Laser-cut seams are changing how activewear is made. They use lasers to cut and seal fabric edges, offering smoother, lighter, and more durable seams compared to stitched ones. This method eliminates bulky stitching, reduces friction, and improves comfort during workouts. It also allows for precise designs, better airflow, and faster production. Plus, it minimizes fabric waste and creates longer-lasting garments. The result? Activewear that feels better, performs better, and lasts longer.

Key Points:

- Uses lasers for precise, no-contact cutting and sealing.

- Prevents fraying and eliminates bulky seams.

- Helps reduce chafing and improves breathability.

- Enables intricate designs and faster production.

- Reduces waste and supports longer garment life.

Laser technology is reshaping activewear by combining comfort, durability, and efficiency in production.

What Are Laser-Cut Seams?

Laser-Cut Seams vs Traditional Stitching in Activewear: Performance Comparison

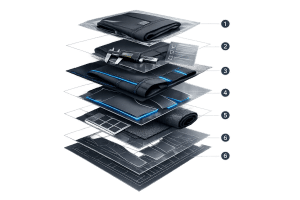

Laser-cut seams have transformed the way activewear is made, offering a cutting-edge approach to garment construction. Instead of relying on needles and thread, this method uses high-energy laser beams to cut and seal fabric edges in one seamless motion. These lasers are powered by controlled energy discharges, generating focused light beams that handle the cutting with precision.

Here’s how it works: A laser beam is guided through a tube-like device, where it passes through a focal lens that directs it to an exact point on the fabric. When the beam hits the material, it raises the temperature so quickly that the fabric either vaporizes or melts, effectively sealing the edges on synthetic fabrics like polyester, nylon, and spandex. This sealed finish prevents fraying, a common issue with traditional methods.

One key advantage of this technique is its non-contact nature – the laser never physically touches the fabric. CO2 lasers, which operate at a wavelength of 10 μm, are the go-to choice for wearable textiles. Their infrared light is easily absorbed by both synthetic and organic fabrics, making them ideal for precision cutting. This level of accuracy opens the door for advanced designs and better performance, as explained further below.

The Laser-Cutting Process

Modern laser-cutting systems are equipped with vision systems and cameras that scan sublimated prints, automatically detecting contours for precise cuts. This technology ensures accuracy even if the fabric has stretched or shrunk during the printing process. It works especially well with popular activewear materials like nylon, polyester, spandex, neoprene, and other synthetic blends.

These systems not only improve precision but also significantly boost production speed, making the process more efficient.

"Cutting fabric with a laser allows for extremely accurate cuts without ever touching the fabric, which means that a garment comes out as untainted by a manufacturing process as possible." – Engadget

