Choosing the right GSM (grams per square meter) is key to creating activewear that performs well, lasts longer, and meets customer expectations. Here’s what you need to know upfront:

- GSM impacts fabric thickness, durability, and cost. Lighter fabrics (under 220 GSM) often lack opacity and durability, while heavier fabrics (>300 GSM) may restrict movement and trap heat.

- Match GSM to the garment’s purpose. Leggings need 250–300 GSM for full coverage, while breathable tops work best at 140–180 GSM.

- Climate matters. Lightweight fabrics suit warmer regions, while heavier ones perform better in colder climates.

- Test before production. Stretch, drape, and wash tests ensure the fabric meets performance and durability standards.

The wrong GSM can lead to transparency, shrinkage, and poor fit. By understanding how GSM affects fabric performance, you can avoid costly mistakes and deliver high-quality garments.

GSM Explained/ The #1 Secret Behind Quality Activewear

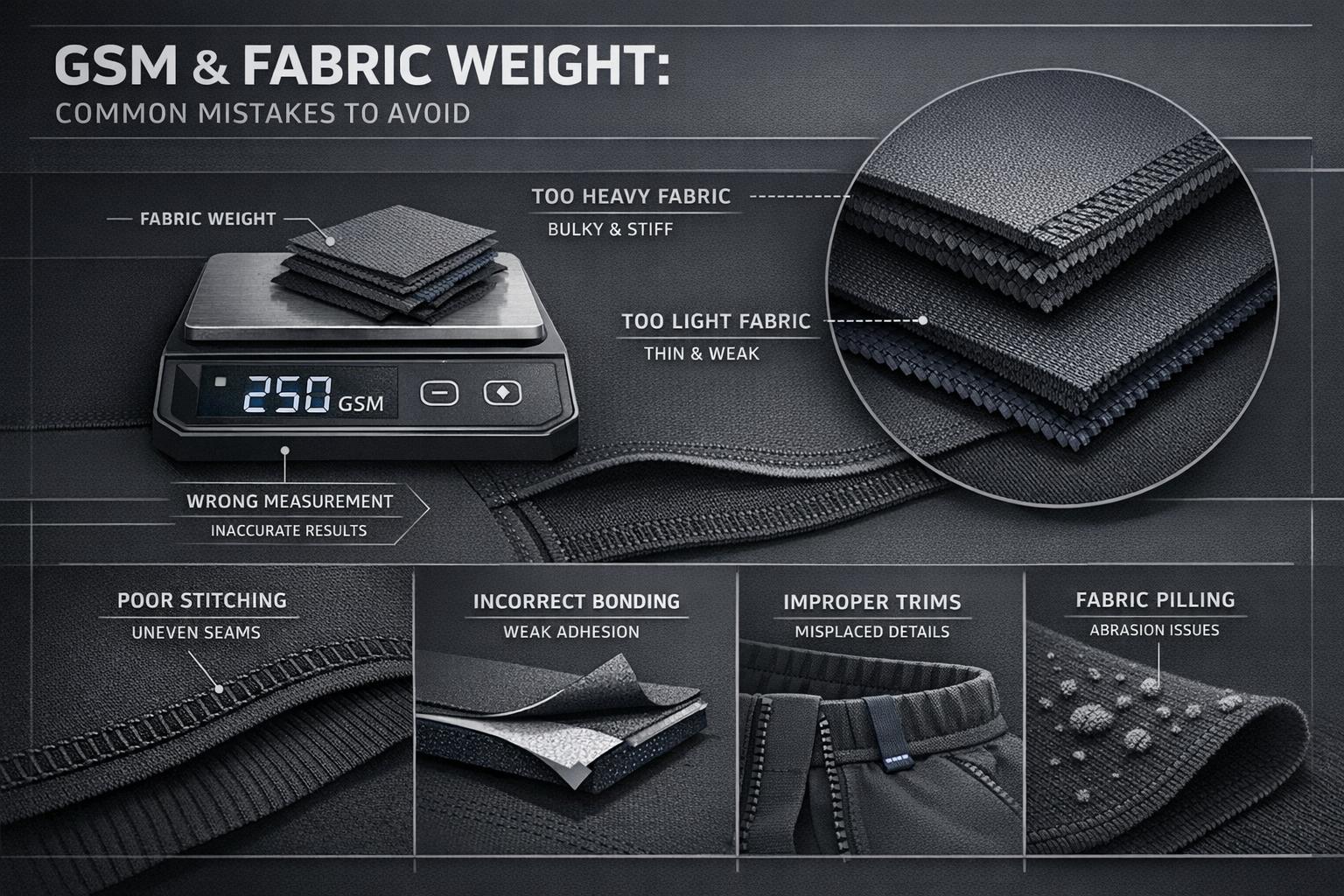

5 Common GSM Selection Mistakes in Activewear

Choosing the right GSM (grams per square meter) is crucial for avoiding common issues in activewear, like transparency or poor fit. Recognizing these mistakes can help ensure your garments perform well and meet customer expectations.

Mistake 1: Choosing Fabrics That Are Too Light for Leggings and Bottoms

Fabrics with a GSM below 220 often become see-through when stretched. For black leggings, a minimum of 230 GSM is necessary for basic opacity, while high-performance styles require 250–300 GSM to provide full coverage and adequate muscle support.

Lighter fabrics also tend to pill, snag, and lose elasticity more quickly. When it comes to intricate patterns or prints, a GSM of 250 or higher is recommended since thinner fabrics can distort designs or cause them to "white out" under tension. Yoga leggings in the 180–220 GSM range might feel like a "second skin", but they often lack squat-proof security.

"Inappropriate fabric weight choices can jeopardize entire clothing collections." – Fumao Fabric

The solution? Opt for a GSM range of 250–280 for leggings and bottoms, paired with 25–30% mechanical stretch. Always test fabric opacity at a 30% stretch before production to ensure it meets coverage standards under real-world conditions.

Beyond transparency, GSM plays a role in thermal comfort, which is critical for adapting to different climates.

Mistake 2: Ignoring Climate and Temperature Needs

