Ultrasonic welding is transforming how activewear is made. This process bonds synthetic fabrics using high-frequency vibrations and pressure, creating smooth, durable seams without needles, thread, or adhesives. It’s faster, reduces production costs, and improves garment performance by eliminating bulky seams and chafing. Key benefits include:

- Speed: Bonds form in under 1 second, cutting production time significantly.

- Seam Quality: Flat, smooth seams enhance comfort and durability.

- Energy Efficiency: Uses less electricity compared to sewing.

- Material Compatibility: Works best with fabrics containing at least 65% thermoplastic fibers like polyester and nylon.

From leggings to sports bras and outdoor jackets, ultrasonic welding delivers lightweight, strong, and waterproof seams that meet the demands of performance-focused apparel. By fine-tuning machine settings, maintaining equipment, and collaborating with skilled manufacturers, brands can achieve high-quality results.

How to Make Perfect Seamless Clothing Like LuluLemon

sbb-itb-8dbc09a

What Is Ultrasonic Welding?

How Ultrasonic Welding Works: 4-Step Process for Activewear Manufacturing

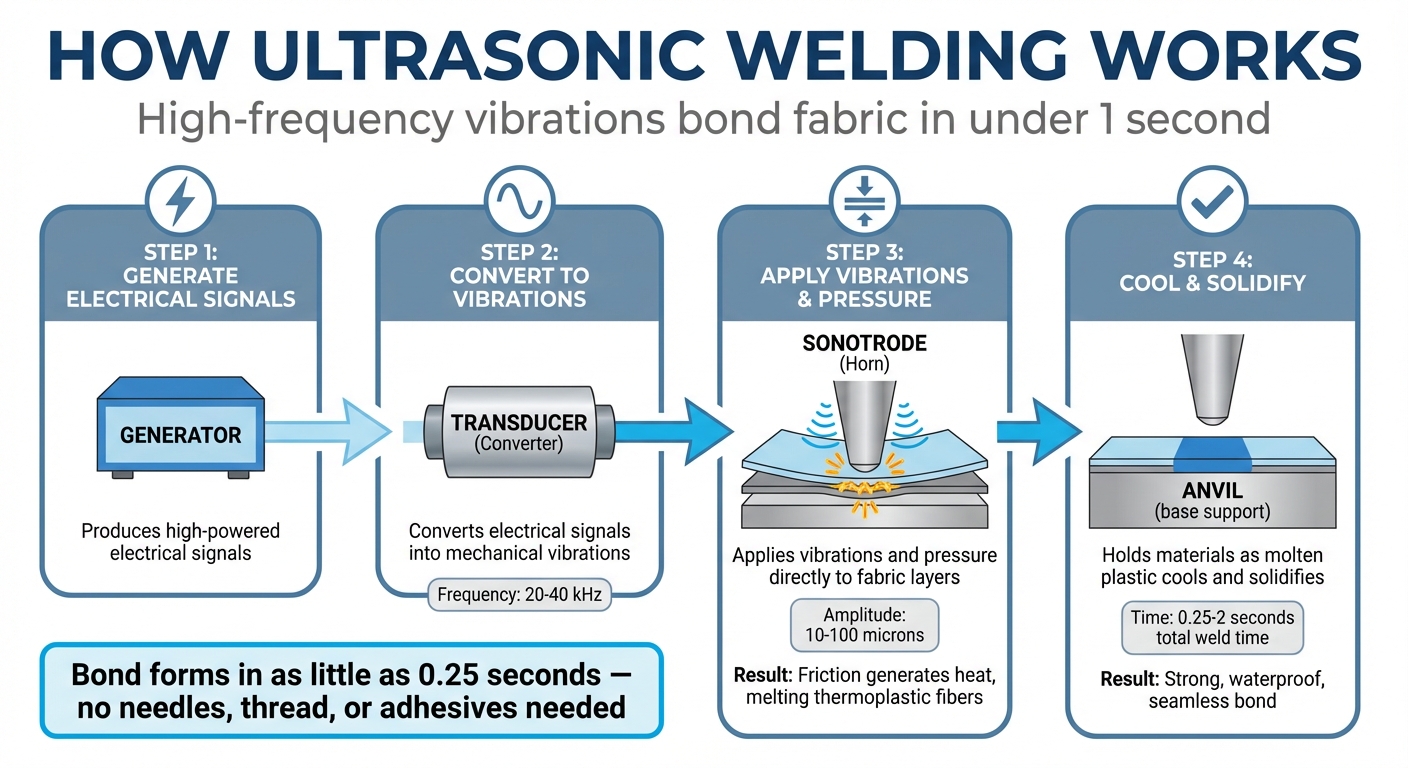

Ultrasonic welding is a method used in industrial settings to bond fabric layers by applying high-frequency acoustic vibrations and pressure. What’s unique about this process is that it doesn’t require needles, thread, or adhesives. Instead, it relies on converting electrical energy into mechanical vibrations through a component called a transducer. These vibrations are then delivered to the fabric layers using a tool known as a sonotrode (or horn).

Here’s how it works: the vibrations cause the fibers in the fabric to rub together at incredibly high speeds. This friction generates heat in specific areas, melting thermoplastic fibers like polyester or nylon just enough for their molecules to join. Once the vibrations stop, the fabric cools under pressure, solidifying the bond. The entire process is incredibly fast – bonds can form in as little as 0.25 seconds. And since the heat is created internally, the fabric’s outer surfaces remain untouched, making the method both efficient and precise.

How the Process Works

An ultrasonic welding system has four main components: the generator, the transducer (also called the converter), the sonotrode, and the anvil. Here’s what each part does:

- The generator: Produces high-powered electrical signals.

- The transducer: Converts those signals into mechanical vibrations.

- The sonotrode: Applies the vibrations and pressure directly to the fabric.

- The anvil: Acts as a sturdy base to support the materials during welding.