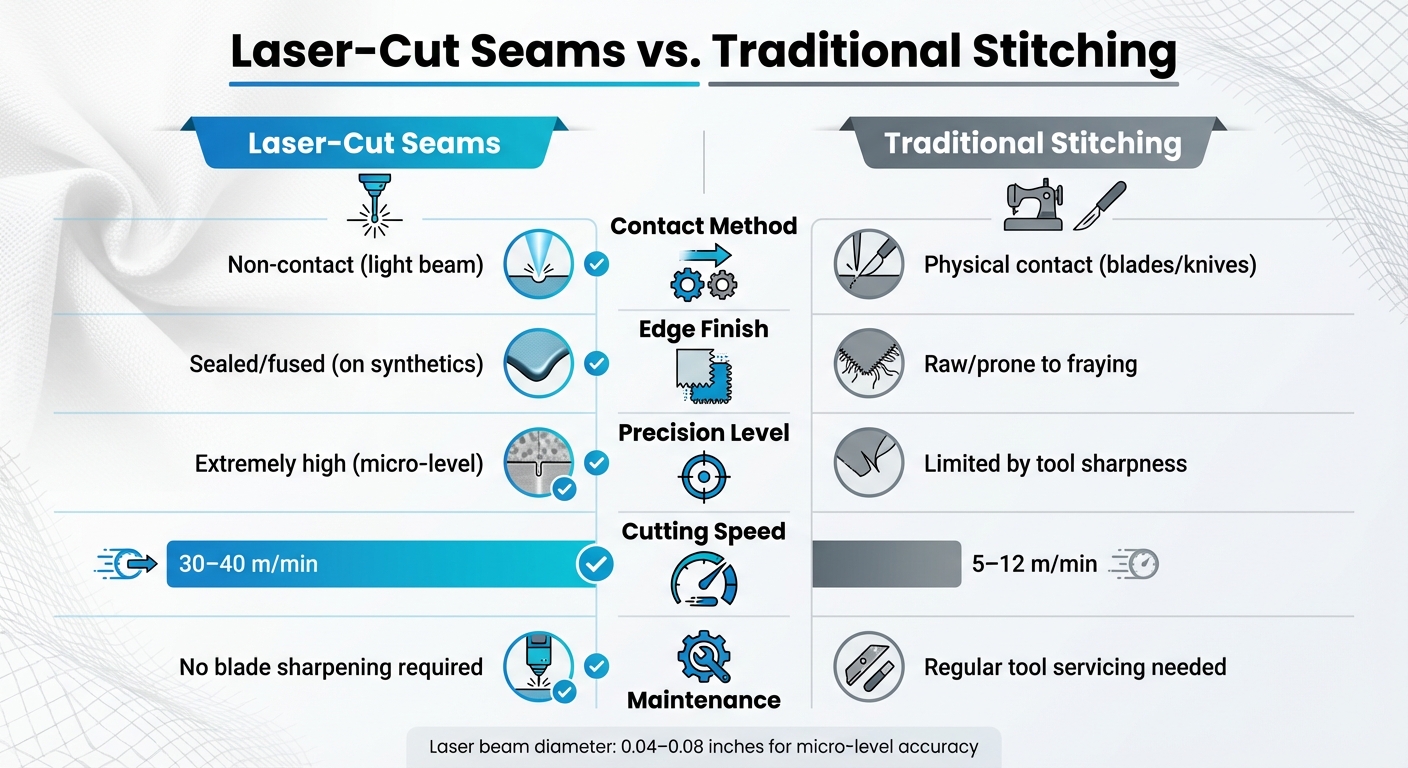

Laser-Cut Seams vs. Traditional Stitching

Laser-cut seams offer clear advantages over traditional stitching, not just in how they’re made but in how they enhance garment performance. Traditional cutting tools like knives or discs rely on mechanical force, which can distort delicate or stretchy fabrics, reducing precision. In contrast, lasers operate with micro-level precision, avoiding physical contact and ensuring the material remains undisturbed.

Another downside of traditional stitching is the need for hemming to prevent fraying, which adds bulk to seams. Laser cutting eliminates this step entirely for synthetic fabrics, as the edges are sealed during the cutting process. This results in "seamless" designs that are lighter, less bulky, and more comfortable. As highlighted in the Fashion and Textiles Journal:

"In synthetic fabrics, laser cutting produces well-finished edges as the laser melts and fuses the edge, which avoids the problem of fraying produced by conventional knife cutters"

Here’s a quick comparison of the two methods:

| Feature | Laser-Cut Seams | Traditional Stitched Seams |

|---|---|---|

| Contact | Non-contact (light beam) | Physical contact (blades/knives) |

| Edge Finish | Sealed/fused (on synthetics) | Raw/prone to fraying |

| Precision | Extremely high (micro-level) | Limited by tool sharpness |

| Speed | 30–40 m/min | 5–12 m/min |

| Maintenance | No blade sharpening required | Regular tool servicing needed |

These technical benefits make laser-cut seams a game-changer for activewear, offering improved comfort, durability, and design flexibility.

Comfort and Performance Benefits

The right activewear can completely transform your workout experience. Laser-cut seams have emerged as a game-changer, addressing common problems like irritation and overheating while boosting overall athletic performance.

Reduced Friction and Chafing

One standout advantage of laser-cut seams is their ability to eliminate the bulky stitching that often causes discomfort during movement. Unlike traditional seams that create ridges and friction, laser cutting produces flat, sealed edges by melting the fabric fibers. This process ensures a smooth, fray-resistant finish that feels gentle on the skin. Plus, because lasers cut without physical contact, they avoid the fabric deformation that mechanical blades can cause.

"Because seams would disrupt the cutout design, most laser-cut leggings are seamless, reducing the likelihood of chafing." – MimoWork

Laser technology also allows manufacturers to fuse or bond fabrics, creating joins that are smoother than those made with traditional stitching. The result? A "second-skin" sensation that moves effortlessly with your body, free of any irritating pressure points. On top of that, the process enhances fabric ventilation, making it ideal for intense physical activities.

Better Breathability and Airflow

Laser cutting doesn’t just improve comfort – it also boosts breathability. Designers can use high-powered lasers to create micro perforations in areas prone to sweating, allowing heat to escape efficiently. These tiny, precise cutouts let air flow directly to the skin, while sealed edges maintain the fabric’s strength and durability.

