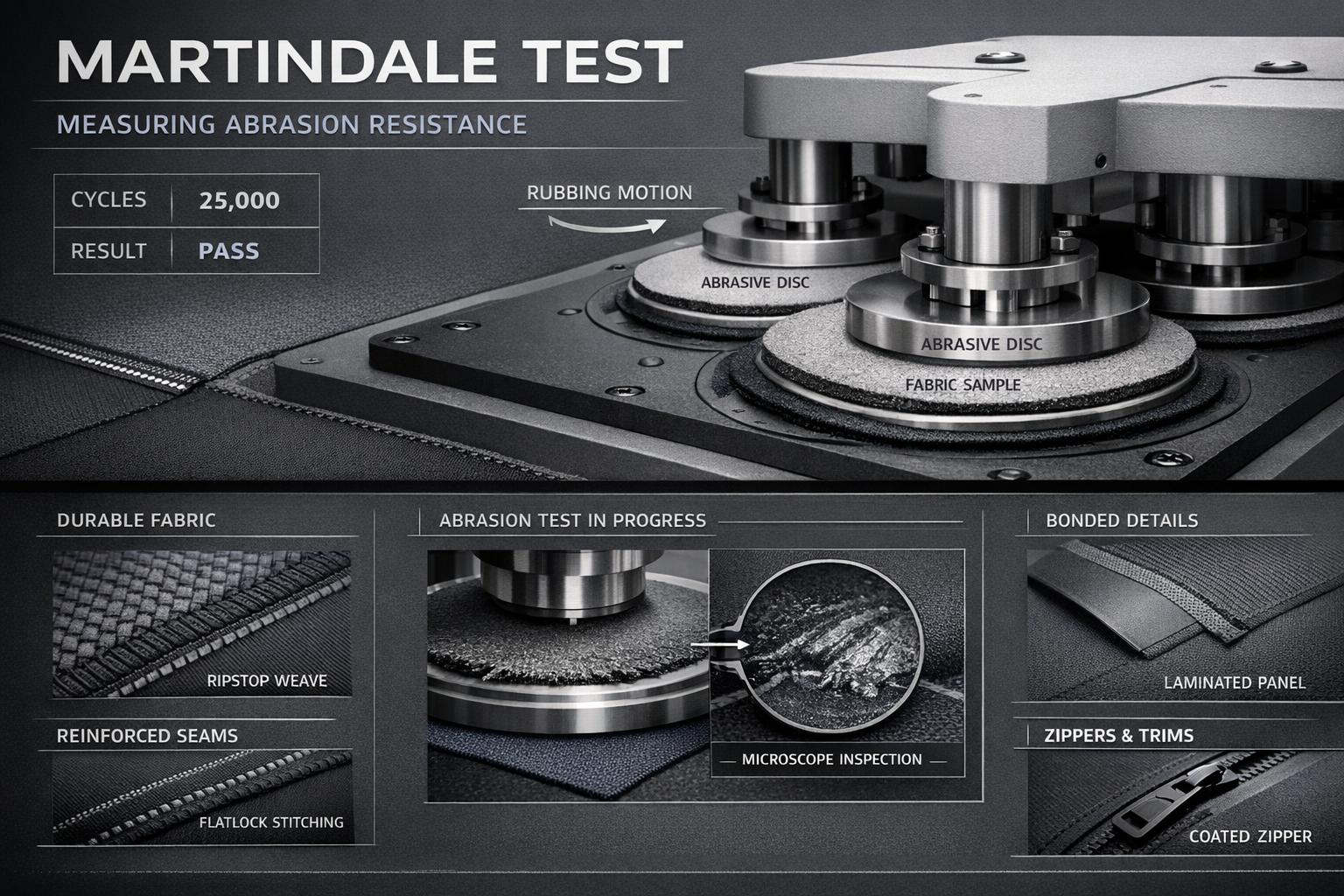

The Martindale test is a trusted method to measure how well fabrics resist wear and tear. It uses a unique figure-eight motion to simulate friction, offering a realistic evaluation of durability. This test is crucial for products like activewear, which face constant friction from movement and washing. Here’s what you need to know:

- How it works: Fabric samples are rubbed against abrasive material under controlled pressure. Durability is measured by the number of cycles the fabric withstands before damage occurs.