When the sonotrode presses down on the fabric layers, the vibrations create heat at the point where the layers meet. This heat melts the thermoplastic fibers, allowing them to fuse together. Once the ultrasonic energy stops, the materials are held together briefly – usually for half the weld time – so the molten plastic can cool and solidify. This targeted heating ensures a strong bond while keeping the surrounding fabric cooler than traditional methods would.

Compatible Fabric Materials

The success of ultrasonic welding depends heavily on the type of fabric being used. It works best with thermoplastic materials, which are synthetic fibers that soften when heated and resolidify upon cooling. For ultrasonic welding to be effective without extra adhesives, the fabric typically needs to contain at least 65% thermoplastic fibers and have a minimum thickness of about 0.0005 inches (0.0127 mm). These requirements are key to achieving durable bonds, especially in activewear.

Common thermoplastic fibers used in activewear include polyester, nylon (such as Nylon 6 and 6.6), polypropylene, acrylic, urethane, vinyl, polyethylene, and thermoplastic rubber. Stretchy blends like Spandex and Lycra also perform well, particularly in areas like waistbands and stretch panels. While natural fibers like cotton and wool don’t melt on their own, they can still be welded if blended with a high percentage of synthetic fibers or paired with a thermoplastic adhesive film. Since different thermoplastics vary in melt points, structure, and additives, it’s a good idea to test specific fabric blends before moving to large-scale production. This ensures the best results for both durability and comfort.

Benefits of Ultrasonic Welding for Activewear

Ultrasonic welding brings several advantages to activewear production, tackling common challenges like production inefficiencies and discomfort in garments. It delivers results that traditional sewing methods often fall short of achieving.

Faster Production and Cost Savings

With ultrasonic welding, bonds form in just 0.25 seconds, significantly reducing production times compared to sewing. But speed isn’t the only advantage. This method eliminates the need for consumables like thread, needles, and adhesives, cutting down on material costs. It also uses less electricity since heat is applied only at the precise contact point and only when necessary – unlike sewing, which involves continuous heat application and maintenance. Additionally, edge-to-edge joining minimizes fabric waste, boosting efficiency and contributing to better seam quality.

Strong, Smooth Seams

Beyond speed and cost, ultrasonic welding delivers seams that are ideal for high-performance activewear. These seams are incredibly flat and smooth – unlike the bulky seams created by traditional sewing. In fact, ultrasonic welding can produce seams as narrow as 0.5 mm, which is critical for activewear, as thick seams are a leading cause of chafing and irritation during intense activity.