"Laser cutting allows for the inclusion of tiny perforations or mesh areas in strategic locations to promote airflow, keeping athletes cool during high-intensity activities." – Golden Laser Team

Without bulky seams trapping heat, laser-cut garments offer excellent air circulation. This added ventilation is crucial for activities like hot-weather runs, Bikram yoga, or high-intensity interval training, where staying cool can make all the difference.

Many performance-focused brands have embraced this technology to create activewear that prioritizes comfort and functionality. For instance, New Dong Huang Garment Co., Ltd. uses advanced laser cutting techniques to craft activewear that excels in breathability, durability, and overall comfort. These precision-engineered designs not only enhance comfort but also support athletes in achieving peak performance.

Precision and Durability

When it comes to activewear built to last, precision plays a crucial role. Laser cutting offers a level of accuracy that traditional methods simply can’t achieve, ensuring garments retain their shape and performance over time.

Micro-Level Cutting Accuracy

Laser-cut seams aren’t just precise – they’re consistently precise. By using computer-guided lasers to follow CAD designs, manufacturers achieve uniformity across production runs. The laser beam itself can be focused to an incredibly fine point, ranging from 0.04 to 0.08 inches in diameter, allowing for micro-level cutting accuracy.

Unlike traditional blades, which can cause fabric distortion, lasers operate without physical contact. This prevents deformation in delicate performance fabrics like spandex and nylon. Some advanced systems even go a step further, using cameras to scan fabrics for registration marks. These systems automatically adjust for any shrinkage or stretching that may occur during production.

With cutting speeds reaching up to 131 feet per minute and dual laser heads increasing output by as much as 50%, laser cutting not only outpaces traditional methods but also maintains its exceptional precision.

Sealed Edges That Prevent Fraying

Another standout advantage of laser cutting is its ability to create sealed edges. The high-energy laser beam doesn’t just cut through fabric – it melts and fuses the fibers along the edge, forming a permanent seal. This prevents fraying, even after repeated washes and rigorous physical activity.

"Laser-cut edges are cleaner and less likely to fray." – Golden Laser Team

This thermal sealing process works especially well with synthetic fabrics like polyester, nylon, and spandex. Thanks to their thermoplastic properties, the laser bonds the fibers during cutting, delivering a "lint-free" and "clean" finish. The result? Activewear that holds up under pressure and maintains its structural integrity far longer than garments cut with traditional methods.

The precision and durability offered by laser cutting redefine the standards for high-performance activewear, making it a go-to choice for advanced manufacturing techniques.

sbb-itb-8dbc09a

Design Flexibility and Customization

Laser cutting doesn’t just bring precision and durability to activewear manufacturing – it also opens up a world of design possibilities. Thanks to computer-controlled accuracy, manufacturers can now produce intricate patterns, functional details, and custom features that were once out of reach or too costly to create.

Complex Patterns and Functional Details

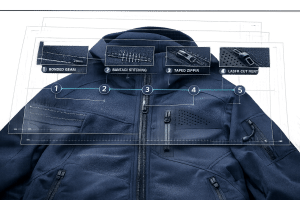

With laser cutting’s pinpoint accuracy, even the most intricate designs – like wave patterns, geometric cutouts, or detailed logos – can be executed flawlessly and consistently across entire production runs. Unlike traditional cutting tools, laser cutting is a contactless process, which means delicate fabrics like spandex and nylon remain undistorted. No physical pressure means no risk of pulling or tearing, which is a game-changer for activewear made from these sensitive materials.

This technology also supports "mass customization", allowing garments to be tailored to specific body measurements or personalized with team branding – without the need for expensive physical molds or dies. The result? High-quality, custom designs that cater to both aesthetic and functional needs.

Applications in Different Activewear Products

Laser-cut customization shines across various activewear categories, each benefiting in unique ways. For leggings, designs like side slashes, wave patterns, or ripped cutouts add style and breathability. Sports bras can feature decorative crisscross elements that lie flat against the skin, blending comfort with style. Cyclists see performance gains with aerodynamic shapes and lightweight constructions that reduce drag during high-speed rides. Even compression wear gets an upgrade, as laser welding creates smooth, skin-friendly seams that enhance flexibility while maintaining support.

New Dong Huang Garment Co., Ltd. exemplifies the potential of laser cutting in activewear. Their advanced machinery enables them to deliver custom designs that combine intricate patterns with practical performance features across their range of leggings, sports bras, jackets, and base layers.

Production Efficiency and Environmental Benefits

Laser-cut seam technology isn’t just about performance and sleek designs – it also brings measurable improvements to manufacturing efficiency and reduces environmental impact. Here’s how this technology transforms production processes.

