When it comes to manufacturing, MOQ (Minimum Order Quantity) and lead time are two key factors that can make or break your production strategy. Here’s what you need to know:

- MOQ determines the smallest number of units you can order. Higher MOQs lower costs per unit but tie up cash in inventory. Lower MOQs offer flexibility for testing but at higher unit prices.

- Lead time is the time from placing an order to receiving the product. Shorter lead times help you respond faster to trends but often increase costs. Longer lead times reduce costs but require better forecasting.

Both are interconnected and impact costs, cash flow, storage needs, and your ability to meet customer demands. Striking the right balance is essential for efficient production planning.

Quick Comparison

| Factor | Pros | Cons |

|---|---|---|

| MOQ | Lower unit costs, streamlined logistics, stronger supplier relationships | High upfront investment, inventory risk, limited testing opportunities |

| Lead Time | Lower costs, better quality control, improved planning | Slow market response, cash flow strain, risk of missed market opportunities |

Minimum Order Quantity – MOQ Meaning and Best Practices

1. Minimum Order Quantity (MOQ)

MOQ refers to the smallest number of units a manufacturer will produce to cover the costs of materials, machinery, and labor. Grasping how MOQs influence your operations is key to making smart decisions about suppliers and production planning. Let’s break down how MOQs affect cost structures, flexibility, and supply chain management.

Cost Efficiency

Larger order volumes often translate to lower costs per unit. Why? Manufacturers can purchase materials in bulk, reduce setup costs per unit, and operate production lines more efficiently. This economy of scale can improve your profit margins. But there’s a catch – ordering too much can drain cash reserves and rack up storage fees.

The sweet spot depends on your sales pace and available cash flow. Established brands with steady demand can benefit from higher MOQs, cutting costs in the long run. On the other hand, newer brands might prefer lower MOQs to test the waters before committing substantial capital.

While cost efficiency is important, being flexible enough to adapt to market changes is equally crucial.

Production Flexibility

Lower MOQs are ideal for experimenting with new designs or styles without taking on too much risk. In contrast, higher MOQs require a long-term commitment to specific designs, which can limit your ability to pivot – especially in fast-moving industries like activewear, where trends change quickly.

Material sourcing can also complicate things. Textile mills often set their own minimums, which might restrict your fabric choices or design options. A practical workaround? Create coordinated collections where multiple products use the same fabric base. This way, you can meet supplier requirements while still offering a variety of styles.

Impact on Supply Chain Management

MOQs play a big role in shaping your supply chain strategy, from warehousing needs to cash flow management. High-volume orders demand more storage space and a larger upfront investment, potentially tying up funds needed elsewhere in your business.

Managing inventory becomes critical. Large orders require careful planning to avoid overstocking or running out of stock – both of which can hurt customer satisfaction. Reordering at the right time is just as important to keep operations running smoothly.

Working with multiple suppliers can sometimes help ease these challenges, but it also adds complexity. You’ll need to coordinate production schedules, maintain quality control, and consolidate shipments – making it even more important to fully understand MOQs and their impact on your supply chain.

Scalability

As your brand grows, your MOQ strategy will need to evolve. Early on, brands often work with suppliers offering lower MOQs, even if it means paying more per unit. This approach allows flexibility during the testing phase. As sales increase, moving to higher MOQs can unlock better pricing and improve profit margins.

Scaling up, however, requires careful financial planning. Larger orders demand greater capital and accurate demand forecasting to avoid costly missteps.

Some brands adopt a dual-supplier strategy: smaller suppliers for test runs and new products, and larger suppliers for proven bestsellers. This approach strikes a balance between flexibility and cost savings but requires tight coordination to manage effectively.

2. Lead Time

Lead time refers to the period from when an order is confirmed to when the product is delivered. This includes every step – development, sampling, production, quality control, and shipping. It’s not just a logistical detail; lead time plays a crucial role in shaping your business operations, much like MOQs. Both directly influence your costs and how agile your operations can be.