Structurally, ultrasonic welding offers another key benefit. Sewing needles create holes in the fabric, which can weaken the material – especially in fine-knit performance fabrics. Ultrasonic welding avoids this issue entirely, forming a solid-state bond without perforations. The result? Seams that retain the fabric’s original strength while being naturally waterproof and airtight. For items like compression leggings, sports bras, and moisture-wicking layers, this means garments that are more durable and comfortable, even under demanding conditions.

Ultrasonic Welding vs. Traditional Sewing

Here’s a quick comparison of how ultrasonic welding stacks up against sewing in key areas:

| Aspect | Ultrasonic Welding | Traditional Sewing |

|---|---|---|

| Speed | Extremely fast; bonds form in under 1 second | Slower; limited by needle movement |

| Seam Quality | Flat, smooth, and bulk-free | Raised seams with visible holes and potential puckering |

| Durability | Strong molecular bonds; waterproof and airtight | Weaker at stress points due to needle holes |

| Energy Efficiency | Low energy use; heat localized and applied only as needed | Higher energy demands; continuous operation |

| Consumables | None needed (no thread, needles, or adhesives) | Regular thread and needle replacements required |

| Comfort | Smooth seams prevent irritation | Thick seams can cause chafing during activity |

For performance-activewear, where every detail impacts comfort, durability, and movement, the advantages of ultrasonic welding are hard to ignore. It offers a seamless solution that aligns perfectly with the needs of high-intensity garments.

Common Uses in Activewear Production

Ultrasonic welding has become a go-to technique in activewear manufacturing, thanks to its ability to create flat seams, enhance waterproofing, and maintain elasticity. These qualities make it particularly useful for garments designed for movement and performance.

Leggings and Compression Wear

Leggings and compression wear are prime examples of how ultrasonic welding shines. Unlike traditional sewing, which overlaps fabric and creates bulk, ultrasonic welding joins fabrics edge-to-edge, eliminating seam allowances and reducing irritation during activities like running, cycling, or yoga. This is crucial for comfort, as even a minor seam can cause discomfort during repetitive motion.

Moreover, ultrasonic welds preserve the natural stretch and recovery of compression fabrics, ensuring they maintain their shape even after repeated use. For materials with at least 65% thermoplastic content (like polyester or nylon blends), the welds are strong enough to withstand constant tension. The result? Ultra-narrow, flexible seams that move naturally with the body. This precision also benefits garments requiring targeted support, such as sports bras and base layers.

Sports Bras and Base Layers

Sports bras and base layers depend on ultrasonic welding for flat, supportive seams that avoid the irritation and weakening caused by needle holes. This method is especially valuable for high-impact activities, where comfort and durability are non-negotiable. Components like bra straps and bodysuits are welded to create smooth, flat seams that enhance both support and comfort during intense movement.

By eliminating needle holes, ultrasonic welding maintains the fabric’s strength and ensures the seams can handle repeated stretching. As Ardmel highlights:

"On traditional sewing machines, the needle punctures holes into the fabric, weakening its structure while the overlap of fabrics at the joint creates thick seams that are bulky, can restrict movement, are wasteful and adds weight to the garment. A multitude of negatives in the sportswear market."

– Ardmel

This durability is particularly important for sports bras, which endure constant stretching and compression. Ultrasonic welding ensures these garments retain their shape and support, even after multiple washes.

Outdoor Performance Jackets

When it comes to outdoor performance jackets, ultrasonic welding delivers seamless, non-perforated joins that are both liquid and gas-tight. Unlike traditional sewing, which requires seam-sealing tape to prevent water from seeping through needle holes, ultrasonic welding eliminates this issue entirely.

As Claudia Ollenhauer-Ries from Apparel Resources explains:

"The fact, that the needle punches holes into the material… matters again in special cases, where the holes could damage the super fine knitted material… or compromise the fabric’s tight seal."

– Claudia Ollenhauer-Ries, Apparel Resources

This technique also improves details like zip slots and hemming. For outdoor gear that demands moisture protection without sacrificing breathability, ultrasonic welding provides a lighter, more flexible alternative to adhesive-based sealing. Whether for high-performance workouts or weather-resistant outerwear, ultrasonic welding consistently improves the functionality and comfort of activewear.

How to Optimize Ultrasonic Welding Results

Achieving the best outcomes with ultrasonic welding involves focusing on three main areas: fine-tuning machine settings, maintaining equipment regularly, and collaborating with skilled manufacturers.

