Air permeability testing measures how well air flows through a fabric, directly impacting heat dissipation, moisture control, and comfort in activewear. High air permeability fabrics keep you cool and dry during workouts, while low permeability materials offer wind resistance and warmth. Standards like ASTM D737 (U.S.) and ISO 9237 (international) ensure consistent testing methods for reliable results. Manufacturers use these tests to create fabrics tailored to specific activities, balancing breathability with other performance needs.

Key Points:

- Purpose: Ensures activewear is breathable for comfort and performance.

- Standards: ASTM D737 (U.S.) and ISO 9237 (global) provide guidelines.

- Applications: High airflow (600–1,000 L/m²/s) for sports shirts; low airflow (5–20 L/m²/s) for windproof jackets.

- Testing Process: Includes conditioning fabric, using calibrated equipment, and following precise procedures.

Understanding air permeability helps brands design activewear that meets performance expectations while maintaining quality and consistency.

What is Air Permeability and Why It Matters for Activewear

Definition and Core Principles

Air permeability refers to the rate at which air flows perpendicularly through a specific area of fabric under a set air pressure difference. While people often use "air permeability" and "breathability" as if they mean the same thing, they’re actually different. Air permeability is about how much air physically moves through the fabric’s pores, while breathability focuses on how well the material handles body heat and moisture vapor.

This measurable quality is key to understanding why breathable fabrics are so important in activewear.

Benefits of Breathable Fabrics in Activewear

Fabrics with good air permeability improve both heat regulation and moisture control during exercise. By allowing air to circulate freely, these fabrics help keep your body temperature in check, reducing the chance of overheating during intense workouts. Plus, better airflow means less sweat buildup, which helps avoid that sticky, uncomfortable feeling.

Comfort is another major factor influenced by air permeability. It’s not just about staying cool – it’s also about how the fabric feels on your skin. For outdoor gear like hiking pants or raincoats, finding the right balance is essential. Fabrics with lower air permeability provide wind resistance and help retain heat, while those with higher permeability offer better ventilation and cooling. Natural fibers like cotton and wool generally allow more air through than synthetic ones like polyester or nylon, thanks to their more open structures. However, synthetic fabrics can be specially designed with unique weaves or treatments to improve their air permeability.

These test results guide manufacturers in choosing the right materials and designs, ensuring that activewear meets the specific needs of various activities and environments.

Testing Standards for Air Permeability in Activewear Fabrics

Key Standards: ASTM D737, ISO 9237, BS 5636

ASTM D737 is the go-to standard in the U.S. for testing woven, nonwoven, and knitted fabrics. This method uses a pressure differential of 125 Pa (0.5 inches of water) across a 38.3 cm² (5.93 in²) test area. Results are expressed in ft³/min/ft² (CFM) or cm³/s/cm², ensuring precision across labs. Priced at $72.00, it’s a reliable choice for maintaining consistent testing practices domestically. For global applications, ISO 9237 offers a comparable framework.

ISO 9237 serves as the international benchmark, widely used in Europe, Asia, and beyond. It applies a pressure differential of 100 Pa for apparel fabrics and 200 Pa for industrial fabrics, with a smaller test area of 20 cm². Results are reported in L/m²/s or mm/s, making it easier to compare data across borders. Peter Goodwin notes that this standard ensures breathability results can be replicated worldwide. For those manufacturing in China, GB/T 5453 mirrors ISO 9237 closely, ensuring compatibility.

