When designing activewear, tech pack sketches and CAD drawings are essential tools to ensure clear communication between designers and manufacturers. Both serve different purposes in the production process:

- Tech pack sketches: Simple, black-and-white 2D drawings focusing on garment construction details like seams, stitching, and hardware placement. Used in early stages to secure quotes and guide initial samples.

- CAD drawings: Digital, detailed blueprints created with software like Adobe Illustrator. They include precise measurements, fabric textures, and even 3D renderings, making them ideal for production and quality control.

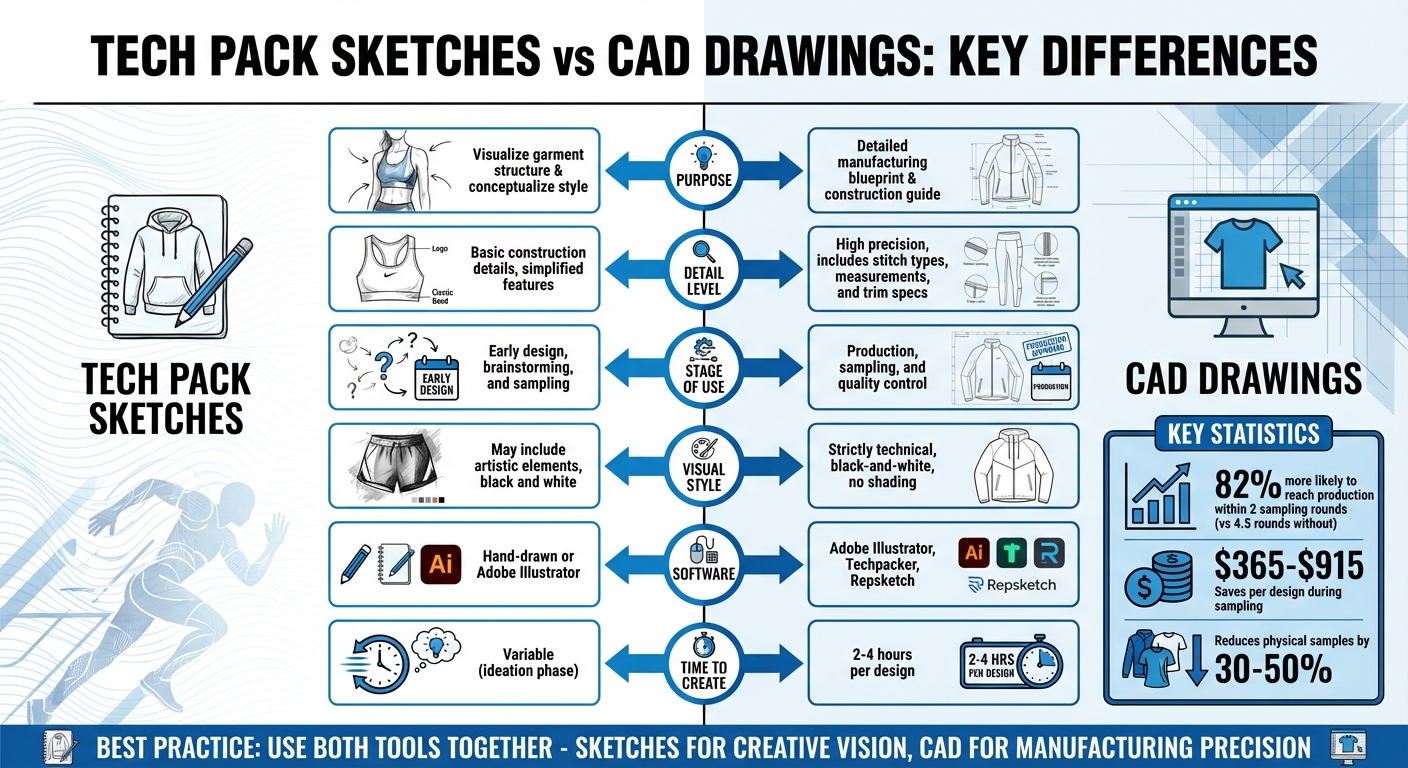

Each tool reduces errors, saves costs, and speeds up production timelines when used effectively. Combining them ensures both creative vision and manufacturing accuracy align. Below is a quick comparison:

Quick Comparison

| Feature | Tech Pack Sketches | CAD Drawings |

|---|---|---|

| Purpose | Visualize garment structure | Detailed manufacturing blueprint |

| Detail Level | Basic construction details | High precision, includes trims |

| Stage | Early design and sampling | Production and quality control |

| Software | Hand-drawn or Adobe Illustrator | Adobe Illustrator, Techpacker |

| Time to Create | Variable | 2–4 hours per design |

Tech Pack Sketches vs CAD Drawings Comparison for Activewear Design

TECHNICAL DRAWING FOR FASHION: Part 1 – Creating simple silhouettes & design details

sbb-itb-8dbc09a

What Are Tech Pack Sketches?

