Ultimate Guide to Activewear Production Workflows

Step-by-step guide to activewear production from tech packs and fabric sourcing to cutting, stitching, quality control, and packaging.

How to Build a Factory Performance Scorecard

Turn factory data into action: pick 4–9 KPIs, organize them in a balanced framework, automate collection, and review regularly to improve production.

GSM and Fabric Weight: Common Mistakes to Avoid

Learn how GSM affects opacity, durability, drape and shrinkage in activewear — avoid common mistakes and choose the right fabric weight by garment and climate.

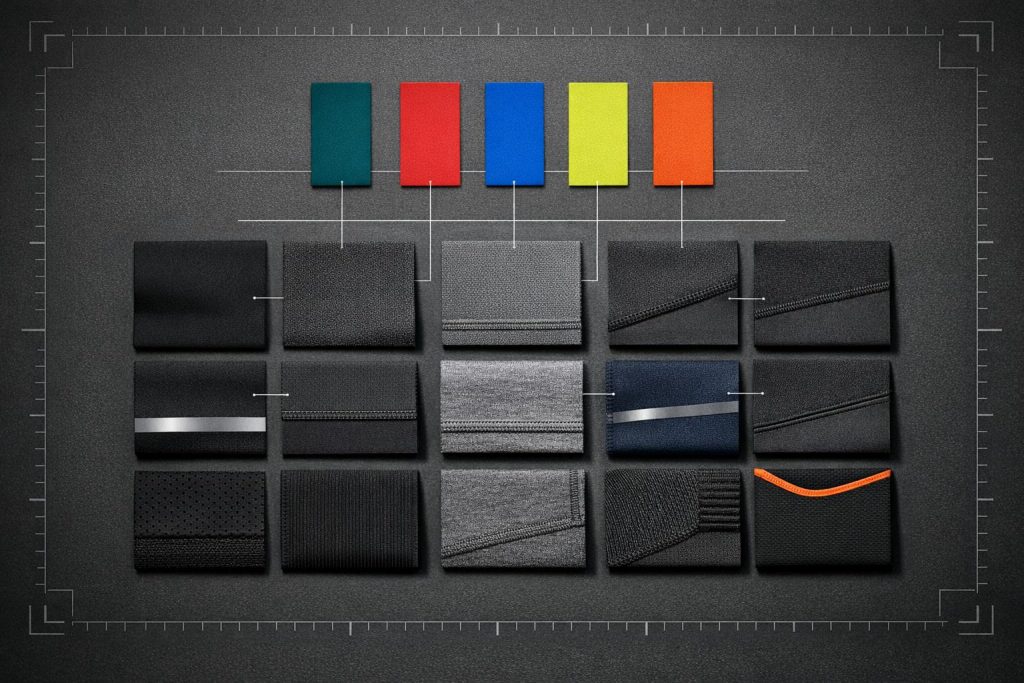

Color Forecasting Tools for Activewear Designers

AI-driven color forecasting improves accuracy and feasibility for activewear, reducing sampling waste and aligning trend palettes with production-ready fabrics.

Martindale Test: Measuring Abrasion Resistance

Martindale testing measures fabric abrasion using a figure‑eight motion to count rub cycles and assess pilling, mass loss, and durability for activewear.

Checklist for Reducing Supply Chain Risks in China

Practical checklist to vet Chinese factories, build precise tech packs, enforce multi-stage quality control, diversify suppliers, and manage customs and delivery.