BS 5636, an older British standard, has largely been replaced by ISO 9237 in modern testing. While it may still show up in older specifications, most activewear brands now rely on ISO 9237 for consistency in international markets.

| Feature | ASTM D737 | ISO 9237 |

|---|---|---|

| Primary Region | United States | International / Europe |

| Pressure Differential | 125 Pa (0.5 in. H₂O) | 100 Pa for apparel; 200 Pa for industrial |

| Standard Test Area | 38.3 cm² (5.93 in²) | 20 cm² (3.1 in²) |

| Common Units | ft³/min/ft² (CFM) or cm³/s/cm² | L/m²/s or mm/s |

| Sample Mounting | Mounted without tension | Mounted with slight tension to remove wrinkles |

Why Standards Matter for Activewear Brands

For activewear brands, understanding these standards is essential to ensure their products perform as advertised. Standardized testing offers measurable, objective data to back up breathability claims. As Peter Goodwin explains, "The breathability of a garment is impacted by the material’s air permeability, but they are not the same thing… how well air can pass through a fabric is not subjective – it’s measurable".

Global supply chains make these standards even more critical. They guarantee that a fabric tested in one facility will deliver the same results elsewhere, ensuring consistency in quality control and meeting customer expectations. This is particularly important for athletic brands, where cooling and sweat-evaporation features are non-negotiable. By linking test results to heat dissipation and moisture management, manufacturers can refine fabric designs to meet specific performance needs.

Standardized testing also helps manufacturers maintain production quality. Finishing techniques, like hot calendaring or coatings, can unintentionally reduce breathability. These tests can catch such issues early, allowing for adjustments before products hit the market.

For U.S.-focused products, ASTM D737 is the standard to follow. For international markets, ISO 9237 is the better fit. Aligning with these standards not only meets local trade requirements but also smooths communication with retailers and regulatory agencies.

Air permeability testing procedure on method ASTM D 737

How to Conduct Air Permeability Testing for Activewear Fabrics

Now that the key testing standards have been covered, it’s time to dive into the actual testing procedures. By following ASTM D737 or ISO 9237 guidelines, you can ensure reliable and consistent air permeability results.

Equipment Needed for Testing

Different fabrics call for specific tools:

- Frazier Air Permeability Tester: Ideal for high-permeability fabrics, as it measures air velocity through the material under a constant pressure drop.

- Gurley Tester: Best for low-permeability fabrics like windproof or waterproof layers, measuring the time it takes for a set air volume to pass through.

- Shirley Air Permeability Tester: A versatile option for both woven and non-woven fabrics, commonly used in research and development.

Other essential tools include:

- Test heads/plates: Use 38.3 cm² plates for ASTM D737 or 20 cm² plates for ISO 9237.

- Pneumatic clamping system: Ensure it applies a minimum pressure of 50 ± 5 N.

- Manometer or pressure gauge: Must have an accuracy tolerance of ±2%.

- Flow meter: Measures the volume of airflow.

- Calibration disks: These disks, with known air permeability values, are crucial for verifying equipment accuracy .

Step-by-Step Testing Process

- Condition the Specimens: Before testing, let the fabric samples stabilize for 24 hours at 70 ± 2°F (20 ± 2°C) and 65 ± 2% humidity. This step is critical because moisture absorption can lower air permeability by 15-20% compared to dry fabric .

- Select and Prepare Specimens: Take 10 specimens per laboratory sample, ensuring they are evenly distributed across the fabric’s width and length, often diagonally. Avoid the first meter of the roll and stay at least 1/10 of the fabric width away from the edges. Handle the samples carefully to avoid stretching, folding, or creasing, which could alter the pore structure . For coated or laminated fabrics, place the coating side down (facing the low-pressure side) to reduce edge air leakage .

- Set Up the Equipment: Zero the instrument and check the airflow system as per the manufacturer’s instructions. Apply the appropriate pressure: 125 Pa for ASTM D737 or 100 Pa for ISO 9237 . Use the clamping system to mount the specimen securely. For heavier or coated fabrics, neoprene clamp rings or rubber gaskets may be necessary.

- Conduct the Test: Start the airflow and record the air volume passing through the fabric over time. Digital testers with automatic pressure controls and data storage provide better precision and repeatability compared to manual systems.