GSM affects how breathable or insulating a fabric is. Lightweight fabrics (80–150 GSM) are loosely woven, allowing for better airflow and cooling – perfect for hot environments. On the other hand, heavier fabrics (>300 GSM) are better suited for cold weather but can cause overheating indoors.

For example, using a 320–350 GSM fleece for gym shirts might cause athletes to overheat within minutes. Meanwhile, ultra-light fabrics may not provide adequate protection in cooler conditions. Additionally, fabrics under 140 GSM may wear out quickly at stress points, while those in the 160–180 GSM range can typically endure around 30 washes without significant pilling.

To match GSM with climate, consider using 140–160 GSM for tropical regions and 180–200+ GSM for temperate markets. For winter gear, layering two lighter fabrics – like a 200 GSM shell with a 100 GSM lining – can provide a combined 300 GSM effect while maintaining flexibility.

Mistake 3: Overlooking Fabric Drape and Movement

How a fabric moves and drapes is just as important as its durability. GSM affects whether a fabric clings to the body or hangs loosely. Higher GSM fabrics (250+) tend to create a more structured, boxy fit, while lower GSM fabrics (under 160) flow more freely and contour to the body. However, overly heavy fabrics can feel stiff and limit mobility during high-intensity activities.

Drape impacts both performance and appearance. Lower GSM fabrics generally offer better stretch recovery, meaning they bounce back to their original shape after being stretched. But if the GSM is too low in activewear bottoms, the fabric might lack the firmness needed for muscle compression.

"GSM influences how the fabric drapes and whether it hugs or hangs off the body." – FittDesign

For tops, lightweight fabrics (140–180 GSM) are ideal since they don’t feel heavy during workouts. Before finalizing production, test the fabric’s stretch recovery and prototype garments with different GSM levels to get feedback on comfort and movement from athletes.

Mistake 4: Believing Heavier Fabrics Always Last Longer

It’s a common misconception that higher GSM fabrics are automatically more durable. In reality, durability depends more on the quality of the yarn and knit structure than on fabric weight. For instance, a tightly spun 220 GSM fabric can outlast a loosely spun 280 GSM fabric.

"Choose GSM based on product function, not just feel." – FittDesign

Focus on yarn quality instead of just weight. A well-made 230 GSM nylon-spandex blend can match the opacity of a 250 GSM polyester-spandex blend. Always test fabric samples under real-world conditions, including washing, stretching, and wearing, before placing large orders.