Tech pack sketches, often referred to as fashion flats or technical flats, are 2D line drawings that represent a garment in its flat form. Unlike artistic illustrations, these sketches focus entirely on the garment’s technical construction details. Their purpose is to provide manufacturers and pattern makers with a clear understanding of elements like seam placement, stitching styles, and hardware locations.

"A technical drawing is the fashion industry equivalent to a blueprint, it shows the factory or pattern cutter the shape of the garment when laid flat, without any artistic flare or stylisation." – Vicki Wallis, The Fashion Business Coach

These sketches are typically done in black and white to keep the focus on critical construction details. Without the distraction of color or shading, features like flatlock seams, mesh panel placements, and zipper pocket positions stand out clearly.

Main Components of Tech Pack Sketches

At a minimum, tech pack sketches include front and back views of a garment. For more intricate designs – like jackets with hidden pockets or leggings featuring concealed compartments – additional views, such as side or inside-out perspectives, may be added. These sketches are often drawn to scale (commonly 1:8 for adult clothing) to ensure accuracy for pattern makers.

Designers rely on specific line styles to convey construction details: solid lines indicate seams, while dashed lines represent stitching. Annotations are also included to label features like collar shapes, placket types, fastenings, and artwork placement, ensuring every aspect of the garment is clearly communicated.

When to Use Tech Pack Sketches

Tech pack sketches are invaluable during the early stages of design, helping teams and manufacturers visualize garment structure. They play a crucial role in securing accurate factory quotes and creating the first sample. Research shows that brands using professional tech packs are 82% more likely to reach production within two sampling rounds, compared to an average of 4.5 rounds without them.

These sketches are especially useful when working with offshore manufacturers, as they act as a universal language to bridge communication gaps. For activewear, where precision in fit and functionality is critical, tech pack sketches ensure details like seam placements and mesh panel positions are conveyed with clarity.

Next, we’ll dive into how CAD drawings enhance the role of these traditional sketches.

What Are CAD Drawings?

CAD (Computer-Aided Design) drawings are digital, precision-based representations of garments in flat form. Unlike traditional hand-drawn sketches, CAD drawings rely on vector-based software – most commonly Adobe Illustrator – to create highly accurate, scalable blueprints. These blueprints act as a vital link between the design and production stages.

"Think of it as your garment’s blueprint – a clear visual map that guides the people responsible for bringing your design to life." – Cathryn May, Freelance Fashion Designer

Modern CAD drawings often include 3D renderings, allowing designers to simulate how fabrics will drape or how garments will fit. This reduces the need for physical samples by as much as 30–50% and can speed up design timelines by up to tenfold. For activewear designers, this means you can preview how mesh panels will sit or how compression zones will function – without waiting for lengthy prototype cycles.

The precision of CAD drawings eliminates common misunderstandings. Every aspect, from stitch type and seam placement to zipper alignment and logo positioning, is defined with exact measurements. Skilled designers using Adobe Illustrator can produce a professional technical CAD in as little as 20 minutes, making it a faster and more reliable approach.

Main Components of CAD Drawings

CAD drawings are packed with detailed information to ensure the smooth production of even the most complex activewear designs.

Here’s what they typically include:

- Stitching and seam details: Standardized line weights make it easy to identify garment outlines (solid 1pt lines) and stitching details (dashed 0.5pt lines) like flatlock or cover stitches.

- Multiple perspectives: Views from the front, back, side, and interior, along with close-up callouts for intricate elements.

- Trims and branding placement: Exact positioning of zippers, drawstrings, toggles, reflective details, logos, and care labels.

- Colorway visualization: A breakdown of how fabric panels, mesh inserts, and color-blocked sections will look in the final product.

When to Use CAD Drawings

CAD drawings are essential as designs transition from the concept phase to production. They serve as a detailed communication tool during factory handoffs, ensuring manufacturers – especially those offshore – understand every construction detail. This clarity helps reduce costly errors and sampling rounds, potentially saving $370 to $920 per design during the sampling phase.