- Calibrate Regularly: Calibration is key to consistency. Use standard flow orifices to ensure accuracy, as results for the same fabric can differ by as much as 50 L/m²/s between labs without proper calibration. If testing at altitudes above 2,000 ft (600 meters), apply altitude correction factors to align results with sea-level data.

sbb-itb-8dbc09a

Factors That Affect Air Permeability Results

After covering the testing methods, it’s important to dive into the elements that naturally impact air permeability results. Recognizing these factors allows for better control during testing and smarter choices when selecting fabrics.

Fabric Structure and Fiber Type

The way a fabric is constructed plays a major role in how air flows through it. For instance, knitted fabrics generally let more air pass compared to woven ones because their looped structure creates more open spaces. Within woven fabrics, plain weaves tend to have higher permeability due to the greater number of interlacement points, which result in more voids.

Thread density also matters. A higher thread count means smaller pores, which reduces air permeability. For example, increasing the ends and picks per inch (EPI/PPI) tightens the fabric structure, significantly cutting down airflow. To illustrate, lightweight cotton voile can hit air permeability values around 900 L/m²/s, while high-thread-count poplin may drop to just 50 L/m²/s. Dense fabrics like standard denim typically fall between 10 and 20 L/m²/s.

Yarn properties also come into play. Increased yarn twist makes the structure denser, initially reducing its diameter. Multifilament yarns, on the other hand, create gaps between filaments, allowing more airflow. Monofilament yarns limit airflow to the pores formed by the weave. Fiber composition further influences results: natural fibers like cotton and wool absorb moisture and swell, which closes off pores and increases resistance to airflow. For example, a polyester sports shirt’s air permeability can drop from 700 L/m²/s at 40% humidity to 600 L/m²/s at 70% humidity.

Beyond the fabric’s construction, additional treatments can significantly alter airflow.

Coatings and Finishes

Surface treatments can dramatically decrease a fabric’s air permeability. For example, calendaring – a process that uses heat and pressure to flatten yarns – can reduce air permeability by 35-70%. This makes it an effective method for creating wind-resistant or down-proof fabrics, but it’s a factor that must be considered during testing.

Chemical treatments like waterproof coatings or quick-dry finishes also impact airflow by filling the gaps between yarns or compressing the fabric structure. In heavily coated or laminated fabrics where air permeability is nearly zero, breathability is instead measured using metrics like Water Vapor Transmission Rate (WVTR) or Resistance to Evaporative Heat Loss (Ret).

"Air permeability is influenced by the chemicals and coatings used on the outer layers of clothing, which can modify and/or restrict the flow of air through the material." – Peter Goodwin, Technical Specialist, James Heal

Wet processing and laundering also play a role. Shrinkage during these processes causes yarns to pack more closely and flatten, which reduces void dimensions and lowers the overall air permeability of the finished fabric compared to untreated grey material.

These variables are critical when designing fabrics that balance cooling and moisture control, especially for activewear.