- Key metrics: Specimen breakage (holes or broken fibers), mass loss (weight reduction after cycles), and appearance changes (pilling or fuzzing).

- Standards: ISO 12947 outlines the requirements for equipment, testing procedures, and evaluation methods.

- Activewear benchmarks: Everyday activewear should endure 25,000–30,000 cycles, while professional gear must exceed 30,000 cycles.

The Martindale test helps manufacturers ensure their fabrics meet durability standards, improving performance and longevity for consumers.

Test Standards and Equipment

ISO 12947 Standards

ISO 12947 is the go-to international standard for measuring abrasion resistance using the Martindale method. It’s broken down into four parts, each focusing on a specific aspect of testing to ensure consistent and reliable results across laboratories worldwide.

- Part 1: Covers the requirements for the testing machine and auxiliary materials, such as abradants and foam backings.

- Part 2: Focuses on determining when the fabric fails, typically indicated by thread breakage or the formation of holes.

- Part 3: Explains how to measure mass loss by tracking the reduction in material weight after a specified number of cycles.

- Part 4: Details how to assess appearance changes, including surface texture alterations like fuzzing or pilling.

These standards apply to woven, knitted, and nonwoven fabrics, though pile textiles are restricted to a maximum height of 0.08 inches (2 mm) for accurate testing. For those interested, ISO 12947-1 and ISO 12947-3 are available for purchase at approximately $67 each, while ASTM D4966-22 is priced at $72.00. These guidelines also inform the design of Martindale tester components, which are outlined below.

Martindale Tester Components

The Martindale tester, designed in line with ISO standards, includes several key components that replicate how fabrics wear under real-world conditions.

- The specimen holder keeps the fabric sample in place. However, fabrics thicker than 0.12 inches (3 mm) cannot be mounted for pilling tests.

- The abradant holder houses the material that rubs against the fabric sample. Typically, worsted wool cloth is used, but specialized materials like Trizact™ are employed for hosiery testing.

- Load weights (or head weights) apply standardized pressure to the specimen holder. For hosiery tests, these weights must exert exactly 12 ± 0.3 kPa (1.74 ± 0.004 psi).

- A press cutter ensures specimens and abradants are cut to precise diameters – 1.5 inches (38 mm) for specimens and 5.5 inches (140 mm) for abradant tables.

- The motion plate generates the unique Lissajous figure-eight pattern, setting Martindale testing apart from simpler linear methods.

Regular maintenance is essential for accurate testing. Abradants on the holder should be replaced every 10,000 cycles, while those on the sample holder need changing every 50,000 cycles. Additionally, testing conditions should be carefully controlled, with the environment maintained at 70 ± 2°F (21 ± 1°C) and 65 ± 2% relative humidity.

sbb-itb-8dbc09a

How to Prepare and Run the Test

Sample Preparation

Start by cutting circular fabric samples to the required sizes: 1.5 inches (38 mm) for pilling tests and 5.5 inches (140 mm) for abrasion tests. Use a press cutter for precision, and make sure the cutting edges are clean and free of fraying to avoid any interference with the testing machine. Once cut, condition the samples for four hours at a controlled environment of 70 ± 2°F (21 ± 1°C) and 65 ± 2% relative humidity.

To ensure accurate results, select samples from different areas of the fabric to account for any variability. If you’re testing activewear, pre-wash or dry-clean the samples to simulate real-world conditions. Mount the fabric face-up on a 3.5-inch (90 mm) wool felt pad within the sample fixture. Secure it tightly with a ring to keep the sample smooth and wrinkle-free. With the samples prepped, you’re ready to set up the testing machine.

Test Procedure Steps

Once the sample is mounted, follow these steps to conduct the test:

- Place a 5.5-inch (140 mm) wool felt on the abrasion table, and layer it with worsted wool cloth (or Trizact™ for hosiery) as the abradant. Secure the abradant using a pressure weight, which should be set to 12 ± 0.3 kPa for hosiery.

- Program the machine for the required number of cycles, depending on the fabric’s expected durability. The machine will simulate multi-directional wear using a Lissajous figure-eight pattern.

- For hosiery, pause the test every 200 cycles to check for signs of yarn breakage or pilling. Use a medium-bristle toothbrush to gently remove any pills that form during the test.

- Replace the abradant after 50,000 cycles or whenever a new sample is tested to maintain consistency.