Adjusting Machine Settings

Getting the right machine settings is essential for effective welding:

- Frequency: Standard frequencies for textile welding range between 20 kHz and 40 kHz. Higher frequencies are better for thin fabrics, while lower ones are ideal for thicker materials.

- Amplitude: This controls the energy of mechanical vibrations. If the amplitude is too high, it can burn the material; too low, and the bond may be weak. The typical range is 10 to 100 microns.

- Pressure: Proper pressure ensures the fabric layers stay in close contact. Too much pressure risks tearing the material, while too little results in weak bonds.

- Welding Time: This typically falls between 0.25 seconds and 2 seconds. For continuous welding, roller speed must align with power and pressure to create consistent, waterproof seams.

- Energy Setpoint: Modern machines often use an energy setpoint (measured in Joules) to maintain consistency, even when material properties vary.

Once these parameters are dialed in, regular maintenance ensures they stay effective.

Maintenance and Quality Control

Keeping the machinery in top condition is critical for maintaining welding quality. Regular diagnostic horn scans are a must – an increase in open-air power draw could signal a crack forming. Comparing real-time weld graph data (like amplitude, power, current, frequency, and phase) with baseline data from when the machine was new can help detect performance issues early.

Inspect the sonotrode and anvil frequently, especially the knurled gripping surfaces, to check for wear. Environmental factors like humidity and temperature also play a role; too much moisture can cause bubbles or uneven welds. After production, inspect seams for burrs or excess material, which can be trimmed for a clean finish.

Working with Experienced Manufacturers

Partnering with experienced manufacturers can further improve results. Experts in ultrasonic welding bring valuable insights and resources to the table, ensuring consistent, high-quality production.

Take New Dong Huang Garment Co., Ltd., for example. With over 27 years of experience in activewear production, they utilize advanced equipment like bonding and laser cutting machines. Their process includes lab testing new fabric blends before mass production, ensuring strong, waterproof seams. Certified by BSCI, Sedex, and GRS, and boasting a 99% on-time delivery rate, they help brands manage the complexities of ultrasonic welding while maintaining excellent quality standards.

Conclusion

Ultrasonic welding has reshaped the way activewear is made by creating flat, seamless bonds in just seconds. This method removes the bulk and irritation caused by stitched seams while preserving the garment’s strength since no needles puncture the fabric. It’s a win-win for both production efficiency and waste reduction.

This technology enhances the design and performance of a wide range of activewear, from leggings and sports bras to performance jackets. By using polyester and nylon blends – the go-to materials for modern activewear – ultrasonic welding helps create garments that are lighter, stronger, and more comfortable.

To get the best results with ultrasonic welding, manufacturers need to focus on three critical areas: dialing in precise machine settings like frequency and pressure, performing regular maintenance to catch issues early, and working with skilled manufacturers. Companies like New Dong Huang Garment Co., Ltd. are already harnessing these practices to push the boundaries of performance apparel. When done right, the outcome is activewear that meets the high expectations of today’s athletes and fitness enthusiasts.

FAQs

Can ultrasonic-welded seams handle heavy stretch and repeated washing?

Ultrasonic-welded seams are capable of withstanding heavy stretching and repeated washing when designed correctly. This technique forms strong, seamless bonds, making it perfect for high-performance clothing. That said, the durability of these seams largely depends on the materials involved and how they’re applied.

What fabric blends work best for ultrasonic welding?

Fabric blends that are mostly synthetic – such as polyester, nylon, polypropylene, and spandex – are perfect for ultrasonic welding in activewear. These materials bond effectively because of their synthetic makeup. Blends containing up to 40% natural fibers can still be used, though a higher percentage of natural fibers might weaken the bond or call for adjustments. To achieve stronger and more dependable bonds for seamless, high-performance garments, a higher synthetic content is recommended.

When should I choose ultrasonic welding over sewing for activewear?

Choose ultrasonic welding for activewear when you need seams that are waterproof, flat, and seamless. This technique avoids the material damage caused by needle holes, cuts down on weight and restriction, and improves both comfort and durability. It’s perfect for high-performance garments, allowing for sleek, functional designs while maintaining the fabric’s strength and quality.