Interpreting Air Permeability Results for Activewear Applications

Air Permeability Values Guide for Activewear Fabrics

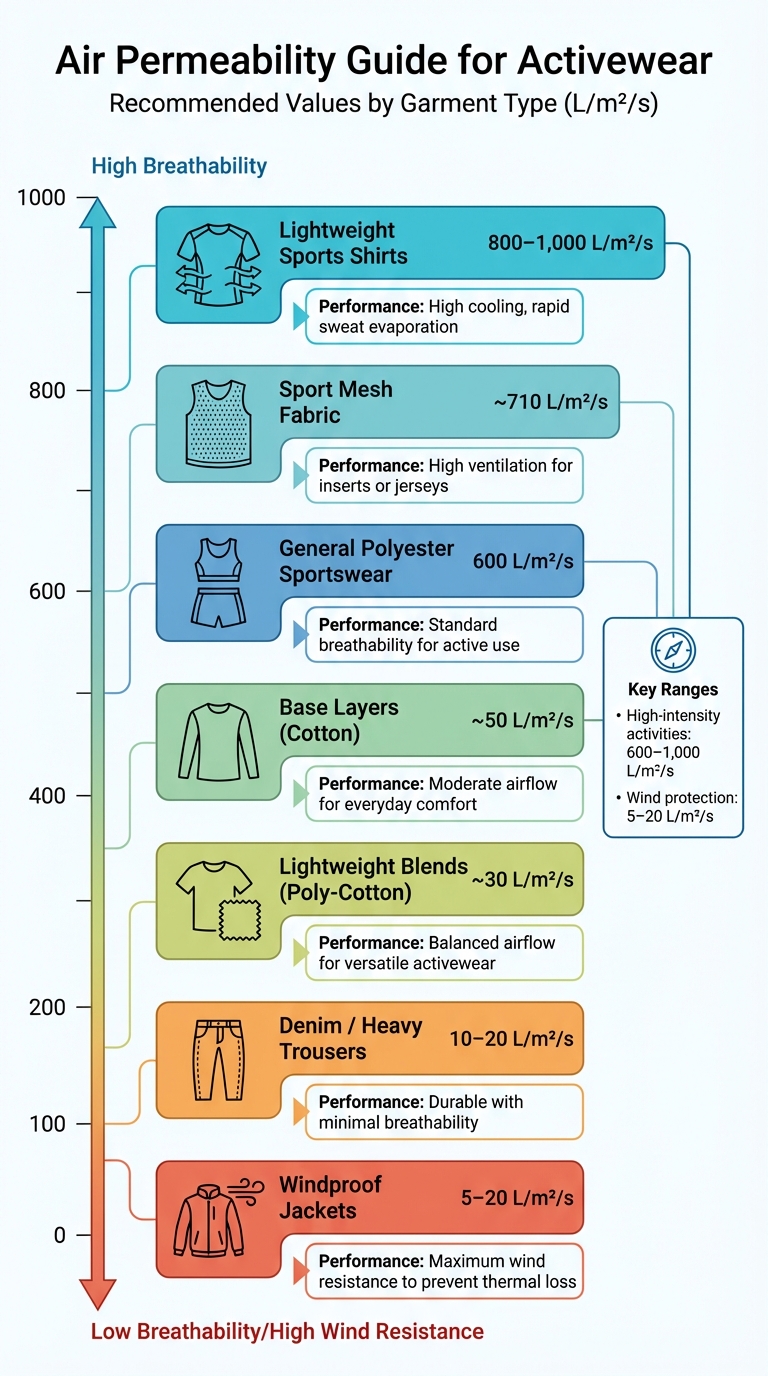

Once testing is complete, the next step is to interpret the results to understand how the garment will perform. Air permeability values measure how much air flows through the fabric, but their significance depends on the garment’s intended purpose. The chart below provides a helpful guide to recommended air permeability values for various garment types.

Recommended Air Permeability Values for Different Garments

Different types of activewear call for different levels of air permeability. For instance, a lightweight running shirt needs plenty of airflow to keep the wearer cool, while a windproof jacket must block air to retain warmth. Here’s a breakdown of the numbers:

| Garment/Fabric Type | Recommended Air Permeability (L/m²/s) | Performance Application |

|---|---|---|

| Lightweight Sports Shirts | 800–1,000 | High cooling, rapid sweat evaporation |

| General Polyester Sportswear | 600 | Standard breathability for active use |

| Sport Mesh Fabric | ~710 | High ventilation for inserts or jerseys |

| Base Layers (Cotton) | ~50 | Moderate airflow for everyday comfort |

| Lightweight Blends (Poly-Cotton) | ~30 | Balanced airflow for versatile activewear |

| Windproof Jackets | 5–20 | Maximum wind resistance to prevent thermal loss |

| Denim / Heavy Trousers | 10–20 | Durable with minimal breathability |

For high-intensity activities, fabrics with 600–1,000 L/m²/s airflow are ideal for quick sweat evaporation. Polyester sportswear typically meets the industry standard with around 600 L/m²/s. On the other hand, garments like windproof jackets require very low air permeability – between 5 and 20 L/m²/s – to block wind and maintain warmth.