Cost Efficiency

Shorter lead times often come with higher costs. Why? Expedited production and tight scheduling adjustments can drive up expenses. On the flip side, longer lead times allow manufacturers to optimize their processes, negotiate better deals on materials, and save on shipping. With proper planning and realistic timelines, you can avoid the premium costs associated with rush orders and express shipping.

Production Flexibility

Lead time also dictates how quickly you can adapt to market changes. In industries like activewear, where trends shift rapidly, longer lead times mean you’ll need to predict customer preferences far in advance – a tricky task. Factories that offer flexibility, such as small-batch production or quick design revisions, can help. However, if your product requires specialized materials, shorter lead times might be harder to achieve.

Impact on Supply Chain Management

Beyond cost and flexibility, lead time has a significant impact on your supply chain. Longer timelines require careful inventory forecasting and earlier decision-making, which can stretch the time between paying for production and seeing revenue from sales. This makes precise planning essential. On the other hand, shorter timelines can lead to rushed quality control, increasing the risk of defects. Coordinating production schedules for multiple product types adds another layer of complexity, requiring meticulous planning to keep everything on track.

Scalability

As your business grows, managing lead times becomes a strategic challenge. Early-stage brands often accept longer lead times to secure lower MOQs or better payment terms. But as production scales up, tighter scheduling becomes essential to meet growing market demand. Diversifying your suppliers – such as balancing shipments from China with regional sources – can reduce logistical risks, especially during peak seasons. Seasonal planning is another key factor; accounting for delays and industry slowdowns ensures your products hit the market when they’re needed most. Tools like production management software can also help you track orders, anticipate delays, and fine-tune reorder schedules effectively.

sbb-itb-8dbc09a

Advantages and Disadvantages

This section breaks down the practical pros and cons of Minimum Order Quantity (MOQ) and lead time, highlighting how these two factors are closely linked. Adjusting one often impacts the other, along with costs and operational flexibility.

| Factor | Advantages | Disadvantages |

|---|---|---|

| MOQ | Lower unit costs: Larger orders reduce the cost per garment.

Simplified logistics: Fewer, bulk shipments streamline delivery management and lower per-unit shipping costs. Stronger supplier relationships: Consistently meeting higher MOQs can build trust and reliability with suppliers. |

Higher upfront investment: Bigger orders require significant capital to be tied up in inventory before generating sales.

Inventory risk: Producing in bulk increases the likelihood of excess stock if trends change unexpectedly. Limited testing opportunities: High MOQs make it harder to test new designs or colors without committing to large quantities. |

| Lead Time | Cost efficiency: Longer production schedules allow manufacturers to optimize processes and source materials more affordably.

Better quality control: Extended timelines enable thorough inspections, reducing rushed errors. Improved planning: Longer lead times encourage disciplined forecasting and better inventory management. |

Reduced market responsiveness: Longer production cycles require predicting trends far in advance, making it harder to react to sudden changes.

Cash flow strain: A longer gap between production costs and sales revenue can create financial pressure. Competitive disadvantage: Slower turnaround times may cause brands to miss timely opportunities in the market. |

The table above summarizes the key trade-offs, but let’s delve deeper into how these factors shape strategic decisions.

Negotiating lower MOQs often means accepting longer lead times. Manufacturers tend to prioritize larger orders to maintain production efficiency, which can slow down smaller batches. On the flip side, quicker production often requires higher MOQs to justify expedited scheduling and resource allocation.

Flexibility is critical when responding to trends, launching limited collections, or testing new ideas. Shorter lead times improve agility, but they usually come with higher costs. Manufacturers often charge a premium for faster production, so it’s essential to weigh whether quicker turnarounds are worth the added expense and inventory risks.

Understanding how MOQ, lead time, and cost interact equips you to negotiate effectively with suppliers and set realistic production goals. Striking the right balance between these elements is crucial for aligning your production strategy with market demands.

