbc09a

Designing Compression Fabrics with the Right Spandex Ratio

Selecting the right spandex percentage is just one piece of the puzzle. To create effective compression garments, it’s crucial to consider how spandex interacts with the base fiber, fabric weight, and construction methods. These factors collectively determine whether your activewear delivers the performance you’re aiming for.

Pairing Spandex with Base Fibers

The choice of base fiber significantly impacts how the fabric performs when combined with spandex. For example, nylon–spandex blends are known for their smooth texture, durability, and excellent recovery. These properties make them a go-to option for high-compression garments like leggings, sleeves, and base layers. Typically, a blend with 15–25% spandex offers a firm and supportive fit, ideal for performance wear.

On the other hand, polyester–spandex blends shine in situations where moisture management is key. Fabrics made with 80–90% polyester and 10–20% spandex are highly effective at wicking away sweat and drying quickly. For instance, tests show that polyester–spandex fabrics can dry in under 6.5 seconds, compared to about 18 seconds for nylon blends. This makes them perfect for running tights or cross-training gear, where 12–14% spandex provides both stretch and compression while keeping sweat under control.

Meanwhile, cotton–spandex blends are better suited for casual or light compression wear. These blends offer breathability and softness but tend to retain moisture and lose shape over time. For this reason, they’re typically used in athleisure or light compression styles with 5–10% spandex, rather than in garments requiring high-performance or medical-grade compression.

How Spandex Works with GSM and Fabric Construction

The level of compression in a fabric depends not only on the spandex ratio but also on the fabric’s weight, measured in grams per square meter (GSM).

- Light compression is achieved with fabrics in the 180–220 g/m² range containing 8–12% spandex, making them suitable for training tights or base layers.

- Medium compression requires mid-weight fabrics, around 220–260 g/m², with 12–18% spandex for enhanced muscle support and all-day comfort.

- Firm or performance-grade compression typically involves heavier fabrics, 260–320 g/m² or more, combined with 18–25% spandex for maximum support.

Fabric construction also plays a critical role. Warp-knit fabrics are more stable and provide controlled compression, making them ideal for applications like compression sleeves, shapewear, and performance leggings. These fabrics feel firmer and more structured. In contrast, circular knits offer greater stretch in all directions and a softer feel. This makes them better suited for yoga pants or training gear, where flexibility and ease of movement are essential. These construction methods directly influence pattern design and the overall fit of the garment.

Spandex’s Effect on Pattern Making and Fit

The elasticity provided by spandex means that pattern making for compression garments often involves negative ease. This means designing patterns slightly smaller than the wearer’s body measurements so that the fabric stretches to create the desired compression.

- With 5–10% spandex, designers apply modest negative ease, typically focused on the width, to achieve light compression.

- For higher spandex levels, around 15–25%, more substantial negative ease is required in both width and length. This helps prevent over-compression in areas with high movement, like the knees and hips.

Creating patterns for high-spandex garments also requires careful attention to seams, panel sizes, and grading. More seams and smaller panels help control the stretch and maintain consistent tension across the body. Traditional linear grading methods often fall short for these fabrics, as they can lead to inconsistencies – larger sizes may feel too loose, while smaller sizes might be overly tight. Instead, non-linear grading techniques are used to ensure uniform compression across all sizes.

Experienced manufacturers, such as New Dong Huang Garment Co., Ltd., bring valuable expertise to the table. Their knowledge of grade rules and panel engineering ensures that high-stretch compression garments not only fit well but also perform effectively for a diverse range of body types.

How to Source and Develop Compression Fabrics

Sourcing high-quality compression fabrics involves precise measurements and thorough testing, especially when optimizing the spandex ratio for activewear. A well-prepared tech pack is crucial to avoid costly production mistakes. Be sure to include specifics like fiber content (e.g., 80% nylon/20% spandex), GSM (usually 220–280), and fabric construction (warp or circular knit). Clearly outline stretch requirements, such as "minimum 60% stretch in both directions" for 4-way stretch fabrics, and set recovery standards like "≥90% recovery after 30 seconds." Other key details include shrinkage tolerances (≤3% after washing) and colorfastness levels (minimum grade 4+). Referencing standardized test methods, like ASTM D3107 for elasticity, ensures mills know exactly what to measure. Detailed tech packs naturally lead to precise spandex specifications.

Writing Spandex Specifications in Tech Packs

When specifying stretch and recovery requirements, use precise figures. Fabrics with 5–10% spandex typically allow for 150–200% stretch, while blends with 20% or more spandex can stretch 300% or more in all directions. Recovery should be specified as ≥90% return to the original shape after repeated stretching cycles. Include additional metrics, such as the load at 50% stretch – commonly 2–4 lbs for light compression fabrics. Washing instructions are also important: recommend cold or warm water (up to 104°F/40°C), line drying, and limit shrinkage to 3–5% after three washes. To avoid confusion, consider adding visual diagrams that show stretch directions.