"Air permeability can be an indicator of thermal loss in windproof garments, a measure of breathability for face coverings and can prevent infection in medical products." – Peter Goodwin, Technical Specialist, James Heal

While these values provide a guideline, achieving the right balance with other performance requirements is essential.

Balancing Breathability and Other Performance Features

When designing activewear, it’s not just about airflow – manufacturers need to consider how breathability interacts with other features. High air permeability is great for cooling but can lead to heat loss in cold or windy conditions. On the flip side, fabrics used for water-resistant or windproof garments often have very low air permeability, which can feel restrictive during intense activities.

For coated or laminated fabrics like those used in waterproof jackets, it’s important to check additional comfort metrics such as Water Vapor Transmission Rate (WVTR) or Ret (Resistance to Evaporative Heat Loss) values. For reference:

- A Ret value of 0–6 indicates "extremely breathable" fabrics that are comfortable for vigorous activities.

- Ret values above 20 are less suitable for intense exercise.

When it comes to outdoor shells or hiking trousers, the challenge lies in balancing low air permeability for wind resistance with high moisture vapor permeability to allow sweat to escape. Advanced technologies, such as microporous membranes, can help by letting moisture vapor pass through while blocking wind and rain.

Environmental factors also play a role. For example, natural fibers like cotton swell when wet, reducing air permeability by 15–20% compared to dry conditions. This means fabrics that perform well in dry weather might feel less breathable in humid or wet environments.

Conclusion

Air permeability testing plays a key role in creating high-performance activewear. While comfort is a personal experience for each wearer, this testing offers an objective and measurable standard that brands can rely on to ensure their fabrics meet expectations for breathability. Whether it’s a lightweight running shirt designed to wick away sweat quickly or a windproof jacket crafted to block air and retain warmth, these tests confirm that each garment achieves its intended performance.

Standardized methods like ISO 9237 and ASTM D737 ensure consistent fabric performance, not only across production batches but also in meeting the expectations of international trade partners. These protocols do more than validate performance claims – they also guide ongoing improvements in fabric technology.

The real challenge lies in striking the right balance between cooling and wind resistance. For high-intensity activities, fabrics need high air permeability (600–1,000 L/m²/s) to promote cooling, while outdoor gear requires low permeability (5–20 L/m²/s) to shield against the wind. Accurate air permeability testing allows activewear brands to design fabrics that consistently deliver on both comfort and performance.

FAQs

What’s the difference between air permeability and breathability?

Air permeability is all about how easily air can pass through a fabric. This is usually measured by the volume of air that flows through the material under a specific pressure. Breathability, however, focuses on the fabric’s ability to allow moisture vapor to escape, which plays a key role in managing sweat and humidity. While the two concepts are connected, they aren’t the same. A fabric with high air permeability doesn’t necessarily excel at moisture transfer because breathability depends on more intricate processes.

Which test standard should I use: ASTM D737 or ISO 9237?

The ASTM D737 standard is the go-to method for testing the air permeability of textile fabrics. This standard is widely accepted for quality testing and works well with various fabric types, such as woven, nonwoven, and coated materials. While ISO 9237 can also be used for this purpose, ASTM D737 is more frequently preferred in the industry, especially for activewear fabrics.

What air permeability range fits my garment’s end use?

When selecting the right air permeability for a garment, it’s all about its purpose. Fabrics with higher air permeability are perfect for activewear, such as sports or outdoor clothing, where breathability is key. On the other hand, lower air permeability is ideal for windproof or waterproof garments, offering better protection against the elements. The key is finding a balance between breathability and protection to suit how the garment will be used.