Faster Production Times

Laser cutters operate at impressive speeds of 30–40 m/min, far outpacing the 5–12 m/min achieved by traditional knife cutters. Plus, their non-dulling laser beams cut and seal edges in a single step, eliminating the need for extra finishing processes or downtime. Switching between intricate designs is as simple as a software update, unlike traditional methods that often require new dies or lengthy manual setups. For even greater output, dual-head systems can increase production by 30–50%, depending on the complexity of the design.

Less Fabric Waste

Laser systems are designed to maximize material efficiency. They nest patterns with precision, reducing fabric waste. Unlike traditional methods, which can involve adhesives or chemicals, laser technology uses a contactless, dry process that leaves no residue. By vaporizing material instead of shredding it, the process keeps the manufacturing environment cleaner and free of lint. These features not only improve efficiency but also support the creation of longer-lasting, more sustainable activewear.

Longer-Lasting Garments

Durability plays a big role in sustainability, and laser technology excels here. The thermal cutting process melts and fuses fabric edges, sealing them to prevent fraying – a common issue with traditional stitching that shortens garment lifespans. This sealed finish ensures garments last longer, reducing the need for frequent replacements and lowering production demand.

"Compared to ultrasonic welding, laser-welded seams have an undamaged fabric surface; melting points are not visible on the surface. Adhesive material is not required either." – Frederike Lehmeier, Project Manager, Leister Technologies AG

Another advantage is the ability to join identical thermoplastic materials, like polyester to polyester, without introducing foreign fibers such as sewing threads. This "same-material" construction results in mono-material garments that are far easier to recycle, aligning with circular economy goals. These manufacturing efficiencies directly enhance the quality and sustainability of performance wear.

Manufacturers like New Dong Huang Garment Co., Ltd. are already adopting these advanced laser cutting techniques to produce high-performance, eco-conscious activewear, setting a benchmark for quality and environmental responsibility.

Conclusion

Laser-cut seam technology has reshaped the way high-performance activewear is designed and produced. By offering improved comfort, durability, precision, and eco-conscious manufacturing, this advancement has become a game-changer for brands aiming to create premium athletic apparel.

With ultra-smooth, flat finishes, laser-cut seams help prevent chafing and enhance the longevity of garments. But the impact doesn’t stop there. This technology opens up new possibilities in design, allowing for intricate patterns, strategically placed ventilation, and complex geometric details that traditional cutting methods simply can’t achieve. On top of that, it supports sustainability by minimizing fabric waste and reducing production time. The ability to bond similar thermoplastics, such as polyester to polyester, also simplifies recycling, paving the way for easier mono-material garment construction.

For manufacturers like New Dong Huang Garment Co., Ltd., embracing laser-cut seam technology signals a dedication to pushing boundaries in quality and sustainability. It enables them to produce activewear that not only meets the rigorous demands of athletes but also lowers environmental impact.

FAQs

What makes laser-cut seams more durable in activewear?

Laser-cut seams boost durability by cleanly cutting and sealing fabric edges in one efficient step. This technique stops fraying, minimizes wear and tear, and results in smoother, stronger seams that stand the test of time. By skipping traditional stitching, laser-cut seams not only look cleaner but also extend the lifespan of activewear – perfect for demanding, high-performance activities.

Why are laser-cut seams more comfortable than traditional stitching in activewear?

Laser-cut seams offer a sleek, flat finish by sealing fabric edges without relying on heavy stitching. This design minimizes problems like friction, chafing, and fraying often associated with traditional seams, creating a softer and more comfortable feel against the skin.

The precision of laser cutting also delivers a crisp and uniform fit, improving both the comfort and functionality of activewear. It’s a preferred technique for garments like leggings, sports bras, and jackets that are built for movement and extended use.

How does laser cutting make activewear production more sustainable?

Laser cutting plays a key role in making activewear production more eco-friendly by cutting down on material waste and energy use. Thanks to the precision of laser technology, fabrics are cut with incredible accuracy, leaving behind little to no excess material. This means fewer scraps and less need for additional trimming. Plus, the technique enables seamless designs and perforated patterns that require less fabric and fewer stitches.

On top of that, laser cutting is energy-efficient. Modern laser systems are designed to convert a significant portion of electrical energy into usable heat, consuming less power than traditional cutting methods. Since the process is non-contact, it generates minimal dust and fumes, reducing pollution and helping manufacturers meet environmental standards. Companies like New Dong Huang Garment Co., Ltd. are leveraging laser technology to produce durable, high-performance activewear while keeping resource use and environmental impact to a minimum.