Mistake 5: Skipping Shrinkage and Wash Testing

Neglecting wash tests can lead to shrinkage, distortion, and sizing problems. Even small variations in GSM during production can significantly impact garment fit, especially considering the typical tolerance range of ±5–10% in activewear manufacturing.

Different fabrics react differently to washing. For example, cotton blends tend to shrink more than synthetic ones at the same GSM. Heavier fabrics can also absorb more moisture, making them feel heavy and cold when wet, unless designed to dry quickly.

To avoid these issues, test all fabrics for shrinkage and wash durability before mass production. Check if the fabric maintains its shape, elasticity, and opacity after multiple washes to ensure it meets the necessary performance standards.

How to Fix GSM Selection Problems

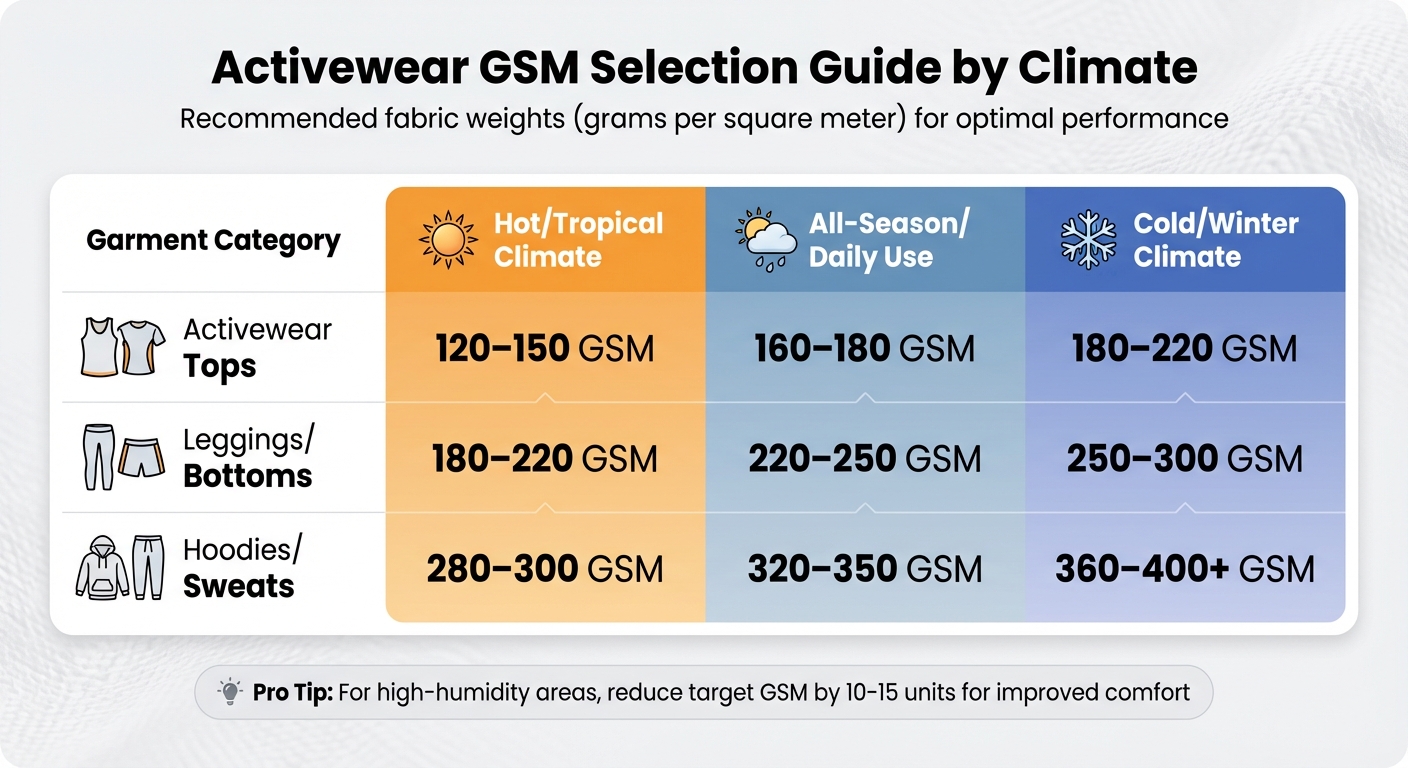

GSM Fabric Weight Guide for Activewear by Climate and Garment Type

If you’re dealing with GSM selection challenges, these practical solutions can help you fine-tune your approach and sidestep costly production mishaps.