Conclusion

Balancing MOQ and lead time isn’t about choosing one over the other – it’s about creating a strategy that ties directly into your production goals. Every adjustment you make impacts costs, inventory levels, and how quickly you can respond to market demands.

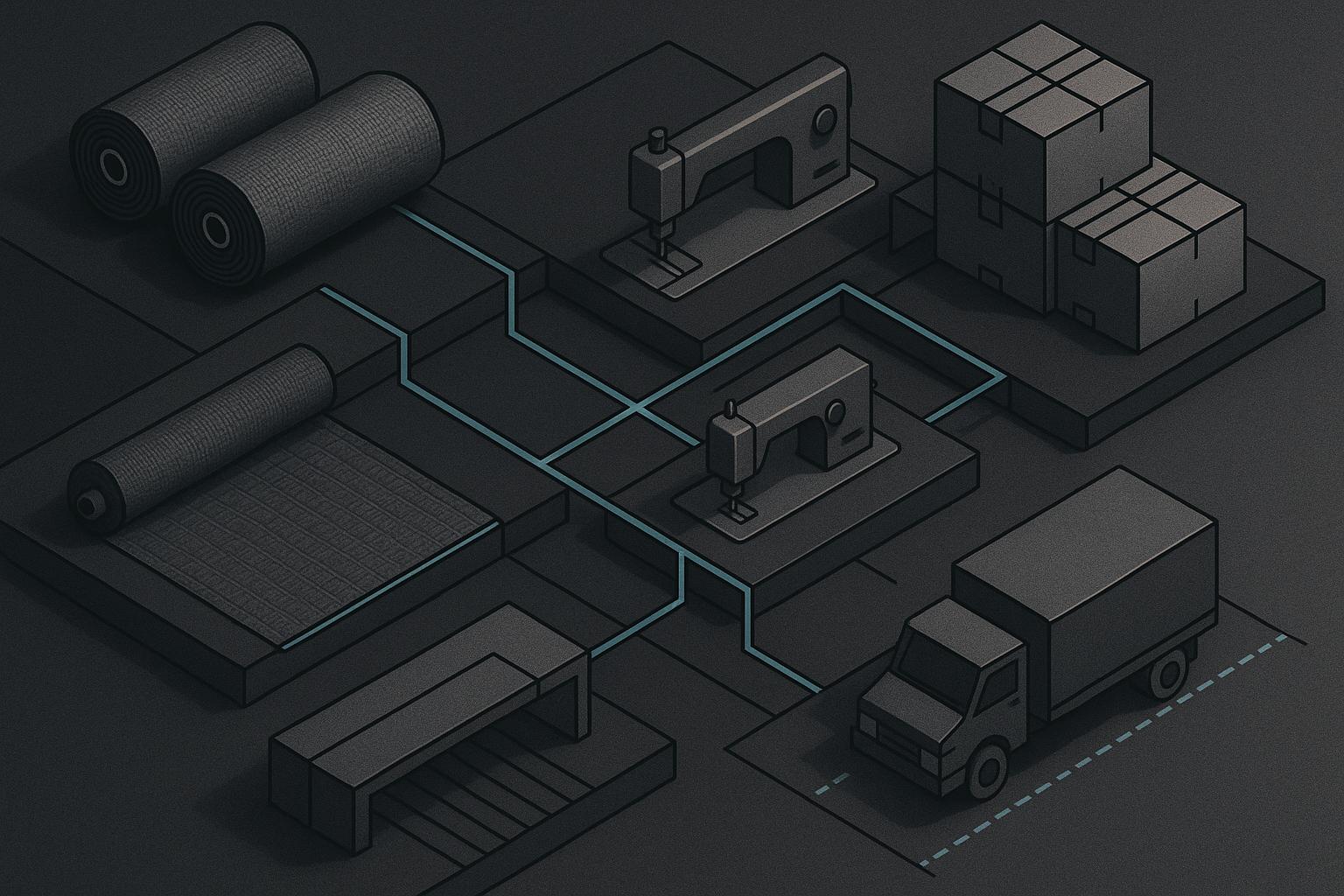

Start by mapping out your entire production timeline. It’s common for MOQs at different stages – like fabric suppliers, trim providers, and sewing facilities – not to match up. Pinpoint the main bottleneck in your supply chain. For example, if your fabric supplier requires a larger minimum order than your sewing facility can handle, the fabric MOQ becomes the key constraint. Recognizing this allows you to negotiate smarter and plan more effectively.