Working with Mills and Factories

Start by sending your mills benchmark swatches that represent the desired compression and handfeel. Request trial fabrics with varying spandex ratios to compare stretch percentages, recovery times, and overall texture. Be prepared for multiple rounds of adjustments to fine-tune the spandex content or switch base fibers – for instance, nylon for added durability or polyester for better moisture-wicking. Manufacturers like New Dong Huang Garment Co., Ltd., with decades of experience in activewear, can help refine spandex ratios, GSM, and fabric finishes during sampling to meet U.S. performance and fit standards. Once the trials are complete, rigorous testing will ensure the fabric aligns with your design goals.

Testing and Quality Control

Quality control starts by verifying spandex content using methods like burn tests or FTIR spectroscopy to confirm the fabric composition – for example, 15–20% spandex for firm compression. Test tensile strength (using ASTM D5034) and stretch/recovery (with an Instron machine) to ensure ≥90% recovery after repeated use. Check dimensional stability by washing the fabric five times and inspect for issues like uneven dyeing. For long-term performance, simulate real-world usage by conducting 20–50 wear and wash cycles – think treadmill runs followed by machine washing at 104°F (40°C). Measure recovery loss (which should stay below 10% after 50 cycles for fabrics with high spandex content), colorfastness (AATCC 61, minimum grade 4+), and pilling resistance (ASTM D3512, minimum grade 3+). Keep in mind that while higher spandex ratios, such as 20%, improve recovery, they can also increase pilling in high-friction areas, making thorough wear testing essential before moving to bulk production.

Choosing the Right Spandex Ratio for Your Activewear

Spandex ratios play a crucial role in determining fabric performance, and choosing the right percentage depends heavily on the activity the garment is designed for. For casual athleisure or lifestyle leggings, a lower spandex content – around 2–5% – blended with cotton, modal, or polyester provides just the right amount of stretch. This ensures comfort and shape retention without feeling overly tight, making it perfect for everyday wear.

For activities like yoga or Pilates, where flexibility is key, a moderate spandex ratio of 8–12% works best. This level offers excellent stretch, quick recovery, and light-to-moderate compression, supporting movements like deep stretches and poses. On the other hand, running tights and gym leggings often benefit from a slightly higher range, around 10–15% spandex combined with 86–90% polyester or nylon. This blend delivers a snug, supportive fit and ensures durability, even during intense or repetitive workouts.

For more specialized garments, such as performance tights or recovery wear, a higher spandex percentage – 15–20% or more – is ideal. These garments require firm compression and effective muscle support, which is best achieved with dense, high-GSM knits. A common blend here is 86–92% polyester with 8–14% spandex, striking a balance between moisture-wicking, durability, and multi-directional stretch. Even small tweaks to the spandex ratio can refine the fabric’s performance.

Prototyping is a critical step in ensuring the fabric performs as intended. Testing the garments through real-life movements – like squats, lunges, and running – helps confirm that the fabric maintains opacity at full stretch, recovers well after repeated use, and feels comfortable in key areas such as the waist and hems. If the material feels too restrictive, adjusting the pattern ease may be a better solution than altering the fiber composition.

When collaborating with experienced manufacturers like New Dong Huang Garment Co., Ltd., it’s important to specify elastane content as a range in your tech packs (e.g., "10–12% elastane, balance recycled polyester"). This approach accounts for production tolerances while ensuring consistency and meeting performance expectations, aligning with earlier quality control recommendations.

For hot-weather activities, fabrics with moisture-wicking fibers like polyester or nylon paired with moderate spandex levels (8–14%) are ideal. They provide support without causing overheating. Also, clearly labeling compression levels – such as "light", "medium", or "firm compression" – can help U.S. consumers choose the most comfortable option. Keep in mind that fabric structure and GSM also influence compression. For instance, a denser knit with moderate spandex may feel more supportive than a lighter fabric with the same spandex percentage.

FAQs

What impact does the spandex ratio have on the comfort and performance of activewear?

The amount of spandex in activewear fabrics is a game-changer when it comes to stretch, recovery, and performance. A higher percentage of spandex means more flexibility, allowing the fabric to move effortlessly with your body during activities like yoga, running, or any workout.

Fabrics with more spandex also excel at keeping their shape and offering support, ensuring your clothes fit well even after multiple wears and washes. This combination of flexibility and durability makes spandex-heavy fabrics a go-to choice for high-performance activewear.

What’s the difference between two-way and four-way stretch fabrics?

Two-way stretch fabrics are designed to stretch in just one direction – either horizontally or vertically. This gives them a decent amount of flexibility, making them suitable for activities requiring moderate movement.

On the other hand, four-way stretch fabrics take things up a notch. They stretch in all directions – horizontally and vertically – providing greater elasticity, excellent shape retention, and a more comfortable fit. Because of these qualities, four-way stretch fabrics are a go-to choice for activewear and compression garments. They move effortlessly with the body, offering the support and flexibility needed for intense physical activities.

Why does the type of base fiber matter when choosing compression fabrics?

The choice of base fiber is essential in determining how compression fabrics function. It directly impacts stretch, recovery, and moisture management, which are crucial for allowing flexibility while helping the fabric retain its shape over time.

The right fiber also boosts durability and comfort, tailoring the fabric to specific activities such as yoga, running, or outdoor sports. Selecting the appropriate fiber ensures the material delivers on both performance and comfort.