Solution 1: Use 200–280 GSM for Activewear Bottoms

For activewear bottoms, aim for fabrics in the 200–280 GSM range to ensure a balance of opacity, durability, and support. For example, black leggings need at least 230 GSM for basic coverage, while 250–270 GSM offers the squat-proof performance many customers expect. Yoga leggings, which require more flexibility, perform best at 180–220 GSM, whereas high-impact training gear benefits from 220–300 GSM for added durability and support.

The fiber blend also plays a role. A 230 GSM nylon-spandex fabric can provide the same opacity as a 250 GSM polyester-spandex blend because nylon is naturally denser.

Solution 2: Select GSM Based on Season and Climate

When addressing climate-specific needs, align fabric weight with the conditions of your target market. For tops and base layers in tropical climates, lighter fabrics in the 120–150 GSM range are ideal. In temperate regions, 160–180 GSM works well for year-round use, while colder climates require heavier fabrics, ranging from 180–220 GSM for tops. If you’re designing for high-humidity areas, consider reducing target GSM by 10–15 units to improve comfort.

| Garment Category | Hot/Tropical Climate | All-Season/Daily Use | Cold/Winter Climate |

|---|---|---|---|

| Activewear Tops | 120–150 GSM | 160–180 GSM | 180–220 GSM |

| Leggings/Bottoms | 180–220 GSM | 220–250 GSM | 250–300 GSM |

| Hoodies/Sweats | 280–300 GSM | 320–350 GSM | 360–400+ GSM |

Solution 3: Test Fabric Drape Before Production

Fabric behavior during production can vary significantly, so it’s essential to test the drape on prototypes before committing to bulk orders. Lighter fabrics tend to flow more freely, while heavier ones provide better structure. Create prototypes at different GSM levels and test them with your target audience, focusing on stretch recovery – how well the fabric returns to its original shape after stretching. For oversized garments, increasing the fabric weight by 10 GSM can help maintain structure.

Solution 4: Focus on Yarn Quality Over Weight Alone

The durability of a fabric isn’t just about GSM; the quality of the yarn and knit structure are equally important.

"The best fabric isn’t the one with the highest numbers, but the one with the right numbers for the product’s intended use, target customer, and price point." – Helen, Founder of China Fabric Supply Chain

For increased tear resistance and stretch recovery, look for tightly knit nylon-spandex blends in the 250–300 GSM range. Nylon fabrics tend to offer greater softness and abrasion resistance, while polyester excels in UV and chlorine protection. Interestingly, an 180 GSM interlock (a double-knit fabric) can outperform a 220 GSM single jersey due to its denser construction.

Solution 5: Test All Fabrics for Shrinkage Before Orders

Shrinkage is a common issue, but it can be avoided by testing fabrics before production. Use the AATCC 135 method to measure dimensional changes by washing and drying fabric samples at least three times. Ideally, premium fabrics should shrink less than 3%, while retail-grade fabrics should stay below 4%.

To verify GSM post-wash, cut a 10 cm x 10 cm square (1/100th of a square meter), weigh it in grams, and multiply by 100 to calculate the actual GSM. Include the required GSM after finishing and washing in your technical packs, allowing for a ±5–7% tolerance to account for dye lot variations. Seal "golden samples" of both pre-wash and post-wash fabrics as benchmarks to maintain consistency during bulk production.

sbb-itb-8dbc09a

Fabric Weight Comparison for Activewear

Fabric weight plays a crucial role in shaping the performance and design of activewear. It’s not just about how thick a fabric feels – its weight directly impacts how the garment performs, looks, and feels during use. Let’s break down the differences between lightweight, midweight, and heavyweight fabrics to help you make more informed choices when creating activewear.

Lightweight fabrics (120–180 GSM) are all about breathability. These fabrics allow excellent airflow, making them perfect for linings, base layers, and summer tops. However, they often lack opacity, especially below 220 GSM, and fabrics under 140 GSM may wear out faster at stress points. While they’re great for keeping cool, they’re better suited for garments where durability and full coverage aren’t top priorities.