These drawings are especially useful for activewear with technical features, like compression garments with graduated pressure zones, jackets with taped seams, or leggings with engineered mesh panels. Additionally, modern CAD software’s 3D rendering capabilities allow teams to align visually with stakeholders early on, confirming design details before moving into physical sampling.

Tech Pack Sketches vs. CAD Drawings: Main Differences

Now that we’ve defined tech pack sketches and CAD drawings, let’s break down how they differ and the roles they play in activewear design.

Each tool has a unique purpose in the design process. Tech pack sketches are meant to outline the overall look of a design. They focus on silhouettes and basic details like pockets or necklines, offering a quick way to convey the concept or mood of a piece without diving into the nitty-gritty of construction.

On the other hand, CAD drawings are all about precision. These are detailed, factory-ready blueprints that include everything from stitch types (like overlock or coverstitch) to seam allowances, hardware placements, and trim specifications. For activewear, which often relies on technical features like waterproof seams, CAD drawings are essential for ensuring the design is executed correctly in production.

"A technical drawing focuses on reality, using actual proportions so the whole team can reference the same version of a style as it moves forward." – Onbrand PLM

Another key difference lies in the time and stage of use. Tech pack sketches are quick to create and are primarily used during the brainstorming phase when ideas are still being fleshed out. In contrast, CAD drawings require more time – typically 2 to 4 hours per design as part of a full tech pack – and are used during later stages like production, sampling, and quality control.

Here’s a side-by-side look at their differences:

Comparison Table: Tech Pack Sketches vs. CAD Drawings

| Feature | Tech Pack Sketches | CAD Drawings |

|---|---|---|

| Primary Purpose | Conceptualizing style and silhouette | Manufacturing blueprint and construction guide |

| Detail Level | Simplified; shows basic features | High; includes stitch types, measurements, and trim specs |

| Stage of Use | Early brainstorming and ideation | Production, sampling, and quality control |

| Visual Style | May include artistic elements | Strictly technical, black-and-white, no shading |

| Software Used | Adobe Illustrator, hand-drawn | Adobe Illustrator, Techpacker, Repsketch |

| Time Required | Variable (ideation phase) | 2–4 hours per design (as part of tech pack) |

| Dimensions | 2D simplified outline | Drawn to scale (1:8 for adults) |

This comparison highlights how each tool is tailored to different needs, from creative exploration to precise manufacturing guidance. Both are crucial, but they’re used at very different points in the design journey.

Benefits and Drawbacks of Each Tool

Understanding the strengths and limitations of each tool is key to aligning them with the specific stages of activewear production.

Tech pack sketches shine when it comes to clear, universal communication. They act as a "universal language" that connects designers, pattern makers, and manufacturers, particularly when collaborating with overseas factories where language barriers might arise. For activewear, these sketches are indispensable for illustrating specialized features like flatlock stitches, which are crucial for stretchy seams, ensuring factories use the correct machinery. Industry statistics reveal that tech packs can significantly reduce sampling rounds, saving anywhere from $375 to $940 per design during the sampling phase.

That said, tech pack sketches come with challenges. They require a deep understanding of garment construction. As Vicki Wallis, The Fashion Business Coach, states:

"A technical drawing is much more than a digital drawing and needs to be created by someone with a lot of garment making experience, rather than just someone who knows how to draw digitally".

Additionally, while these sketches effectively detail construction, they fall short in showing how fabrics drape or fit on a body, which can lead to misunderstandings and costly mistakes.

CAD drawings, on the other hand, bring precision and efficiency to the table. Designers can create libraries of reusable components, such as collars, cuffs, and activewear-specific trims, cutting design time from hours to minutes for future projects. These drawings are typically scaled to match how factories measure garments for quality control. However, mastering CAD requires specialized skills. Designers need proficiency in tools like Adobe Illustrator and a solid grasp of technical garment knowledge. These challenges highlight the importance of balancing both tools in your design process.