Negotiating with suppliers is another essential piece of the puzzle. Sharing your growth plans and seasonal timelines can encourage them to work your needs into their schedules. Open communication often leads to better terms, especially when sourcing from regions like China, where strong supplier relationships can significantly influence production flexibility.

Keep in mind that shorter lead times usually come at a higher price. Rushing production often means suppliers have to prioritize your order, which can result in premium costs. Before opting for expedited timelines, weigh whether the faster delivery is worth the extra expense – this is especially relevant for trend-driven collections or when testing new designs. In many cases, sticking to a standard timeline can save money without sacrificing quality.

The most successful activewear brands see MOQ and lead time as variables they can adjust, not rigid constraints. They carefully forecast demand to justify larger MOQs when reducing unit costs is essential, while using smaller runs with longer timelines to test new products. This flexibility – knowing when to prioritize cost savings versus speed – helps avoid inventory headaches down the line.

Ultimately, aligning your production strategy with your business model is key. Established brands with steady demand can benefit from higher MOQs and lower costs, while newer labels might prioritize smaller orders to minimize financial risk. The right approach depends on your market position, cash flow, and growth goals. By integrating these factors into your decision-making, you can create a production strategy that supports your broader business objectives.

FAQs

How can companies find the right balance between MOQ and lead time for their production needs?

To find the right balance between Minimum Order Quantities (MOQs) and lead times, it’s essential to weigh factors like production costs, demand forecasts, and inventory needs. Start by assessing your supplier’s production capacity, the availability of materials, and the level of customization your products require.

Work on negotiating MOQs that fit your cash flow and sales forecasts, keeping in mind typical lead times for activewear production, which usually range from 12 to 20 weeks. Building strong relationships with your suppliers and staying flexible with order sizes and schedules can help you adapt to shifting demands, avoiding both delays and excess inventory. Prioritizing clear communication and thoughtful planning will set the stage for a production process that aligns with your business objectives.

How can brands reduce the risks of high MOQs and long lead times in a fast-changing market?

To tackle the challenges posed by high Minimum Order Quantities (MOQs) and lengthy lead times, brands can implement a few smart strategies to remain flexible and efficient:

- Focus on 1-2 key styles in a handful of popular colors. This approach helps meet MOQ requirements while keeping risks low.

- Choose stock materials instead of custom fabrics. Stock options not only cut down lead times but also make production simpler.

- Work with manufacturers offering lower MOQs for standard designs. This allows you to test the market without committing to large quantities upfront.

You might also explore negotiating MOQs based on annual purchase commitments or combining orders across different styles to benefit from volume discounts. Building strong supplier relationships and maintaining consistent order patterns can go a long way in securing better terms and reducing risks in an ever-changing market.

How do MOQ and lead time changes impact cash flow and inventory management for growing brands?

Changes in Minimum Order Quantities (MOQs) and lead times can significantly affect both cash flow and inventory management, especially for brands that are expanding. When MOQs are higher, businesses need to invest more money upfront, which can lead to increased storage expenses and tie up working capital. On the flip side, lower MOQs require less upfront spending but often result in more frequent orders, which can push up administrative and shipping costs.

Longer lead times add another layer of complexity. To avoid running out of stock, businesses may need to hold extra safety stock, which puts additional pressure on cash flow and raises carrying costs. Finding the right balance between MOQ and lead time is key to managing inventory effectively, reducing waste, and ensuring cash flow stays steady.