Midweight fabrics (180–250 GSM) strike a balance between breathability and opacity. T-shirts in the 160–180 GSM range, for example, tend to hold up well over time, resisting pilling even after 30 washes. These fabrics are versatile, making them ideal for yoga pants, standard leggings, and casual sports bras. They provide moderate compression and durability, making them a go-to choice for everyday activewear.

Heavyweight fabrics (250–400+ GSM) prioritize durability and support over breathability. With their dense fiber structure, they trap more heat but deliver the "squat-proof" performance needed for high-intensity activities. Fabrics in the 250–300 GSM range are often used for high-performance leggings, offering full coverage and muscle support. These fabrics are also common in compression gear, swimwear, and shapewear, where strength and structure are key.

| Feature | Lightweight (120–180 GSM) | Midweight (180–250 GSM) | Heavyweight (250–400+ GSM) |

|---|---|---|---|

| Opacity | Low; may appear semi-sheer | Moderate to High; generally opaque | Very High; fully "squat-proof" |

| Breathability | High; excellent airflow | Moderate; balanced for daily use | Low; retains heat and insulates |

| Durability | Low; prone to wear and snagging | Moderate; resists daily wear | High; withstands abrasion and stretching |

| Support | Minimal; focuses on flexibility | Moderate; light compression | High; strong muscle support |

| Recommended Uses | Linings, base layers, summer tops | Yoga pants, leggings, sports bras | Compression gear, swimwear, shapewear |

Each fabric weight serves a specific purpose, from lightweight materials that keep you cool to heavyweight options designed for durability and support. By understanding these differences, you can make smarter choices in designing activewear tailored to specific needs.

Conclusion

Choosing the right GSM for your activewear is more than just a technical decision – it’s what ensures your garments perform as promised. The wrong GSM can lead to transparency issues, poor fit, reduced durability, and shrinkage problems, all of which can tarnish your product’s reputation.

The good news? Avoiding these pitfalls is manageable with a disciplined approach. For example, 250–300 GSM is ideal for performance leggings, offering the support and opacity needed for active use. Align your fabric’s weight with the season and intended activity. Always test how the fabric feels and moves before finalizing production, and remember: yarn quality often outweighs GSM itself. A tightly knit 175 GSM compact jersey can outperform a loosely woven 200 GSM fabric in both durability and shape retention.

Shrinkage and wash tests are non-negotiable. Fabrics over 300 GSM should be treated to keep shrinkage below 3%, and using a "golden sample" ensures consistency across production runs. With 79% of consumers prioritizing quality and price, getting GSM right can mean the difference between activewear that delights and activewear that disappoints.

FAQs

What GSM range is best for activewear leggings to provide support and prevent transparency?

For activewear leggings that provide full coverage, reliable support, and long-lasting durability, the ideal fabric weight usually ranges between 250 and 300 GSM (grams per square meter). This thickness strikes the perfect balance, offering enough opacity to prevent see-through issues while still being flexible and comfortable for activities like yoga, running, or hitting the gym.

Picking the right GSM is essential to sidestep problems like pilling, shrinkage, or an awkward fit. Always match the fabric weight to the specific performance needs of your customers or brand to ensure the leggings meet their expectations.

How does GSM affect fabric performance in different weather conditions?

GSM, short for grams per square meter, is a crucial factor in how fabric performs across different weather conditions. Essentially, it measures the weight and thickness of the material, which influences key aspects like comfort, breathability, and insulation. For hotter climates, lighter fabrics with a GSM between 50 and 150 are a great choice. They’re breathable and promote airflow, keeping you cool. On the flip side, colder climates call for heavier fabrics with a GSM of 300 to 400, as they provide better insulation to trap body heat and keep you warm.

Picking the right GSM ensures the fabric matches its purpose and the environment it’s meant for. Lightweight materials are perfect for summer wear, like activewear or T-shirts, while heavier options are ideal for winter essentials like jackets or hoodies. Choosing the appropriate GSM not only improves comfort but also boosts durability and overall satisfaction.

Why should fabric drape and shrinkage be tested before starting mass production?

Testing fabric drape and shrinkage before moving into mass production is a crucial step to guarantee that garments retain their intended fit, appearance, and durability. Skipping this process can result in problems like excessive shrinkage, awkward drape, or fabric deformation – issues that not only frustrate customers but can also lead to financial setbacks.

By tackling these potential problems early on, you can save on costly rework, enhance product quality, and ensure the finished garments align with both design goals and performance standards.