- Continue the test until the endpoint is reached – this is typically defined as two yarn breakages or the appearance of a visible hole.

This process ensures the durability benchmarks outlined earlier are met and provides a clear evaluation of the fabric’s performance.

Martindale Abrasion Testing Process – Governed by ISO 12947 2

How to Read Test Results

Martindale Test Abrasion Resistance Benchmarks for Activewear Durability

Evaluation Methods

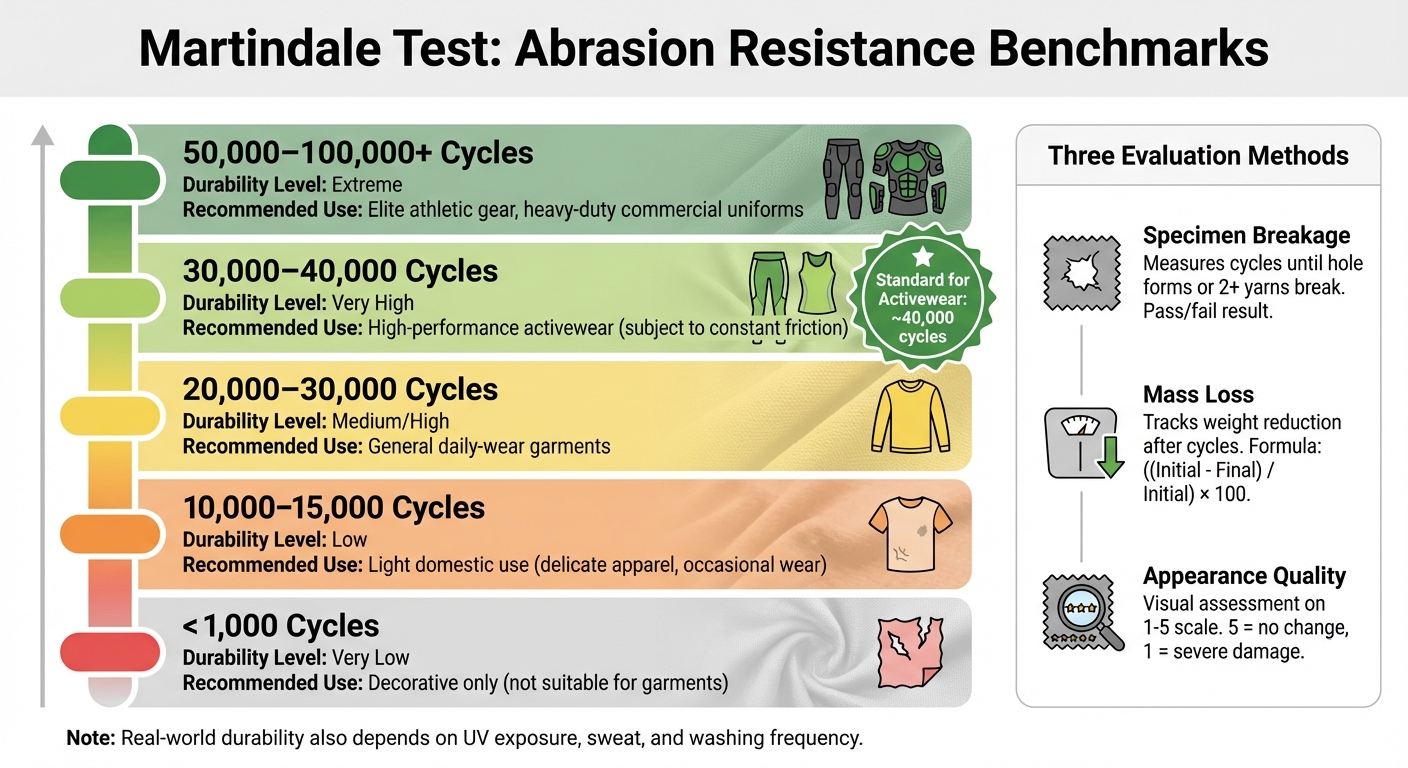

The Martindale test uses three key methods to measure a fabric’s resistance to abrasion:

- Specimen Breakage Method: This method tracks how many cycles the fabric can endure before a hole forms or at least two yarns break. It provides a straightforward pass/fail result, making it ideal for quick production checks [3, 10].