Benefits and Drawbacks Table

| Tool | Benefits | Drawbacks |

|---|---|---|

| Tech Pack Sketches | • Facilitates communication across language barriers • Reduces sampling costs • Highlights activewear-specific construction (e.g., flatlock stitches) • Protects intellectual property |

• Requires advanced garment expertise • Doesn’t convey fabric drape or fit • Poorly executed sketches can lead to errors |

| CAD Drawings | • Provides precise, factory-ready blueprints • Digital files can be reused • Scaled for accurate measurements • Reduces ambiguity in production • Enhances professional brand presentations |

• Demands Adobe Illustrator skills • Takes 2–4 hours per design • Requires technical garment expertise • Lacks ability to show 3D fit or movement |

Using Tech Pack Sketches and CAD Drawings Together

In activewear design, where both style and functionality are key, combining tech pack sketches with CAD drawings creates a seamless workflow. It all begins with fashion floats – those initial mood sketches that capture the essence of the garment. These early visuals help convey how the apparel should look and move, whether it’s for yoga sessions or intense runs. Once the concept is approved, technical designers translate these artistic sketches into detailed CAD flats.

Think of it as a two-step communication process. The initial sketches express the creative vision to your team and stakeholders, while the CAD drawings act as a detailed guide for manufacturers. As Vicki Wallis, Fashion Business Coach, puts it:

"The technical drawing, in conjunction with the tech pack act as an ‘instruction manual’ for the factory, so they can make samples and quote a price to you".

For more intricate activewear designs, this dual approach is crucial. Providing multiple CAD versions – like black-and-white for construction details and colored versions for fabric placement – ensures nothing gets lost in translation. This is especially vital when working with manufacturers like New Dong Huang Garment Co., Ltd., where precision-driven machinery like bonding machines or laser cutters rely on exact technical specifications. This process bridges creative ideas with manufacturing accuracy.

Improving Activewear Production Workflow

Using both tech pack sketches and CAD drawings doesn’t just make design intent clearer – it also speeds up production. According to White2Label Manufacturing, brands that included comprehensive tech packs with both types of visuals were 82% more likely to reach bulk production within just two sampling rounds. Without these documents, the average was 4.5 sampling rounds; with them, it dropped to 1.8 rounds.

For activewear, this method helps avoid expensive errors. Including detailed views – front, back, side, and internal – in your CAD drawings allows for precise instructions. For instance, you can specify the exact placement of flatlock stitching for stretch performance or seam taping for waterproofing. The payoff? Fewer misunderstandings, quicker production timelines, and activewear that performs exactly as intended when it hits the market.

Conclusion

Tech pack sketches and CAD drawings work hand in hand in the world of activewear design. While tech pack sketches articulate the creative vision, CAD drawings provide the precise details needed for manufacturing success. Freelance fashion designer Jonathan Mitchell sums it up perfectly:

"CADs provide the visual foundation, while tech packs lay out the technical framework. This combination offers a holistic approach to garment design, making it easier to communicate specifications with clarity and precision."

The numbers back this up. Anthony Mellor reports that incorporating tech packs can cut sampling rounds from 4.5 to just 1.8, saving anywhere from $365 to $915 per design. That’s a game-changer for activewear, where technical performance isn’t just important – it’s essential. Features like moisture-wicking fabrics and ergonomic paneling demand a level of precision that only this combination can deliver.

Here’s how it works: CAD drawings highlight the aesthetic and structural aspects of your design, while tech pack sketches drill down into the technical details – everything from stretch percentages to the exact placement of flatlock stitching. Together, they ensure every part of your design is clearly communicated.

But to make the most of this approach, synchronization is key. Every update to a CAD drawing must be mirrored in its tech pack to avoid discrepancies. When these tools are perfectly aligned, manufacturers like New Dong Huang Garment Co., Ltd. can execute designs with exacting precision, turning your creative ideas into high-performance products without missing a beat.

FAQs

Do I need both a tech pack sketch and a CAD drawing?

Yes, both play a critical role. A tech pack sketch (also called a flat sketch) highlights the design elements and construction details of your activewear. On the other hand, a CAD drawing offers a precise, scaled blueprint that manufacturers rely on for production. When used together, they ensure your design is communicated clearly and is ready for manufacturing.

What should I include in a CAD drawing for activewear?

A CAD drawing for activewear needs to present a precise, technical sketch of the garment’s design and structure. This typically includes flat, black-and-white illustrations that display the front, back, and any additional required views. The details should clearly highlight elements like seams, stitching, and closures. It’s crucial to ensure the sketches are to scale, avoid any decorative stylization, and include annotations or measurements to provide clear guidance for pattern makers and manufacturers.

How do these drawings help reduce sampling rounds and costs?

These drawings cut down on sampling rounds and expenses by offering clear and detailed technical specifications. They ensure precise communication of design and construction details, which reduces mistakes and limits the need for extra prototypes. By simplifying the process, they save both time and resources while keeping the design accurate.