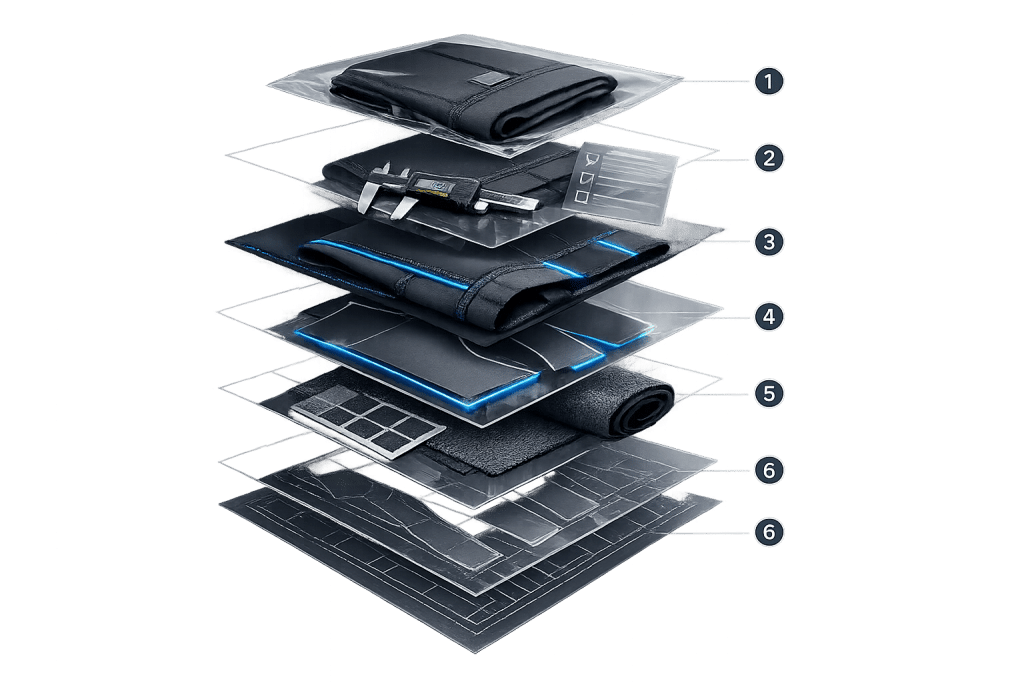

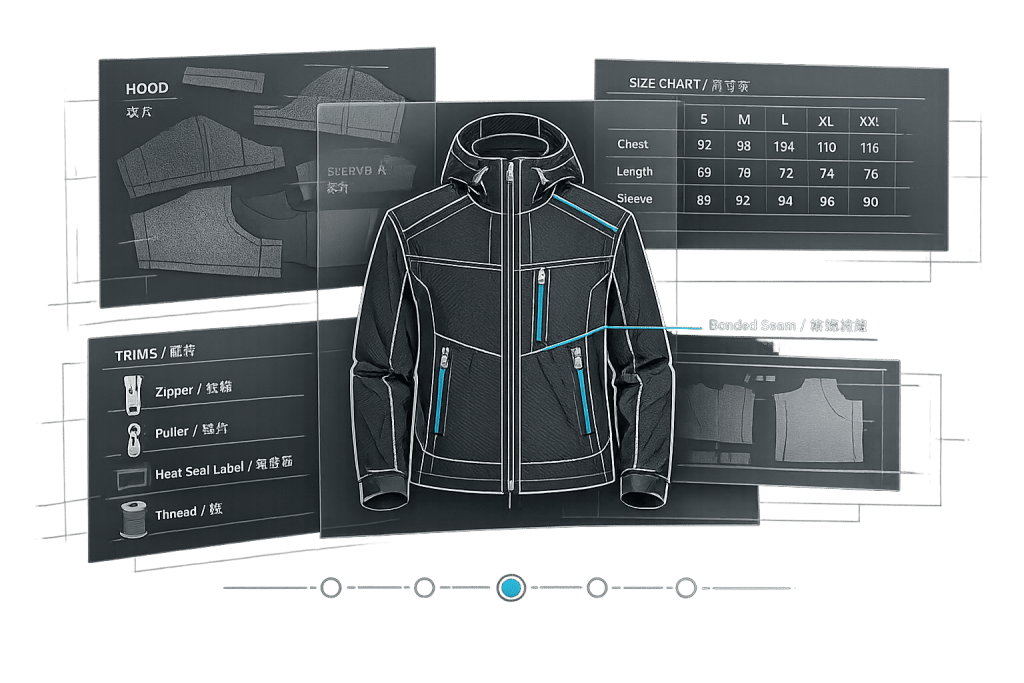

Best Practices for Tech Pack Integration in China

Create detailed tech packs for Chinese activewear factories: flat sketches, size charts, BOMs, bilingual files, sampling timelines and clear communication.

How to Maintain QC Standards in High-Volume Runs

Step-by-step QC for high-volume activewear: tech packs, pre-production samples, inline inspections, fabric and trim testing, and AQL final audits.

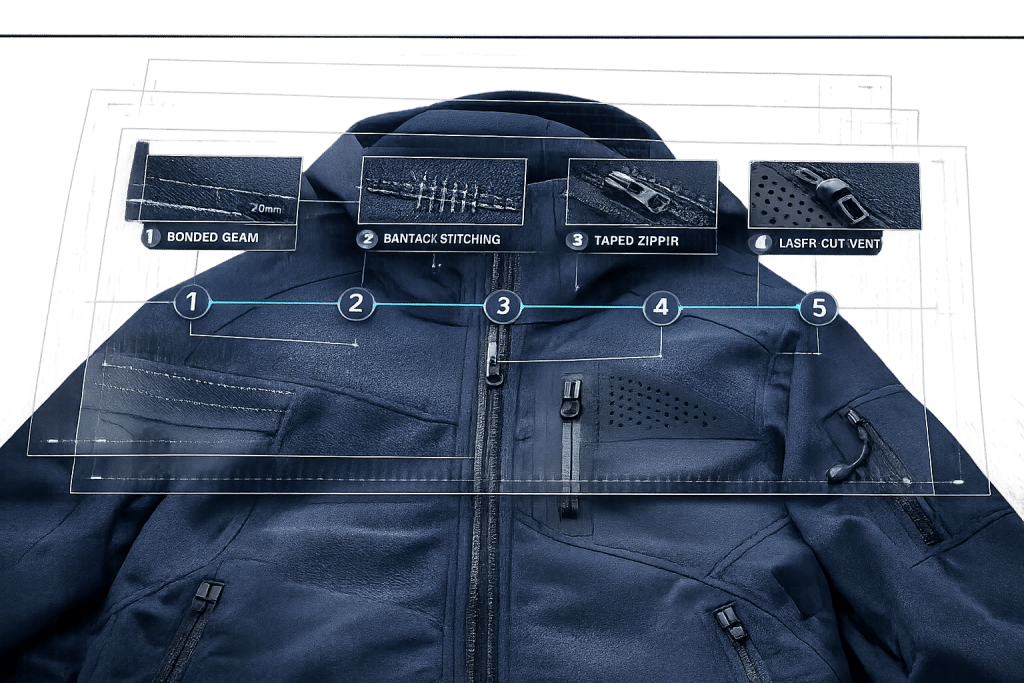

Laser-Cut Seams in Activewear: Benefits Explained

Laser-cut seams boost activewear comfort and performance with sealed low-profile edges, reduced chafing, precise designs, faster production, and less fabric waste.

China Sourcing: Ensuring Fabric Testing Standards

Step-by-step guide to China’s GB/T 21655.1-2023 tests for moisture-wicking, quick-dry, and breathability — verify suppliers, read reports, and avoid QC issues.