- Mass Loss Method: In this approach, the fabric is weighed before and after a set number of cycles. The percentage of weight lost is calculated using the formula:

((Initial Weight – Final Weight) / Initial Weight) x 100

This method helps monitor how the fabric wears down over time. - Appearance Quality Change: Here, the fabric is visually assessed on a 1–5 scale, where 5 means no change and 1 indicates severe pilling or fuzzing. A single inspector evaluates all samples for consistency, and half-grades are allowed [3, 14].

These methods give manufacturers critical insights into fabric durability, particularly for activewear.

Abrasion Resistance Benchmarks for Activewear

Using these testing methods, manufacturers establish "rub count" benchmarks to gauge fabric durability. Rub count measures the number of cycles a fabric can withstand before failing [3, 12]. For activewear, which faces constant movement and friction, a Martindale score of around 40,000 cycles is typically seen as the standard for durability.

| Cycle Count (Rubs) | Durability Level | Recommended Use |

|---|---|---|

| < 1,000 | Very Low | Decorative only (not suitable for garments) |

| 10,000–15,000 | Low | Light domestic use (delicate apparel, occasional wear) |

| 20,000–30,000 | Medium/High | General daily-wear garments |

| 30,000–40,000 | Very High | High-performance activewear (subject to constant friction) |

| 50,000–100,000+ | Extreme | Elite athletic gear, heavy-duty commercial uniforms |

It’s important to note that Martindale scores focus solely on abrasion resistance. Real-world factors like UV exposure, sweat, and frequent washing also play a role in how long activewear lasts. These benchmarks should be viewed as a guide, with the fabric’s overall performance environment taken into account [3, 12].

Conclusion

The Martindale test offers manufacturers a dependable way to evaluate how activewear fabrics hold up against friction and wear. By mimicking real-life movements with a multi-directional rubbing pattern, this test helps pinpoint weaknesses early on. This allows manufacturers to fine-tune material composition, yarn structure, or finishing techniques to improve performance. Plus, it contributes to sustainability by extending fabric life and minimizing waste.

For instance, New Dong Huang Garment Co., Ltd. incorporates abrasion resistance testing as a key part of its quality control process. By doing so, the company ensures its fabrics meet the durability demands of yoga wear, running gear, and outdoor performance clothing. This meticulous testing process helps maintain the quality and longevity expected by global brands.

FAQs

How does the Martindale test differ from other abrasion resistance tests?

The Martindale test is a go-to method for evaluating how well fabrics can handle everyday wear and tear. It uses a rotating disk with an abrasive surface – like wool or sandpaper – that rubs the fabric in a figure-eight motion. This setup is designed to closely mimic the natural abrasion fabrics face during regular use.

Unlike other methods, such as the rotary platform or oscillatory cylinder tests, the Martindale test stands out for its ability to replicate real-world abrasion patterns. This makes it a versatile choice for testing a wide variety of textiles. However, one drawback is its tendency for variability between laboratories, which can limit its reliability for acceptance testing where consistent results across labs are essential. Still, its strength lies in offering a practical glimpse into how fabrics might perform in everyday conditions, even if other methods might provide more controlled or material-specific insights.

How do manufacturers decide the durability requirements for different types of activewear?

Manufacturers set durability standards for activewear by analyzing the fabric’s intended purpose and how it will be used. To gauge abrasion resistance, they rely on tests like the Martindale test, which simulates wear and tear by rubbing fabric samples against rough surfaces under controlled conditions. The test measures how many rubs – or cycles – the fabric can endure before showing visible signs of wear, providing a clear indication of its durability.

For activewear meant for intense activities like outdoor sports or high-performance training, manufacturers test fabrics with higher cycle counts to ensure they can withstand rigorous use. On the other hand, fabrics designed for casual or low-impact activities are tested with fewer cycles. This tailored approach helps ensure each garment strikes the right balance between durability, comfort, and performance based on its intended use.

Why are controlled environmental conditions crucial for the Martindale test?

Maintaining stable conditions is crucial during the Martindale test to ensure reliable and consistent results. Variables such as temperature and humidity can significantly impact how a fabric performs under abrasion, potentially skewing results. By controlling these factors, the test accurately measures a fabric’s resistance to wear, ensuring it aligns with durability expectations for activewear.